Professional Documents

Culture Documents

System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)

System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)

Uploaded by

darwish.hiltiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)

System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)

Uploaded by

darwish.hiltiCopyright:

Available Formats

CAJ 2342

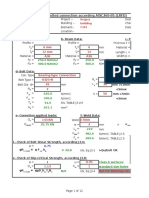

System No. C-AJ-2342

F Rating — 3 Hr

T Rating — 0 Hr

W Rating - Class 1 (See Item 3B)

3B 1

A A

3A

SECTION A-A

1. Floor or Wall Assembly — Min 2-1/2 in. (64 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete floor or

wall. Wall may also be constructed of any UL Classified Concrete Blocks*. Max diam of opening is 6 in.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Through Penetrants — One nonmetallic pipe to be installed concentrically or eccentrically within the firestop system. Annular space within the

firestop system is dependent upon the max diam and type of penetrant used as tabulated in Item 3A. Pipe to be rigidly supported on both sides of

floor or wall assembly. The following types and sizes of nonmetallic pipes may be used:

A. Polyvinyl Chloride (PVC) Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 40 solid or cellular core PVC for use in closed (process or

supply) or vented (drain, waste or vent) piping systems.

B. Chlorinated Polyvinyl Chloride (CPVC) Pipe — Nom 4 in. (102 mm) diam (or smaller) SDR13.5 CPVC for use in closed (process or supply) piping

systems.

C. Acrylonitrile Butadiene Styrene (ABS) Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 40 solid or cellular core ABS for use in closed

(process or supply) or vented (drain, waste or vent) piping systems.

D. Flame Retardant Polypropylene (FRPP) Pipe — Nom 4 in. (102 mm) diam (or smaller) Schedule 40 FRPP pipe for use in closed (process or

supply) or vented (drain, waste or vent) piping system.

3. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Material* — Wrap Strip — Layers of intumescent wrap strip are continuously wrapped around the pipe with ends held in place

with tape. Wrap strip installed recessed max 1/4 in. (6 mm) from bottom surface of floor or from both surfaces of wall. Size of wrap strip and number

of layers for a given size penetrant are shown in table below:

HILTI CONSTRUCTION CHEMICALS, DIV OF

HILTI INC — CP648-E W25/1" or CP648-E W45/1-3/4" Firestop Wrap Strip

S IFI

Reproduced by HILTI, Inc. Courtesy of AS

CL

ED

Underwriters Laboratories, Inc.

August 29, 2007

Page: 1 of 2

CAJ 2342

System No. C-AJ-2342

F Rating — 3 Hr

T Rating — 0 Hr

W Rating - Class 1 (See Item 3B)

Pipe Size in. Max Opening Annular Space Annular Space Number of Nom Wrap Strip

Product Designation

(mm) Diam (in.) Min in.(mm) Max in. (mm) Layers Width in. (mm)

CP648-E W25/1" 1 1/2 (38) 3 (76) 3/16 (4.8) 15/16 (24) 1 1 (25)

CP648-E W45/1-3/4" 1 1/2 (38) 3 (76) 3/16 (4.8) 15/16 (24) 1 1 3/4 (45)

CP648-E W25/1" 2 (51) 3 1/2 (89) 3/16 (4.8) 15/16 (24) 1 1 (25)

CP648-E W45/1-3/4" 2 (51) 3 1/2 (89) 3/16 (4.8) 15/16 (24) 1 1 3/4 (45)

CP648-E W45/1-3/4" 3 (76) 4 (102) 3/16 (4.8) 15/16 (24) 1 1 3/4 (45)

CP648-E W45/1-3/4" 3 (76) 5 (127) 3/8 (10) 1 1/16 (27) 2 1 3/4 (45)

CP648-E W45/1-3/4" 4 (102) 6 (152) 3/8 (10) 1 1/8 (29) 2 1 3/4 (45)

A1. Fill, Void or Cavity Material* — Wrap Strip — (As an alternate to the wrap strip in Item 3A) - One layer of intumescent wrap strip is continuously

wrapped around the pipe with ends butted and held in place with integrated tape. Wrap strip installed recessed max 1/4 in. (6 mm) from top surface

of floor or from both surfaces of wall. Size of wrap strip for a given size penetrant are shown in the table below.

HILTI CONSTRUCTION CHEMICALS, DIV OF

HILTI INC — CP648-S-1.5" US, CP648-S-2" US, CP648-S-3" US or CP648-S-4" US Wrap Strip

Nom Wrap Nom Wrap

Pipe Size Max Opening Annular Space Annular Space Nom Wrap Strip

Product Designation Strip Thick in. Strip Width in.

in.(mm) Diam (in.) Min in. (mm) Max in. (mm) Length in. (mm)

(mm) (mm)

CP648-S-1.5" US 1 1/2 (38) 3 (76) 3/16 (4.8) 15/16 (24) 6.5 (165) 0.18 (4.6) 1 (25)

CP648-S-2" US 2 (51) 3 1/2 (89) 3/16 (4.8) 15/16 (24) 8 (203) 0.18 (4.6) 1 (25)

CP648-S-3" US 3 (76) 4 (102) 3/16 (4.8) 5/16 (8) 11.5 (292) 0.18 (4.6) 1 3/4 (45)

CP648-S-4" US 4 (102) 6 (152) 3/8 (10) 1 1/8 (29) 15.1 (384) 0.36 (9) 1 3/4 (45)

A1. Fill, Void or Cavity Material* — Wrap Strip — (As an alternate to the wrap strip in Item 3A) - One layer of intumescent wrap strip is continuously

wrapped around the pipe with ends butted and held in place with integrated tape. Wrap strip installed recessed max 1/4 in. (6 mm) from top surface

of floor or from both surfaces of wall. Size of wrap strip for a given size penetrant are shown in the table below.

HILTI CONSTRUCTION CHEMICALS, DIV OF

HILTI INC — CP648-S-1.5" US, CP648-S-2" US, CP648-S-3" US or CP648-S-4" US Wrap Strip

B. Fill, Void or Cavity Material* - Sealant — Min 1/4 in. (6 mm) thickness of fill material applied within the annulus, flush with top surface of floor of

both surfaces of wall. W Rating applies only when CP 601S or CP 604 sealant is used.

HILTI CONSTRUCTION CHEMICALS, DIV OF

HILTI INC — FS-ONE Sealant, CP 601S Sealant or CP 604 Sealant

C. Packing Material (not shown) — Min 1/2 in. (13 mm) thickness of 4 pcf (64 kg/m3) mineral wool batt insulation firmly packed into annular space

and recessed from the top surface of floor to accommodate the required thickness of fill material. Required only when CP 604 Sealant is used.

*Bearing the UL Classification Mark

S IFI

Reproduced by HILTI, Inc. Courtesy of AS

CL

ED

Underwriters Laboratories, Inc.

August 29, 2007

Page: 2 of 2

You might also like

- Astm d1785Document6 pagesAstm d1785Falak KhanNo ratings yet

- ACO ShowerDrain S-LineDocument8 pagesACO ShowerDrain S-LinevanjaNo ratings yet

- System No. C-AJ-2371: F Rating - 3 HR T Rating - 2 HR and 3 HR (See Item 3)Document2 pagesSystem No. C-AJ-2371: F Rating - 3 HR T Rating - 2 HR and 3 HR (See Item 3)darwish.hiltiNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Approval Document ASSET DOC LOC 709Document2 pagesApproval Document ASSET DOC LOC 709fazil yoosufNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- TFP1865 03 2013Document4 pagesTFP1865 03 2013Srikanth ShanmugamNo ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Avio Print J-3 Cub User Guide 1.1Document28 pagesAvio Print J-3 Cub User Guide 1.1Sauli KlaavuNo ratings yet

- System PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - Caj2298 - DL PDFEmanuel PastlNo ratings yet

- Grinnel Fig 522 - Salida StrapDocument6 pagesGrinnel Fig 522 - Salida StraprutyNo ratings yet

- REHS4184-00 Procedure For Inspecting and Replacing The Cartridge Assemblies On 992G, 992K, 993K LoadersDocument5 pagesREHS4184-00 Procedure For Inspecting and Replacing The Cartridge Assemblies On 992G, 992K, 993K Loaderszawmoe aungNo ratings yet

- D 3311 - 94 - RdmzmtetotqDocument22 pagesD 3311 - 94 - RdmzmtetotqPrakash MakadiaNo ratings yet

- Circuit PlateDocument8 pagesCircuit PlateMosa Elnaid ElnaidNo ratings yet

- Approval Document ASSET DOC LOC 953Document2 pagesApproval Document ASSET DOC LOC 953andy_ramblaNo ratings yet

- Data Sheet For Flow TeeDocument2 pagesData Sheet For Flow TeeTauqueerAhmadNo ratings yet

- Codeware, Inc.: Houston, TX, USADocument45 pagesCodeware, Inc.: Houston, TX, USAballisnothingNo ratings yet

- Rociadores STD TycoDocument86 pagesRociadores STD TycoIvAldreteNo ratings yet

- Alfa Laval FilterStrainer - PDDocument4 pagesAlfa Laval FilterStrainer - PDBayu RahmansyahNo ratings yet

- Phase Identification PlateDocument8 pagesPhase Identification PlateMosa Elnaid ElnaidNo ratings yet

- Api 579Document16 pagesApi 579Muhammad Omar100% (2)

- Ho So San Pham CODDocument14 pagesHo So San Pham CODwebhareggebru06No ratings yet

- Number PlateDocument8 pagesNumber PlateMosa Elnaid ElnaidNo ratings yet

- NCHRP w197AppendixCDocument87 pagesNCHRP w197AppendixCBarroso Perez DiegoNo ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- Api 579 7 PDF FreeDocument16 pagesApi 579 7 PDF FreeJacson FonsecaNo ratings yet

- Changes in DS-1Document5 pagesChanges in DS-1Chandrasekhar SonarNo ratings yet

- Product InformationDocument56 pagesProduct InformationJose Enrique Mendoza RodriguezNo ratings yet

- DDocument26 pagesDBalkis FatihaNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- Brother P-Touch 60, 65 Parts ManualDocument18 pagesBrother P-Touch 60, 65 Parts ManualDuplessisNo ratings yet

- Flex TrayDocument56 pagesFlex TrayOzan AtıcıNo ratings yet

- British StardardDocument9 pagesBritish StardardSagubar SathikaliNo ratings yet

- AV-29BS26-JVC by Laurent PSDocument100 pagesAV-29BS26-JVC by Laurent PSHarvestNo ratings yet

- HTRI-COMPRESS Kettle CalculationsDocument227 pagesHTRI-COMPRESS Kettle Calculationsb363nk100% (2)

- OTR Installation Instruction - EngDocument14 pagesOTR Installation Instruction - EngAmir Hooshang Ghadymi MahaniNo ratings yet

- Napca Bulletins 1-65-94 Thru 17-98Document72 pagesNapca Bulletins 1-65-94 Thru 17-98lemuel bacsaNo ratings yet

- Api 579-2 - 4.2Document28 pagesApi 579-2 - 4.2Robiansah Tri AchbarNo ratings yet

- MCXADocument1 pageMCXALiz Fco PérezNo ratings yet

- 399ADocument24 pages399ADana Mera100% (2)

- Threaded Accessories: Fig. B3188 - Standard U-Bolt With 4 Hex Nuts Fig. B3188C - Standard Plastic Coated U-BoltDocument2 pagesThreaded Accessories: Fig. B3188 - Standard U-Bolt With 4 Hex Nuts Fig. B3188C - Standard Plastic Coated U-BoltJulio César MaltezNo ratings yet

- Website Catalog Icon File WebfileDocument49 pagesWebsite Catalog Icon File WebfileusdproductsNo ratings yet

- Surge and Filter ProtectionDocument3 pagesSurge and Filter Protectionjunioralamo17No ratings yet

- MN LowE Packing TS GEA32991B EnglishDocument8 pagesMN LowE Packing TS GEA32991B EnglishShantanu BiswasNo ratings yet

- Aitc 404 2005Document13 pagesAitc 404 2005Ayman IssaNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- Killark Kil - Geb-Ge - Series - Outlet - BodiesDocument9 pagesKillark Kil - Geb-Ge - Series - Outlet - BodiesjklelvisNo ratings yet

- Service Manual: AV-2106BE, AV-21B16, AV-21BMG6B, AV-21BMG6Document114 pagesService Manual: AV-2106BE, AV-21B16, AV-21BMG6B, AV-21BMG6Victor SampaNo ratings yet

- Accesorios CT3Document12 pagesAccesorios CT3Maria Teresa LRNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- Drill StemDocument28 pagesDrill Stemchonubobby100% (1)

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- Api 579-2 - 4.2Document8 pagesApi 579-2 - 4.2AliDadKhanNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Engine Does Not StartDocument10 pagesEngine Does Not Startyash1239No ratings yet

- Appendix - 6 - Site Logistics PlanDocument16 pagesAppendix - 6 - Site Logistics PlanRamesh BabuNo ratings yet

- Airflow Management SolutionsDocument16 pagesAirflow Management SolutionsJosh Thomas PanochNo ratings yet

- Catalog 44 1100 Pressure Regulator Control Tescom en 5322212Document4 pagesCatalog 44 1100 Pressure Regulator Control Tescom en 5322212Reza AranNo ratings yet

- Demolition Plan Reverb and Contop Matte and Acid PlantsDocument12 pagesDemolition Plan Reverb and Contop Matte and Acid Plantsk_arindam1No ratings yet

- Introduction LetterDocument22 pagesIntroduction LetterVvipul MaheshwariNo ratings yet

- Study On Behaviour of Partial Replacement of Cement With Sugarcane Bagasse Ash For High Strength Concrete MixDocument5 pagesStudy On Behaviour of Partial Replacement of Cement With Sugarcane Bagasse Ash For High Strength Concrete MixIAEME PublicationNo ratings yet

- Intern at Gammon (Report)Document28 pagesIntern at Gammon (Report)Azaz Ahmed50% (2)

- Macmat: Technical Data SheetDocument2 pagesMacmat: Technical Data Sheetsundra0No ratings yet

- ZStar ZQ08 Parts Service ManualDocument28 pagesZStar ZQ08 Parts Service ManualMarium ShamsiNo ratings yet

- Hvac Engineer - Equipment Heat GainDocument3 pagesHvac Engineer - Equipment Heat GainGeélisson Morello Cazotti0% (1)

- Solved ISRO Scientist or Engineer Civil 2020 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Civil 2020 Paper With SolutionsPranav NathNo ratings yet

- Lecture 6.0 - Analysis and Design For TorsionDocument22 pagesLecture 6.0 - Analysis and Design For TorsionRonnie BarreraNo ratings yet

- 285 Scale Paper BuildingsDocument7 pages285 Scale Paper BuildingsRichard KNo ratings yet

- AISC360-05 LRFD Shear Bolted Connection CheckDocument12 pagesAISC360-05 LRFD Shear Bolted Connection CheckMario FeghaliNo ratings yet

- Isolation JointDocument1 pageIsolation JointFarook MohideenNo ratings yet

- Instant Cooling System: Désignation Spécifications MateriallyDocument1 pageInstant Cooling System: Désignation Spécifications MateriallymretNo ratings yet

- Sany215c8m2k PDFDocument313 pagesSany215c8m2k PDFIsmael Grünhäuser100% (1)

- EIMS ProfileDocument33 pagesEIMS ProfileShajal KhanNo ratings yet

- 04 SpekDocument2 pages04 SpekDanis Eko TanowoNo ratings yet

- Failure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-ReviewedDocument7 pagesFailure Analysis of A Bucket Elevator Shaft: Technicalarticle-Peer-Revieweddouglasncamilo100% (1)

- SWCS - Lesson 13. Design Requirements of Gully Control StructuresDocument7 pagesSWCS - Lesson 13. Design Requirements of Gully Control StructuresIbrahim DanishNo ratings yet

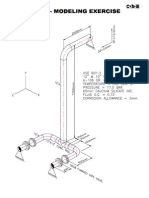

- Caesar II Modeling ExcisersDocument40 pagesCaesar II Modeling ExcisersBùi Văn Hợp100% (2)

- Direct Method Obtaining Plate Buckling Coefficient Double-Coped BeamDocument2 pagesDirect Method Obtaining Plate Buckling Coefficient Double-Coped Beamclam2014No ratings yet

- Nitofill LV TDSDocument3 pagesNitofill LV TDSkhraieric16No ratings yet

- Iso FootingDocument8 pagesIso FootingDark SpiritNo ratings yet

- Uniform Technical Guidelines For Water Reticulation and PlumbingDocument214 pagesUniform Technical Guidelines For Water Reticulation and PlumbingGan Chin PhangNo ratings yet

- Quality Modular: Pontoon SystemsDocument20 pagesQuality Modular: Pontoon SystemsMeliany SariNo ratings yet

- Sluice Valve PN.1.0 1.6 RisingDocument5 pagesSluice Valve PN.1.0 1.6 RisingDeepak PatelNo ratings yet