Professional Documents

Culture Documents

Refrigerating Plant

Refrigerating Plant

Uploaded by

Muhammad WafiqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refrigerating Plant

Refrigerating Plant

Uploaded by

Muhammad WafiqCopyright:

Available Formats

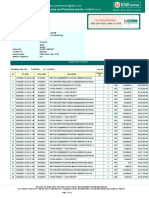

REFRIGERATING PLANT

SPK REFRIGERATING PLANT

2 TECHNICAL DATA - GENERAL FEATURES

TECHNICAL DATA - GENERAL FEATURES

This Equipment Should Be Designed to

Support the Technical Training of

This Equipment Should Be Designed to Support the Technical Air-Conditioning / Refrigerant System for Servicing

Training of Air-Conditioning / Refrigerant System for Servicing And Installation Suitable For The Diploma In Air

And Installation Suitable For The Diploma In Air Conditioning And Refrigeration Engineering

Conditioning And Refrigeration Engineering Technology Technology Program

Program.

1.0 CHILLER REFRIGERATION WATER COOLED CHILLER REFRIGERATION WATER COOLED

1.0

CONDENSING SYSTEM (1 Lot) CONDENSING SYSTEM (1 Lot)

1.1 Reciprocating Compressor 1.1 Semi-hermatic Compressor

- Open Driven Type 4 - Open Driven Type 1

- Displacement (1450 RPM) - Evaporating Temperature +5°C to -5°C

- Evaporating Temperature +5°C to -5°C - Gas 404A / CFC Free

- Gas 404A / CFC Free - Capacity 30°C / 6.9KW / 0°C

- Capacity 30°C / 6.9KW / 0°C - Suction Line 22mm

- Suction Line 22mm

- Discharge Line 18mm

- Discharge Line 18mm

- Globe Valve

- Globe Valve

- 306 Liquid Line Filter Drier

- 306 Liquid Line Filter Drier

- Expansion Valve TS2 / 7.7KW / Designed Orifice

- Expansion Valve TS2 / 7.7KW / Designed Orifice

- Sight / Oil Glass

- Sight / Oil Glass

- Oil Separator

- Oil Separator

- High / Low Pressure Switch - High / Low Pressure Switch

- Refrigerant Solenoid Valve / SCEM - Refrigerant Solenoid Valve / SCEM

- Working Pressure: 35 bar - Working Pressure: 35 bar

- Working Temperature: -40°C; +150°C - Working Temperature: -40°C; +150°C

- Motor pulley 150mm - Motor pulley 150mm

- Condenser capacity volume 4 Hp - Condenser capacity volume 4 Hp

1.2 Motor 1.2 Motor

- Pulley - Pulley

- Electrical / 3 phase / 50Hz - Electrical / 3 phase / 50Hz

1.3 Blower DAKA - Chiller 1.3 Blower DAKA - Chiller

- Size: 895 x 570 x 365mm (LxHxD)

- Capacity 0°C / 4.2KW / 20K BTU

- Size: 895 x 570 x 365mm (LxHxD)

- Surface Area 14.1 m2 - Capacity 0°C / 4.2KW / 20K BTU

- Fan Dia: 350mm - Surface Area 14.1 m2

- Air Flow 2430 m3/h - Fan Dia: 350mm

- Defrost Heater Power 1.5KW - Air Flow 2430 m3/h

- Defrost Heater Max Amps 2.3A - Defrost Heater Power 1.5KW

- 3phase / 50Hz - Defrost Heater Max Amps 2.3A

1.4 Control Box - 3phase / 50Hz

- Digital controller with indicator

- ELCB & MCB 1.4 Control Box

- 3phase relay - Digital controller with indicator

- Contactor for Blower - ELCB & MCB

- Contactor for Compressor - 3phase relay

- Contactor for Defrost heater - Contactor for Blower

1.5 Chiller Coldroom - Contactor for Compressor

- Colourbond rigid polyurethane panel - Contactor for Defrost heater

- Stainless steel interior

- Thickness 100mm 1.5 Chiller Coldroom

- Aluminium checker plate flooring - Colourbond rigid polyurethane panel

- Room Lighting - Stainless steel interior

- Heated frame door panel - Thickness 100mm

- 2-way knob and accessory

- Aluminium checker plate flooring

- Size: 8’ x 6’ x 8’ (LxWxH)

- Room Lighting

- Heated frame door panel

- 2-way knob and accessory

- Size: 8’ x 6’ x 8’ (LxWxH)

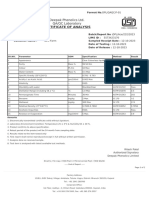

2.0 FREEZER REFRIGERATION WATER COOLED 2.0 FREEZER REFRIGERATION WATER COOLED

CONDENSING SYSTEM (1 Lot) CONDENSING SYSTEM (1 Lot)

2.1 Reciprocating Compressor 2.1 Reciprocating Compressor

- Semi Hermetic - Semi Hermetic

- 3phase / 50Hz - 3phase / 50Hz

- Displacement (1450 RPM/ 50Hz) - Displacement (1450 RPM/ 50Hz)

- Evaporating Temperature 0°C to -15°C - Evaporating Temperature 0°C to -15°C

- Gas 404A / CFC Free - Gas 404A / CFC Free

- Capacity 30°C / 4.7KW / -20°C

- Capacity 30°C / 4.7KW / -20°C

- Suction Line 22mm

- Suction Line 22mm

- Discharge Line 16mm

- Discharge Line 16mm

- Ball Valve

- Ball Valve

- 305 Liquid Line Filter Drier

- 305 Liquid Line Filter Drier - Expansion Valve TES2 / 6.0KW / Designed Orifice

- Expansion Valve TES2 / 6.0KW / Designed Orifice - Sight / Oil Glass

- Sight / Oil Glass - Oil Separator

- Oil Separator - Suction Accumulator

- Suction Accumulator - High / Low Pressure Switch Refrigerant Solenoid Valve / SCEM

- High / Low Pressure Switch Refrigerant Solenoid - Working Pressure: 35 bar

Valve / SCEM - Working Temperature: -40°C; +150°C

- Working Pressure: 35 bar - Condenser capacity volume 4 Hp

- Working Temperature: -40°C; +150°C

- Condenser capacity volume 4 Hp 2.2 Blower DAKA - Freezer

- Size: 895 x 570 x 365mm (LxHxD)

2.2 Blower DAKA - Freezer - Capacity -18°C / 3.8KW / 8K BTU

- Size: 895 x 570 x 365mm (LxHxD) - Surface Area 14.6 m2

- Capacity -18°C / 3.8KW / 8K BTU - Fan Dia : 350mm

- Surface Area 14.6 m2 - Air Flow 2400 m3/h

- Defrost Heater Power 2.5KW

- Fan Dia : 350mm

- Defrost Heater Max Amps 4.5A

- Air Flow 2400 m3/h

- Defrost Heater Power 2.5KW

- Defrost Heater Max Amps 4.5A

- 1phase / 50Hz

1phase / 50Hz

2.3 Control Box

2.3 Control Box

- Digital controller with indicator / Germany - Digital controller with indicator / Germany

- ELCB & MCB - ELCB & MCB

- 3phase relay - 3phase relay

- Contactor for Blower - Contactor for Blower

- Contactor for Compressor - Contactor for Compressor

- Contactor for Defrost heater - Contactor for Defrost heater

2.4 Freezer Coldroom 2.4 Freezer Coldroom

- Colourbond rigid polyurethane panel - Colourbond rigid polyurethane panel

- Stainless steel interior - Stainless steel interior

- Thickness 100mm - Thickness 100mm

- Aluminium checker plate flooring - Aluminium checker plate flooring

- Room Lighting - Room Lighting

- Heated frame door panel - Heated frame door panel

- 2 way knob and accessory - 2 way knob and accessory

- Size: 8’ x 6’ x 8’ (LxWxH) - Size: 8’ x 6’ x 8’ (LxWxH)

3.0 Cooling Tower

3.0 Cooling Tower

- Capacity 8 ton

- Capacity 8 ton

- Tower body is made from F.R.P.

- Tower body is made from F.R.P. - Special fan with variable section, twist and pitching blade.

- Special fan with variable section, twist and pitching - Electric motor with whole sealed cooling tower

blade. - Water distribution with rotating pipe

- Electric motor with whole sealed cooling tower - Fill with round counter flow fill, made of air vacuum forming PVC

- Water distribution with rotating pipe sheets which are with corrugated surface

- Fill with round counter flow fill, made of air vacuum - Come with tower support stand

forming PVC sheets which are with corrugated surface - 3-Phase water pump and piping system

- Come with tower support stand

- 3-Phase water pump and piping system

4.0 Water Reservoir

4.0 Water Reservoir - Construction of HDPE

- Construction of HDPE - Capacity 600 galon

- Capacity 600 galon - Full cover top

- Full cover top - Piping system

- Piping system

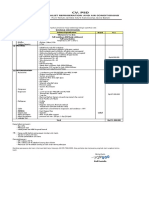

5.0 Locol Control Panel

5.0 Locol Control Panel All control switches and Temperature and Flow digital indicators to be display

for control purposes. A special function switch over toggle for Local and PLC

All control switches and Temperature and Flow digital to be installed at the control panel.

indicators to be display for control purposes. A special

function switch over toggle for Local and PLC to be 6.0 Workstation With PLC and SCADA

installed at the control panel. The tenderer shall be responsible to provide and configure the Siemens PLC

and the SCADA software to operate as full industrial PLC interface. All the

system control software must be embedded industry type by the PLC

6.0 Workstation With PLC and SCADA

manufacturer and not by the third party and must use the same display

faceplate and commands to simply configuration and operation for TVET

The tenderer shall be responsible to provide and configure the introduction and training purposes.

Siemens PLC and the SCADA software to operate as full

industrial PLC interface. All the system control software must The software functionality should consist of but not limited to the followings:

be embedded industry type by the PLC manufacturer and not a) Symbolic equipment arrangement of all equipment on the screen.

by the third party and must use the same display faceplate and b) Standardized industrial PLC / SCADA capabilities for operating and

commands to simply configuration and operation for TVET engineering.

introduction and training purposes.

The software functionality should consist of but not limited to

the followings:

a) Symbolic equipment arrangement of all equipment on

the screen.

b) Standardized industrial PLC / SCADA capabilities for

operating and engineering.

c) Graphic, trend, overview, detail faceplate with tuning c) Graphic, trend, overview, detail faceplate with tuning parameters, alarm

parameters, alarm summary and diagnostic window. summary and diagnostic window.

d) Individual configurable tabular list of as many values as desired.

d) Individual configurable tabular list of as many values as e) Real-time display of measured values in diagrams.

desired. f) Recording and plotting of measured values in diagrams.

e) Real-time display of measured values in diagrams. g) Optional Industry 4.0 Technology to apply for technology upgrading.

f) Recording and plotting of measured values in 7.0 All-In-One Touchscreen Computer (1 unit)

- Intel Core i9 (similar or higher specification)

diagrams.

- Genuine Windows 11 Professional (similar or higher specification)

g) Optional Industry 4.0 Technology to apply for - 8GB Memory

technology upgrading. - 2TB Hard Drive (similar or higher)

- 8X DVD±RW drive

7.0 All-In-One Touchscreen Computer (1 unit) - Keyboard & Optical Mouse

- Additional 40” Flat Wide Screen Monitor

- Intel Core i9 (similar or higher specification)

8.0 Manual / Experiment sheet

- Genuine Windows 11 Professional (similar or higher The unit is supplied with Operating and Experimental Manual in English

specification) giving full descriptions of the unit summary in theory, experimental

- 8GB Memory procedures, and typical experimental results.

- 2TB Hard Drive (similar or higher)

- 8X DVD±RW drive

- Keyboard & Optical Mouse

- Additional 40” Flat Wide Screen Monitor

8.0 Manual / Experiment sheet

The unit is supplied with Operating and Experimental Manual in

English giving full descriptions of the unit summary in theory,

experimental procedures, and typical experimental results.

You might also like

- Pellet Stove T300P Tech ManualDocument29 pagesPellet Stove T300P Tech Manualtheimproviser100% (1)

- Samsung RS275-RS277 - Refrigerator TrainingDocument93 pagesSamsung RS275-RS277 - Refrigerator Trainingblackwellbert92% (13)

- SMK Bandar Sungai Petani 2021 Yearly Planner (Mapping Table) For English Language Form 5Document3 pagesSMK Bandar Sungai Petani 2021 Yearly Planner (Mapping Table) For English Language Form 5Siti Rohana Darus100% (1)

- Tirupati Telecom Primary Account Holder Name: Your A/C StatusDocument12 pagesTirupati Telecom Primary Account Holder Name: Your A/C StatusMy PhotosNo ratings yet

- Classic CatalogueDocument48 pagesClassic CataloguelmelendeziNo ratings yet

- Fogel User GuideDocument8 pagesFogel User GuideJBESNo ratings yet

- Condensate SystemDocument49 pagesCondensate SystemBalendraShah100% (2)

- Danuhm Bush Air Cooled Condensing UnitsDocument24 pagesDanuhm Bush Air Cooled Condensing UnitsFalak KhanNo ratings yet

- 01 - Booms Burners PDFDocument36 pages01 - Booms Burners PDFAhmad kevin100% (1)

- Air Cooled Screw Chiller R134aDocument12 pagesAir Cooled Screw Chiller R134aalkaf08No ratings yet

- FM 160 FotoDocument7 pagesFM 160 Foto潘学淼No ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- B1900 NOTES Page 21-40Document20 pagesB1900 NOTES Page 21-40Hayden CourtneyNo ratings yet

- Atlas Copco ZS Series BlowersDocument46 pagesAtlas Copco ZS Series BlowersMamta Raybage100% (1)

- YMSJ - SMSFZHAAN-150330 Revised FormatDocument4 pagesYMSJ - SMSFZHAAN-150330 Revised FormatGuadalupe Pérez LaraNo ratings yet

- Fujitsu Inverter Ac Service ManualDocument18 pagesFujitsu Inverter Ac Service ManualPratibanNo ratings yet

- Ice Plant Test RigDocument3 pagesIce Plant Test RigLeo Van Ezel ArcayNo ratings yet

- Asta09lccsm PDFDocument19 pagesAsta09lccsm PDFlinmar7071No ratings yet

- Turbine & AuxilariesDocument64 pagesTurbine & Auxilariesulhatolkargmailcom100% (2)

- Wall Mounted: Split Type Room Air Conditioner TypeDocument18 pagesWall Mounted: Split Type Room Air Conditioner TypeDavid Lemos Sanchez100% (1)

- Manejadora Ducto YMSFDocument4 pagesManejadora Ducto YMSFjuanNo ratings yet

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthNo ratings yet

- Refrigeration InforDocument152 pagesRefrigeration InforRavi Roberson100% (2)

- Heliotherme 4000 - Brosura Tehnica-1Document19 pagesHeliotherme 4000 - Brosura Tehnica-1ptopic10No ratings yet

- HD ND ZUE - enDocument28 pagesHD ND ZUE - enwylie01No ratings yet

- ACDS R410A 50hzDocument24 pagesACDS R410A 50hzTanjim FakirNo ratings yet

- Ms0488a 0810 PDFDocument40 pagesMs0488a 0810 PDFEduardo Luis SouzaNo ratings yet

- Final Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Document23 pagesFinal Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Raúl Oscar LedesmaNo ratings yet

- Blue Box - Geyser 2Document90 pagesBlue Box - Geyser 2tzisis100% (1)

- Very Important XPS - Thermal Insulation BoardsDocument10 pagesVery Important XPS - Thermal Insulation BoardsPravin MundeNo ratings yet

- RotairDocument2 pagesRotairKhaled Kamel100% (2)

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel Arif0% (1)

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel ArifNo ratings yet

- Magnum Series: Key FeaturesDocument1 pageMagnum Series: Key Featuresconstantin.iacomi3837No ratings yet

- Evaporadoras 3HpDocument44 pagesEvaporadoras 3HpAlexis PradoNo ratings yet

- 英文 - Finished Docu.-fin. (Part One)Document107 pages英文 - Finished Docu.-fin. (Part One)joseflores888No ratings yet

- IMI - STI - Product - AC Series - AW - LowRes-1Document40 pagesIMI - STI - Product - AC Series - AW - LowRes-1dharmendrabholeNo ratings yet

- Fujitsu RLS2HDocument2 pagesFujitsu RLS2HEric HalsteadNo ratings yet

- 2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriDocument51 pages2 X 115 TPH CFBC Boiler: Ultratech Cement Limited - Apcw TadipatriChanna BasavaNo ratings yet

- Hitachi RCUE CLGDocument7 pagesHitachi RCUE CLGFabio Moacir KorndoerferNo ratings yet

- PART 4. Size and Number of UnitsDocument11 pagesPART 4. Size and Number of UnitsDL ArtsNo ratings yet

- Carrier Air Con 38QRR ManualDocument30 pagesCarrier Air Con 38QRR ManualYorkistNo ratings yet

- Catalogo YorkDocument4 pagesCatalogo YorkJulio S. MuñozNo ratings yet

- Bluebox Zeta Rev HP 5.2Document7 pagesBluebox Zeta Rev HP 5.2NikolaNo ratings yet

- Project Survey: Selected CompressorsDocument6 pagesProject Survey: Selected CompressorsMr. RfNo ratings yet

- Ultra Thin Fan Coil - Arctic Heat PumpsDocument9 pagesUltra Thin Fan Coil - Arctic Heat Pumpsjohnking5555No ratings yet

- ECOFLOW PH 11-3-19 V2 - For MergeDocument22 pagesECOFLOW PH 11-3-19 V2 - For MergebobtiltdNo ratings yet

- ACDS Series 60Hz: Air Cooled Scroll Compressor Direct Expansion Chillers Cooling Capacity: 10 To 180 TR (35 To 633 KW)Document40 pagesACDS Series 60Hz: Air Cooled Scroll Compressor Direct Expansion Chillers Cooling Capacity: 10 To 180 TR (35 To 633 KW)Tanjim FakirNo ratings yet

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaDocument36 pagesCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaNo ratings yet

- Fujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualDocument18 pagesFujitsu Klima Uredjaj Zidni Inverter Awyz14lbc Aoyz14lbc Service ManualDino wowowNo ratings yet

- Service Manual CarrierDocument22 pagesService Manual CarrierGeopas GreeceNo ratings yet

- AH AV CatalogDocument16 pagesAH AV CatalognomurapreNo ratings yet

- 06 (1) Vol de Ran MedDocument7 pages06 (1) Vol de Ran MedLhau009No ratings yet

- Hoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!Document2 pagesHoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!NugagodaNo ratings yet

- Duct Firing SystemDocument40 pagesDuct Firing Systemrahul_choubey_9No ratings yet

- A 9 D 15 1297776657222 Euroconfort Ciat New Space PF BTDocument8 pagesA 9 D 15 1297776657222 Euroconfort Ciat New Space PF BTProiectare InstalatiiNo ratings yet

- RUSSELDocument24 pagesRUSSELgabyNo ratings yet

- TM sls407 W 3gbDocument52 pagesTM sls407 W 3gbJasenko Nino GrboNo ratings yet

- Berkas Baru Untuk DQ, IQ, OQDocument16 pagesBerkas Baru Untuk DQ, IQ, OQM MiftakhNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- 3 Assessment2jobinterview30-25Document3 pages3 Assessment2jobinterview30-25Muhammad WafiqNo ratings yet

- Complaint Letter (CB200047)Document1 pageComplaint Letter (CB200047)Muhammad WafiqNo ratings yet

- Documentary ConclusionDocument3 pagesDocumentary ConclusionMuhammad WafiqNo ratings yet

- GuidelineofbusinessplanDocument23 pagesGuidelineofbusinessplanMuhammad WafiqNo ratings yet

- MufrodmuthannajamakDocument3 pagesMufrodmuthannajamakMuhammad WafiqNo ratings yet

- 4 5933997296566927827Document73 pages4 5933997296566927827Milad ShahabiNo ratings yet

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Bar Bending Schedule (Service BLDG)Document20 pagesBar Bending Schedule (Service BLDG)Rania SaiedNo ratings yet

- Schaefer Martin 2018 The Semantic Transparency of English Compound NounsDocument423 pagesSchaefer Martin 2018 The Semantic Transparency of English Compound NounsRania MohammedNo ratings yet

- Managerial Economics: Dr. Arun Kumar Dr. Arun Kumar Assistant Professor ABV-IIITM, GwaliorDocument11 pagesManagerial Economics: Dr. Arun Kumar Dr. Arun Kumar Assistant Professor ABV-IIITM, GwaliorAbhishek SinghNo ratings yet

- Article WritingDocument10 pagesArticle WritingMosteroidNo ratings yet

- An Introduction To Augmented Reality Aided ManufacturingDocument29 pagesAn Introduction To Augmented Reality Aided ManufacturingSahilNo ratings yet

- Mark SheetDocument1 pageMark SheetLokeshNo ratings yet

- MGT410 Take Home Final 1 - Fall2010Document10 pagesMGT410 Take Home Final 1 - Fall2010Belinda Elois ToNo ratings yet

- American Scientific Research Journal For Engineering, Technology, and Sciences (Asrjets), Vol 6, No 1 (2013), Issn (Print) 2313-44106Document2 pagesAmerican Scientific Research Journal For Engineering, Technology, and Sciences (Asrjets), Vol 6, No 1 (2013), Issn (Print) 2313-44106atilaelciNo ratings yet

- Dashboard Digital VoltmeterDocument7 pagesDashboard Digital VoltmetercrashoveriteNo ratings yet

- Chapter 1 Transaction Management and Concurrency Control Lec 1 andDocument68 pagesChapter 1 Transaction Management and Concurrency Control Lec 1 andFiromsa DineNo ratings yet

- Parametric & Non Parametric TestDocument8 pagesParametric & Non Parametric TestAngelica Alejandro100% (1)

- Metal Forming ProcessDocument19 pagesMetal Forming ProcessragulnarayanNo ratings yet

- Literature Review of The Job SatisfactionDocument3 pagesLiterature Review of The Job SatisfactionsuryaNo ratings yet

- Competency Enhancing Courses Jan June2023Document2 pagesCompetency Enhancing Courses Jan June2023Yashveer TakooryNo ratings yet

- Levels of ProficiencyDocument13 pagesLevels of Proficiencyjizun geveroNo ratings yet

- PHPA Polymer ConcentrationDocument15 pagesPHPA Polymer ConcentrationWaleedm MariaNo ratings yet

- 109is 37150 - 50310Document2 pages109is 37150 - 50310dip461No ratings yet

- BRS ExerciseDocument7 pagesBRS ExerciseMuskan LohariwalNo ratings yet

- The Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionDocument16 pagesThe Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionShirlya LimaNo ratings yet

- Video Encoding: Basic Principles: Felipe Portavales GoldsteinDocument33 pagesVideo Encoding: Basic Principles: Felipe Portavales GoldsteinPrasad GvbsNo ratings yet

- (Appendix 4A) Teacher Reflection Form For T I-III For RPMS SY 2021-2022Document10 pages(Appendix 4A) Teacher Reflection Form For T I-III For RPMS SY 2021-2022Quia Ferraren UmayaoNo ratings yet

- 300 Compact/1233: ManualDocument22 pages300 Compact/1233: ManualbogdanNo ratings yet

- Altium To q3dDocument3 pagesAltium To q3dWesley de PaulaNo ratings yet

- CS 123 I2P Assignment 2Document3 pagesCS 123 I2P Assignment 2Hafiz AbdullahNo ratings yet

- The Paper Airplane GameDocument5 pagesThe Paper Airplane GamegoonygoogooNo ratings yet

- Chem 1-8Document43 pagesChem 1-8Cabacungan, John VinceNo ratings yet