Professional Documents

Culture Documents

ASTM B 498 B 498M 98 Reapproved 2002

ASTM B 498 B 498M 98 Reapproved 2002

Uploaded by

Engr. Mehadi Hassan NahidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM B 498 B 498M 98 Reapproved 2002

ASTM B 498 B 498M 98 Reapproved 2002

Uploaded by

Engr. Mehadi Hassan NahidCopyright:

Available Formats

Designation: B 498/B 498M – 98 (Reapproved 2002)

Standard Specification for

Zinc-Coated (Galvanized) Steel Core Wire for Aluminum

Conductors, Steel Reinforced (ACSR)1

This standard is issued under the fixed designation B 498/B 498M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope diameter and unit lengths submitted for inspection at the same

1.1 This specification covers round, zinc-coated, steel core time.

wire with three classes of zinc coating used for mechanical 4. Classification

reinforcement in the manufacture of aluminum conductors,

steel-reinforced (ACSR). 4.1 The wire is furnished in three classes of coating, Class

1.2 This specification covers wire of diameter from 0.0500 A, Class B, or Class C, as specified, in conformance with the

requirements of Section 10 and Table 1 or Table 2.

--`,,,,``````,``````,`,`````,`-`-`,,`,,`,`,,`---

to 0.1900 in. or 1.60 to 4.80 mm, inclusive.

1.3 The values stated in inch-pound units or SI units are to 5. Ordering Information

be regarded separately as standard. The values in each system

are not exact equivalents; therefore, each system shall be used 5.1 Orders for material under this specification shall include

independently of the other. Combining values from the two the following information:

systems may result in nonconformance with this specification. 5.1.1 Quantity of each size,

5.1.2 Wire diameter in inches or millimetres (Section 14),

2. Referenced Documents 5.1.3 Class of coating (see 4.1),

2.1 The following documents of the issue in effect on date 5.1.4 Certification, if required (Section 19),

of material purchase form a part of this specification to the 5.1.5 Test report, if required (Section 19), and

extent referenced herein. 5.1.6 Package size (Section 20).

2.2 ASTM Standards: 6. Materials and Manufacture

A 90/A 90M Test Method for Weight [Mass] of Coating on

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings2 6.1 The base metal shall be steel produced by the open-

A 370 Test Methods and Definitions for Mechanical Testing hearth, electric-furnace, or basic-oxygen process.

of Steel Products3 6.2 The wire shall be cold drawn and coated with zinc to

A 751 Test Methods, Practices, and Terminology for produce the desired properties.

Chemical Analysis of Steel Products3 6.3 The slab zinc used for coating shall be high-grade or

B 6 Specification for Zinc4 better, conforming to Specification B 6.

B 193 Test Method for Resistivity of Electrical Conductor 7. Chemical Composition

Materials5

7.1 The steel shall conform to the requirements prescribed

3. Terminology in Table 3.

3.1 Definition: 7.2 Chemical analysis shall be conducted in accordance

3.1.1 lot—unless otherwise specified in the contract or with Test Methods, Practices, and Terminology A 751.

order, a lot shall consist of all coils of wire of the same 8. Tensile Test

8.1 The zinc-coated steel core wire shall conform to the

1

This specification is under the jurisdiction of ASTM Committee B01 on tensile and elongation requirements prescribed in Table 4 and

Electrical Conductors and is the direct responsibility of Subcommittee B01.05 on Table 5.

Conductors of Ferrous Metals.

Current edition approved Sept. 10, 1998. Published November 1998. Originally

8.2 Tensile tests shall be conducted in accordance with Test

published as B 498 – 69 to replace B 245 and B 261. Last previous edition Methods and Definitions A 370, using the initial settings for

B 498 – 93. determining stress at 1 % extension given in Table 6 or Table

2

Annual Book of ASTM Standards, Vol 01.06. 7 of this specification.

3

Annual Book of ASTM Standards, Vol 01.03.

4

Annual Book of ASTM Standards, Vol 02.04.

8.3 Test Specimens—The test specimens shall be free of

5

Annual Book of ASTM Standards, Vol 02.03. bends or kinks other than the curvature resulting from the usual

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=korea univ/5930616001, User=jack, leo

No reproduction or networking permitted without license from IHS Not for Resale, 01/08/2007 05:01:28 MST

B 498/B 498M – 98 (2002)

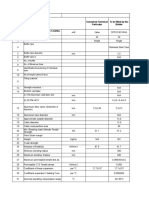

TABLE 1 Zinc Coating NOTE 1—During the adhesion test the loosening or detachment of

Area Density of Coating, min, oz/ft2 of superficial, small particles of zinc formed by mechanical polishing of the

Specified Diameter of Coated Uncoated Wire Surface surface of the zinc-coated wire shall not be considered cause for rejection.

Wire, in.

Class A Class B Class C

12. Joints

0.0500 to 0.599, incl 0.60 1.20 1.80

0.0600 to 0.0749, incl 0.65 1.30 1.95 12.1 No joints shall be made in the finished wire.

0.0750 to 0.0899, incl 0.70 1.40 2.10 12.2 Joints may be made at any stage of processing before

0.0900 to 0.1039, incl 0.75 1.50 2.25

0.1040 to 0.1199, incl 0.80 1.60 2.40

final cold drawing by the electric butt-weld or flash-welding

0.1200 to 0.1399, incl 0.85 1.70 2.55 process.

0.1400 to 0.1799, incl 0.90 1.80 2.70 12.3 Welding equipment and procedure shall be such that it

0.1800 to 0.1900, incl 1.00 2.00 3.00

can be demonstrated that the tensile strength of a finished wire

specimen containing the welded section shall not be less than

96 % of the specified minimum stress at 1 % extension.

TABLE 2 Zinc Coating

12.4 A welded section shall not be required to meet the

Area Density of Coating, min, g/m2 of

Specified Diameter of Coated Uncoated Wire Surface

stress at 1 % extension, elongation, and wrap tests.

Wire, mm

Class A Class B Class C 13. Density and Resistivity

1.60 to 1.90, incl 210 420 630 13.1 For the purposes of calculating mass per unit length,

--`,,,,``````,``````,`,`````,`-`-`,,`,,`,`,,`---

Over 1.90 to 2.30, incl 220 440 660

Over 2.30 to 2.70, incl 230 460 690 cross-sections, and so forth, the density of galvanized steel

Over 2.70 to 3.10, incl 240 480 720 wire at 20°C shall be taken as 0.281 lb/in.3(7780 kg/m3).

Over 3.10 to 3.50, incl 260 520 780 13.2 A maximum resistivity of galvanized steel wire is not

Over 3.50 to 3.90, incl 270 540 810

Over 3.90 to 4.50, incl 275 550 825 guaranteed, but a typical value of 0.191 57 V·mm 2/m may be

Over 4.50 to 4.80, incl 300 600 900 used for purposes of calculation. For conversion to other units

of conductivity or resistivity, refer to Test Method B 193.

TABLE 3 Chemical Requirements 14. Dimensions and Permissible Variations

Element Composition, % 14.1 The specified diameter shall be expressed in decimal

Carbon 0.50 to 0.85 fractions of an inch to four decimal places or in millimetres and

Manganese 0.50 to 1.10 decimal fractions of a millimetre to two decimal places.

Phosphorus, max 0.035 14.2 For diameter measurements and diameter tolerances,

Sulfur, max 0.045

Silicon 0.10 to 0.35 specified diameters shall be rounded to the closest 0.0005 in. or

0.01 mm.

14.3 Determine the greatest and least diameters each to the

neareast 0.001 in. or 0.01 mm, at the same cross-section. The

coiling operations. Any hand straightening necessary to permit

average of these two diameters shall not differ from the

insertion of the specimen in the jaws of the testing machine

specified diameter by more than the tolerances shown in Table

shall be performed by drawing between wood blocks or by

10 and Table 11.

some other equally satisfactory means.

15. Workmanship, Finish, and Appearance

9. Wrap Test

15.1 The zinc coating shall be reasonably smooth, continu-

9.1 The material, as represented by the test specimens, shall ous, of reasonably uniform thickness, and free from imperfec-

not fracture when the galvanized wire is wrapped at a rate not tions not consistent with good commercial practice.

exceeding 15 turns/min in a close helix of at least eight turns

around a cylindrical mandrel with a diameter equal to two 16. Number of Tests and Retests

times the specified diameter of the wire under test, 65 %. 16.1 One test specimen shall be taken from each 5000 lbs or

2500 kg. or fraction, thereof, in the inspection lot.

10. Coating Test 16.2 Each specimen shall be tested for compliance with

10.1 The material, as represented by the test specimens, Sections 8, 9, 11, and 14. At least half of the specimens shall

shall conform to the coating requirements of Table 1 or Table be tested for compliance with Section 10.

2. for the diameter and class of coating specified. 16.3 Should one or more of the test specimens fail any of

10.2 The coating test shall be conducted in accordance with the tests specified, the nonconforming coil or coils may be

Test Method A 90/A 90M. removed and the balance of the lot subjected to retests. For

retest purposes, two additional coils for each 5000 lbs or 2500

11. Adherence of Coating Test kg. in the lot shall be sampled and tested for the property in

11.1 The zinc-coated wire shall be capable of being which the original sample failed to comply.

wrapped in a close helix at a rate not exceeding 15 turns/min 16.4 Should any of the retest specimens fail to meet the

around a cylindrical mandrel having a diameter as prescribed in properties specified, the lot represented by the test specimens

Table 8 and Table 9, without cracking or flaking the zinc shall be rejected.

coating to such an extent that any zinc can be removed by 16.5 Instead of rejecting the entire lot as provided in 16.4,

rubbing with the bare fingers. the producer may test specimens from every coil in the lot for

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=korea univ/5930616001, User=jack, leo

No reproduction or networking permitted without license from IHS Not for Resale, 01/08/2007 05:01:28 MST

B 498/B 498M – 98 (2002)

TABLE 4 Tensile Requirements

Stress at 1 % Extension, min, Ksi Ultimate Tensile Strength, min, Ksi Elongation in 10 in., min, %

Specified Diameter, in. Class Class Class Class Class Class Class Class Class

A B C A B C A B C

0.0500 to 0.0899, incl 190 180 170 210 200 190 3.0 3.0 3.0

0.0900 to 0.1199, incl 185 175 165 205 195 185 3.5 3.0 3.0

0.1200 to 0.1399, incl 180 170 160 205 195 185 4.0 3.0 3.0

0.1400 to 0.1900, incl 170 160 155 200 185 180 4.0 4.0 4.0

TABLE 5 Tensile Requirements

Stress at 1 % Extension, min, MPa Ultimate Tensile Strength, min, MPa Elongation in 250 mm, min, %

Specified Diameter, mm Class Class Class Class Class Class Class Class Class

A B C A B C A B C

1.60 to 2.30, incl 1310 1240 1170 1450 1380 1310 3.0 3.0 3.0

Over 2.30 to 3.05, incl 1280 1210 1140 1410 1340 1280 3.5 3.0 3.0

Over 3.05 to 3.60, incl 1240 1170 1100 1410 1340 1280 4.0 3.0 3.0

Over 3.60 to 4.80, incl 1170 1100 1070 1380 1280 1240 4.0 4.0 4.0

TABLE 6 Initial Settings for Determining Stress at 1 % Extension TABLE 10 Permissible Variations in Diameter of Zinc-Coated

Specified Diameter, Initial Stress, Initial Setting of Extensometer, Steel Wire

in. Ksi in./ in.

NOTE 1—It is recognized that the surface of zinc coatings, particularly

0.0500 to 0.0899, incl 14 0.0005 (0.05 % extension) those produced by hot-dip galvanizing, are not perfectly smooth and

0.0900 to 0.1199, incl 28 0.0010 (0.10 % extension) devoid of irregularities. If the tolerances shown in the table are rigidly

0.1200 to 0.1900, incl 42 0.0015 (0.15 % extension)

applied to such irregularities that are inherent to the product, unjustified

rejections of wire that would actually be satisfactory for use could occur.

Therefore, it is intended that these tolerances be used in gaging the

TABLE 7 Initial Settings for Determining Stress at 1 % Extension uniform areas of the galvanized wire.

Specified Diameter, Initial Stress, Initial Setting of Extensometer, Permissible Variation, in.

mm MPa mm/mm Specified Diameter, in

Plus Minus

1.60 to 2.30, incl 100 0.0005 (0.05 % extension)

Over 2.30 to 3.05, incl 190 0.0010 (0.10 % extension) 0.0500 to 0.0749, incl 0.0015 0.001

Over 3.05 to 4.80, incl 290 0.0015 (0.15 % extension) 0.0750 to 0.1199, incl 0.002 0.002

0.1200 to 0.1399, incl 0.003 0.002

0.1400 to 0.1900, incl 0.004 0.003

TABLE 8 Mandrel Size for Adherence Test

Ratio of Mandrel Diameter to Wire TABLE 11 Permissible Variations in Diameter of Zinc-Coated

Specified Wire Diameter, in.

Diameter Steel Wire

0.0500 to 0.0899, incl 3

0.0900 to 0.1399, incl 4 NOTE 1—It is recognized that the surface of zinc coatings, particularly

0.1400 to 0.1900, incl 5 those produced by hot-dip galvanizing, are not perfectly smooth and

devoid of irregularities. If the tolerances shown in the table are rigidly

--`,,,,``````,``````,`,`````,`-`-`,,`,,`,`,,`---

applied to such irregularities that are inherent to the product, unjustified

TABLE 9 Mandrel Size for Adherence Test rejections of wire that would actually be satisfactory for use could occur.

Therefore, it is intended that these tolerances be used in gaging the

Ratio of Mandrel Diameter to Wire

Specified Wire Diameter, mm uniform areas of the galvanized wire.

Diameter

Permissible Variation, mm

1.60 to 2.30, incl 3 Specified Diameter, mm

Over 2.30 to 3.05, incl 4 Plus Minus

Over 3.05 to 4.80, incl 5

1.60 to 2.30, incl 0.04 0.03

Over 2.30 to 3.05, incl 0.05 0.05

Over 3.05 to 3.60, incl 0.08 0.05

the property in which failure occurred, and reject only the Over 3.60 to 4.80, incl 0.10 0.08

nonconforming coils.

17. Inspection satisfy him that the material is being furnished in accordance

17.1 Unless otherwise specified in the contract or purchase with this specification.

order, the manufacturer shall be responsible for the perfor-

mance of all inspection and test requirements specified. 18. Rejection and Rehearing

17.2 All inspections and tests shall be made at the place of 18.1 Material that fails to conform to the requirements of

manufacture, unless otherwise especially agreed upon between this specification shall be rejected. Rejection should be re-

the manufacturer and the purchaser at the time of the purchase. ported to the producer or supplier promptly and in writing. In

17.3 The manufacturer shall afford the inspector represent- case of dissatisfaction with the results of the test, the producer

ing the purchaser all reasonable manufacturer’s facilities to or supplier may make claim for a rehearing.

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=korea univ/5930616001, User=jack, leo

No reproduction or networking permitted without license from IHS Not for Resale, 01/08/2007 05:01:28 MST

B 498/B 498M – 98 (2002)

19. Certification 20.2 Package dimensions, kind of package (coils, reels or

19.1 When specified in the purchase order or contract, a reelless coils), and quantity of wire in each package shall be

producer’s or supplier’s certification shall be furnished to the agreed upon between the manufacturer and purchaser.

purchaser showing that the material was manufactured, 20.3 A durable tag shall be securely attached to each

sampled, tested, and inspected in accordance with this speci- package showing the nominal diameter of wire, class of

fication and has been found to meet the requirements. When coating, length, approximate weight, purchaser’s order num-

specified in the purchase order or contract, a report of the test ber, and manufacturer’s name.

results shall be furnished. 20.4 The starting end shall be identified.

20.5 In case there is more than one piece in a package, the

20. Packaging and Package Marking length and position of each piece shall be shown on the tag.

20.1 The unit lengths shall be as specified in the contract or 21. Keywords

order. Length tolerances shall be plus or minus 2 %, unless 21.1 coated steel wire; steel core wire; steel wire; zinc-

otherwise specified by the purchaser. coated steel wire

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,,,``````,``````,`,`````,`-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=korea univ/5930616001, User=jack, leo

No reproduction or networking permitted without license from IHS Not for Resale, 01/08/2007 05:01:28 MST

You might also like

- Astm A 475 (1998)Document5 pagesAstm A 475 (1998)Jeffry CuartasNo ratings yet

- Astm A653 1Document13 pagesAstm A653 1AlbertoNo ratings yet

- E1 30 PDFDocument7 pagesE1 30 PDFreza515heiNo ratings yet

- Astm B411B411M-14Document3 pagesAstm B411B411M-14Gabriel Perez CruzNo ratings yet

- Tata Steel - YMPRESS S500MC - Data SheetDocument2 pagesTata Steel - YMPRESS S500MC - Data SheetpnagarajjNo ratings yet

- Development of Non-Oriented and Grain-Oriented Silicon SteelDocument6 pagesDevelopment of Non-Oriented and Grain-Oriented Silicon Steelد. علا محمد حداويNo ratings yet

- Aged Conductor and Groud WireDocument4 pagesAged Conductor and Groud Wirevikgob100% (1)

- ErDocument2 pagesErBaugh Graphic DesignNo ratings yet

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 pagesHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNo ratings yet

- Daikin Presentation - Chiller SystemDocument112 pagesDaikin Presentation - Chiller Systemlucio ruiz jr100% (1)

- Astm 401Document4 pagesAstm 401JOSEPH REFUERZONo ratings yet

- Zinc-Coated (Galvanized) Steel Core Wire For Aluminum Conductors, Steel Reinforced (ACSR)Document4 pagesZinc-Coated (Galvanized) Steel Core Wire For Aluminum Conductors, Steel Reinforced (ACSR)Metoo ChyNo ratings yet

- B 173 - 01 - Qje3my1sruqDocument6 pagesB 173 - 01 - Qje3my1sruqCarlos LiceaNo ratings yet

- Compact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionDocument4 pagesCompact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionHanh-Trang DangNo ratings yet

- Aluminum Rectangular and Square Wire For Electrical PurposesDocument7 pagesAluminum Rectangular and Square Wire For Electrical Purposesvuqar0979No ratings yet

- WGR 273 1Document5 pagesWGR 273 1jan rogerNo ratings yet

- Standard Specification For Aluminum-Alloy 5005 Drawing Stock For Electrical Purposes1Document3 pagesStandard Specification For Aluminum-Alloy 5005 Drawing Stock For Electrical Purposes1HugoStiglicNo ratings yet

- EMEA WC Sec 6Document55 pagesEMEA WC Sec 6andy175No ratings yet

- Asme Section II A-2 Sa-688 Sa-688mDocument10 pagesAsme Section II A-2 Sa-688 Sa-688mAnonymous GhPzn1xNo ratings yet

- Copper Conductors For Use in Hookup Wire For Electronic EquipmentDocument5 pagesCopper Conductors For Use in Hookup Wire For Electronic EquipmentmahfuzNo ratings yet

- Iec 61869 - 87 2009Document16 pagesIec 61869 - 87 2009Anonymous UbwGTAcKlsNo ratings yet

- Astm B 398Document4 pagesAstm B 398Ryan LasacaNo ratings yet

- B 47 - 95a (2017)Document5 pagesB 47 - 95a (2017)Ahmed BilalNo ratings yet

- Standard Specification For Metallic-Coated Steel Wire Strand PDFDocument5 pagesStandard Specification For Metallic-Coated Steel Wire Strand PDFsjeniferq100% (1)

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoNo ratings yet

- Ansi c80-6 2005Document22 pagesAnsi c80-6 2005supervisor.electricistaNo ratings yet

- TDDocument4 pagesTDJaime Arellano HuertaNo ratings yet

- Al Busbar 6060 DatasheetDocument1 pageAl Busbar 6060 DatasheetpiirsaluNo ratings yet

- BS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core PDFDocument30 pagesBS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core PDFwaseem kausarNo ratings yet

- As 1222.1-1992 Steel Conductors and Stays - Bare Overhead Galvanized (SC GZ)Document7 pagesAs 1222.1-1992 Steel Conductors and Stays - Bare Overhead Galvanized (SC GZ)SAI Global - APAC0% (1)

- Astm B 398Document4 pagesAstm B 398vadmanh100% (1)

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyNo ratings yet

- Influence of Shed Profile On The Pollution Performance of Porcelain InsulatorsDocument4 pagesInfluence of Shed Profile On The Pollution Performance of Porcelain InsulatorsRamkumar N VaithilingamNo ratings yet

- Concentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForDocument11 pagesConcentric-Lay-Stranded Aluminum 1350 Conductors: Standard Specification ForAlexis AguillonNo ratings yet

- No Smoke Without FireDocument1 pageNo Smoke Without FireArdi Do0% (1)

- B400B400M-14 Standard Specification For Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsDocument6 pagesB400B400M-14 Standard Specification For Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsmithileshNo ratings yet

- ASTM A656 Grade 50: General Product DescriptionDocument1 pageASTM A656 Grade 50: General Product DescriptionHarsh ChopraNo ratings yet

- Is 10810 43 1984 PDFDocument5 pagesIs 10810 43 1984 PDFRushangNo ratings yet

- ABB Hollow Composite Insulators - Brochure enDocument13 pagesABB Hollow Composite Insulators - Brochure enipraoNo ratings yet

- Iec-209-Aluminium Conductors, Steel-ReinforcedDocument16 pagesIec-209-Aluminium Conductors, Steel-ReinforcedLasitha FernandoNo ratings yet

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Document8 pages600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirNo ratings yet

- Is 4759 1996 PDFDocument12 pagesIs 4759 1996 PDFSandeep SundriyalNo ratings yet

- Tabla IEC 62219Document5 pagesTabla IEC 62219ManuelNo ratings yet

- Astm B 400-04Document6 pagesAstm B 400-04chaivatNo ratings yet

- OPGW GTP of Various VendorsDocument19 pagesOPGW GTP of Various VendorsRamphani Nunna100% (1)

- HiTemp® Series Accessories For ACCC® ConductorsDocument32 pagesHiTemp® Series Accessories For ACCC® ConductorsAndre Luis Fontes FerreiraNo ratings yet

- GTP For DPDC HTDocument2 pagesGTP For DPDC HTjamilNo ratings yet

- Astm B317Document7 pagesAstm B317Ales KainzNo ratings yet

- Astm A 394 - 93Document8 pagesAstm A 394 - 93Ahmad KhreisatNo ratings yet

- B496Document3 pagesB496rohit kumarNo ratings yet

- Concentric-Lay-Stranded Aluminum-Alloy 6201-T81 Conductors: Standard Specification ForDocument6 pagesConcentric-Lay-Stranded Aluminum-Alloy 6201-T81 Conductors: Standard Specification ForRed RedNo ratings yet

- Astm Volume 02 02Document4 pagesAstm Volume 02 02RonNo ratings yet

- B115 PDFDocument9 pagesB115 PDFSanth v SaksenaNo ratings yet

- Compression PDFDocument49 pagesCompression PDFKhem Loid CumingNo ratings yet

- Astm B8 99Document4 pagesAstm B8 99Raul EirisNo ratings yet

- SNOWBIRD ACSS Aluminum ConductorDocument1 pageSNOWBIRD ACSS Aluminum ConductorssappanNo ratings yet

- Icea Nema S-61-402 Parte 6Document24 pagesIcea Nema S-61-402 Parte 6DamiánNo ratings yet

- Table Busbar - Tekno MegaDocument1 pageTable Busbar - Tekno MegaputrasejahtraNo ratings yet

- Flat Bottom Railway Rail RDSO Spec.Document92 pagesFlat Bottom Railway Rail RDSO Spec.gunalanegisNo ratings yet

- Astm b498 b498m 98 Acsr用镀锌钢芯线 英文 AcsrDocument4 pagesAstm b498 b498m 98 Acsr用镀锌钢芯线 英文 AcsrnarinderNo ratings yet

- B498B498MDocument4 pagesB498B498MAlcides NetoNo ratings yet

- Astm B 498Document5 pagesAstm B 498Nirmal WiresNo ratings yet

- Astm B 606 - 98Document3 pagesAstm B 606 - 98Fernando AngioliniNo ratings yet

- Common Requirements For Steel Fasteners or Fastener Materials, or Both, Intended For Use at Any Temperature From Cryogenic To The Creep RangeDocument8 pagesCommon Requirements For Steel Fasteners or Fastener Materials, or Both, Intended For Use at Any Temperature From Cryogenic To The Creep RangeJerry BeanNo ratings yet

- Steel Forgings, Austenitic, For Pressure and High Temperature PartsDocument7 pagesSteel Forgings, Austenitic, For Pressure and High Temperature PartsJerry BeanNo ratings yet

- Steel Wire, Oil-Tempered For Mechanical SpringsDocument4 pagesSteel Wire, Oil-Tempered For Mechanical SpringsJerry BeanNo ratings yet

- Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument4 pagesSteel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceJerry BeanNo ratings yet

- Steel Castings, Stainless, Precipitation Hardening: Standard Specification ForDocument4 pagesSteel Castings, Stainless, Precipitation Hardening: Standard Specification ForJerry BeanNo ratings yet

- Common Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsDocument8 pagesCommon Requirements For Steel Flanges, Forged Fittings, Valves, and Parts For Piping ApplicationsJerry BeanNo ratings yet

- Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesDocument10 pagesWelded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesJerry BeanNo ratings yet

- Steel Castings Suitable For Pressure ServiceDocument6 pagesSteel Castings Suitable For Pressure ServiceJerry BeanNo ratings yet

- Castings, Iron-Chromium-Nickel, Corrosion Resistant, For Severe ServiceDocument5 pagesCastings, Iron-Chromium-Nickel, Corrosion Resistant, For Severe ServiceJerry BeanNo ratings yet

- C 1277 - 03 PDFDocument8 pagesC 1277 - 03 PDFJerry BeanNo ratings yet

- Chromium Metal: Standard Specification ForDocument2 pagesChromium Metal: Standard Specification ForJerry Bean100% (1)

- Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsDocument4 pagesCentrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsJerry BeanNo ratings yet

- Steel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceDocument3 pagesSteel Castings, Martensitic Stainless and Alloy, For Pressure-Containing Parts, Suitable For High-Temperature ServiceJerry BeanNo ratings yet

- Sampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForDocument2 pagesSampling and Testing Ferroalloys For Determination of Size: Standard Test Methods ForJerry BeanNo ratings yet

- Quenched and Tempered Low-Alloy Structural Steel Plate With 70 Ksi (485 Mpa) Minimum Yield Strength To 4 In. (100 MM) ThickDocument2 pagesQuenched and Tempered Low-Alloy Structural Steel Plate With 70 Ksi (485 Mpa) Minimum Yield Strength To 4 In. (100 MM) ThickJerry BeanNo ratings yet

- Sizes of Ferroalloys and Alloy Additives: Standard Specification ForDocument2 pagesSizes of Ferroalloys and Alloy Additives: Standard Specification ForJerry BeanNo ratings yet

- Astm A309Document7 pagesAstm A309Jerry BeanNo ratings yet

- Centrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsDocument4 pagesCentrifugally Cast Ferritic/Austenitic Stainless Steel Pipe For Corrosive EnvironmentsJerry BeanNo ratings yet

- Carbon and Alloy Steel Forgings For Rings For Reduction GearsDocument4 pagesCarbon and Alloy Steel Forgings For Rings For Reduction GearsJerry BeanNo ratings yet

- Rasb 10 GkvpeDocument134 pagesRasb 10 GkvpeAR&MENDES ENGENHARIANo ratings yet

- Aluminum 5052Document2 pagesAluminum 5052Praveen ThomasNo ratings yet

- Chemistry PDFDocument12 pagesChemistry PDFaNo ratings yet

- FFU160HAX DatasheetDocument3 pagesFFU160HAX Datasheetracini454No ratings yet

- Method of Statement For Filling Grout Into Sonic PipeDocument5 pagesMethod of Statement For Filling Grout Into Sonic PipeNara Kong100% (3)

- PMD55 Catalogue EngDocument40 pagesPMD55 Catalogue EngTayachew BerhanNo ratings yet

- Gujarat Technological University Environmental EngineeringDocument3 pagesGujarat Technological University Environmental EngineeringHarshil KachhadiyaNo ratings yet

- Maktex Py 200: Product DescriptionDocument1 pageMaktex Py 200: Product DescriptionHatem ElGabryNo ratings yet

- Looking For The Right SolventDocument2 pagesLooking For The Right SolventAileen Grace AugustoNo ratings yet

- 181Document65 pages181nikolastevic100% (2)

- Steel Product List Rev2Document52 pagesSteel Product List Rev2lavyNo ratings yet

- Astralloy-V Bars enDocument2 pagesAstralloy-V Bars enRjgandhi65No ratings yet

- Px3 Lubrication: Wire Rope GreaseDocument1 pagePx3 Lubrication: Wire Rope GreaseEhsan AhmadiNo ratings yet

- Rittal Floor Mounted PanelsDocument16 pagesRittal Floor Mounted Panelsomh129No ratings yet

- Topic 17Document50 pagesTopic 17C.S.ABHILASHNo ratings yet

- Testing: Needle Valve SeriesDocument3 pagesTesting: Needle Valve SeriesToty DzNo ratings yet

- 140H 9TN Sistema Hydraulico AjusteDocument13 pages140H 9TN Sistema Hydraulico Ajusterprim100% (1)

- Indesit IWC 7105Document84 pagesIndesit IWC 7105Sofronije1982No ratings yet

- Automatic Control of Food Manufacturing ProcessesDocument5 pagesAutomatic Control of Food Manufacturing ProcesseskvnsaiNo ratings yet

- Finite Element Analysis of Cutting Forces in High Speed MachiningDocument8 pagesFinite Element Analysis of Cutting Forces in High Speed MachiningShruthi N. KumarNo ratings yet

- Co2 BrochureDocument2 pagesCo2 BrochureNabil HassanNo ratings yet

- PSM 10 - Assembly PDFDocument25 pagesPSM 10 - Assembly PDFAdi KarionugrohoNo ratings yet

- Rockets and MissilesDocument19 pagesRockets and MissilesrishithNo ratings yet

- Wall Thickness - Report PDFDocument1 pageWall Thickness - Report PDFPetroNo ratings yet

- Valve Type Acceptance Test Experiences APIDocument22 pagesValve Type Acceptance Test Experiences APIJames ChaiNo ratings yet

- Development of Aluminium Scrap Melting Technology: © V. I. Gel, D. N. Rudakov UDC 669.054.8:669.71Document5 pagesDevelopment of Aluminium Scrap Melting Technology: © V. I. Gel, D. N. Rudakov UDC 669.054.8:669.71PrasanthanNo ratings yet

- FINEX TechnologyDocument16 pagesFINEX Technologyferozcan19640% (1)