Professional Documents

Culture Documents

MSP300 0078 Conica 37

MSP300 0078 Conica 37

Uploaded by

aktivrudarpCopyright:

Available Formats

You might also like

- 2001 FORD EXPLORER Service Repair Manual PDFDocument62 pages2001 FORD EXPLORER Service Repair Manual PDFdfjjskemmdm67% (3)

- MCRS Fuel System Overview PDFDocument100 pagesMCRS Fuel System Overview PDFAnonymous ABPUPbK91% (11)

- LECTURE 14 - Implementing The Designed Curriculum As A Change ProcessDocument4 pagesLECTURE 14 - Implementing The Designed Curriculum As A Change ProcessAeleu JoverzNo ratings yet

- VOLVO SD70D SINGLE-DRUM ROLLER Service Repair Manual PDFDocument15 pagesVOLVO SD70D SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmme0% (2)

- Amarillo Gear Repair ManualDocument32 pagesAmarillo Gear Repair Manualfazzlie100% (1)

- BHW Balance Shaft Module ReplacementDocument32 pagesBHW Balance Shaft Module Replacementszasz100% (1)

- Alfa Alfasud 1.3 PDFDocument50 pagesAlfa Alfasud 1.3 PDFnubercard6111100% (1)

- Lipe Clutch Installation Service ManualDocument35 pagesLipe Clutch Installation Service ManualCostel Antonie100% (3)

- Rear Axle 1994 Volvo 960 SamosvorDocument19 pagesRear Axle 1994 Volvo 960 Samosvoraaa222No ratings yet

- Remove & Install Bucket CylinderDocument8 pagesRemove & Install Bucket CylinderchanlinNo ratings yet

- Build A CMS in An Afternoon With PHP and MySQLDocument45 pagesBuild A CMS in An Afternoon With PHP and MySQLhnguyen_698971No ratings yet

- 450A-750A Pump Drive Repair ManualDocument21 pages450A-750A Pump Drive Repair ManualECO Green and BlueNo ratings yet

- GEARBOX MANUAL SF Revision DDocument37 pagesGEARBOX MANUAL SF Revision DaliNo ratings yet

- MSP300 0078 Conica 15Document1 pageMSP300 0078 Conica 15aktivrudarpNo ratings yet

- Section 10 - Power Take-OffDocument19 pagesSection 10 - Power Take-OffMiller Andres ArocaNo ratings yet

- Service BulletinDocument12 pagesService BulletinEdward Adrian Moreno FernandezNo ratings yet

- C014 Assembly-Disassembly ManualDocument21 pagesC014 Assembly-Disassembly Manualwillyan100% (2)

- Group 4 Disassembly and Assembly: 1. Brake PumpDocument6 pagesGroup 4 Disassembly and Assembly: 1. Brake PumpPriscila RodriguesNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Series 51 Motor Repair ManualDocument20 pagesSeries 51 Motor Repair ManualAngel Dlsg100% (5)

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- C6.6 Cam Shaft InstallDocument5 pagesC6.6 Cam Shaft InstallsenNo ratings yet

- SM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1Document19 pagesSM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1jose cuevas100% (2)

- Manual Terex # 55 (Iguana) - 2Document26 pagesManual Terex # 55 (Iguana) - 2Victor Manuel riveraNo ratings yet

- Impak 2Document11 pagesImpak 2Vasudev AgrawalNo ratings yet

- Front Suspension 4wdDocument17 pagesFront Suspension 4wdcarloslopez85No ratings yet

- Steering System PowerDocument9 pagesSteering System PowerJosé Torcato AlmeidaNo ratings yet

- Suspension Chevy Beretta 1990Document98 pagesSuspension Chevy Beretta 1990sabre boyNo ratings yet

- EI-4195 SERIES: Instruction ManualDocument16 pagesEI-4195 SERIES: Instruction ManualKhalid AbdelRahimNo ratings yet

- Axial Detuner MaintenanceDocument5 pagesAxial Detuner MaintenanceKarthik ReddiarNo ratings yet

- Drive Axle FrontDocument23 pagesDrive Axle Frontcarloslopez85No ratings yet

- Outdrive RR RevisedDocument6 pagesOutdrive RR RevisedZlatko JermanNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Procedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoDocument7 pagesProcedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoadrianvieroNo ratings yet

- Honda CRF110F Service Repair ManualDocument10 pagesHonda CRF110F Service Repair ManualΕυθυμης ΖουμπαδελληςNo ratings yet

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDocument9 pagesEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264No ratings yet

- Steering System: DescriptionDocument18 pagesSteering System: DescriptionNoe CuandonNo ratings yet

- 428f connecting rod boltsDocument1 page428f connecting rod boltsjohnsaad15No ratings yet

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocument12 pagesCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoNo ratings yet

- 181828435449e5eac7794e9 PDFDocument1 page181828435449e5eac7794e9 PDFtornomanNo ratings yet

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- How To Change Deutz 1011Document11 pagesHow To Change Deutz 1011melakuNo ratings yet

- Nissan Front AxleDocument34 pagesNissan Front AxleFrederikusNo ratings yet

- 1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualDocument2 pages1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualvictoverNo ratings yet

- Volvo Power SteeringDocument10 pagesVolvo Power SteeringFordiNo ratings yet

- SKF Wheel Bearing Installation Guide With Free End PlayDocument20 pagesSKF Wheel Bearing Installation Guide With Free End Play2bjornNo ratings yet

- Reassembly of Basic EngineDocument19 pagesReassembly of Basic EnginePepe AlNo ratings yet

- 200f-917121-Chapter Six-Timing Case and Drive Assembly PDocument16 pages200f-917121-Chapter Six-Timing Case and Drive Assembly PindrajayaNo ratings yet

- Manual AMARILLO Drive Pump Repair Man 250 350 v0215Document23 pagesManual AMARILLO Drive Pump Repair Man 250 350 v0215Widi PrasetyoNo ratings yet

- Description: Rear AxleDocument16 pagesDescription: Rear AxleNoe CuandonNo ratings yet

- 05 1964 CH-Rear AxleDocument3 pages05 1964 CH-Rear AxleJose LaproviteraNo ratings yet

- Dana Spicer WJ Dana44Document35 pagesDana Spicer WJ Dana44Stefano MirabelliNo ratings yet

- A/C Compressor Servicing: Please Read This FirstDocument22 pagesA/C Compressor Servicing: Please Read This FirstbaylorguyNo ratings yet

- SUZUKI DF200 225 250 Service Man 5Document78 pagesSUZUKI DF200 225 250 Service Man 5Candido IsazaNo ratings yet

- Gearbox DisassemblyDocument8 pagesGearbox DisassemblyMuhammad Usman KaimkhaniNo ratings yet

- PV776 TSP161566Document7 pagesPV776 TSP161566Jesús Jaguer MeisterNo ratings yet

- Install Instructions ExedyDocument2 pagesInstall Instructions Exedyrolo210100% (1)

- Identification: Drive Axle Noise DiagnosisDocument48 pagesIdentification: Drive Axle Noise DiagnosisRoberto Ortega MicalizziNo ratings yet

- HI-KALIBRE ActuatorDocument22 pagesHI-KALIBRE ActuatorProyectil De ProyectoNo ratings yet

- Brute IIIDocument4 pagesBrute IIIjarrodjohns927No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Graphene Cement Concrete WhitePaper 2021Document30 pagesGraphene Cement Concrete WhitePaper 2021tytaityNo ratings yet

- Sample Plans PDFDocument40 pagesSample Plans PDFMichal SlavíčekNo ratings yet

- Dwnload Full Financial Statement Analysis 11th Edition Subramanyam Test Bank PDFDocument17 pagesDwnload Full Financial Statement Analysis 11th Edition Subramanyam Test Bank PDFtestifpishgzshi100% (20)

- TOG 2022 Volume 24 Issue 4Document80 pagesTOG 2022 Volume 24 Issue 4saeed hasan saeedNo ratings yet

- Relevant Ethico-Legal GuidelinesDocument50 pagesRelevant Ethico-Legal GuidelinesHira UsmanNo ratings yet

- Labor RelationDocument125 pagesLabor RelationVj DelatadoNo ratings yet

- Property Law Conso Digested Cases 1st Sem 2019 2020Document487 pagesProperty Law Conso Digested Cases 1st Sem 2019 2020Mik ZeidNo ratings yet

- Mac Formatting ElCapDocument7 pagesMac Formatting ElCapJC SardiniaNo ratings yet

- Fti Consulting DocumentDocument20 pagesFti Consulting DocumenttarunchatNo ratings yet

- Career at PrachayDocument15 pagesCareer at PrachayGirish LakhotiyaNo ratings yet

- P2 Forces and Terminal Velocity HigherDocument12 pagesP2 Forces and Terminal Velocity HigherdownendscienceNo ratings yet

- Reno Hells Angel Troy Regas DetailsDocument34 pagesReno Hells Angel Troy Regas Detailsapi-3787993100% (2)

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- Tender Document - Haryana Data CentreDocument58 pagesTender Document - Haryana Data CentreBullzeye StrategyNo ratings yet

- 74HC4538Document13 pages74HC4538roozbehxoxNo ratings yet

- Random-Access Memory - WikipediaDocument14 pagesRandom-Access Memory - WikipediaHeera SinghNo ratings yet

- A LoRa 868MHz Collinear Antenna - Projects by KeptenkurkDocument8 pagesA LoRa 868MHz Collinear Antenna - Projects by Keptenkurkjax almarNo ratings yet

- Edpack 103 - Assessment of Learning 2 Victoria P. Janeo, LPT, Ms 1Document4 pagesEdpack 103 - Assessment of Learning 2 Victoria P. Janeo, LPT, Ms 1Hector CandidoNo ratings yet

- Permit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6Document3 pagesPermit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6RihardsNo ratings yet

- (Methods in Enzymology 183) Abelson J.N., Simon M.I., Doolittle R.F. (Eds.) - Molecular Evolution - Computer Analysis of Protein and Nucleic Acid Sequences-Academic Press (1990)Document725 pages(Methods in Enzymology 183) Abelson J.N., Simon M.I., Doolittle R.F. (Eds.) - Molecular Evolution - Computer Analysis of Protein and Nucleic Acid Sequences-Academic Press (1990)Rilberte CostaNo ratings yet

- Brand Guideline - Channel PartnerDocument12 pagesBrand Guideline - Channel PartnerNishantNo ratings yet

- Liebert CRV Row Based Cooling System User ManualDocument190 pagesLiebert CRV Row Based Cooling System User ManualAngel David Osorio RiveroNo ratings yet

- Reduce: Bharti Infratel Bhin inDocument11 pagesReduce: Bharti Infratel Bhin inashok yadavNo ratings yet

- Quiz 5 Chap 5 AnswerDocument4 pagesQuiz 5 Chap 5 AnswerPhương NgaNo ratings yet

- NEMA Motor Data Calculator - EEPDocument3 pagesNEMA Motor Data Calculator - EEPEngr TariqNo ratings yet

- The Business Value of Design: InsightsDocument18 pagesThe Business Value of Design: Insightsamber krishanNo ratings yet

- Name Email Phone Hometown: Authorized To Work in The US For Any EmployerDocument3 pagesName Email Phone Hometown: Authorized To Work in The US For Any EmployerR.T. CoffmanNo ratings yet

MSP300 0078 Conica 37

MSP300 0078 Conica 37

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSP300 0078 Conica 37

MSP300 0078 Conica 37

Uploaded by

aktivrudarpCopyright:

Available Formats

reduce return oil flow speed, to let Top Frame descend evenly.

When cylinders at back let Top Frame descend faster than cylinders in front, adjust lower flow valve to

increase return oil flow speed, to let Top Frame descend evenly.

10 DAILY INSPECTION

Inspect the following items daily for loosening:

① Tightening Nut (4060)

② Main Frame Bottom Cover and bolts (1131,113A)

③ Countershaft Housing and bolts (5031,503E)

④ Foundation Bolts

⑤ Check Oil Leaking of Main Frame Hydraulic Locking Cylinder and Top Cell Hydraulic Locking

Cylinder.

At the beginning of loaded operation, nuts and bolts are more likely to become loose and must be

checked frequently. The nuts and bolts will stabilize and remain tight after a period of loaded operation, but

should still be checked periodically.

11 REGULAR PERIODIC INSPECTION

11.1 Preventative Maintenance

Overhaul and carefully inspect the Cone Crusher every six months to a year, depending on operating

conditions. Even with daily operation, lubrication oil deteriorates or becomes contaminated; and sliding and

contact parts can wear. Thus, periodic inspection is essential.

First, clean the entire outer surface of the Cone Crusher. Then perform the following procedures:

① Remove Feed Platform if so equipped. Then remove the Cap Frame (2691).

② Remove the Top Cell (2101) from the Top Frame (2011), and check the Concave (2111, 2121) and the

Top Cell Liner (2241) for wear.

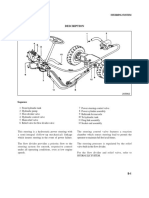

③ Lift out the Main Shaft Assembly (4011) as shown in Figure No. 10, and check the Mantle Core

(4021) and Main Shaft (4011) for wear. Check Seat Liner (1111) and fixing screws (111C) for tightness, and

apply locking compound (Permatex:PX#68050) to the seat liner fixing screws.

④ Remove the Spherical Seat (1061). As shown in Figure No. 7, tighten the Eccentric Seat (3011) and

the Thrust Plates with bolts, then suspend and remove the Eccentric. Check the Eccentric Bushing (3021),

Bevel Gears (3091,5061), Frame Bushing (1041), Seat Liner (1111), and Dust Seal Ring (1121) for Wear.

⑤ Check the Countershaft Assembly installed in the Main Frame (1011) for wear to the bearing. Do

this by manually turning the pulley and moving the bearing up and down.

⑥ Remove the Bottom Cover (1131), and clean it carefully.

⑦ Replace deteriorated or contaminated lubrication oil with fresh oil.

⑧ There is a grease opening at the rear side of the crusher main frame (see picture below), to ensure

29

You might also like

- 2001 FORD EXPLORER Service Repair Manual PDFDocument62 pages2001 FORD EXPLORER Service Repair Manual PDFdfjjskemmdm67% (3)

- MCRS Fuel System Overview PDFDocument100 pagesMCRS Fuel System Overview PDFAnonymous ABPUPbK91% (11)

- LECTURE 14 - Implementing The Designed Curriculum As A Change ProcessDocument4 pagesLECTURE 14 - Implementing The Designed Curriculum As A Change ProcessAeleu JoverzNo ratings yet

- VOLVO SD70D SINGLE-DRUM ROLLER Service Repair Manual PDFDocument15 pagesVOLVO SD70D SINGLE-DRUM ROLLER Service Repair Manual PDFfjjsjekdmme0% (2)

- Amarillo Gear Repair ManualDocument32 pagesAmarillo Gear Repair Manualfazzlie100% (1)

- BHW Balance Shaft Module ReplacementDocument32 pagesBHW Balance Shaft Module Replacementszasz100% (1)

- Alfa Alfasud 1.3 PDFDocument50 pagesAlfa Alfasud 1.3 PDFnubercard6111100% (1)

- Lipe Clutch Installation Service ManualDocument35 pagesLipe Clutch Installation Service ManualCostel Antonie100% (3)

- Rear Axle 1994 Volvo 960 SamosvorDocument19 pagesRear Axle 1994 Volvo 960 Samosvoraaa222No ratings yet

- Remove & Install Bucket CylinderDocument8 pagesRemove & Install Bucket CylinderchanlinNo ratings yet

- Build A CMS in An Afternoon With PHP and MySQLDocument45 pagesBuild A CMS in An Afternoon With PHP and MySQLhnguyen_698971No ratings yet

- 450A-750A Pump Drive Repair ManualDocument21 pages450A-750A Pump Drive Repair ManualECO Green and BlueNo ratings yet

- GEARBOX MANUAL SF Revision DDocument37 pagesGEARBOX MANUAL SF Revision DaliNo ratings yet

- MSP300 0078 Conica 15Document1 pageMSP300 0078 Conica 15aktivrudarpNo ratings yet

- Section 10 - Power Take-OffDocument19 pagesSection 10 - Power Take-OffMiller Andres ArocaNo ratings yet

- Service BulletinDocument12 pagesService BulletinEdward Adrian Moreno FernandezNo ratings yet

- C014 Assembly-Disassembly ManualDocument21 pagesC014 Assembly-Disassembly Manualwillyan100% (2)

- Group 4 Disassembly and Assembly: 1. Brake PumpDocument6 pagesGroup 4 Disassembly and Assembly: 1. Brake PumpPriscila RodriguesNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Series 51 Motor Repair ManualDocument20 pagesSeries 51 Motor Repair ManualAngel Dlsg100% (5)

- Front Drive AxleDocument19 pagesFront Drive AxleGeraldo Pozos VazquezNo ratings yet

- C6.6 Cam Shaft InstallDocument5 pagesC6.6 Cam Shaft InstallsenNo ratings yet

- SM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1Document19 pagesSM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1jose cuevas100% (2)

- Manual Terex # 55 (Iguana) - 2Document26 pagesManual Terex # 55 (Iguana) - 2Victor Manuel riveraNo ratings yet

- Impak 2Document11 pagesImpak 2Vasudev AgrawalNo ratings yet

- Front Suspension 4wdDocument17 pagesFront Suspension 4wdcarloslopez85No ratings yet

- Steering System PowerDocument9 pagesSteering System PowerJosé Torcato AlmeidaNo ratings yet

- Suspension Chevy Beretta 1990Document98 pagesSuspension Chevy Beretta 1990sabre boyNo ratings yet

- EI-4195 SERIES: Instruction ManualDocument16 pagesEI-4195 SERIES: Instruction ManualKhalid AbdelRahimNo ratings yet

- Axial Detuner MaintenanceDocument5 pagesAxial Detuner MaintenanceKarthik ReddiarNo ratings yet

- Drive Axle FrontDocument23 pagesDrive Axle Frontcarloslopez85No ratings yet

- Outdrive RR RevisedDocument6 pagesOutdrive RR RevisedZlatko JermanNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Procedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoDocument7 pagesProcedimento Desmonte Bequilha 39400030 Cessna 182 Skylane Procedimentos de ManutencaoadrianvieroNo ratings yet

- Honda CRF110F Service Repair ManualDocument10 pagesHonda CRF110F Service Repair ManualΕυθυμης ΖουμπαδελληςNo ratings yet

- Eaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate DesignDocument9 pagesEaton: Model 74318 and 74348 Piston Motors Fixed Displacement, Valve Plate Designluisbravo1264No ratings yet

- Steering System: DescriptionDocument18 pagesSteering System: DescriptionNoe CuandonNo ratings yet

- 428f connecting rod boltsDocument1 page428f connecting rod boltsjohnsaad15No ratings yet

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocument12 pagesCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoNo ratings yet

- 181828435449e5eac7794e9 PDFDocument1 page181828435449e5eac7794e9 PDFtornomanNo ratings yet

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- How To Change Deutz 1011Document11 pagesHow To Change Deutz 1011melakuNo ratings yet

- Nissan Front AxleDocument34 pagesNissan Front AxleFrederikusNo ratings yet

- 1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualDocument2 pages1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualvictoverNo ratings yet

- Volvo Power SteeringDocument10 pagesVolvo Power SteeringFordiNo ratings yet

- SKF Wheel Bearing Installation Guide With Free End PlayDocument20 pagesSKF Wheel Bearing Installation Guide With Free End Play2bjornNo ratings yet

- Reassembly of Basic EngineDocument19 pagesReassembly of Basic EnginePepe AlNo ratings yet

- 200f-917121-Chapter Six-Timing Case and Drive Assembly PDocument16 pages200f-917121-Chapter Six-Timing Case and Drive Assembly PindrajayaNo ratings yet

- Manual AMARILLO Drive Pump Repair Man 250 350 v0215Document23 pagesManual AMARILLO Drive Pump Repair Man 250 350 v0215Widi PrasetyoNo ratings yet

- Description: Rear AxleDocument16 pagesDescription: Rear AxleNoe CuandonNo ratings yet

- 05 1964 CH-Rear AxleDocument3 pages05 1964 CH-Rear AxleJose LaproviteraNo ratings yet

- Dana Spicer WJ Dana44Document35 pagesDana Spicer WJ Dana44Stefano MirabelliNo ratings yet

- A/C Compressor Servicing: Please Read This FirstDocument22 pagesA/C Compressor Servicing: Please Read This FirstbaylorguyNo ratings yet

- SUZUKI DF200 225 250 Service Man 5Document78 pagesSUZUKI DF200 225 250 Service Man 5Candido IsazaNo ratings yet

- Gearbox DisassemblyDocument8 pagesGearbox DisassemblyMuhammad Usman KaimkhaniNo ratings yet

- PV776 TSP161566Document7 pagesPV776 TSP161566Jesús Jaguer MeisterNo ratings yet

- Install Instructions ExedyDocument2 pagesInstall Instructions Exedyrolo210100% (1)

- Identification: Drive Axle Noise DiagnosisDocument48 pagesIdentification: Drive Axle Noise DiagnosisRoberto Ortega MicalizziNo ratings yet

- HI-KALIBRE ActuatorDocument22 pagesHI-KALIBRE ActuatorProyectil De ProyectoNo ratings yet

- Brute IIIDocument4 pagesBrute IIIjarrodjohns927No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Graphene Cement Concrete WhitePaper 2021Document30 pagesGraphene Cement Concrete WhitePaper 2021tytaityNo ratings yet

- Sample Plans PDFDocument40 pagesSample Plans PDFMichal SlavíčekNo ratings yet

- Dwnload Full Financial Statement Analysis 11th Edition Subramanyam Test Bank PDFDocument17 pagesDwnload Full Financial Statement Analysis 11th Edition Subramanyam Test Bank PDFtestifpishgzshi100% (20)

- TOG 2022 Volume 24 Issue 4Document80 pagesTOG 2022 Volume 24 Issue 4saeed hasan saeedNo ratings yet

- Relevant Ethico-Legal GuidelinesDocument50 pagesRelevant Ethico-Legal GuidelinesHira UsmanNo ratings yet

- Labor RelationDocument125 pagesLabor RelationVj DelatadoNo ratings yet

- Property Law Conso Digested Cases 1st Sem 2019 2020Document487 pagesProperty Law Conso Digested Cases 1st Sem 2019 2020Mik ZeidNo ratings yet

- Mac Formatting ElCapDocument7 pagesMac Formatting ElCapJC SardiniaNo ratings yet

- Fti Consulting DocumentDocument20 pagesFti Consulting DocumenttarunchatNo ratings yet

- Career at PrachayDocument15 pagesCareer at PrachayGirish LakhotiyaNo ratings yet

- P2 Forces and Terminal Velocity HigherDocument12 pagesP2 Forces and Terminal Velocity HigherdownendscienceNo ratings yet

- Reno Hells Angel Troy Regas DetailsDocument34 pagesReno Hells Angel Troy Regas Detailsapi-3787993100% (2)

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- Tender Document - Haryana Data CentreDocument58 pagesTender Document - Haryana Data CentreBullzeye StrategyNo ratings yet

- 74HC4538Document13 pages74HC4538roozbehxoxNo ratings yet

- Random-Access Memory - WikipediaDocument14 pagesRandom-Access Memory - WikipediaHeera SinghNo ratings yet

- A LoRa 868MHz Collinear Antenna - Projects by KeptenkurkDocument8 pagesA LoRa 868MHz Collinear Antenna - Projects by Keptenkurkjax almarNo ratings yet

- Edpack 103 - Assessment of Learning 2 Victoria P. Janeo, LPT, Ms 1Document4 pagesEdpack 103 - Assessment of Learning 2 Victoria P. Janeo, LPT, Ms 1Hector CandidoNo ratings yet

- Permit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6Document3 pagesPermit-To-Work - General Electrical (Under 1000 Volts) : ANNEX 16.1.6RihardsNo ratings yet

- (Methods in Enzymology 183) Abelson J.N., Simon M.I., Doolittle R.F. (Eds.) - Molecular Evolution - Computer Analysis of Protein and Nucleic Acid Sequences-Academic Press (1990)Document725 pages(Methods in Enzymology 183) Abelson J.N., Simon M.I., Doolittle R.F. (Eds.) - Molecular Evolution - Computer Analysis of Protein and Nucleic Acid Sequences-Academic Press (1990)Rilberte CostaNo ratings yet

- Brand Guideline - Channel PartnerDocument12 pagesBrand Guideline - Channel PartnerNishantNo ratings yet

- Liebert CRV Row Based Cooling System User ManualDocument190 pagesLiebert CRV Row Based Cooling System User ManualAngel David Osorio RiveroNo ratings yet

- Reduce: Bharti Infratel Bhin inDocument11 pagesReduce: Bharti Infratel Bhin inashok yadavNo ratings yet

- Quiz 5 Chap 5 AnswerDocument4 pagesQuiz 5 Chap 5 AnswerPhương NgaNo ratings yet

- NEMA Motor Data Calculator - EEPDocument3 pagesNEMA Motor Data Calculator - EEPEngr TariqNo ratings yet

- The Business Value of Design: InsightsDocument18 pagesThe Business Value of Design: Insightsamber krishanNo ratings yet

- Name Email Phone Hometown: Authorized To Work in The US For Any EmployerDocument3 pagesName Email Phone Hometown: Authorized To Work in The US For Any EmployerR.T. CoffmanNo ratings yet