Professional Documents

Culture Documents

Datasheet 1

Datasheet 1

Uploaded by

Thắng Trần QuangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet 1

Datasheet 1

Uploaded by

Thắng Trần QuangCopyright:

Available Formats

TYPICAL ENGINEERING DOCUMENTATION

VSP-NIPI-TYP-TS-PI1-DS-10

DATASHEET FOR BALL VALVE CLASS BC1/BX1 -

300# Rev. 2 Page 9 of 23

DESIGN REQUIREMENTS 26 Drains, vents No

1 Valve code BAB4BL 27 Sealant injection on seats No

2 Size Range 4" to 6” 28 Sealant injection on stem Yes

3 Rating 300# 29 Lifting lugs Valve support No No

4 Piping class BC1 - Carbon Steel 30 Lock open / Lock close Yes

5 Corrosion allowance 3 mm 31 Manufacturer / Model Number Vendor to advise

6 Design Pressure range 20 ÷ 45 barg MATERIAL REQUIREMENTS

7 Design Temperature range -29 ÷ 120 C 0 32 Body & Bonnet ASTM A105N or ASTM A216 WCB

Process Gas & Liquid, Crude Oil, Process Mixed Flow,

8 Service 33 Stem/Body PTFE / Manufacture's Standard (Note 3)

Condensate Water, Closed Drain, Steam, Oily Water

Seal:

9 Insulation Yes or No (Note 1) 34 O'ring -

10 End Connection Flanged Raised Face to ASME B16.5 (Note 4) 35 Seat PTFE (Note 3)

11 Pup Piece - 36 Ball ASTM A182 F316

12 Construction standard API 6D or BS EN ISO 17292 or ASME B16.34 37 Seat inserts RPTFE

Internal Trim:

13 Construction -body Split body, replaceable ball& seats 38 Stem ASTM A182 F316 or 17-4 PH Stainless Steel

14 Reduced or full bore Full bore 39 Springs 316 Stainless Steel

15 Construction - ball Trunnion mounted type 40 Gasket Body / Bonnet 316 SS + Graphite / Manufacture's Standard

16 Extended Stem Yes or No (Note 1) 41 Bolting: Bolts ASTM A193 Gr. B7M SermaGard 1105/1280 coated

17 Operator Lever with position indicator 42 Nuts ASTM A194 Gr. 7M SermaGard 1105/1280 coated

18 Action Quarter turn TECHNICAL DELIVERY REQUIREMENTS

19 Face to face dimensions As per ASME B16.10 Long Pattern 43 Pressure test Yes, as per API 598, API 6D and Specification

20 Fire Safe Yes, as per API 607 / API6FA / BS6755 part 2 44 Non destructive tests Yes, as per API 598, API 6D and Specification

21 Anti-static device Yes, as per API 6D or BS EN ISO 17292 45 Fire Safe Test Certificate Yes, as per API 607 / API6FA / BS6755 part 2

Auto body cavity pressure

22 Yes 46 Material Certificates Yes, EN ISO 10204-3.1

relief

23 Blow out proof stem Yes 47 Marking Yes, as per MSS-SP-25 and Specification

Stem position (Vertical /

24 Suitable for both 48 Painting As per VSP-NIPI-TYP-GEN-AC7-SP-01

Horizontal)

Flow axes (Vertical /

25 Suitable for both 49 Colour code Yellow RAL 1003

Horizontal)

Notes:

1. Insulation thickness and extended stem requirement to be specified in purchase requisition.

2. Manufacturer to furnish catalogue with quotation and as-built drawing during delivery.

3. Manufacturer shall select seat and seal material to meet the design pressure / temperature range and shall be completed with quotation.

4. Raised Face (RF) flange end connections shall have surface roughness between 125 µin to 250 µin in accordance with ASME B16.5.

Văn bVảănnnbàảynđnưàợycđxưáợccth

xự

ác thạự ạsih

i hctttp :/t/teposf:f/i/ceeo.vffiiectes.ovvie.ctsoom

v..vcn

omvớ vớđiịn

.vinsố ốđ

sh dịannhhd:a

3n6h4:43/2749-/H

2S

4-M

DTH--PCTKM/K/BTMĐH

You might also like

- AS1530.7 1998 Part 7 Smoke Control Door and Shutter Assemblies - Ambient and Medium Temperature Leakage Test ProcedureDocument18 pagesAS1530.7 1998 Part 7 Smoke Control Door and Shutter Assemblies - Ambient and Medium Temperature Leakage Test Procedureluke hainesNo ratings yet

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- 120lab Report 3Document4 pages120lab Report 3Valerie Mae Librero Areño100% (2)

- Structure Loadbearing Crosswall PDFDocument41 pagesStructure Loadbearing Crosswall PDFSKhandelwalNo ratings yet

- Datasheet 5Document1 pageDatasheet 5Thắng Trần QuangNo ratings yet

- Datasheet Valve ПДНГ 0440 22Document3 pagesDatasheet Valve ПДНГ 0440 22Ngoc Huyen NguyenNo ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- NPT Sop Pde 004 f06 Bom Ball ValveDocument40 pagesNPT Sop Pde 004 f06 Bom Ball ValveMohamed SelimNo ratings yet

- XXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDocument8 pagesXXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDương HoàngNo ratings yet

- Liquip TrapDocument1 pageLiquip TrapKhánh TrầnNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- 10in 1500 MOV DatasheetDocument1 page10in 1500 MOV DatasheetkarthikNo ratings yet

- Data Sheet For Gas FilterDocument1 pageData Sheet For Gas FilterKhánh TrầnNo ratings yet

- NPT Sop Pde 004 f08 Bom Globe ValveDocument18 pagesNPT Sop Pde 004 f08 Bom Globe ValveMohamed SelimNo ratings yet

- SEAS-Manual Ball Valves Datasheet (SS)Document4 pagesSEAS-Manual Ball Valves Datasheet (SS)Dương HoàngNo ratings yet

- 01.data SheetDocument1 page01.data SheetBhargav PatelNo ratings yet

- Plummech Check ValvesDocument1 pagePlummech Check ValvesNguyễn Đăng PhúcNo ratings yet

- Warren 1155 8 Valvulas Compuert Api600 Trim 8Document4 pagesWarren 1155 8 Valvulas Compuert Api600 Trim 8Luis ArenasNo ratings yet

- Datasheet DBB Ball Valves PDFDocument1 pageDatasheet DBB Ball Valves PDFVivi OktaviantiNo ratings yet

- 2055 Ed 2FGGF7 B1 9Document1 page2055 Ed 2FGGF7 B1 9amirNo ratings yet

- Isulation GasketDocument1 pageIsulation GasketKhánh TrầnNo ratings yet

- General: Crude Oil - 219 1.117 4.6 Crude Oil - 219Document1 pageGeneral: Crude Oil - 219 1.117 4.6 Crude Oil - 219amirNo ratings yet

- Valve Datasheets KASBDocument15 pagesValve Datasheets KASBRidhuan RaisNo ratings yet

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- High Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFDocument2 pagesHigh Pressure Multi Stage Blowdown Valve ACT 83 Data Sheet PDFjayakumarNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- Val-Comp Z45XDocument1 pageVal-Comp Z45XDaniel04pvNo ratings yet

- Data Sheet UbsvDocument6 pagesData Sheet UbsvMeet JaniNo ratings yet

- Page 1 of 1Document2 pagesPage 1 of 1lich0312No ratings yet

- Automatic Air and Gas Vents For Liquid Systems - AE44Document2 pagesAutomatic Air and Gas Vents For Liquid Systems - AE44Mohamed Osama El GendiNo ratings yet

- 4510678501-50 GadDocument1 page4510678501-50 GadJamsurf DeanNo ratings yet

- TBV Series 21 80 Cryogenic Large Bore Split Body Ball ValveDocument2 pagesTBV Series 21 80 Cryogenic Large Bore Split Body Ball ValveRizal NasutionNo ratings yet

- PBV Como OrdenarDocument1 pagePBV Como OrdenarauxiliaradministrativoNo ratings yet

- Two Orifice Float Trap: DescriptionDocument4 pagesTwo Orifice Float Trap: DescriptionHiranthaNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- GLT Small ValvesDocument5 pagesGLT Small ValvesAristo MNo ratings yet

- NPT Sop Pde 004 f13 Bom Check ValveDocument18 pagesNPT Sop Pde 004 f13 Bom Check ValveMohamed SelimNo ratings yet

- Datasheet Butterfly Valve Edit (Rev)Document2 pagesDatasheet Butterfly Valve Edit (Rev)Misbachul ChoirNo ratings yet

- General: Crude Oil Crude Oil - 219 219Document1 pageGeneral: Crude Oil Crude Oil - 219 219amirNo ratings yet

- GNAK7Document1 pageGNAK7Aizat RomainoNo ratings yet

- Swing Check Valve Data Sheet: Comision Federal de ElectricidadDocument1 pageSwing Check Valve Data Sheet: Comision Federal de Electricidadjos ToricesNo ratings yet

- Page 1 of 1Document2 pagesPage 1 of 1mb.pipingNo ratings yet

- Check ValveDocument4 pagesCheck Valvescarpredator5No ratings yet

- General: Crude Oil - 219 Crude Oil - 219 1.117 82.6Document1 pageGeneral: Crude Oil - 219 Crude Oil - 219 1.117 82.6amirNo ratings yet

- 19 Series: Submittal Sheet ASME Safety ValveDocument4 pages19 Series: Submittal Sheet ASME Safety ValveRodrigo TeodoroNo ratings yet

- HidraulicaDocument4 pagesHidraulicaAntonio Anatoly Viamont PintoNo ratings yet

- Data Sheet: Cpi (Corrugated Plate Interceptor)Document1 pageData Sheet: Cpi (Corrugated Plate Interceptor)wahyu hidayatNo ratings yet

- 02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Document1 page02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Roman UgarteNo ratings yet

- Trunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500Document20 pagesTrunnion Mounted Forged Ball Valves Model FF and GG: Reduced Bore 3"-36" Full Bore 2" - 48" ASME Class 150 - 2500aleeimeranNo ratings yet

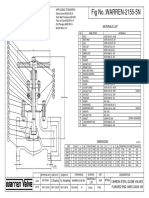

- Fig No.:WARREN-1155-5N: Materials ListDocument2 pagesFig No.:WARREN-1155-5N: Materials ListDiego OrtegaNo ratings yet

- Valvula Warren-2155-5nDocument2 pagesValvula Warren-2155-5nFernando castellano castroNo ratings yet

- Wedge Gate Valves PDFDocument4 pagesWedge Gate Valves PDFkopnangNo ratings yet

- 6 Series Pipe Fittings: FITOK GroupDocument17 pages6 Series Pipe Fittings: FITOK GroupJemmyNo ratings yet

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlar100% (1)

- ASCBZ-S-4041 Rev ADocument1 pageASCBZ-S-4041 Rev AVivek JoshiNo ratings yet

- Technical Sheet AVC32Document2 pagesTechnical Sheet AVC32Malik DaniyalNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- 4A Figure 31-41 Bronze SeriesDocument8 pages4A Figure 31-41 Bronze SeriesCarlos Alberto OspinaNo ratings yet

- PAN Ind. CatalogueDocument68 pagesPAN Ind. CatalogueThắng Trần QuangNo ratings yet

- Certificate 9A-0119Document1 pageCertificate 9A-0119Thắng Trần QuangNo ratings yet

- PAN-1005-2024 SCF Company Limited, VitenamDocument1 pagePAN-1005-2024 SCF Company Limited, VitenamThắng Trần QuangNo ratings yet

- 7me3723-1gk71-1we3-Z A82+b11+c19+e06+f00+g01+k28+l72+s30Document2 pages7me3723-1gk71-1we3-Z A82+b11+c19+e06+f00+g01+k28+l72+s30Thắng Trần QuangNo ratings yet

- Filter DatasheetDocument1 pageFilter DatasheetThắng Trần QuangNo ratings yet

- Development of A Water Treatment Plant For A RolliDocument14 pagesDevelopment of A Water Treatment Plant For A RolliThắng Trần QuangNo ratings yet

- Cooling Water QualityDocument69 pagesCooling Water QualityThắng Trần QuangNo ratings yet

- Coalescer Filter DrawingDocument1 pageCoalescer Filter DrawingThắng Trần QuangNo ratings yet

- Severn 3000 Series V1.1Document8 pagesSevern 3000 Series V1.1Thắng Trần QuangNo ratings yet

- Introduction To Technical ReportsDocument3 pagesIntroduction To Technical ReportsThắng Trần QuangNo ratings yet

- 09 WHPHT1RD3101 07Document1 page09 WHPHT1RD3101 07Thắng Trần QuangNo ratings yet

- Bs Iec 61882 2001 Hazop GuideDocument1 pageBs Iec 61882 2001 Hazop GuideThắng Trần QuangNo ratings yet

- MOM SK311 91 ME30 CS 0012 00 Blowdown Calculation For Fuel Gas SkidDocument4 pagesMOM SK311 91 ME30 CS 0012 00 Blowdown Calculation For Fuel Gas SkidThắng Trần QuangNo ratings yet

- Test Pack Contents SQ No. Title DescriptionDocument14 pagesTest Pack Contents SQ No. Title DescriptionThắng Trần QuangNo ratings yet

- Make List SLTD-J-1401-L-6-00003-02Document4 pagesMake List SLTD-J-1401-L-6-00003-02tribhuvan ShankarNo ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Sewing Skills Checklist PDFDocument44 pagesSewing Skills Checklist PDFyemkem100% (1)

- T2T 32T BTC Master Manual enDocument10 pagesT2T 32T BTC Master Manual enRAMON RUIZNo ratings yet

- Everlast INTERVAL TRAINING ROUND TIMER PDFDocument1 pageEverlast INTERVAL TRAINING ROUND TIMER PDFanniaanniaNo ratings yet

- EVM TechmaxDocument96 pagesEVM Techmaxnikhileshdhuri97No ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- Free Download All Aeronautical Engg Books: AERO 3-1 BOOKSDocument11 pagesFree Download All Aeronautical Engg Books: AERO 3-1 BOOKSMacen SnoodleNo ratings yet

- Safety Data SheetDocument5 pagesSafety Data SheetAkshay SomaniNo ratings yet

- The Fruit Garden CAL: Columbine & AcanthusDocument7 pagesThe Fruit Garden CAL: Columbine & AcanthusMiraNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Palliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Document10 pagesPalliative Ultrasound-Guided Endoscopic Diode Laser Ablation of Transitional Cell Carcinomas of The Lower Urinary Tract in Dogs.Dante Nathaniel FajardoNo ratings yet

- Gear Trains: 8.1. Angular Velocity RatioDocument16 pagesGear Trains: 8.1. Angular Velocity RatioaddisudagneNo ratings yet

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- Water Content in SoilDocument4 pagesWater Content in SoilJohn Paul CristobalNo ratings yet

- Catalogo ColonneDocument140 pagesCatalogo Colonneapi-18378576No ratings yet

- 02 Flyer Beverly LR enDocument2 pages02 Flyer Beverly LR enluisgabrielbuca2246No ratings yet

- The Efects of Tree Characteristics On Rainfall Interception in UrbanDocument8 pagesThe Efects of Tree Characteristics On Rainfall Interception in UrbanGuilherme SantanaNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- Control of Spinal Anesthesia-Induced Hypotension in Adults - PMCDocument14 pagesControl of Spinal Anesthesia-Induced Hypotension in Adults - PMCAkash SharmaNo ratings yet

- He Is A Chocolate Lover: Kamaladevi RengasamyDocument4 pagesHe Is A Chocolate Lover: Kamaladevi RengasamyKamala DeviNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- Behaviour of Hollow Core Slabs Under Point LoadsDocument17 pagesBehaviour of Hollow Core Slabs Under Point LoadsVálter LúcioNo ratings yet

- Toro Homelite 3354-726Document8 pagesToro Homelite 3354-726Cameron ScottNo ratings yet

- KDIGO CKD MBD Quick Reference Guide June 2022Document11 pagesKDIGO CKD MBD Quick Reference Guide June 2022Esy LNo ratings yet

- Md. Rizwanur Rahman - CVDocument4 pagesMd. Rizwanur Rahman - CVHimelNo ratings yet

- Bael-Tree Details and Medicinal UsesDocument4 pagesBael-Tree Details and Medicinal UsesSanjay PatilNo ratings yet