Professional Documents

Culture Documents

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Uploaded by

rathish.aCopyright:

Available Formats

You might also like

- J506Fe - 天津市金桥焊材集团有限公司 - Tianjin Golden Bridge Welding Materials Internationl Trading Co.,LtdDocument1 pageJ506Fe - 天津市金桥焊材集团有限公司 - Tianjin Golden Bridge Welding Materials Internationl Trading Co.,LtdMAYMODERN STEELNo ratings yet

- BS 7639 Short Circuit Current Calculation in 3phase AC SysteDocument92 pagesBS 7639 Short Circuit Current Calculation in 3phase AC SysteAimee Rachel Dean Rabe100% (2)

- Specification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolyteDocument5 pagesSpecification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolytepadmanabhanNo ratings yet

- Luckylight: 0805 Package Blue Chip LED Technical Data SheetDocument9 pagesLuckylight: 0805 Package Blue Chip LED Technical Data SheetWaltencirNo ratings yet

- 3066 TPS659102Document17 pages3066 TPS659102Глеб ЖигловNo ratings yet

- 01 - 1 0.6 1kV PVC Insulated Control KosmolinkDocument5 pages01 - 1 0.6 1kV PVC Insulated Control KosmolinkJose Javier SerracinNo ratings yet

- Vbhw1149jte 100 TRDocument26 pagesVbhw1149jte 100 TRdenysenkovovan84No ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- RK3066 Standar DiagramsDocument17 pagesRK3066 Standar DiagramsdomisoftNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Ce ScanDocument1 pageCe ScanAvishek GuptaNo ratings yet

- EOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFDocument4 pagesEOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFRaj RajeshNo ratings yet

- 38-p-16-68 - Copper Wire For EarthingDocument6 pages38-p-16-68 - Copper Wire For EarthingRamzanNo ratings yet

- Catalog Building Wire CableDocument2 pagesCatalog Building Wire CableFirmansyah Ramdan MNo ratings yet

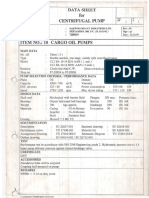

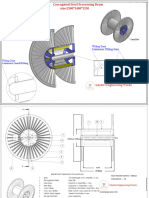

- Cargo Pump Curve - MT BourneDocument2 pagesCargo Pump Curve - MT Bournetimayaa1000100% (1)

- Polymer Aluminum Electrolytic Capacitors: - ECAS SeriesDocument9 pagesPolymer Aluminum Electrolytic Capacitors: - ECAS Serieseurostarimpex1No ratings yet

- Mra05 E03Document1 pageMra05 E03magikalea90No ratings yet

- ARD SocketsDocument3 pagesARD SocketsRenan TavaresNo ratings yet

- ABB Motor Painting SpecificationDocument2 pagesABB Motor Painting SpecificationNhien ManNo ratings yet

- Universal: WiresDocument2 pagesUniversal: WiresDeepak PawarNo ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- 19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mDocument6 pages19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mRamu DNo ratings yet

- 2500 DrumDocument2 pages2500 DrumPM PandianNo ratings yet

- SkyCiv Beam Summary ReportDocument7 pagesSkyCiv Beam Summary ReportplanninganddesignpetalsNo ratings yet

- RC1005F561CSDocument2 pagesRC1005F561CSDarwin SipayungNo ratings yet

- Sunlord TWPEP131313B305T DSDocument7 pagesSunlord TWPEP131313B305T DSrathish.aNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- T 775 PG 215-218 PDFDocument4 pagesT 775 PG 215-218 PDFJossimar PerezNo ratings yet

- Piston Seals: Technical DetailsDocument2 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Abd 0000 Ce 6 Pto 47 Uf 100 VbseriesDocument6 pagesAbd 0000 Ce 6 Pto 47 Uf 100 VbseriesIrvin FrederickNo ratings yet

- Feeler Building Instructions v1.0.1Document7 pagesFeeler Building Instructions v1.0.1ultratumbaNo ratings yet

- 2450LP15B050Document2 pages2450LP15B050Venkatesh ANo ratings yet

- Loadcell RTN 100tDocument4 pagesLoadcell RTN 100tVũ Văn Thành100% (1)

- Célula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Document4 pagesCélula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Gabriel WeissNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- SMG Folder Emea EngDocument4 pagesSMG Folder Emea EngsyNo ratings yet

- SMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416Document1 pageSMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416CADTDDNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- Ltl2r3sek 002Document11 pagesLtl2r3sek 002Pro ProNo ratings yet

- ONPOW SWITCH LAS2F Without LEDDocument1 pageONPOW SWITCH LAS2F Without LEDcosNo ratings yet

- Data Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorDocument1 pageData Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorkayakurbanoNo ratings yet

- Front: Packaging: Surface Covered Be Hanging Rolls On Palette andDocument4 pagesFront: Packaging: Surface Covered Be Hanging Rolls On Palette andksharidasNo ratings yet

- Mini Electret Mike PreamplifierDocument1 pageMini Electret Mike PreamplifierAlvaro Espagnolo García100% (1)

- 12 TerminalDocument1 page12 Terminalgrhvg_mct8224No ratings yet

- A1001 EXE A23003 ELEO Fiche - Technique - 6mm - SolaireDocument1 pageA1001 EXE A23003 ELEO Fiche - Technique - 6mm - Solaireo.sbai.sfecoNo ratings yet

- 0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enDocument1 page0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enRupaliNo ratings yet

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocument4 pagesPolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNo ratings yet

- SocketspipedryDocument1 pageSocketspipedryLuís Felipe GuimaraesNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- 536-Weld ConsumablesDocument3 pages536-Weld ConsumableschabocohueNo ratings yet

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- Aws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014Document2 pagesAws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014andirahmantanjung100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Petrr RavvNo ratings yet

- A 447 (USA / ASTM) : Group Subgroup Comment Application MaterialDocument2 pagesA 447 (USA / ASTM) : Group Subgroup Comment Application MaterialBrio LevNo ratings yet

- BF 065Document1 pageBF 065vahid hajihasaniNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- керам 4Document1 pageкерам 4Georgii DavlianidzeNo ratings yet

- Cinemag TransformerDocument1 pageCinemag TransformeraanjinnNo ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- BIRCHER Manual RFGate 3.2Document4 pagesBIRCHER Manual RFGate 3.2DmitriiȘtirbuNo ratings yet

- Portable Plasma Torch Height Controller Manual: Type F1620Document46 pagesPortable Plasma Torch Height Controller Manual: Type F1620Syurriya LeedangNo ratings yet

- Grundfos - 43-100f Submittal SheetDocument4 pagesGrundfos - 43-100f Submittal Sheetsas999333No ratings yet

- Part 001 CNT Guide To Control Panel Cable Identification PDFDocument7 pagesPart 001 CNT Guide To Control Panel Cable Identification PDFDany ArriagadaNo ratings yet

- Co Project: Edge Avoiding Robot USING 8051 MicrocontrollerDocument14 pagesCo Project: Edge Avoiding Robot USING 8051 MicrocontrollerJuthik BVNo ratings yet

- 25 KV Equipment Sizing Calculationv5 - PDFDocument56 pages25 KV Equipment Sizing Calculationv5 - PDFAbhas Gupta100% (2)

- 04 05 2016 PDFDocument6 pages04 05 2016 PDFLovielyn Poquiz De VeraNo ratings yet

- X-Ray Lithography Can Be Extended To An Optical Resolution of 15 NM byDocument10 pagesX-Ray Lithography Can Be Extended To An Optical Resolution of 15 NM byThư CaoNo ratings yet

- Narmada Diff Relay SettingsDocument33 pagesNarmada Diff Relay SettingsJayam kondan100% (1)

- Iec Standards PDFDocument2 pagesIec Standards PDFNestrami100% (1)

- Cable For VFD DriveDocument16 pagesCable For VFD Driveanindya19879479No ratings yet

- 150W Explosion Proof LED Flood Light - Surface Mount - 21,000 Lumens - C1D1 - 120-277V ACDocument3 pages150W Explosion Proof LED Flood Light - Surface Mount - 21,000 Lumens - C1D1 - 120-277V ACpo truongNo ratings yet

- How To Connect 2 Speakers To 1 AmplifierDocument4 pagesHow To Connect 2 Speakers To 1 AmplifiermarranNo ratings yet

- Single-Phase Core Regulator For Imvp-6 Mobile Cpus Features: Fn9251.1 Data Sheet September 27, 2006Document34 pagesSingle-Phase Core Regulator For Imvp-6 Mobile Cpus Features: Fn9251.1 Data Sheet September 27, 2006FrankNo ratings yet

- 2022 IRDS CryogenicElectronicsQuantumIPDocument113 pages2022 IRDS CryogenicElectronicsQuantumIPJalu ReswaraNo ratings yet

- Banner LS4 LS10 Part Sensing SensorsDocument7 pagesBanner LS4 LS10 Part Sensing SensorsMemik TylnNo ratings yet

- Installation: Base Transceiver Station Equipment Imn:Btse Bs-82 EmicroDocument48 pagesInstallation: Base Transceiver Station Equipment Imn:Btse Bs-82 EmicroAlexandarNo ratings yet

- Electric Potential: Answers To QuestionsDocument26 pagesElectric Potential: Answers To QuestionsgaferoprNo ratings yet

- Type Approval Certificate Extension: Prod UcerDocument4 pagesType Approval Certificate Extension: Prod Ucermuhammad ali shamozaiNo ratings yet

- Lesco Junior Engineer PaperDocument22 pagesLesco Junior Engineer Papermuhammad awaisNo ratings yet

- LSG 300Document2 pagesLSG 300Martin NNo ratings yet

- Module 1 Medium Voltage Switchgear AssembliesDocument46 pagesModule 1 Medium Voltage Switchgear Assembliesabhijit_wceNo ratings yet

- Microwave BasicsDocument30 pagesMicrowave BasicsOlonibua Abiodun83% (6)

- Arb 702 IDocument2 pagesArb 702 Iyu3zaNo ratings yet

- Consul Online UpsDocument2 pagesConsul Online UpsElectrical JKFMNo ratings yet

- V Guard Wires CablesDocument16 pagesV Guard Wires CablesRitesh TyagiNo ratings yet

- COMPASS ERROR Copy5Document3 pagesCOMPASS ERROR Copy5Francis ParisNo ratings yet

- Chapter 2Document62 pagesChapter 2Yufan DingNo ratings yet

- Colortran Mini Broad Spec Sheet 1995Document2 pagesColortran Mini Broad Spec Sheet 1995Alan MastersNo ratings yet

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Uploaded by

rathish.aOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Confidential, PLZ Donot Photocopy-R&D-Sel-Ii: Controlled

Uploaded by

rathish.aCopyright:

Available Formats

Page:1 of 5

CONTROLLED

Core COPY

Specification

II

EL-

-S

&D

-R

PY

Core Details

Material: ZDMH

O

Strip Thickness: 0.23MM

C

Stacking Factor: 97.50% TO

O

PH

Core Description:CORE 270X195X135MM ZDMH 0.23MM THICKNESS

Core Size 1.55T 1.70T

T

Core I/P I/P

O

SalzerP/n OD ID HT Weight Testing Voltage No Load Voltage No Load

(±1.0mm) (±1.0mm) (±0.2mm) in Kgs Turns (V)@50HZ Current(A) (V)@50HZ Current(A)

N

O

A630747 270 195 135 26.88 15 24.82 0.88 27.31 1.20

D

L Z

Surface Treatment

,P

1.Wound toroidal cores shall be supplied with a coating of Dr.Beck's Elmoluft 1AFD

2.Application of any other paint is not acceptable.The Varnish/resin coating shall be continuous and smooth.No lumps/Blemishes allowed.

AL

3.This varnish/resin shall be applied immediately after annealing process and shall be properly cured before handling

4.No traced of rust shall be found before the job is taken for varnish or resin impregnation

TI

EN

Additional Parameters

1.Packing method: Palletized packing, share us the packing photos before shipping

D

2.Oval core not accepted

FI

3.Loose winding not accepted.

4.Sufficient spot welding should be placed at start and end.

N

5.Joint cores are not accepted

O

6.Painted core are not accepted.

C

7.Before dispatch share us the core photos.

8.Varnish should be properly cured, uneven surface finish after varnish dipping are not accepted.

9.Core oxidation/color change after annealing will not be accepted.

10.core should not have burr at the start and finish strip end

11.Inside and outside laps to be welded in a manner that will not break under normal manufacturing handling and winding.

Manufacture COC and inspection report should be sent along with each consignment which is a mandatory requirement.

Confidential Drawing Prepared by

This Drawing is a property of Salzer Electronics Ltd.II BLESSY

should not be copied or communicated to any body without

The Permission of Salzer Electronics LTD. Date:13/Apr/2024

This is Auto Generated drawing.

CONTORLLED COPY

1. QUALITY REQUIREMENTS:

1.1 MATERIAL TYPE : CORE ROLLED GRAIN ORIENTED SILICONE STEEL

Parameters M4 MOH ZDMH

Strip thickness 0.27 mm 0.23 mm 0.23 mm

Permeability ( µ4) 2000 ( approx) 2000 ( approx) 2000 ( approx)

Peak permeability > 35000 > 35000 > 35000

Saturation

2 2 2

induction(min)

II

7.65kg/cm3 7.65kg/cm3 7.65kg/cm3

L-

Density

E

Stacking factor 0.96 0.96 0.96

-S

Power loss at 1.7T

1.25watts 0.95 watts 0.85 watts

&D

(as per IS 3024)

Magnetizing force

-R

Of wound annealed @14200 gauss @15000 gauss @15500 gauss

PY

core

AT/cm max =0.260 0.220 =0.181

O

Magnetizing force

C

of wound annealed @15620 gauss @16500 gauss @170500 gauss

TO

core

AT/cm max =0.320 0.30 =0.246

O

PH

Material Grade M4 MOH ZDMH

1.3 SURFACE TREATMENT:

T

O

N

Wound toroidal cores shall be supplied with a coating of Dr.Beck’s Elmoluft/equivalent insulating

O

varnish on all outer surface. Alternatively,Atul make A35/K35 resin hardener system may be used for

D

resin impregnation. Application of any other paint is not acceptable.The varnish /resin coating shall

be continuous and smooth. No lumps / Blemishes allowed.

L Z

This varnish / resin shall be applied immediately after annealing process and shall be properly

,P

cured before handling. No traces of rust shall be found before the job is taken for varnishing or

AL

resin impregnation.

TI

EN

D

FI

N

O

C

Pre: A.D 03.07.17 Salzer Electronics Limited Unit-II, CBE-641019 Material

This drawing is a property of Salzer Electronics Limited Unit-II .

Che: A.V 03.07.17 It should not be copied or communicated to any body with out DWG No Ref Page 1

written permission

Apd: S.P 03.07.17 Page 2 of 5 REV 00

Description: Core Specification FORM NO:TX-PI-01-00

CONTORLLED COPY

1.4 RAW MATERIAL:

Prime material manufactured by reputed manufacturers like AK Steel / Cogent

/Nippon Steel/Thyssen Krupp shall be used for manufacturing CT cores.

Each core shall be traceable to the mother coil with all process parameters in place.

For a given batch, select a common raw material. Do not mix different raw materials

(batch or make) for producing a given lot under an order. This may cause variation of

excitation current beyond the specified band. Using different brands of raw materials may

be used subject to having consistent results for the complete lot of CTs.

For continuous improvement, the raw material manufactures may periodically come up

II

with new grades of materials with low losses and enhanced electrical properties. Salzer to

L-

not averse to use of such better materials, but shall be consulted before using

E

any such new materials for manufacturing the cores.

-S

&D

1.5 MANUFACTURING

-R

1. The winding shall be continuous and smooth under constant tension.

2. The edges shall be in one plane after the winding. Waviness on edges not accepted.

PY

However, the waviness is not specified, generally shall be controlled by visual inspection.

O

3. Materials with rust or loss of insulation shall not be used.

C

4. The start and end of the core shall be spot welded and secured.

TO

5. Each core shall bear a serial number and traceable to its mother coil and all

process parameters including final test results shall be available for all the cores.

O

6. The annealing of the cores shall be done using a batch furnace. The annealing cycle

PH

shall be clearly specified. The serial numbers of the cores and position of each core in

the oven must be recorded. Preferably, the annealing process shall be automatically

controlled.

T

7. The annealing shall be done at an inert atmosphere like Nitrogen gas. Methodology of

O

Nitrogen purging shall be clearly specified.

N

8. The cores shall be allowed to cool naturally. No forced cooling shall be done.

O

9. All cores shall be stacked horizontally inside the oven during annealing.

D

10. The cores shall be handled with utmost care during each manufacturing stage and

Z

as far as possible, shall be handled in horizontal position.

L

11. Surface treatment against rust /moisture ingress shall be done with specified

,P

varnish soon after the core attains room temperature. The cores shall be handled

AL

only after curing / touch drying the varnish coating.

TI

EN

D

FI

N

O

C

Pre: A.D 03.07.17 Salzer Electronics Limited Unit-II, CBE-641019 Material

This drawing is a property of Salzer Electronics Limited Unit-II .

Che: A.V 03.07.17 It should not be copied or communicated to any body with out DWG No Ref Page 1

written permission

Apd: S.P 03.07.17 Page 3 of 5 REV 00

Description: Core Specification FORM NO:TX-PI-01-00

CONTORLLED COPY

2. TESTING REUIREMENTS:

2.1 TYPE TEST:

Conductivity

Chemial analysis (Typical chemical composition of grain oriented silicon steel are:

C=0.003%, Mn=0.07% ,P=0.01%, S=0.001% and Si=3.0-3.5%) .There could be minor

changes from these values for different manufacturers.

AT/cm evaluation at specified flux densities (BH Curve.)

1. FREQUENCY OF TYPE TEST:

II

Once in every 6 months.

L-

E

2. ROUTINE TEST:

-S

&D

1. Dimensional check. 100% cores shall be checked for dimensions.

-R

2. Magnetic Characteristics Test ( VI test) –applicable for frequency =50 Hz only. 100% cores shall

PY

be tested for VI test.

3. Each core should have serial number and traceable back to mother coil.

O

C

4. Test report shall contain dimensional report and VI test values at 15 turns for CRGO and 15 turns for

MOH & ZDMH.

TO

O

PH

5. The excitation current values shall be within a range of 20% band (the maximum variation

allowed from the average value shall be ±10% ) for a given order quantity for the same size of a

T

core.

O

3. TEST REPORTS/DEVIATIONS:

N

Supplier should send the test report to SALZER and get approval before dispatch.

O

D

L Z

,P

AL

TI

EN

Features Annotated Inside the Box are CTQ.

D

FI

N

O

C

Pre: A.D Salzer Electronics Limited Unit-II, CBE-641019 Material

03.07.17

This drawing is a property of Salzer Electronics Limited Unit-II .

Che: A.V 03.07.17 It should not be copied or communicated to any body with out DWG No Ref Page 1

written permission

Apd: S.P 03.07.17 Page 4 of 5 REV 00

Description: Core Specification FORM NO:TX-PI-01-00

CONTORLLED COPY

3. PACKING AND TRANSPORT CONDITIONS:

3.1 PACKING :

The cores need to be individually put inside a polythene bag ( 60-80 microns thick) and

sealed and then packed in a wooden box with adequate cushions. Cores shall be properly

anchored to avoid relative movements during transport. Sufficient cushion shall me

provided between each cores in case they are stacked one over another. Do not use

hygroscopic materials ( like any form of paper) as cushion as they will ingress moisture and

may lead to rusting of cores. Ensure that entire set of cores are wrapped by polythene

sheet of adequate thickness within the packing case to avoid moisture ingress or

II

accident contact with water. Proper pallets shall be provided on packing case for ease of

L-

handling and movement.

E

-S

3.2 TRANSPORT:

&D

The packing cases shall be transported horizontally so as to avoid mechanical stress on the

-R

Cores. The boxes shall be properly stacked and anchored to avoid movement / jerks

PY

during transportation. Further, protection like plastic sheet / tarpaulin shall be provided

over the packing cases to avoid contact with rain water. Transporter shall be adequately

O

advised the importance of safe transport of the cores. No transshipment is allowed.

C

TO

O

PH

T

O

N

O

D

L Z

,P

AL

TI

EN

D

FI

N

O

C

Pre: A.D 03.07.17 Salzer Electronics Limited Unit-II, CBE-641019 Material

This drawing is a property of Salzer Electronics Limited Unit-II .

Che: A.V 03.07.17 It should not be copied or communicated to any body with out DWG No Ref Page 1

written permission

Apd: S.P 03.07.17 Page 5 of 5 REV 00

Description: Core Specification FORM NO:TX-PI-01-00

You might also like

- J506Fe - 天津市金桥焊材集团有限公司 - Tianjin Golden Bridge Welding Materials Internationl Trading Co.,LtdDocument1 pageJ506Fe - 天津市金桥焊材集团有限公司 - Tianjin Golden Bridge Welding Materials Internationl Trading Co.,LtdMAYMODERN STEELNo ratings yet

- BS 7639 Short Circuit Current Calculation in 3phase AC SysteDocument92 pagesBS 7639 Short Circuit Current Calculation in 3phase AC SysteAimee Rachel Dean Rabe100% (2)

- Specification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolyteDocument5 pagesSpecification For Fixed, Insulated, Hermetically Sealed Tantalum Capacitors With Solid ElectrolytepadmanabhanNo ratings yet

- Luckylight: 0805 Package Blue Chip LED Technical Data SheetDocument9 pagesLuckylight: 0805 Package Blue Chip LED Technical Data SheetWaltencirNo ratings yet

- 3066 TPS659102Document17 pages3066 TPS659102Глеб ЖигловNo ratings yet

- 01 - 1 0.6 1kV PVC Insulated Control KosmolinkDocument5 pages01 - 1 0.6 1kV PVC Insulated Control KosmolinkJose Javier SerracinNo ratings yet

- Vbhw1149jte 100 TRDocument26 pagesVbhw1149jte 100 TRdenysenkovovan84No ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- RK3066 Standar DiagramsDocument17 pagesRK3066 Standar DiagramsdomisoftNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Ce ScanDocument1 pageCe ScanAvishek GuptaNo ratings yet

- EOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFDocument4 pagesEOS Ti64 9011-0039 M400-MDS FlexLine 02-17 en PDFRaj RajeshNo ratings yet

- 38-p-16-68 - Copper Wire For EarthingDocument6 pages38-p-16-68 - Copper Wire For EarthingRamzanNo ratings yet

- Catalog Building Wire CableDocument2 pagesCatalog Building Wire CableFirmansyah Ramdan MNo ratings yet

- Cargo Pump Curve - MT BourneDocument2 pagesCargo Pump Curve - MT Bournetimayaa1000100% (1)

- Polymer Aluminum Electrolytic Capacitors: - ECAS SeriesDocument9 pagesPolymer Aluminum Electrolytic Capacitors: - ECAS Serieseurostarimpex1No ratings yet

- Mra05 E03Document1 pageMra05 E03magikalea90No ratings yet

- ARD SocketsDocument3 pagesARD SocketsRenan TavaresNo ratings yet

- ABB Motor Painting SpecificationDocument2 pagesABB Motor Painting SpecificationNhien ManNo ratings yet

- Universal: WiresDocument2 pagesUniversal: WiresDeepak PawarNo ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- 19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mDocument6 pages19052018-QATAR-MAN-CEILING MOUNTED-SPACING 1.2mRamu DNo ratings yet

- 2500 DrumDocument2 pages2500 DrumPM PandianNo ratings yet

- SkyCiv Beam Summary ReportDocument7 pagesSkyCiv Beam Summary ReportplanninganddesignpetalsNo ratings yet

- RC1005F561CSDocument2 pagesRC1005F561CSDarwin SipayungNo ratings yet

- Sunlord TWPEP131313B305T DSDocument7 pagesSunlord TWPEP131313B305T DSrathish.aNo ratings yet

- 1LE1003 1DA43 4AB4 Datasheet enDocument1 page1LE1003 1DA43 4AB4 Datasheet enElio TavaresNo ratings yet

- T 775 PG 215-218 PDFDocument4 pagesT 775 PG 215-218 PDFJossimar PerezNo ratings yet

- Piston Seals: Technical DetailsDocument2 pagesPiston Seals: Technical DetailsRPINILLA (EICO S.A.)No ratings yet

- Abd 0000 Ce 6 Pto 47 Uf 100 VbseriesDocument6 pagesAbd 0000 Ce 6 Pto 47 Uf 100 VbseriesIrvin FrederickNo ratings yet

- Feeler Building Instructions v1.0.1Document7 pagesFeeler Building Instructions v1.0.1ultratumbaNo ratings yet

- 2450LP15B050Document2 pages2450LP15B050Venkatesh ANo ratings yet

- Loadcell RTN 100tDocument4 pagesLoadcell RTN 100tVũ Văn Thành100% (1)

- Célula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Document4 pagesCélula de Carga - Download-Hbm-Rtnc3-A5d7a2ff56Gabriel WeissNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- SMG Folder Emea EngDocument4 pagesSMG Folder Emea EngsyNo ratings yet

- SMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416Document1 pageSMR-TS-1.7-1.6-3.6GRE Draft Spec Sheet - 200416CADTDDNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesAmit HasanNo ratings yet

- Ltl2r3sek 002Document11 pagesLtl2r3sek 002Pro ProNo ratings yet

- ONPOW SWITCH LAS2F Without LEDDocument1 pageONPOW SWITCH LAS2F Without LEDcosNo ratings yet

- Data Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorDocument1 pageData Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorkayakurbanoNo ratings yet

- Front: Packaging: Surface Covered Be Hanging Rolls On Palette andDocument4 pagesFront: Packaging: Surface Covered Be Hanging Rolls On Palette andksharidasNo ratings yet

- Mini Electret Mike PreamplifierDocument1 pageMini Electret Mike PreamplifierAlvaro Espagnolo García100% (1)

- 12 TerminalDocument1 page12 Terminalgrhvg_mct8224No ratings yet

- A1001 EXE A23003 ELEO Fiche - Technique - 6mm - SolaireDocument1 pageA1001 EXE A23003 ELEO Fiche - Technique - 6mm - Solaireo.sbai.sfecoNo ratings yet

- 0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enDocument1 page0.37 KW 1LE7503-0CB32-3FA4 - Datasheet - enRupaliNo ratings yet

- Polishing Process For Heatcure Fiber Optic Connectors: 1. GeneralDocument4 pagesPolishing Process For Heatcure Fiber Optic Connectors: 1. GeneralAbNo ratings yet

- SocketspipedryDocument1 pageSocketspipedryLuís Felipe GuimaraesNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument2 pagesData Sheet For Three-Phase Squirrel-Cage-MotorsKadehar4No ratings yet

- 536-Weld ConsumablesDocument3 pages536-Weld ConsumableschabocohueNo ratings yet

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- Aws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014Document2 pagesAws b2.1 BMG Base Metal Grouping For Welding Procedure and Performance Qualification 2014andirahmantanjung100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Petrr RavvNo ratings yet

- A 447 (USA / ASTM) : Group Subgroup Comment Application MaterialDocument2 pagesA 447 (USA / ASTM) : Group Subgroup Comment Application MaterialBrio LevNo ratings yet

- BF 065Document1 pageBF 065vahid hajihasaniNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- керам 4Document1 pageкерам 4Georgii DavlianidzeNo ratings yet

- Cinemag TransformerDocument1 pageCinemag TransformeraanjinnNo ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- BIRCHER Manual RFGate 3.2Document4 pagesBIRCHER Manual RFGate 3.2DmitriiȘtirbuNo ratings yet

- Portable Plasma Torch Height Controller Manual: Type F1620Document46 pagesPortable Plasma Torch Height Controller Manual: Type F1620Syurriya LeedangNo ratings yet

- Grundfos - 43-100f Submittal SheetDocument4 pagesGrundfos - 43-100f Submittal Sheetsas999333No ratings yet

- Part 001 CNT Guide To Control Panel Cable Identification PDFDocument7 pagesPart 001 CNT Guide To Control Panel Cable Identification PDFDany ArriagadaNo ratings yet

- Co Project: Edge Avoiding Robot USING 8051 MicrocontrollerDocument14 pagesCo Project: Edge Avoiding Robot USING 8051 MicrocontrollerJuthik BVNo ratings yet

- 25 KV Equipment Sizing Calculationv5 - PDFDocument56 pages25 KV Equipment Sizing Calculationv5 - PDFAbhas Gupta100% (2)

- 04 05 2016 PDFDocument6 pages04 05 2016 PDFLovielyn Poquiz De VeraNo ratings yet

- X-Ray Lithography Can Be Extended To An Optical Resolution of 15 NM byDocument10 pagesX-Ray Lithography Can Be Extended To An Optical Resolution of 15 NM byThư CaoNo ratings yet

- Narmada Diff Relay SettingsDocument33 pagesNarmada Diff Relay SettingsJayam kondan100% (1)

- Iec Standards PDFDocument2 pagesIec Standards PDFNestrami100% (1)

- Cable For VFD DriveDocument16 pagesCable For VFD Driveanindya19879479No ratings yet

- 150W Explosion Proof LED Flood Light - Surface Mount - 21,000 Lumens - C1D1 - 120-277V ACDocument3 pages150W Explosion Proof LED Flood Light - Surface Mount - 21,000 Lumens - C1D1 - 120-277V ACpo truongNo ratings yet

- How To Connect 2 Speakers To 1 AmplifierDocument4 pagesHow To Connect 2 Speakers To 1 AmplifiermarranNo ratings yet

- Single-Phase Core Regulator For Imvp-6 Mobile Cpus Features: Fn9251.1 Data Sheet September 27, 2006Document34 pagesSingle-Phase Core Regulator For Imvp-6 Mobile Cpus Features: Fn9251.1 Data Sheet September 27, 2006FrankNo ratings yet

- 2022 IRDS CryogenicElectronicsQuantumIPDocument113 pages2022 IRDS CryogenicElectronicsQuantumIPJalu ReswaraNo ratings yet

- Banner LS4 LS10 Part Sensing SensorsDocument7 pagesBanner LS4 LS10 Part Sensing SensorsMemik TylnNo ratings yet

- Installation: Base Transceiver Station Equipment Imn:Btse Bs-82 EmicroDocument48 pagesInstallation: Base Transceiver Station Equipment Imn:Btse Bs-82 EmicroAlexandarNo ratings yet

- Electric Potential: Answers To QuestionsDocument26 pagesElectric Potential: Answers To QuestionsgaferoprNo ratings yet

- Type Approval Certificate Extension: Prod UcerDocument4 pagesType Approval Certificate Extension: Prod Ucermuhammad ali shamozaiNo ratings yet

- Lesco Junior Engineer PaperDocument22 pagesLesco Junior Engineer Papermuhammad awaisNo ratings yet

- LSG 300Document2 pagesLSG 300Martin NNo ratings yet

- Module 1 Medium Voltage Switchgear AssembliesDocument46 pagesModule 1 Medium Voltage Switchgear Assembliesabhijit_wceNo ratings yet

- Microwave BasicsDocument30 pagesMicrowave BasicsOlonibua Abiodun83% (6)

- Arb 702 IDocument2 pagesArb 702 Iyu3zaNo ratings yet

- Consul Online UpsDocument2 pagesConsul Online UpsElectrical JKFMNo ratings yet

- V Guard Wires CablesDocument16 pagesV Guard Wires CablesRitesh TyagiNo ratings yet

- COMPASS ERROR Copy5Document3 pagesCOMPASS ERROR Copy5Francis ParisNo ratings yet

- Chapter 2Document62 pagesChapter 2Yufan DingNo ratings yet

- Colortran Mini Broad Spec Sheet 1995Document2 pagesColortran Mini Broad Spec Sheet 1995Alan MastersNo ratings yet