Professional Documents

Culture Documents

Smaw q3 DLP Aligned Rpms

Smaw q3 DLP Aligned Rpms

Uploaded by

jannetfrancia.sorretaCopyright:

Available Formats

You might also like

- Course Syllabus in (P.E. 112 - Movement Competency)Document8 pagesCourse Syllabus in (P.E. 112 - Movement Competency)Fernando BornasalNo ratings yet

- Research 1 SyllabusDocument6 pagesResearch 1 SyllabusJeho Rey D. Alfaro100% (5)

- Detailed Lesson Plan For Classroom Observation: Angelico J. Medina Memorial SchoolDocument8 pagesDetailed Lesson Plan For Classroom Observation: Angelico J. Medina Memorial SchoolMs. AyyaNo ratings yet

- SCI 122 Syllabus Done - rv6Document9 pagesSCI 122 Syllabus Done - rv6yvaiynelhauralopezNo ratings yet

- COT DLP RelativityDocument10 pagesCOT DLP Relativitykarinajean.padriganoNo ratings yet

- Colegio de Kidapawan: Information Technology Education Department I. VissionDocument8 pagesColegio de Kidapawan: Information Technology Education Department I. VissionMangansakan JayfNo ratings yet

- English 2 CO1Document6 pagesEnglish 2 CO1Kyle CabunilasNo ratings yet

- OBE Ethics SyllabusGE 8Document21 pagesOBE Ethics SyllabusGE 8MAWIIINo ratings yet

- Cot DLP Physical-ScienceDocument9 pagesCot DLP Physical-Sciencemaritel dawaNo ratings yet

- Nail Care Tools and EquipmentDocument6 pagesNail Care Tools and EquipmentCherry Marie BudoNo ratings yet

- ELECTRICAL WIRING SYSTEM AND DESIGN FINALDocument9 pagesELECTRICAL WIRING SYSTEM AND DESIGN FINALmelecio.franzontNo ratings yet

- DLL-ETECH W2 1stDocument2 pagesDLL-ETECH W2 1stHarold MoralesNo ratings yet

- DLLAug 29-Sept 1Document9 pagesDLLAug 29-Sept 1Marilyn LaquindanumNo ratings yet

- DLL Empowerment Tech Week 1 and 2Document3 pagesDLL Empowerment Tech Week 1 and 2Christopher SelebioNo ratings yet

- DLL For COT 1 EDROLINDocument8 pagesDLL For COT 1 EDROLINHarold LumayodNo ratings yet

- Prof Ed 8 TTL 1 SyllabusDocument16 pagesProf Ed 8 TTL 1 SyllabusMhel Ryan FloresNo ratings yet

- LessonPlan Electrical CircuitDocument7 pagesLessonPlan Electrical Circuitgrace.ledresNo ratings yet

- CCS1 - Introduction To Collegiate Education Course Manual 23241TDocument81 pagesCCS1 - Introduction To Collegiate Education Course Manual 23241Tdaryldosayco133No ratings yet

- Envi Sci 2022 SyllabusDocument9 pagesEnvi Sci 2022 SyllabusJojimar JulianNo ratings yet

- Tarlac State University: College Teacher Education Department Beed/Bsed/Beced/Btvte/BpeDocument11 pagesTarlac State University: College Teacher Education Department Beed/Bsed/Beced/Btvte/BpeUkulele PrincessNo ratings yet

- Fotippopcyclefall 2020Document7 pagesFotippopcyclefall 2020api-528657420No ratings yet

- EVED Good Manners and Right ConductDocument9 pagesEVED Good Manners and Right ConductRaul B. Gironella100% (1)

- Technology For Teaching and LearningDocument14 pagesTechnology For Teaching and LearningKim Roi CiprianoNo ratings yet

- Week 4Document4 pagesWeek 4shella mar barcialNo ratings yet

- 1st Quarter COT 2023-2024Document7 pages1st Quarter COT 2023-2024Anjenneth Castillo-Teñoso FontamillasNo ratings yet

- Educ 102 THE TEACHING PROFESSIONDocument8 pagesEduc 102 THE TEACHING PROFESSIONGlory Grace E. LimcoNo ratings yet

- EED 223 WORKSHEET Balela RobelDocument3 pagesEED 223 WORKSHEET Balela RobelIzuku MidoriyaNo ratings yet

- Math 133 SyllabusDocument5 pagesMath 133 SyllabusJim TomoricNo ratings yet

- HEE106 Clothing Selection Purchase and Care2Document7 pagesHEE106 Clothing Selection Purchase and Care2anjo bendanilloNo ratings yet

- NSTP 1 CWTS 1FM Revised SyllabusDocument8 pagesNSTP 1 CWTS 1FM Revised SyllabusSamson CapayNo ratings yet

- FL - Masining Na Pagpapahayag PDFDocument13 pagesFL - Masining Na Pagpapahayag PDFMa. Kristel OrbocNo ratings yet

- Cot 1 - Oral ComDocument5 pagesCot 1 - Oral ComMaria Liza CamoNo ratings yet

- DLL 1stjermaineDocument5 pagesDLL 1stjermaineTyrone SedilloNo ratings yet

- FL - Kulturang PopularDocument21 pagesFL - Kulturang PopularMa. Kristel OrbocNo ratings yet

- Cot 4 Mapeh (Health)Document15 pagesCot 4 Mapeh (Health)RELYN LUCIDONo ratings yet

- Fotippopcyclefall 2020Document6 pagesFotippopcyclefall 2020api-528657420No ratings yet

- College of Criminology: Central Bicol State University of AgricultureDocument5 pagesCollege of Criminology: Central Bicol State University of AgricultureKaren JimenezNo ratings yet

- LOGISTICS INTEGRATED SYLLABUS Template Obedized.Document7 pagesLOGISTICS INTEGRATED SYLLABUS Template Obedized.Myrnil TilbeNo ratings yet

- Atp Exemplar Week 1 Feb13 17 IsoDocument4 pagesAtp Exemplar Week 1 Feb13 17 IsoLEONARDO FLORESNo ratings yet

- FL - Technology For Teaching and Learning 1Document16 pagesFL - Technology For Teaching and Learning 1Ma. Kristel Orboc100% (1)

- Syllabus NWU - ACA - 010: Laoag CityDocument12 pagesSyllabus NWU - ACA - 010: Laoag CityLombroso's followerNo ratings yet

- Syllabus AstronomyDocument8 pagesSyllabus AstronomyLeonel MendozaNo ratings yet

- SCEINCE CO2nd 4th QuarterDocument11 pagesSCEINCE CO2nd 4th QuarterAnaliza BalunanNo ratings yet

- TVE104 SyllabusDocument8 pagesTVE104 SyllabusWiljhon Espinola JulapongNo ratings yet

- College of Business and Management: A Revised Course Syllabus in Soc. Sci. 102 - EthicsDocument14 pagesCollege of Business and Management: A Revised Course Syllabus in Soc. Sci. 102 - EthicsKris John SilvanoNo ratings yet

- Technology For Teaching and Learning 1Document16 pagesTechnology For Teaching and Learning 1Ma. Kristel OrbocNo ratings yet

- Republic of The Philippines Department of Education: Weekly Home Learning PlanDocument1 pageRepublic of The Philippines Department of Education: Weekly Home Learning PlanNove Grace Dela CruzNo ratings yet

- Syllabus NWU - ACA - 010: Special Topic 3 in EducationDocument11 pagesSyllabus NWU - ACA - 010: Special Topic 3 in EducationMariecris Barayuga Duldulao-AbelaNo ratings yet

- DLL Lesson Exemplar Returned DemoDocument8 pagesDLL Lesson Exemplar Returned DemoDon James VillaroNo ratings yet

- CC3L-CP2 SyllabusDocument8 pagesCC3L-CP2 SyllabusherlainecortadoNo ratings yet

- FUNDAMENTALS OF ELECTRICITY (2)Document8 pagesFUNDAMENTALS OF ELECTRICITY (2)melecio.franzontNo ratings yet

- Info Sheet 3.1-1 (TLED 113)Document15 pagesInfo Sheet 3.1-1 (TLED 113)Lawson SohNo ratings yet

- SYLLABUS Principles of TeachingDocument26 pagesSYLLABUS Principles of TeachinghelenaNo ratings yet

- DLSP Obtlp 2019 FormatDocument7 pagesDLSP Obtlp 2019 FormatCeejay JimenezNo ratings yet

- TTL1 Syllabus RCTambo-ong-2Document10 pagesTTL1 Syllabus RCTambo-ong-2Renzo GueribaNo ratings yet

- Research in Daily Life 2 SyllabusDocument7 pagesResearch in Daily Life 2 SyllabusAyyahNo ratings yet

- TVE104 SyllabusDocument8 pagesTVE104 SyllabusWiljhon Espinola JulapongNo ratings yet

- Motivating and Rewarding University Teachers to Improve Student Learning: A Guide for Faculty and AdministratorsFrom EverandMotivating and Rewarding University Teachers to Improve Student Learning: A Guide for Faculty and AdministratorsNo ratings yet

- Enhancing Learning Through the Scholarship of Teaching and Learning: The Challenges and Joys of JugglingFrom EverandEnhancing Learning Through the Scholarship of Teaching and Learning: The Challenges and Joys of JugglingNo ratings yet

- Transparent Teaching of Adolescents: Defining the Ideal Class for Students and TeachersFrom EverandTransparent Teaching of Adolescents: Defining the Ideal Class for Students and TeachersRating: 5 out of 5 stars5/5 (1)

- Subion, Jed BongonDocument9 pagesSubion, Jed Bongonjannetfrancia.sorretaNo ratings yet

- Canon, Leigh GiefunDocument9 pagesCanon, Leigh Giefunjannetfrancia.sorretaNo ratings yet

- TEMPLATE-GRAD-23-24 (12-Fidelity)Document4 pagesTEMPLATE-GRAD-23-24 (12-Fidelity)jannetfrancia.sorretaNo ratings yet

- Anecdotal Template Anecdotal RecordsDocument3 pagesAnecdotal Template Anecdotal Recordsjannetfrancia.sorretaNo ratings yet

- Catch Up Fridays - Orientation PresentationDocument21 pagesCatch Up Fridays - Orientation Presentationjannetfrancia.sorretaNo ratings yet

- General Chemistry 1 Module 1 Answer Sheet (Page 1 of 3) : Examples of Physical Properties IncludeDocument6 pagesGeneral Chemistry 1 Module 1 Answer Sheet (Page 1 of 3) : Examples of Physical Properties IncludeJeremiah Se-engNo ratings yet

- Schaefer Martin 2018 The Semantic Transparency of English Compound NounsDocument423 pagesSchaefer Martin 2018 The Semantic Transparency of English Compound NounsRania MohammedNo ratings yet

- Datasheet Af11Document11 pagesDatasheet Af11kian pecdasenNo ratings yet

- Hamsters and Their OffspringDocument3 pagesHamsters and Their OffspringClaire FarronNo ratings yet

- COVID-19 EpidemicDocument3 pagesCOVID-19 EpidemicJuniesha SenieNo ratings yet

- Bockman, Johanna (2013) NeoliberalismDocument3 pagesBockman, Johanna (2013) NeoliberalismJosh VeigaNo ratings yet

- On Annemarie Mols The Body MultipleDocument4 pagesOn Annemarie Mols The Body MultipleMAGALY GARCIA RINCONNo ratings yet

- cmsc420 Fall2020 LectsDocument156 pagescmsc420 Fall2020 LectsAnthony-Dimitri ANo ratings yet

- The Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionDocument16 pagesThe Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionShirlya LimaNo ratings yet

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Specification For Marker PostsDocument5 pagesSpecification For Marker PostsTai ChoonNo ratings yet

- Einstein - Remarks On Bertrand RussellDocument15 pagesEinstein - Remarks On Bertrand RussellGabriel Rogé Such100% (1)

- Porter's Generic Strategies: Cost Leadership DifferentiationDocument5 pagesPorter's Generic Strategies: Cost Leadership DifferentiationbiswasjoyNo ratings yet

- CBME 102 REviewerDocument17 pagesCBME 102 REviewerEilen Joyce BisnarNo ratings yet

- Java Atm PtojectDocument10 pagesJava Atm PtojectKrinal kathiriyaNo ratings yet

- Thorn Outdoor CatalogueDocument46 pagesThorn Outdoor CatalogueEmeka Patrick OgbuNo ratings yet

- IELTS Essay 1 With AnswerDocument1 pageIELTS Essay 1 With AnsweraazizmajidNo ratings yet

- Korean WaveDocument12 pagesKorean WaveJm PogiNo ratings yet

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDocument2 pagesFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezNo ratings yet

- Gear Tooth Contact PatternsDocument3 pagesGear Tooth Contact PatternsToua YajNo ratings yet

- शिक्षामनोविज्ञानDocument2 pagesशिक्षामनोविज्ञानlalit sharmaNo ratings yet

- Mahmoud Ben Romdhane & Sam Moyo (Eds) - Peasant Organisations and The Democratisation Process in AfricaDocument3 pagesMahmoud Ben Romdhane & Sam Moyo (Eds) - Peasant Organisations and The Democratisation Process in AfricaArlindo FortesNo ratings yet

- Water and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDocument7 pagesWater and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDinesh dhakarNo ratings yet

- InternationalDocument11 pagesInternationalVijaya SethiNo ratings yet

- IDOCs For IntroDocument62 pagesIDOCs For IntroGeetikaNo ratings yet

- Competency Enhancing Courses Jan June2023Document2 pagesCompetency Enhancing Courses Jan June2023Yashveer TakooryNo ratings yet

- Chapter Two: Linear Programming: Basic ConceptsDocument42 pagesChapter Two: Linear Programming: Basic ConceptsNguyễn Bùi Gia HuyNo ratings yet

- Hindustan Lever: Case 15-4Document11 pagesHindustan Lever: Case 15-4anilnair88100% (1)

- Typical Spelling Patterns For Consonant SoundsDocument7 pagesTypical Spelling Patterns For Consonant SoundsJan LambertNo ratings yet

- 109is 37150 - 50310Document2 pages109is 37150 - 50310dip461No ratings yet

Smaw q3 DLP Aligned Rpms

Smaw q3 DLP Aligned Rpms

Uploaded by

jannetfrancia.sorretaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smaw q3 DLP Aligned Rpms

Smaw q3 DLP Aligned Rpms

Uploaded by

jannetfrancia.sorretaCopyright:

Available Formats

lOMoARcPSD|36640670

SMAW Q3-DLP-Aligned RPMS

MAT-Mathematics (Sultan Kudarat State University)

Scan to open on Studocu

Studocu is not sponsored or endorsed by any college or university

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

School: POLOMOLOK NATIONAL Grade: 9-MODERACION

HIGH SCHOOL

Teacher: Christopher J. Depita T-1 Learning Area: SMAW GRADE-9

Observation Date: Quarter: 3

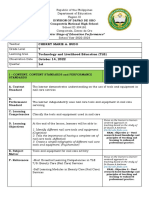

I. Objectives RPMS: KRA’s

Objectives

A. Content The learner demonstrates an

Standard understanding of the concepts and

underlying principles in Shielded

Metal Arc Welding (SMAW).

B. Performance The learners independently performs

Standard Sheilded Meatal Arc Welding Process

based on market standards.

C. Learning LESSON 1: WELD CARBON STEEL

Competencies PLATES IN FLATPOSITION (1G)

TLE CODE:TLE_IAAW9-12GW-IIIa-

Vj-3

3.2 Check root penetration in

accordance with acceptable standards

D. Objectives 1. Identify the Essential of

Welding

2. Determine the Acceptable Weld

Profile.

II. Content 1.Essential of Welding

2. Perform root penetration in

accordance with acceptable

standards

III. Learning

Resources

A. References Crouse W. and Anglin D. 2004. Automotive

mechanic (Tenth Edition). Makati Philippines.

Macmillan/McGraw-Hill School Publishing

Company. pp. 454

B. Learning Laptop, ppt presentation, video clip

Resources

IV. Procedure

A. Drill, review

previous lesson Start the lesson with a prayer and let Objective 6

or present the them pray according to their religion, The teacher

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

new lesson also to explain to them after the maintained learning

prayer the importance of respect to environments that

all the diversities and beliefs in the promote fairness,

class and in the community. respect and care to

encourage learning.

(Code of Ethics

Objective 14

Article 3 “Prayer” Section 8,

Resolution 435 series, 1997) Reviewed regularly

personal teaching

Instruct the class secretary to check practices using

the attendance of the class to existing laws and

monitor the number student regulations that

Recall the previous lesson about apply to the

usage of PPE/ Safety precautions teaching profession

symbols, polarity connection and and responsibilities

welding connection. specified in the code

Give motivation: who among you can of ethics for

give a brief recap on PPE usage and professional

importance. I will give 5 points in the teachers

performance rating for the

participating students.

B. Establishing a Setting the objectives for the day. Let

purpose for the the whole class read the objectives

lesson for the day.(Literacy Skills) KRA 1

This activity is based from the Objective 2

constructivism theory. Used research

John Dewey and other pragmatists are based knowledge

convinced that students or other and principles in

persons who are learning must teaching and

experience reality as it is. From learning to enhance

John Dewey's educational point of professional

view, this means that students must practice

adapt to their environment in order to

learn. Learning by doing principle.

(Stating the objectives using

Philosophy of teaching)

The pipe welder is considered by

some other welders to be one of the

most

skilled welders in industry. Often pipe

welder share a great deal pride. Some

finished welded piping systems are

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

considered works of art. Mastering the

skills

required to be pipe welder often takes

a large commitment on the part of the

welding

student, but this commitment is

rewarded by the industry.

The five essentials of welding are

Correct Electrode, Correct Current,

Correct

Arc Length or Voltage, Correct Travel

Speed, Correct Electrode Angle.

I.

TERMS AND DEFINITION

WELDING A joining process that

produces coalescence of materials by

heating

to a melting point, with or without the

application of pressure and with or

without

the use of filler metal.

COALESCENCE The growing together

or growth into one body of the

materials

being welded.

ELECTRODE Metal rod which conduct

a current from the electrode holder to

the

base metal.

BASE METAL The metal or alloy that

is welded, brazed, brazed, soldered,

or cut

FUSION WELDING The melting

together of filler metal and metal, or

of base

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

metal only, to produce a weld.

ARC The flow of the electric current

from the tip of the electrode to the

base

metal being welded.

DEPOSITION RATE The amount of

filler metal deposited in any welding

process

fated in pounds per hour.

STRING BEAD A weld bead made

with very little rod manipulation.

II.

Tools, Materials and Equipment

The Tools, Material and Equipment

must be appropriate to the job

you are doing. Make sure the safety of

the tools, materials and also to

the equipment.

II.

Essentials to obtain quality weld

A. Choosing the right electrode

The choose of the right electrode for a

particular job depends on the

following factors.

1. Kind of the base metal –

electrodes are classified according to

the kind of base metal for which they

are recommended into mild

steel, low hydrogen, low alloy, cast

iron, stainless steel, and

various non-ferrous electrodes.

2. Type of welding equipment –

determine what welding current

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

is available, as not all electrodes can

used from both DC or AC,

and others are more economical to

use with one type of current

than the other. It may also be

necessary to check the open

circuit voltage of the welding machine

to be used. For some electrodes

require higher open circuit voltage than

others for

best performance.

3. Dimensions and Design of Parts

– Heavy materials of

complicated design require electrodes

of high ductility. Thin

plates require low penetration

electrodes with stable arcs at low

current values.

4. Joint Preparation and Set-up –

deep penetration electrodes

are required when edges are not

beveled and fit-up is tight. Mild

penetration, tin coated electrodes are

best when gaps are open.

5. Welding position – some

electrodes are preferable to others for

off-position welding.

6. Specification and Service

Condition – job specifications may

indicate class of electrodes to be

used: otherwise, the service

requirements should be considered.

7. Practicability of Heat Treatment

– if shop facilities preclude the

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

employment of preheating or post-

heating for critical jobs, the

use of low heat input electrodes is the

only recourse.

8. Cost limits – the choice of

expensive electrodes whose

qualities or properties exceed those

normally demanded by the

job just to be “on the safe side” is

economically unwise when

less expensive electrodes, just as

suitable, are available. On

the other hand, it is false economy to

use cheap low-quality

electrodes and run the risk of the

weldment failing in service or

having the job redone at additional

cost when dependable

brands are in the market.

B. Current Requirement

The heat liberated at the arc is

directly proportional to the arc

voltage and the intensity of the

current. Since the arc voltage under

ordinary condition depends on the arc

length, which ideally should be

held constant, the current or

amperage used is therefore the man

factor in determining the heat input,

which in turn effects the condition

of the weldment.

At high current values the hotter arc

will cause a larger area and

deeper portion of the work piece to be

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

melted and the electrode to melt

faster, giving a deeper penetration

and faster welding speed. However,

too high current will cause harmful

overheating of the base metal with

undercutting or possibility of burn-

through for thin work pieces.

The amperage to be used depends

on:

a. Kind of Electrode – some

electrode coatings require more or

less current than others for more

weldability. Electrodes are so

formulated as to give smooth welding

performance and desire

penetration at low current values than

competitive types.

b. Size of Electrode – the greater

diameter of the core wire, the

greater the current required to

produce sufficient heat to melt at

the desired rate.

C. Presenting Have the learners read the parts Objective 5

Examples/instan and function of the welding Machine. Established safe and

ces of the new Give additional feedback and secure learning

lesson discussion to better deepen the environment to

understanding of the learner. Labeling enhance learning

the hazardous materials and liquids in through the

the workshop is a primary activity consistent

before any performance work starts implementation of

and observing proper waste disposal policies, guidelines

is also monitored. This can be done as and procedures.

a as a class activity. Using verbal

instructions to students and giving

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

them reminders to be always aware of Objective 4

hazards in the automotive workshop, The teacher used

and teaching them the non-verbal effective verbal and

communication through giving and non-verbal

teaching them sign languages in classroom

order to promote safety in the communication

workshop. Have the learners answer strategies to

the following questions after reading support learner

the text, using signs and symbols in understanding,

conducting this activity will promote participation,

participation and engagement to the engagement and

students . They can work on this by achievement.

pairs or by group.

D. Discussing new Show in the video clip on

concepts and welding essentials and welding

pacticing new standards.

skills #1

( Instructional material, use of ICT)

Guide Question:

What are the importance of

identifying the welding machine parts

and functions?

Can you create a modified

welding machine? If yes, make a

diagram of a modified AC welding

machine and DC welding Machine.

( Evaluating and Creating Skills

Questions)

E. Discussing new Give an inspirational experience Objective 6

concepts and which promotes the importance of Maintain learning

practicing new knowing and understanding the environments that

skills #2 different parts and functions of a nurture and inspire

welding machine. Have them discuss learners to

the different parts and functions of

participate,

the different types of the welding

machine. Let each reporter in every cooperate and

group report their output . Give collaborate in

positve feedback and praises to those continued learning.

learners who give the most correct

answers and best presentation.

(Using of ICT in conducting student

activities as a strategy to deliver

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

learning during this pandemic time.

F. Developing Objective 8

Mastery Individual Activity (Quiz 1 Apply a range of

Answer for 20 minutes use one successful

long bond paper) they will be strategies that

graded according to their maintain learning

individual performance from the

environments that

given task.

motivate learners to

work productively

After individual activity assign by assuming

students to clean their area of responsibility for

responsibility. They will be given their own learning

appreciation and score after the

cleaning activity.

Objective 7

Maintained learning

environments that

nurture inspire the

After the activity let the students give learners to

feedback on how this activity participate,

encouraged them to participate,

cooperate and in

cooperate and collaborate, they will

write it at the bottom of their paper. continued learning

G. Finding In your economic class you are KRA 1

practical thought that you should Objective 1

applications of maximise the things we are using Apply knowledge of

concepts an according to its value and content within and

importance in order to save

skills in daily across curriculum

money and make profit at the

living teaching areas.

same time.(Knowledge of content

across learning area in economics.)

The importance of identifying the

parts and functions and knowing the

causes of trouble of a welding

machine and adjusting for correcting

these problems can make the efficient

and increase its working life and

improve safety. This can bring more

profit to the company who is using for

example an industrial equipment. And

if not checked or inspected can lead Objective 9

to failure of machine or equipment

and delay in production which will Design, adapt and

also lead to loss of income and implement teaching

payment for penalties if the shipment strategies that are

is delayed. It can also be a cause of responsive to

accident and added expenses on the

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

business for the payments of the learners with

damage. disabilities,

giftedness and

Students activities 2

Divide the class into 5 groups and talents.

reserve the fifth group to the students

with special needs or disabilities,

example hearing problems, vision

problems far and near sighted very

slow learners. So that they can be

given special instructions to respond

to the needs of the given activity.

They will also be given extra time for

them to comply.

KRA 1

Objective 2

Objectives of the activity

Used research

Create an example scenario in which

they have experienced the based knowledge

importance of understanding the and principles in

welding essentials. They will present it teaching and

through role playing. learning to enhance

Criteria for role playing: professional

Props = 20 percent

Content = 50 percent practice

Group Participation = 30 percent

Total score = 100 percent

This activity is based from the

pragmatism theory.

John Dewey and other pragmatists are

convinced that students or other

persons who are learning must

experience reality as it is. From

John Dewey's educational point of

view, this means that students must

adapt to their environment in order to

learn. (This activity is based on the

Philosophy of teaching by John

Dewey)

H. Making Excessive reinforcement occurs in

generalizations groove welds when more weld metal

and is used

abstractions

than is required to fill a joint.

about the

Excessive reinforcement creates high

lesson

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

concentrations of

stress at the weld toes and usually

results from over welding.

Conclusion – A number of

discontinuities are associated with the

exterior profile or

shape of the completed weld. These

discontinuities are generally detected

through

visual inspection of the weld,

however, some are detectable

through other inspection

methods such as radiography, liquid

penetrant, and magnetic particle

inspection.

The maximum acceptable limitations

associated with these discontinuities

is

dependent on the performance

requirements of the welded

component and is usually

specified in the appropriate welding

code, standard or specification. The

welding

inspector is often required to

determine the extent of these

discontinuities and to

establish their acceptance, or

rejection, based on the relevant

acceptance criteria.

ACCEPTANCE CRITERIA FOR

COMPLETED WELDS

● Butt Welds

1. No cracks are permitted

2. As-welded surfaces are permitted;

however, the surface of welds shall

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

be sufficiently free from overlaps,

abrupt ridges, and valleys.

3. The thickness of reinforcement

shall not exceed 3.2 mm.

4. Undercuts shall not exceed 1 /32 in.

or 12½ % of the wall thickness

whichever is less.

5. For single-welded joints (i.e. butt

joints welded from one side),

concavity of the root surface shall not

reduce the total thickness of the KRA 3

joint, including reinforcement, to less Objective 10

than the nominal thickness of the Adapt and use

culturally

thinner component being joined. appropriate

6. For single welded joints, the excess teaching strategies

root penetration shall be exceed to address the

needs of learners

the lesser of 1 /8 in. or 5 % of the from indigenous

inside diameter of the pipe. groups.

7. The total joint penetration shall not

be less than the thickness of the

thinner component being joined,

except that incomplete root

penetration is acceptable if it does not

exceed the lesser of 1 /32 in. or

20 % of the required thickness, and its

extent is not more than 1 ½ in.

in any 6 in. length of weld.

8. Concavity of the root surface shall

not be reduced the total thickness of

the joint, including reinforcement, to

less than the thickness of the

thinner of the components being

joined.

9. The length of unfused bead or layer

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

areas shall not be more than 20 %

of the circumference of the pipe, or of

the total length of the weld, and

no more than 1½ inches in any 6 in.

length of weld.

SMAW NC II

(Teachers Reminders)

In delivering the topic, carefully

choosing of words in describing,

giving examples, comments and

suggestions. Always consider that we

have students which belongs to the

indigenous groups, in that way we will

not use words or gestures which can

offend their cultural beliefs and

practices.

I. Evaluating

learning

Students will answer the 20 points

KRA 1

quiz below. (Formative Quiz)

Objective 3

Direction: Get ½ sheet of paper. The teacher

Answer the question using your displayed proficient

mother tongue and use at least 200 use of Mother

words.(use your own dialect) Tongue, Filipino and

English to facilitate

1. List 3 common troubles of a

teaching and

welding machine , what are the learning.

causes and how do you correct

it? Explain based on your

understanding.

J. Additional This activity is created from John KRA 1

activities for Dewey's educational point of view, Objective 2

application or this means that students must adapt Used research

remediation to their environment in order to learn,

based knowledge

Learning by doing principle.(This is an

assessment based from the principles and principles in

of teaching) teaching and

learning to enhance

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

lOMoARcPSD|36640670

Republic of the Philippines

Department of Education

Region XII-SOCCSKSARGEN

Schools Division of South Cotabato

Perform the preventive maintenance professional

for an AC welding Machine. practice

(Performance Output)

Rubrics for scoring your output.

1. Timeliness- 5 pts

2. Safety Procedures- 5 pts

3. Organized cleaning – 5 pts

4. Based on standard Procedures-

5

Total Score= 20 pts

Prepared by: Checked and observed:

CHRISTOPHER J. DEPITA JOSEPH V. GARINGO

Teacher 1 Master Teacher I

Address: Octavio Village, Barangay Cannery Site, Polomolok, South Cotabato

Facebook: DepEd Tayo Polomolok National High School

Email Address: ianjohn.oliveros@deped.gov.ph

Downloaded by Jannet Francia Sorreta (jannetfrancia.sorreta@deped.gov.ph)

You might also like

- Course Syllabus in (P.E. 112 - Movement Competency)Document8 pagesCourse Syllabus in (P.E. 112 - Movement Competency)Fernando BornasalNo ratings yet

- Research 1 SyllabusDocument6 pagesResearch 1 SyllabusJeho Rey D. Alfaro100% (5)

- Detailed Lesson Plan For Classroom Observation: Angelico J. Medina Memorial SchoolDocument8 pagesDetailed Lesson Plan For Classroom Observation: Angelico J. Medina Memorial SchoolMs. AyyaNo ratings yet

- SCI 122 Syllabus Done - rv6Document9 pagesSCI 122 Syllabus Done - rv6yvaiynelhauralopezNo ratings yet

- COT DLP RelativityDocument10 pagesCOT DLP Relativitykarinajean.padriganoNo ratings yet

- Colegio de Kidapawan: Information Technology Education Department I. VissionDocument8 pagesColegio de Kidapawan: Information Technology Education Department I. VissionMangansakan JayfNo ratings yet

- English 2 CO1Document6 pagesEnglish 2 CO1Kyle CabunilasNo ratings yet

- OBE Ethics SyllabusGE 8Document21 pagesOBE Ethics SyllabusGE 8MAWIIINo ratings yet

- Cot DLP Physical-ScienceDocument9 pagesCot DLP Physical-Sciencemaritel dawaNo ratings yet

- Nail Care Tools and EquipmentDocument6 pagesNail Care Tools and EquipmentCherry Marie BudoNo ratings yet

- ELECTRICAL WIRING SYSTEM AND DESIGN FINALDocument9 pagesELECTRICAL WIRING SYSTEM AND DESIGN FINALmelecio.franzontNo ratings yet

- DLL-ETECH W2 1stDocument2 pagesDLL-ETECH W2 1stHarold MoralesNo ratings yet

- DLLAug 29-Sept 1Document9 pagesDLLAug 29-Sept 1Marilyn LaquindanumNo ratings yet

- DLL Empowerment Tech Week 1 and 2Document3 pagesDLL Empowerment Tech Week 1 and 2Christopher SelebioNo ratings yet

- DLL For COT 1 EDROLINDocument8 pagesDLL For COT 1 EDROLINHarold LumayodNo ratings yet

- Prof Ed 8 TTL 1 SyllabusDocument16 pagesProf Ed 8 TTL 1 SyllabusMhel Ryan FloresNo ratings yet

- LessonPlan Electrical CircuitDocument7 pagesLessonPlan Electrical Circuitgrace.ledresNo ratings yet

- CCS1 - Introduction To Collegiate Education Course Manual 23241TDocument81 pagesCCS1 - Introduction To Collegiate Education Course Manual 23241Tdaryldosayco133No ratings yet

- Envi Sci 2022 SyllabusDocument9 pagesEnvi Sci 2022 SyllabusJojimar JulianNo ratings yet

- Tarlac State University: College Teacher Education Department Beed/Bsed/Beced/Btvte/BpeDocument11 pagesTarlac State University: College Teacher Education Department Beed/Bsed/Beced/Btvte/BpeUkulele PrincessNo ratings yet

- Fotippopcyclefall 2020Document7 pagesFotippopcyclefall 2020api-528657420No ratings yet

- EVED Good Manners and Right ConductDocument9 pagesEVED Good Manners and Right ConductRaul B. Gironella100% (1)

- Technology For Teaching and LearningDocument14 pagesTechnology For Teaching and LearningKim Roi CiprianoNo ratings yet

- Week 4Document4 pagesWeek 4shella mar barcialNo ratings yet

- 1st Quarter COT 2023-2024Document7 pages1st Quarter COT 2023-2024Anjenneth Castillo-Teñoso FontamillasNo ratings yet

- Educ 102 THE TEACHING PROFESSIONDocument8 pagesEduc 102 THE TEACHING PROFESSIONGlory Grace E. LimcoNo ratings yet

- EED 223 WORKSHEET Balela RobelDocument3 pagesEED 223 WORKSHEET Balela RobelIzuku MidoriyaNo ratings yet

- Math 133 SyllabusDocument5 pagesMath 133 SyllabusJim TomoricNo ratings yet

- HEE106 Clothing Selection Purchase and Care2Document7 pagesHEE106 Clothing Selection Purchase and Care2anjo bendanilloNo ratings yet

- NSTP 1 CWTS 1FM Revised SyllabusDocument8 pagesNSTP 1 CWTS 1FM Revised SyllabusSamson CapayNo ratings yet

- FL - Masining Na Pagpapahayag PDFDocument13 pagesFL - Masining Na Pagpapahayag PDFMa. Kristel OrbocNo ratings yet

- Cot 1 - Oral ComDocument5 pagesCot 1 - Oral ComMaria Liza CamoNo ratings yet

- DLL 1stjermaineDocument5 pagesDLL 1stjermaineTyrone SedilloNo ratings yet

- FL - Kulturang PopularDocument21 pagesFL - Kulturang PopularMa. Kristel OrbocNo ratings yet

- Cot 4 Mapeh (Health)Document15 pagesCot 4 Mapeh (Health)RELYN LUCIDONo ratings yet

- Fotippopcyclefall 2020Document6 pagesFotippopcyclefall 2020api-528657420No ratings yet

- College of Criminology: Central Bicol State University of AgricultureDocument5 pagesCollege of Criminology: Central Bicol State University of AgricultureKaren JimenezNo ratings yet

- LOGISTICS INTEGRATED SYLLABUS Template Obedized.Document7 pagesLOGISTICS INTEGRATED SYLLABUS Template Obedized.Myrnil TilbeNo ratings yet

- Atp Exemplar Week 1 Feb13 17 IsoDocument4 pagesAtp Exemplar Week 1 Feb13 17 IsoLEONARDO FLORESNo ratings yet

- FL - Technology For Teaching and Learning 1Document16 pagesFL - Technology For Teaching and Learning 1Ma. Kristel Orboc100% (1)

- Syllabus NWU - ACA - 010: Laoag CityDocument12 pagesSyllabus NWU - ACA - 010: Laoag CityLombroso's followerNo ratings yet

- Syllabus AstronomyDocument8 pagesSyllabus AstronomyLeonel MendozaNo ratings yet

- SCEINCE CO2nd 4th QuarterDocument11 pagesSCEINCE CO2nd 4th QuarterAnaliza BalunanNo ratings yet

- TVE104 SyllabusDocument8 pagesTVE104 SyllabusWiljhon Espinola JulapongNo ratings yet

- College of Business and Management: A Revised Course Syllabus in Soc. Sci. 102 - EthicsDocument14 pagesCollege of Business and Management: A Revised Course Syllabus in Soc. Sci. 102 - EthicsKris John SilvanoNo ratings yet

- Technology For Teaching and Learning 1Document16 pagesTechnology For Teaching and Learning 1Ma. Kristel OrbocNo ratings yet

- Republic of The Philippines Department of Education: Weekly Home Learning PlanDocument1 pageRepublic of The Philippines Department of Education: Weekly Home Learning PlanNove Grace Dela CruzNo ratings yet

- Syllabus NWU - ACA - 010: Special Topic 3 in EducationDocument11 pagesSyllabus NWU - ACA - 010: Special Topic 3 in EducationMariecris Barayuga Duldulao-AbelaNo ratings yet

- DLL Lesson Exemplar Returned DemoDocument8 pagesDLL Lesson Exemplar Returned DemoDon James VillaroNo ratings yet

- CC3L-CP2 SyllabusDocument8 pagesCC3L-CP2 SyllabusherlainecortadoNo ratings yet

- FUNDAMENTALS OF ELECTRICITY (2)Document8 pagesFUNDAMENTALS OF ELECTRICITY (2)melecio.franzontNo ratings yet

- Info Sheet 3.1-1 (TLED 113)Document15 pagesInfo Sheet 3.1-1 (TLED 113)Lawson SohNo ratings yet

- SYLLABUS Principles of TeachingDocument26 pagesSYLLABUS Principles of TeachinghelenaNo ratings yet

- DLSP Obtlp 2019 FormatDocument7 pagesDLSP Obtlp 2019 FormatCeejay JimenezNo ratings yet

- TTL1 Syllabus RCTambo-ong-2Document10 pagesTTL1 Syllabus RCTambo-ong-2Renzo GueribaNo ratings yet

- Research in Daily Life 2 SyllabusDocument7 pagesResearch in Daily Life 2 SyllabusAyyahNo ratings yet

- TVE104 SyllabusDocument8 pagesTVE104 SyllabusWiljhon Espinola JulapongNo ratings yet

- Motivating and Rewarding University Teachers to Improve Student Learning: A Guide for Faculty and AdministratorsFrom EverandMotivating and Rewarding University Teachers to Improve Student Learning: A Guide for Faculty and AdministratorsNo ratings yet

- Enhancing Learning Through the Scholarship of Teaching and Learning: The Challenges and Joys of JugglingFrom EverandEnhancing Learning Through the Scholarship of Teaching and Learning: The Challenges and Joys of JugglingNo ratings yet

- Transparent Teaching of Adolescents: Defining the Ideal Class for Students and TeachersFrom EverandTransparent Teaching of Adolescents: Defining the Ideal Class for Students and TeachersRating: 5 out of 5 stars5/5 (1)

- Subion, Jed BongonDocument9 pagesSubion, Jed Bongonjannetfrancia.sorretaNo ratings yet

- Canon, Leigh GiefunDocument9 pagesCanon, Leigh Giefunjannetfrancia.sorretaNo ratings yet

- TEMPLATE-GRAD-23-24 (12-Fidelity)Document4 pagesTEMPLATE-GRAD-23-24 (12-Fidelity)jannetfrancia.sorretaNo ratings yet

- Anecdotal Template Anecdotal RecordsDocument3 pagesAnecdotal Template Anecdotal Recordsjannetfrancia.sorretaNo ratings yet

- Catch Up Fridays - Orientation PresentationDocument21 pagesCatch Up Fridays - Orientation Presentationjannetfrancia.sorretaNo ratings yet

- General Chemistry 1 Module 1 Answer Sheet (Page 1 of 3) : Examples of Physical Properties IncludeDocument6 pagesGeneral Chemistry 1 Module 1 Answer Sheet (Page 1 of 3) : Examples of Physical Properties IncludeJeremiah Se-engNo ratings yet

- Schaefer Martin 2018 The Semantic Transparency of English Compound NounsDocument423 pagesSchaefer Martin 2018 The Semantic Transparency of English Compound NounsRania MohammedNo ratings yet

- Datasheet Af11Document11 pagesDatasheet Af11kian pecdasenNo ratings yet

- Hamsters and Their OffspringDocument3 pagesHamsters and Their OffspringClaire FarronNo ratings yet

- COVID-19 EpidemicDocument3 pagesCOVID-19 EpidemicJuniesha SenieNo ratings yet

- Bockman, Johanna (2013) NeoliberalismDocument3 pagesBockman, Johanna (2013) NeoliberalismJosh VeigaNo ratings yet

- On Annemarie Mols The Body MultipleDocument4 pagesOn Annemarie Mols The Body MultipleMAGALY GARCIA RINCONNo ratings yet

- cmsc420 Fall2020 LectsDocument156 pagescmsc420 Fall2020 LectsAnthony-Dimitri ANo ratings yet

- The Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionDocument16 pagesThe Roots of Modern Feminism: Mary Wollstonecraft and The French RevolutionShirlya LimaNo ratings yet

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Specification For Marker PostsDocument5 pagesSpecification For Marker PostsTai ChoonNo ratings yet

- Einstein - Remarks On Bertrand RussellDocument15 pagesEinstein - Remarks On Bertrand RussellGabriel Rogé Such100% (1)

- Porter's Generic Strategies: Cost Leadership DifferentiationDocument5 pagesPorter's Generic Strategies: Cost Leadership DifferentiationbiswasjoyNo ratings yet

- CBME 102 REviewerDocument17 pagesCBME 102 REviewerEilen Joyce BisnarNo ratings yet

- Java Atm PtojectDocument10 pagesJava Atm PtojectKrinal kathiriyaNo ratings yet

- Thorn Outdoor CatalogueDocument46 pagesThorn Outdoor CatalogueEmeka Patrick OgbuNo ratings yet

- IELTS Essay 1 With AnswerDocument1 pageIELTS Essay 1 With AnsweraazizmajidNo ratings yet

- Korean WaveDocument12 pagesKorean WaveJm PogiNo ratings yet

- Feature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDocument2 pagesFeature: SFP Optical Module 1 .25G Double Optical Fiber 20kmDaniel Eduardo RodriguezNo ratings yet

- Gear Tooth Contact PatternsDocument3 pagesGear Tooth Contact PatternsToua YajNo ratings yet

- शिक्षामनोविज्ञानDocument2 pagesशिक्षामनोविज्ञानlalit sharmaNo ratings yet

- Mahmoud Ben Romdhane & Sam Moyo (Eds) - Peasant Organisations and The Democratisation Process in AfricaDocument3 pagesMahmoud Ben Romdhane & Sam Moyo (Eds) - Peasant Organisations and The Democratisation Process in AfricaArlindo FortesNo ratings yet

- Water and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDocument7 pagesWater and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDinesh dhakarNo ratings yet

- InternationalDocument11 pagesInternationalVijaya SethiNo ratings yet

- IDOCs For IntroDocument62 pagesIDOCs For IntroGeetikaNo ratings yet

- Competency Enhancing Courses Jan June2023Document2 pagesCompetency Enhancing Courses Jan June2023Yashveer TakooryNo ratings yet

- Chapter Two: Linear Programming: Basic ConceptsDocument42 pagesChapter Two: Linear Programming: Basic ConceptsNguyễn Bùi Gia HuyNo ratings yet

- Hindustan Lever: Case 15-4Document11 pagesHindustan Lever: Case 15-4anilnair88100% (1)

- Typical Spelling Patterns For Consonant SoundsDocument7 pagesTypical Spelling Patterns For Consonant SoundsJan LambertNo ratings yet

- 109is 37150 - 50310Document2 pages109is 37150 - 50310dip461No ratings yet