Professional Documents

Culture Documents

Oracle Supply Chain Planning Solution Brief

Oracle Supply Chain Planning Solution Brief

Uploaded by

KelnicksCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oracle Supply Chain Planning Solution Brief

Oracle Supply Chain Planning Solution Brief

Uploaded by

KelnicksCopyright:

Available Formats

Oracle Supply Chain Planning

Today's supply chains are more global, complex, and volatile than ever. To increase revenue and reduce costs, you

need future-ready supply chain planning that outpaces change and embeds intelligence in your planning process.

Oracle Fusion Cloud Supply Chain Planning anticipates demand, manages supply, and aligns stakeholder and trading

partner actions to your objectives. It’s also flexible, so you can adapt your planning processes as new challenges arise.

Figure 1. Oracle Supply Chain Planning: a unified cloud platform to improve enterprise visibility, speed, and agility

Plan for the future of supply chain decision making

Digital supply chain planning enhances plan quality and increases planner productivity. Intelligent automation in

Oracle Supply Chain Planning makes digital planning intuitive, starting with embedded real-time analytics that track

progress towards your goals. You can see exceptions at a glance, review recommended actions, and use guided

resolution to make quicker, smarter planning decisions.

As your team gains planning process knowledge, you can manage planning parameters by policy. Oracle Supply

Chain Planning applies segmentation, demand priorities, sourcing rules, and attribute-based demand-supply

matching to perform planning tasks at a detailed level, letting you focus on the big picture.

Similarly, built-in machine learning can identify cause and effect relationships, and prescribe actions for common

issues. Oracle's planning advisor predicts new item demand and potential supply disruptions, and alerts you to

systematic lead time deviations, stale parameter settings, and other issues. You can filter and prioritize advisor

messages, review the predicted accuracy or confidence level of the recommendations, and hyperlink to the

appropriate planning view in context to take action.

Oracle’s ultimate objective is to enable decision-centric planning that presents scenarios and alternatives with the

range of expected outcomes for business issues that need planner input, complemented by fully autonomous

planning for those in which the system can determine the root cause, preferred solution alternative, and execution

path on its own.

1 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

Integrate business planning, tactical planning & execution

Oracle Fusion Cloud Sales and Operations Planning (S&OP) enables continuous and forward-looking integrated

business planning that profitably aligns product, demand, supply, workforce, and sales plans with operational and

financial objectives. You can collaborate with colleagues within the application to arrive at a consolidated plan that

captures assumptions, risks, and opportunities for future reference.

To turn your plans into action, you can use S&OP plan output as a demand schedule in Oracle Supply Planning to

generate detailed tactical constrained plans, and share it with Oracle Enterprise Performance Management as

operational input to financial planning. Most importantly, thanks to built-in integration with Oracle’s broad suite of

supply chain applications, your plan outputs directly manage supply chain execution end-to-end.

Sense, predict, and shape demand

The best supply chains are demand-driven. With Oracle Fusion Cloud Demand Management, you can sense, predict,

and shape demand to reduce uncertainty in the face of changing market conditions.

Oracle Demand Management captures and assimilates diverse demand signals on a continuous basis, prioritizing

those with the greatest causal impact to detect seasonality, trend, and sudden disruptive “regime changes” in demand

patterns. These can include customer-specific demand, sales forecasts, orders, shipments, weather, economic data,

social sentiment, and other variables.

The forecasting engine applies a proven ensemble of analytical and machine learning methods to assesses data

quality, select models, and evaluate the accuracy of results. Automated self-tuning reduces the need for extensive

staff expertise, while enhancing the timeliness, detail, and relevance of forecasting to the business. Feature-based

forecasting uses eXtreme Gradient Boosting to identify the item attributes, physical locations, and time varying

features that drive demand.

Figure 2. Planning Advisor forecasts new items by identifying key features that predict demand, along with their expected accuracy.

2 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

Enable demand-driven replenishment planning

The replenishment planning capability of Oracle Demand Management balances service levels and inventory

investment for stocking locations that have ongoing consumption requirements. It classifies the items and locations

into segments that share the same behavior, and then executes demand or consumption-driven inventory policies to

minimize stockouts across your multiechelon supply chain. Depending on the need, replenishment calculations can

respect economic order quantities, fixed order quantities, vendor minimums, and other constraints.

You can run replenishment as an autonomous process, or resolve problems with individual items, segments, or policy

parameters using real time analytics and interactive workbenches. You can also automatically balance inventory

among stores or depots to alleviate local shortages and excess. Integrated buyer planning simulates the cost savings

and service impacts of combining purchases to consolidate transportation or achieve price breaks.

Plan supply for resilience to change and disruptions

Oracle Fusion Cloud Supply Planning provides simpler, faster, and better ways to plan and execute your operations

strategy in the face of demand changes and supply chain disruptions. It detects demand compression, material

shortages and resource overloads that can put demand at risk. It then prioritizes competing demands, and

intelligently reroutes global supply to minimize negative impacts, while finding new opportunities to leverage

remaining capacity and supply.

Figure 3. Review at risk demands and the potential impact of recommended actions on service and revenue

Manage constraints to meet your commitments

Oracle Supply Planning uses hybrid constraint-based planning to automatically evaluate ways to prevent constraint

violations, while providing recommendations to ensure that demands are fulfilled on time. The solution evaluates

building ahead of time, alternate resources, substitutes, alternate suppliers to overcome material and capacity

constraints. You can set inviolable capacity constraints for some resources and suppliers, while allowing others to be

overloaded if there is no other alternative.

3 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

Schedule production effectively

The production scheduling features of Supply Planning put you in control of your operations, with minute-by-minute

planning and execution of manufacturing tasks. Dynamic visualization and flexible rescheduling help you produce the

right products at the right times. You can easily determine the most feasible schedule to execute on the shop floor to

meet delivery expectations of your customers and, make changes on the fly when needed.

Figure 4. Plan production visually, in real time

You can visualize the health of the schedule through a resource Gantt chart, along with embedded metrics such as

late demands, late work orders, total changeover time, equipment utilization, and labor utilization to evaluate overall

performance.

Manage your sales order backlog with strategic order fulfillment

The order backlog management features of Oracle Fusion Cloud Supply Planning reschedule your open sales orders

based upon the latest supply information according to business rule priorities that you set. You can simulate different

fulfillment alternatives to maximize service, increase revenue, or address specific customer or channel issues. Flexible

allocation rules allow you to set aside a percentage or quantity of supply based upon the customer, channel, region,

or other criteria associated with each order line. Customers who have to manage significant order backlogs or

schedule changes due to supply constraints or frequent supply chain disruptions can save significant effort in

rescheduling, and achieve better business results than by rescheduling orders ad hoc.

Engage and collaborate with trading partners

Oracle Fusion Cloud Supply Chain Collaboration automates business-to-business practices with your trading partners

and alerts you to exceptions as they occur in the network. You can plan demand and supply jointly with partners,

coordinate execution activities, and measure performance across your trading networks using built-in support for:

Demand collaboration with customers

Supply planning collaboration with suppliers

4 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

Contract manufacturing collaboration

Vendor managed inventory

Oracle Supply Chain Collaboration also enhances supply chain visibility: the ability to "see" on-hand balances,

capacity, shipments, order status, and other key supply chain data in real time, both internally and across trading

partners. Greater transparency improves trust in collaborative relationships and provides each supply chain

participant the information they need to make effective decisions.

Plan your way

The deep industry features of Oracle Supply Chain Planning support the specific requirements of a wide variety of

businesses out of the box, dramatically improving time to benefit.

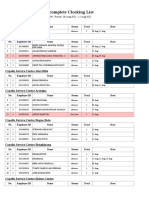

Table 1. Oracle Supply Chain Planning supports a wide range of industry-specific requirements

Industry Industry-specific planning needs Oracle capabilities

High technology Manage contract Multi-tier supply visibility

manufacturing Contract manufacturing planning

Deliver configure-to-order Lead time variability analysis

products

Configure-to-order and engineer-to-order planning

Manufacturing Plan and schedule discrete, Mixed-mode manufacturing planning

(industrial mfg., process, or mixed-mode Hybrid capacity constraints

CG, biotech/bio- production

pharma and heavy Aggregate production (mix) analysis

equipment) Maturity dates for on-hand lots

Asset-intensive Separate supply and assign Attribute-based supply-demand matching

enterprises demand by project Pooled supply for project groups

Service-based Replenish service parts for Dynamic segmentation of inventory policies

supply chains corporate or customer assets Item supersession chains

Wholesalers and Fulfill demand across a large Multiechelon replenishment planning

distributors number of locations Inventory rebalancing

Reduce procurement costs Buyer planning (price breaks & shipment consolidation)

Healthcare Reduce excess inventory Consumption-/receipt-based forecasting

providers Restock clinical networks In-hospital PAR level replenishment

Enable a Supply Chain Command Center for your enterprise

Oracle Supply Chain Planning is a critical component and the starting point for Oracle's Supply Chain Command

Center solution. Planning insights and machine learning models drive manufacturing, inventory, transportation, and

procurement actions, with predefined use cases that detect, decide, and execute responses to issues across your

supply chain network. You can visualize plan-to-actual performance, asses long term trends, and apply ad hoc

machine learning to devise solutions. Deep links into Oracle Supply Chain Execution allow you to take action in

context.

5 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

Figure 5. Visualize the impact of your planning decisions in Supply Chain Command Center

Improve profitability and accelerate supply chain innovation

Implementing a world-class supply chain planning process doesn't have to be costly or disruptive. Cloud deployment

enhances availability and security. You get immediate access to planning innovations, feature enhancements, and

bug fixes upon release, with the flexibility to “opt in” to significant changes. End-to-end integration with execution

processes in Oracle Fusion Cloud Supply Chain Management is built in, saving you time and money.

Related services

The following Oracle Cloud services support Oracle Supply Chain Planning:

Oracle Fusion Cloud Order Management centralizes and standardizes your order fulfillment across

multiple sales channels

Oracle Fusion Cloud Supply Chain Execution handles inventory, costing, maintenance activities and

manufacturing of both in-house and contract-manufactured goods

Oracle Fusion Cloud Procurement integrates sourcing, contracts and purchasing of goods and services

Connect with us

Call +1.800.ORACLE1 or visit oracle.com. Outside North America, find your local office at: oracle.com/contact.

blogs.oracle.com facebook.com/oracle twitter.com/oracle

Copyright © 2024, Oracle and/or its affiliates. This document is provided for information purposes only, and the contents hereof are subject to change without notice. This document is

not warranted to be error-free, nor subject to any other warranties or conditions, whether expressed orally or implied in law, including implied warranties and conditions of merchantability

or fitness for a particular purpose. We specifically disclaim any liability with respect to this document, and no contractual obligations are formed either directly or indirectly by this document.

This document may not be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without our prior written permission.

Oracle, Java, MySQL, and NetSuite are registered trademarks of Oracle and/or its affiliates. Other names may be trademarks of their respective owners.

6 Solution Brief / Oracle Fusion Cloud Supply Chain Planning

Copyright © 2024, Oracle and/or its affiliates / Public

You might also like

- Potential Stakeholders and Their Roles Involved in The Royal Greenland ProjectDocument4 pagesPotential Stakeholders and Their Roles Involved in The Royal Greenland ProjectAnuradha Marapana100% (2)

- LEED v4 BD+C Rating System Credit MatrixDocument2 pagesLEED v4 BD+C Rating System Credit Matrixadil271100% (2)

- Company Leased Vehicle PolicyDocument5 pagesCompany Leased Vehicle PolicyGunjan Sharma100% (2)

- Oracle Financials Cloud EbookDocument11 pagesOracle Financials Cloud Ebookapparao99100% (3)

- Oracle Value Chain PlanningDocument5 pagesOracle Value Chain PlanningAminur RahamanNo ratings yet

- 11 ORACLE MANUFACTURING PLANNING 11iDocument7 pages11 ORACLE MANUFACTURING PLANNING 11iyunie1001No ratings yet

- Oracle - DataSheet - VCP R12 - Rapid Planning (057158)Document5 pagesOracle - DataSheet - VCP R12 - Rapid Planning (057158)Jose LaraNo ratings yet

- Oracle Rapid Planning: Key FeaturesDocument5 pagesOracle Rapid Planning: Key FeaturesRahul KulkarniNo ratings yet

- Oracle - Data Sheet - Demantra Demand Management (057040)Document4 pagesOracle - Data Sheet - Demantra Demand Management (057040)Victor MillanNo ratings yet

- Data Sheet 11i10 Inventory Optimization DsDocument7 pagesData Sheet 11i10 Inventory Optimization DsRamkumar_PuthukodeNo ratings yet

- Inventory OptimizationDocument8 pagesInventory OptimizationDawood Adel DhakallahNo ratings yet

- Oracle Demantra Demand Management: Key FeaturesDocument4 pagesOracle Demantra Demand Management: Key FeaturesjhlaravNo ratings yet

- Oracle Advanced Supply Chain PlanningDocument5 pagesOracle Advanced Supply Chain PlanningShivaraj NNo ratings yet

- Oracle Value Chain PlanningDocument5 pagesOracle Value Chain PlanningcoolgutzNo ratings yet

- Voyager Manufacturing PlanningDocument2 pagesVoyager Manufacturing PlanningGaby SalgueiroNo ratings yet

- Oracle Supply Chain Management Cloud: Spotlight OnDocument9 pagesOracle Supply Chain Management Cloud: Spotlight OnMag MarinaNo ratings yet

- Oracle Procurement and Spend Analytics: Key Features and BenefitsDocument5 pagesOracle Procurement and Spend Analytics: Key Features and BenefitsgcadamsNo ratings yet

- Oracle Hyperion Capital Asset Planning: Key Features and BenefitsDocument4 pagesOracle Hyperion Capital Asset Planning: Key Features and BenefitsNarasimha Rao SNo ratings yet

- Oracle Supply Chain Analytics: Key BenefitsDocument4 pagesOracle Supply Chain Analytics: Key BenefitsDumbrava Caius FlorinNo ratings yet

- Oracle Flow Manufacturing: Key FeaturesDocument7 pagesOracle Flow Manufacturing: Key FeaturesVijay SharmaNo ratings yet

- Oracle Service Parts Planning: Key FeaturesDocument4 pagesOracle Service Parts Planning: Key FeaturesSaman HussainNo ratings yet

- Oracle Financial Analytics PDFDocument5 pagesOracle Financial Analytics PDFGangadri524No ratings yet

- Five Options To Support Demand-Driven Initiatives: An Oracle White Paper Updated October 2006Document6 pagesFive Options To Support Demand-Driven Initiatives: An Oracle White Paper Updated October 2006rajesh_talwar_3No ratings yet

- BWP Demand Supply PlanningDocument4 pagesBWP Demand Supply Planningkhalid_w_saifNo ratings yet

- Oracle Incentive Compensation Data SheetDocument5 pagesOracle Incentive Compensation Data Sheetets9876No ratings yet

- Oracle Project Manufacturing: Key FeaturesDocument8 pagesOracle Project Manufacturing: Key FeaturesAnup Kumar GuptaNo ratings yet

- Modelling and SimulationDocument13 pagesModelling and Simulationsuresh_ramanujam007100% (1)

- Oracle Supply Planning Cloud DsDocument7 pagesOracle Supply Planning Cloud DsAlejandra RangelNo ratings yet

- Operating System Elements - Operations and Supply Chain ManagementDocument10 pagesOperating System Elements - Operations and Supply Chain ManagementyingNo ratings yet

- Oracle Financial Analytics: Key Features and BenefitsDocument5 pagesOracle Financial Analytics: Key Features and Benefitsjbeatofl0% (1)

- Hyperion Planning Datasheet PDFDocument4 pagesHyperion Planning Datasheet PDFWilliam ArispeNo ratings yet

- Organising and Planning For LSCM FunctionsDocument13 pagesOrganising and Planning For LSCM FunctionsAnab ZaishaNo ratings yet

- Your Ultimate Guide To Workforce Efficiency With Oracle ERPDocument9 pagesYour Ultimate Guide To Workforce Efficiency With Oracle ERPMNo ratings yet

- PPPDocument6 pagesPPPshreyikapNo ratings yet

- Oracle Airline Data Model: Key Features and BenefitsDocument2 pagesOracle Airline Data Model: Key Features and BenefitsdonsavvyNo ratings yet

- Supply Chain Order MGMT Analytics DatasheetDocument5 pagesSupply Chain Order MGMT Analytics Datasheetsumanth_0678No ratings yet

- Oracle Replenishment Planning Solution Brief 2Document6 pagesOracle Replenishment Planning Solution Brief 2Alejandra RangelNo ratings yet

- Oracle Demand Management Cloud Ds PDFDocument6 pagesOracle Demand Management Cloud Ds PDFAshes NagNo ratings yet

- SM7 - Oracle Production SchedullingDocument4 pagesSM7 - Oracle Production SchedullingRakha Setyoadi Dwi LeksonoNo ratings yet

- Acsp Vs DemantraDocument3 pagesAcsp Vs DemantraMushtaq AhmedNo ratings yet

- Benefits Ebs Exalogic Exadata WP 1715621 PDFDocument14 pagesBenefits Ebs Exalogic Exadata WP 1715621 PDFSandeep GosainNo ratings yet

- Introduction To Oracle EusinessDocument35 pagesIntroduction To Oracle EusinessSureshNo ratings yet

- Planning Budgeting Cloud Service 1851924Document5 pagesPlanning Budgeting Cloud Service 1851924omda4uuNo ratings yet

- How Supply Chain Works in A CompanyDocument10 pagesHow Supply Chain Works in A CompanyMaster The MatinNo ratings yet

- SCM WRT Oracle AppsDocument6 pagesSCM WRT Oracle AppsRabindra P.SinghNo ratings yet

- Oracle Financials Cloud EbookDocument25 pagesOracle Financials Cloud EbookMariel A. Russo MNo ratings yet

- Oracle Daily Business IntelligenceDocument5 pagesOracle Daily Business Intelligenceziaulhaq31No ratings yet

- How To Design A Business BlueprintDocument4 pagesHow To Design A Business BlueprintVeerabadra RanganathNo ratings yet

- Oracle Hyperion Capital Asset Planning 064058Document3 pagesOracle Hyperion Capital Asset Planning 064058omda4uuNo ratings yet

- SNP - Network PlanningDocument17 pagesSNP - Network PlanningDebasis NandaNo ratings yet

- Oracle SCM Fusion Planning - r13-21D Solution BriefDocument50 pagesOracle SCM Fusion Planning - r13-21D Solution BriefSuraj KonnurNo ratings yet

- Facts Sheet OBIADocument7 pagesFacts Sheet OBIAmadhu9055No ratings yet

- Demand Management Course Rel 18C - Student GuideDocument172 pagesDemand Management Course Rel 18C - Student GuideVictor MillanNo ratings yet

- SAP Portfolio and Project ManagementDocument9 pagesSAP Portfolio and Project ManagementSunil PeddiNo ratings yet

- Sap - SPMDocument12 pagesSap - SPMioan91No ratings yet

- Oracle Collaborative PlanningDocument4 pagesOracle Collaborative PlanningBabu PandeyNo ratings yet

- Fabless WhitepaperDocument9 pagesFabless WhitepaperspaulsNo ratings yet

- E2open CSPDocument5 pagesE2open CSPhydeteruNo ratings yet

- A Handbook on Various Aspects of Business and Its Integration with Finance in Modern World: A Bridgeway to Thoughtful CommunicationFrom EverandA Handbook on Various Aspects of Business and Its Integration with Finance in Modern World: A Bridgeway to Thoughtful CommunicationNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Supply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsFrom EverandSupply Chain and Procurement Quick Reference: How to navigate and be successful in structured organizationsNo ratings yet

- Mrs. Brown's ResumeDocument2 pagesMrs. Brown's ResumekatricebrownNo ratings yet

- The Rise and Fall of SpainDocument2 pagesThe Rise and Fall of SpainZahoor Ahmed100% (1)

- Traditional Reflection EssayDocument3 pagesTraditional Reflection Essayapi-282199358No ratings yet

- 7TH Intra Novice Moot CourtDocument12 pages7TH Intra Novice Moot CourtAshirbad Sahoo100% (1)

- Basic Principles of Democracy Vol One ByVanSangva Dot ComDocument160 pagesBasic Principles of Democracy Vol One ByVanSangva Dot ComLTTuangNo ratings yet

- Yuri GagarinDocument3 pagesYuri GagarinDara DelaneyNo ratings yet

- EngageMB Parks Reservation Service FeedbackDocument25 pagesEngageMB Parks Reservation Service FeedbackChrisDcaNo ratings yet

- Leah Klein - GDDocument1 pageLeah Klein - GDAbi C. WareNo ratings yet

- ICAB - IAS 36 - QuestionsDocument3 pagesICAB - IAS 36 - QuestionsMonirul Islam MoniirrNo ratings yet

- Total Gallium JB15939XXDocument18 pagesTotal Gallium JB15939XXAsim AliNo ratings yet

- Cips 2012 0012Document68 pagesCips 2012 0012Pravin ChallawarNo ratings yet

- Astrokrishna - Blogspot.in-My Encounters With AstrologyDocument7 pagesAstrokrishna - Blogspot.in-My Encounters With AstrologysubramanyaNo ratings yet

- OPSYS Presentation EDDs 180619Document24 pagesOPSYS Presentation EDDs 180619gabriela.corina337006No ratings yet

- Chapter 1Document18 pagesChapter 1Steven ReyesNo ratings yet

- Rohleder PresentationDocument135 pagesRohleder Presentationmcwong_98No ratings yet

- Course Parts: Arab Institute For Accountants & LegalDocument2 pagesCourse Parts: Arab Institute For Accountants & LegalJanina SerranoNo ratings yet

- BULDHANADocument12 pagesBULDHANARiyaz ShaikhNo ratings yet

- Benchmark - Budgeting and Planning - Order 1970112Document5 pagesBenchmark - Budgeting and Planning - Order 1970112Vicky RobiNo ratings yet

- Development Insurance Corporation vs. Intermediate Appellate CourtDocument5 pagesDevelopment Insurance Corporation vs. Intermediate Appellate CourtJaja Ordinario Quiachon-AbarcaNo ratings yet

- One Page Saga V0.1: by OnepageanonDocument1 pageOne Page Saga V0.1: by OnepageanonmrmodNo ratings yet

- Core Network NFV Proposal For TelcelDocument8 pagesCore Network NFV Proposal For TelcelTELCELINNo ratings yet

- UHV II Lecture 10 - HB Self Part 1 v2Document16 pagesUHV II Lecture 10 - HB Self Part 1 v2Babio GandoNo ratings yet

- One Liner QuestionsDocument14 pagesOne Liner Questionskhan4444No ratings yet

- Penjelasan Absen 08 - 15 Agt So SPPDocument25 pagesPenjelasan Absen 08 - 15 Agt So SPPnampatisembiringNo ratings yet

- Project BankingDocument24 pagesProject BankingShubh Dixit0% (1)

- Closing The Engagement Gap, A Roadmap For Driving Superior Business Performance - Tower Perrins Global Workforce Study - 2007-08Document32 pagesClosing The Engagement Gap, A Roadmap For Driving Superior Business Performance - Tower Perrins Global Workforce Study - 2007-08Rohit VarmaNo ratings yet

- Outcasts BiographyDocument42 pagesOutcasts Biographysatya7960No ratings yet

- IC-74 Liability InsuranceDocument334 pagesIC-74 Liability Insurancemani_588No ratings yet