Professional Documents

Culture Documents

RCD Lecture Notes 1 Working Stress Design and Serviceability Requirement

RCD Lecture Notes 1 Working Stress Design and Serviceability Requirement

Uploaded by

Xzk MallaboOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCD Lecture Notes 1 Working Stress Design and Serviceability Requirement

RCD Lecture Notes 1 Working Stress Design and Serviceability Requirement

Uploaded by

Xzk MallaboCopyright:

Available Formats

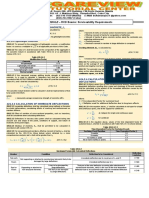

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

mixture in accordance with Table 419.2.4.2 or as

CODE PROVISIONS permitted in Section 419.2.4.3.

429.4 PERMISSIBLE SERVICE LOAD STRESSES

429.4.1 Stresses in concrete shall not exceed:

Flexure ------------------------------------------𝟎. 𝟒𝟓𝒇′𝒄

429.4.2 Tensile stress in reinforcement 𝑓𝑠 shall not

exceed

For Flexural reinforcement -------------------𝟎. 𝟓𝟎𝒇𝒚 419.2.4.3 If the measured average splitting tensile

strength of lightweight concrete, fct , is used to calculate λ,

429.6 FLEXURE laboratory test shall be conducted in accordance with

For investigation of stresses at service loads, straight- ASTM C330M to establish the value of fct ,and the

line theory (for flexure) shall be used with the following corresponding value of fcm and λ shall be calculated by:

assumptions. 𝒇𝒄𝒕

𝝀= ≤ 𝟏. 𝟎 (419.2.4.3)

429.6.1 Strains vary linearly as the distance from the 𝟎. 𝟓𝟔√𝒇𝒄𝒎

neutral axis, except for deep flexural members with The concrete mixture tested in order to calculate λ shall

overall depth-span ratios greater than 2/5 for continuous be representative of that to be used in the Work.

spans and 4/5 for simple spans, a nonlinear distribution where:

of strain shall be considered. 𝑓𝑐𝑚 = measured average compressive strength of

429.6.2 Stress-strain relationship of concrete is a straight concrete, MPa

line under service loads within permissible service load

stresses. 424.2.3 CALCULATION OF IMMEDIATE

429.6.3 In reinforced concrete members, concrete resists DEFLECTIONS

no tension. 429.6.4 It shall be permitted to take the 424.2.3.1 Immediate deflections shall be calculated using

modular ratio 𝑛 = 𝐸𝑠/𝐸𝑐, as the nearest whole number (but methods or formulas for elastic deformations, considering

NOT less than 6). Except for calculations for deflections, effects of cracking and reinforcement on member

value of n for lightweight concrete shall be assumed to be stiffness.

the same as for normal weight concrete of the same 424.2.3.2 Effect of variation of cross-sectional properties,

strength. such as haunches, shall be considered when calculating

429.6.5 In doubly reinforced flexural members, an deflections.

effective modular ratio of 2𝐸𝑠/𝐸𝑐 shall be used to 424.2.3.3 Deflections in two-way slab system shall be

transform compression reinforcement for stress calculated taking into account size and shape of the

computations. Compressive stress in such reinforcement panel, conditions of support, and nature of restraints at the

shall NOT exceed permissible tensile stress. panel edges.

424.2.3.4 Modulus of elasticity, Ec, shall be permitted to

419.2.2 MODULUS OF ELASTICITY be calculated in accordance with section 419.2.2.

419.2.2.1 Modulus of elasticity 𝐸𝑐 for concrete shall be 424.2.3.5 For non-prestressed members, effective

permitted to be taken as moment of inertia, Ie, shall be calculated by Eq.

𝒘𝒄 𝟏.𝟓 𝟎. 𝟎𝟒𝟑√𝒇′𝒄 (𝑖𝑛 𝑀𝑃𝑎) 424.2.3.5a (show below) unless obtained by a more

for values of 𝑤𝑐 between 1,440 and 2,560 kg/m³. comprehensive analysis, but 𝐼𝑒 shall not be greater than

For normal weight concrete, 𝐸𝑐 shall be permitted to be 𝐼𝑔 .

taken as 𝑰𝒄𝒓 ≤ 𝑰𝒆 ≤ 𝑰𝒈

𝑬𝒄 = 𝟒, 𝟕𝟎𝟎√𝒇′𝒄 (𝑖𝑛 𝑀𝑃𝑎) 𝑴𝒄𝒓 𝟑 𝑴𝒄𝒓 𝟑

𝑰𝒆 = ( ) 𝑰𝒈 + [𝟏 − ( ) ] 𝑰𝒄𝒓 (424.2.3.6𝑎)

𝑴𝒂 𝑴𝒂

419.2.3 MODULUS OF RUPTURE OF CONCRETE where:

419.2.3.1 Modulus of rupture, fr, for concrete shall be 𝐼𝑐𝑟 = Moment of inertia of cracked section transformed to

calculated by: concrete.

𝒇𝒓 = 𝟎. 𝟔𝟐𝝀√𝒇′𝒄 (419.2.3.1) 𝐼𝑒 = Effective moment of inertia for computation of

where the value of λ is in accordance with Section 419.2.4 deflection.

(Lightweight Concrete) 𝐼𝑔 = Moment of inertia of gross concrete section about the

419.2.4 Lightweight Concrete 419.2.4.1 To account for centroidal axis, neglecting reinforcement.

the properties of lightweight concrete, a modification 𝑀𝑐𝑟 = Cracking moment.

factor λ is used as a multiplier of √𝑓′𝑐 in all applicable 𝑀𝑎 = Maximum moment in member at stage deflection is

provisions of this Code. 419.2.4.2 The value of λ shall be computed.

based on the composition of the aggregate in the concrete

ENGR. AUGOSTO D. FRACE, ME-CE 1

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

Cracking Moment, 𝑴𝒄𝒓 , is calculated by: FLEXURAL ANALYSIS (WSD)

𝒇𝒓 𝑰𝒈

𝑴𝒄𝒓 = (424.2.3.5𝑏)

𝒚𝒕 A. Uncracked Stage (𝒇𝒕 ≤ 𝒇𝒓 𝒐𝒓 𝑴𝒂 ≤ 𝑴𝒄𝒓 )

where: Rectangular Section

𝑦𝑡 = Distance from centroidal axis of gross section,

neglecting reinforcement.

424.2.3.6 For continuous one-way slabs and beams, Ie

shall be permitted to be taken as the average of values

obtained from Eq. 424.2.3.5a for the critical positive and

negative moment sections.

424.2.3.7 For prismatic one-way slabs and beams, Ie

shall be permitted to be taken as the value obtained from

Eq. 424.2.3.5a at mid-span for simple and continuous

spans, and at the support for cantilevers.

𝒇𝒓 𝑰𝒈

424.2.4 CALCULATION OF TIME-DEPENDENT 𝑴𝒄𝒓 =

DEFLECTIONS 𝒚𝒕

424.2.4.1.1 Unless values from a more comprehensive B. Cracked Stage (𝒇𝒕 > 𝒇𝒓 𝒐𝒓 𝑴𝒂 > 𝑴𝒄𝒓 )

analysis, additional timedependent deflection resulting

from creep and shrinkage of flexural members shall be Transformed Area Method

calculated as the product of the immediate deflection Rectangular Section

caused by the sustained load and the factor 𝜆Δ .

𝝃

𝝀𝚫 = (424.2.4.1.1)

𝟏 + 𝟓𝟎𝝆′

where:

𝜉 = Time-dependent factor for sustained load

𝜆∆ = Multiplier used for additional deflection due to long-

term effects

424.2.4.1.2 In the equation above, 𝜌′ shall be calculated

at mid-span for simple and continuous spans, and at the

support for cantilevers.

For midspan for simple and continuous span

𝑨′𝒔

𝝆′ =

𝒃𝒅 Location of the neutral axis from extreme compression

For cantilever

fiber

𝑨𝒔

𝝆′ = • Singly reinforced beam (SRB):

𝒃𝒅

𝟏 𝟐

424.2.4.1.3 In the equation above, values of the time 𝒃𝒙 = 𝒏𝑨𝒔 (𝒅 − 𝒙)

𝟐

dependent factor for sustained load, ξ, shall be in

• Doubly reinforced beam (DRB):

accordance with Table 424.2.4.1.3 (shown below) 𝟏 𝟐

𝒃𝒙 + (𝟐𝒏 − 𝟏)𝑨′𝒔 (𝒙 − 𝒅′) = 𝒏𝑨𝒔 (𝒅 − 𝒙)

𝟐

Cracked Section moment of inertia (𝑰𝒄𝒓 = 𝑰𝑵.𝑨. )

• Singly reinforced

𝒃𝒙𝟑

𝑰𝒄𝒓 = + 𝒏𝑨𝒔 (𝒅 − 𝒙)𝟐

𝟑

• Doubly reinforced

𝒃𝒙𝟑

𝑰𝒄𝒓 = + (𝟐𝒏 − 𝟏)𝑨′ 𝒔 (𝒙 − 𝒅′ )𝟐 + 𝒏𝑨𝒔 (𝒅 − 𝒙)𝟐

𝟑

Actual stresses

• General flexure formula

𝑴𝒚

𝒇=

𝑰

• Concrete stress at extreme compression fiber

𝑴𝒂 𝒙

𝒇𝒄 =

𝑰𝒄𝒓

• Tension steel

𝒇𝒔 𝑴𝒂 (𝒅 − 𝒙)

=

𝒏 𝑰𝒄𝒓

• Compression steel

𝒇′𝒔 𝑴𝒂 (𝒙 − 𝒅′)

=

𝟐𝒏 𝑰𝒄𝒓

ENGR. AUGOSTO D. FRACE, ME-CE 2

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

FLEXURAL DESIGN (WSD) 𝑨𝒔 = 𝑨𝒔𝟏 + 𝑨𝒔𝟐

For Compression steel reinforcement (𝐴′𝑠 )

i. Solve for 𝐴′𝑠 from balanced condition and use

𝑀 = (𝑀𝑎 − 𝑀𝑏𝑎𝑙 )

ii. If 𝑓′𝑠 ≥ 𝑓𝑠 , use 𝑓′𝑠 = 𝑓𝑠

𝟐𝒏𝒇𝒄 (𝒙𝒃𝒂𝒍 − 𝒅′)

𝒇′𝒔 =

𝒙𝒃𝒂𝒍

𝟐𝒇𝒔 (𝒙𝒃𝒂𝒍 − 𝒅′)

𝒇′𝒔 =

𝒅 − 𝒙𝒃𝒂𝒍

iii. Solve for 𝐴′𝑠

𝟐𝒏(𝑴𝒂 − 𝑴𝒃𝒂𝒍 )

𝑨′𝒔 =

𝒇′𝒔 (𝟐𝒏 − 𝟏)(𝒅 − 𝒅′)

Procedure

Step 1: Calculate the actual expected moment (𝑀𝑎 ) to be

carried by the beam at service level

Step 2: Solve for the balanced moment capacity

𝒅𝒇𝒄

𝒙𝒃𝒂𝒍 =

𝒇

𝒇𝒄 + 𝒔

𝒏

𝟏

𝑪𝒃𝒂𝒍 = 𝒇𝒄 (𝒃 ∙ 𝒙𝒃𝒂𝒍 )

𝟐

𝟏

𝑴𝒃𝒂𝒍 = 𝑪𝒃𝒂𝒍 (𝒅 − 𝒙𝒃𝒂𝒍 )

𝟑

• 𝑴𝒂 ≤ 𝑴𝒃𝒂𝒍 , 𝒅𝒆𝒔𝒊𝒈𝒏 𝒂𝒔 𝑺𝑹𝑩

• 𝑴𝒂 > 𝑴𝒃𝒂𝒍 , 𝒅𝒆𝒔𝒊𝒈𝒏 𝒂𝒔 𝑫𝑹𝑩

Step 3: Design as SRB (𝑴𝒂 ≤ 𝑴𝒃𝒂𝒍 )

Locate the neutral axis

𝒃𝒙𝟑 𝒃𝒙𝟐 (𝒅 − 𝒙) 𝒏𝑴𝒂 (𝒅 − 𝒙)

+ =

𝟑 𝟐 𝒇𝒔

𝑴𝒂

𝑨𝒔 =

𝟏

𝒇𝒔 (𝒅 − 𝒙)

𝟑

Step 4: Design as DRB (𝑴𝒂 > 𝑴𝒃𝒂𝒍 )

For Tension steel reinforcement (𝐴𝑠 )

i. Solve for 𝐴𝑠1 from balanced condition

𝑴𝒃𝒂𝒍

𝑨𝒔𝟏 =

𝟏

𝒇𝒔 (𝒅 − 𝒙𝒃𝒂𝒍 )

𝟑

ii. Solve for 𝐴𝑠2 from excess of 𝑀𝑎 and 𝑀𝑏𝑎𝑙

(𝑴𝒂 − 𝑴𝒃𝒂𝒍 )

𝑨𝒔𝟐 =

𝒇𝒔 (𝒅 − 𝒅′)

iii. Solve for total area of tension reinforcement

ENGR. AUGOSTO D. FRACE, ME-CE 3

PRINCIPLES OF REINFORCED/PRESTRESSED CONCRETE

WORKING STRESS DESIGN (WSD)

EXERCISE PROBLEMS

Problem 1:

A decorative beam with a tubular section is simply Problem 4:

supported on a span of 4.5 m. The tubular section has an A 6 m simply supported beam is reinforced with 3-20 mm

outside diameter of 600 mm and an inside diameter of 300 Ф tension bars is loaded at third points with 20 kN dead

mm. The allowable cracking stress is 3.2 MPa. load and 12 kN live load. Use f’c=28 MPa and fy=420

a. Determine the cracking moment MPa. Use WSD, determine the following:

b. In addition to the weight, determine the a. Instantaneous deflection due to dead load.

concentrated load at midspan that the beam can b. Instantaneous deflection due to dead load and

support. live load.

c. If the 300 mm hollow core were replaced by 300 c. Initial deflection due to full live load

mm square section, calculate the cracking d. Long term deflection, assuming 50% of live load

moment. is continuously applied for two years.

Problem 2: Problem 5:

Precast joist with typical section as shown are cast using A reinforced concrete beam has a width of 280 mm and

a concrete strength f’c=27.5 MPa. The resulting tensile effective depth of 520 mm. It is reinforced for tension only

strength, ft=2.75 MPa. The joist are to be simply with 5-28 mm Ф bars. f’c=21 MPa and fs=128 MPa.

supported on a span of 6m. Unit weigth of concrete is 24 Assume n=9. Use WSD.

kN/m^3. a. Determine the location of the neutral axis

b. Calculate the compressive force on the concrete.

c. Determine the moment capacity of the beam.

Problem 6:

A rectangular reinforced concrete beam having a width of

200 mm and effective depth of 500 mm is subjected to a

service moment of 120 kN-m. The beam is reinforced with

four 25 mm Ф bars. Use modular ratio n=8. Use WSD.

a. Determine the location of the neutral axis.

a. Find the cracking moment b. Calculate the stress on the concrete

b. How much additional uniform load can the joist c. Determine the stress on the steel.

carry if the cracking moment is 50 kN-m?

c. If the joist is reinforced with 3-25 mm diameter Example 7:

bars with their centroid at 435 mm from the top, Design a section of a concrete beam reinforced for

determine the cracking moment. Use n=8. tension only. The beam is simply supported on a span of

7.5 m and carries a total load of 18 kN/m. Use a minimum

Problem 3: with of 250 mm. Use 20 mmФ with yield strength of 280

Consider the T beam shown. The beam is simply MPa. Use f’c=21 MPa an use modular ratio n=9.

supported at a span of 6m and with 2 m overhang. The Sketch the section of the beam.

beam carries a dead load of 15 kN/m excluding the weight

of the beam and a uniform live load of 10 kN/m.

Compressive strength of concrete is 28 MPa and yield

strength of 420 MPa. Calculate the following:

a. Cracking moment

b. Critical moment of inertia

c. Compressive stress on concrete

d. Tensile stress on steel

e. Capacity ratio of concrete under compressive

stress

f. Section curvature at cracking

ENGR. AUGOSTO D. FRACE, ME-CE 4

You might also like

- Reinforced Concrete Chapter 2Document24 pagesReinforced Concrete Chapter 2Yena CabaluNo ratings yet

- Beam Deflection NSCP 2015 1Document4 pagesBeam Deflection NSCP 2015 1Lester Neil Lomod100% (3)

- Chapter 4 PDFDocument5 pagesChapter 4 PDFtrishia arcillaNo ratings yet

- Chapter 7Document5 pagesChapter 7Wilkenn TuazonNo ratings yet

- Deflection Due To PrestressDocument85 pagesDeflection Due To PrestresscamilleNo ratings yet

- 2006 HCS Point Loads NapoliDocument8 pages2006 HCS Point Loads NapoliVálter LúcioNo ratings yet

- Planetary Ball Mill, QuestionsDocument18 pagesPlanetary Ball Mill, QuestionsNoemiInterianNo ratings yet

- Advanced Earthquake Resistant Design TechniquesDocument5 pagesAdvanced Earthquake Resistant Design TechniquesGnanam1No ratings yet

- Working Stress Design and Serviceability RequirementDocument4 pagesWorking Stress Design and Serviceability RequirementSean Kent TagubaNo ratings yet

- 1 Working Stress Design and Serviceability RequirementDocument5 pages1 Working Stress Design and Serviceability RequirementChristian Joseph R. GonzalesNo ratings yet

- REVIEW-MODULE 41-Nov2020-WSD-BeamsDocument3 pagesREVIEW-MODULE 41-Nov2020-WSD-BeamsMa Ella Mae LogronioNo ratings yet

- LECTURE NOTE 1 - Working Stress Design and Serciceability RequirementDocument6 pagesLECTURE NOTE 1 - Working Stress Design and Serciceability RequirementAugosto FraceNo ratings yet

- Review Module 41 RCD 1Document2 pagesReview Module 41 RCD 1Yang RhiaNo ratings yet

- Review MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteDocument2 pagesReview MODULE - RCD Beams: Serviceability Requirements: 419.2.3 Modulus of Rupture of ConcreteJoseph Lanto100% (1)

- Paper No. 609Document15 pagesPaper No. 609ravi kumarNo ratings yet

- Lesson 8 Shear or Diagonal Tension in RC BeamsDocument8 pagesLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioNo ratings yet

- NSCP Coefficients For ContinuousDocument28 pagesNSCP Coefficients For ContinuousLynx101No ratings yet

- RCD Lesson 1b Flexural Analysis of Beams (Cracking Moment)Document14 pagesRCD Lesson 1b Flexural Analysis of Beams (Cracking Moment)EJ Dela CruzNo ratings yet

- RCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFDocument14 pagesRCD Lesson 1b Flexural Analysis of Beams (Cracking Moment) PDFEduard Joseph Dela CruzNo ratings yet

- Reinforced Concrete Design Engr. Rimar C. Liguan: ColumnsDocument24 pagesReinforced Concrete Design Engr. Rimar C. Liguan: ColumnsCristina Sarmiento100% (1)

- Final Draft 1Document19 pagesFinal Draft 1Mohamed mohy el deenNo ratings yet

- Reinforced Concrete Design FormulasDocument5 pagesReinforced Concrete Design FormulasRogie Neth Hallera Abatayo100% (1)

- Review Module - Reinforced Concrete Design (Foundation)Document3 pagesReview Module - Reinforced Concrete Design (Foundation)Jessica Lymwell PunzalanNo ratings yet

- BEAMPASKDocument49 pagesBEAMPASKNils Antoine FreundNo ratings yet

- Modelling Deflection in Reinforced Concrete Structures Using The Layered ApproachDocument21 pagesModelling Deflection in Reinforced Concrete Structures Using The Layered ApproachMohamed mohy el deenNo ratings yet

- Application of Capacity Spectrum Method Based On ATC 40 and BNBC 1993Document4 pagesApplication of Capacity Spectrum Method Based On ATC 40 and BNBC 1993designer STRNo ratings yet

- Column Buckling Test Experiment 4: EMA 3702L - Mechanics and Materials Science LabDocument15 pagesColumn Buckling Test Experiment 4: EMA 3702L - Mechanics and Materials Science LabRamon OrgeNo ratings yet

- Review Module-Reinforced Concrete Design (RCD Columns-USD Part 2)Document3 pagesReview Module-Reinforced Concrete Design (RCD Columns-USD Part 2)Dream CatcherNo ratings yet

- Kippap-Handout-SEC (40 RCD - Footings)Document10 pagesKippap-Handout-SEC (40 RCD - Footings)top1echolocoNo ratings yet

- Calculation Deflection in Accordance To EC-2: 1.1 Design DataDocument15 pagesCalculation Deflection in Accordance To EC-2: 1.1 Design DataMisgun SamuelNo ratings yet

- Ultimate Limit States Design: Article 41. Equilibrium Limit StateDocument35 pagesUltimate Limit States Design: Article 41. Equilibrium Limit StateAyad TalibNo ratings yet

- Design of Compression MembersDocument22 pagesDesign of Compression MembersChee Fong MakeNo ratings yet

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDocument16 pagesT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019No ratings yet

- Continuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFDocument35 pagesContinuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFtimNo ratings yet

- Review Module 45-RCD 5 - Part 1 & 2Document2 pagesReview Module 45-RCD 5 - Part 1 & 2Arlyn ConsumeNo ratings yet

- CM 3.5 LRFD Culvert Flexure DesignDocument21 pagesCM 3.5 LRFD Culvert Flexure DesignNo WoNo ratings yet

- Study Pack and Formulae of Chapter 4Document15 pagesStudy Pack and Formulae of Chapter 4RatanakNo ratings yet

- Buckling Resistance of Uniform Members in BendingDocument3 pagesBuckling Resistance of Uniform Members in Bendinganuj SinghNo ratings yet

- Chapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 EdDocument5 pagesChapter 8 - Bending Members: A Beginner's Guide To The Steel Construction Manual, 14 Edv pavanNo ratings yet

- (Systematic Rehabilitation) : Modeling and AnalysisDocument20 pages(Systematic Rehabilitation) : Modeling and AnalysisMuhammad RizwanNo ratings yet

- Final Project 2021Document97 pagesFinal Project 2021Timothy UmpoNo ratings yet

- Methods of Structural AnalysisDocument6 pagesMethods of Structural AnalysisCarlosNo ratings yet

- WSD Nov 2022Document2 pagesWSD Nov 2022twicetacsNo ratings yet

- Manual of Metal Bellows - 0441e S 56-77!2!04!10!20 - WebDocument11 pagesManual of Metal Bellows - 0441e S 56-77!2!04!10!20 - Webadfafad gfadfNo ratings yet

- Unit 3Document100 pagesUnit 3dagimawgchew777No ratings yet

- Table 6-10 Values of For Joint Strength Calculation: ConcreteDocument1 pageTable 6-10 Values of For Joint Strength Calculation: ConcreteJansen SjaklifNo ratings yet

- Tension StiffeningDocument14 pagesTension StiffeningOlesea NesterencoNo ratings yet

- Forces From Junction - Concrete and Channel Column C1A: Design PhilosopyDocument1 pageForces From Junction - Concrete and Channel Column C1A: Design PhilosopyNitish TakalkarNo ratings yet

- UNIT - 2 Design of RC Structural ElementsDocument55 pagesUNIT - 2 Design of RC Structural ElementsKrishnakanth ChidreNo ratings yet

- 2.2 Load Cominations, Stress Blocks - pp.20-32 - CIVL3320 - 2017!02!08Document13 pages2.2 Load Cominations, Stress Blocks - pp.20-32 - CIVL3320 - 2017!02!08Chan TerenceNo ratings yet

- Toniolo-DiPrisco2017 Chapter CentredAxialForceDocument85 pagesToniolo-DiPrisco2017 Chapter CentredAxialForceÉnio Elias Gonçalves NtambalicaNo ratings yet

- Chapter 12 PDFDocument17 pagesChapter 12 PDFAdolfo ElizondoNo ratings yet

- Reinforced Concrete DesignDocument7 pagesReinforced Concrete DesignRJay DorojaNo ratings yet

- CE135 - 2. Flexural Analysis of Concrete BeamsDocument48 pagesCE135 - 2. Flexural Analysis of Concrete BeamsApril ImNo ratings yet

- Plastic Moment Redistribution 2011Document11 pagesPlastic Moment Redistribution 2011Abuye HD100% (1)

- Concrete Prestressing NotesDocument23 pagesConcrete Prestressing NotesMohammad Iqbal HossainNo ratings yet

- Timpa Arzeena ENGM4675 ProjectDocument10 pagesTimpa Arzeena ENGM4675 ProjectArzeena TimpaNo ratings yet

- Chapter IIDocument5 pagesChapter IIMica BisaresNo ratings yet

- EspargoDocument10 pagesEspargoClyde LabayNo ratings yet

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- BasbasDocument8 pagesBasbasXzk MallaboNo ratings yet

- Principles of Steel Design - WeldsDocument18 pagesPrinciples of Steel Design - WeldsXzk MallaboNo ratings yet

- PQ2 SolutionDocument17 pagesPQ2 SolutionXzk MallaboNo ratings yet

- Cost EstimateDocument26 pagesCost EstimateXzk MallaboNo ratings yet

- Bolt ConnectionDocument24 pagesBolt ConnectionXzk MallaboNo ratings yet

- Lesson 6 EvapotranspirationDocument27 pagesLesson 6 EvapotranspirationXzk MallaboNo ratings yet

- ModuleDocument16 pagesModuleXzk MallaboNo ratings yet

- Lesson 7 Energy Balance and Water BalanceDocument14 pagesLesson 7 Energy Balance and Water BalanceXzk MallaboNo ratings yet

- Midterm Exam EnglDocument32 pagesMidterm Exam EnglXzk MallaboNo ratings yet

- Lesson 4 - Leading and DirectingDocument62 pagesLesson 4 - Leading and DirectingXzk MallaboNo ratings yet

- Fluids 1 Toricelli ExperimentDocument7 pagesFluids 1 Toricelli ExperimentKiasha ChettyNo ratings yet

- Civil Engineering - S3 & S4Document147 pagesCivil Engineering - S3 & S4anushafiNo ratings yet

- Introduction To Instrumented IndentationDocument7 pagesIntroduction To Instrumented Indentationopvsj42No ratings yet

- Test Bank For Brunnstroms Clinical Kinesiology 6th Edition HouglumDocument3 pagesTest Bank For Brunnstroms Clinical Kinesiology 6th Edition HouglumMarquis Dixon100% (39)

- The Wave Mechanics of Electrons in Metals - Raimes PDFDocument388 pagesThe Wave Mechanics of Electrons in Metals - Raimes PDFFernando ElizaldeNo ratings yet

- Hsslive XI IMP July 2018 PhysicsDocument15 pagesHsslive XI IMP July 2018 PhysicsAnilNo ratings yet

- Lesson 3 - Waves, Sound and LightDocument52 pagesLesson 3 - Waves, Sound and LightJoanna Ruth SeproNo ratings yet

- Chapter 11: Dynamic Force AnalysisDocument34 pagesChapter 11: Dynamic Force AnalysisSurenderan LoganNo ratings yet

- Stress-Strain Plastic Curve FEMDocument89 pagesStress-Strain Plastic Curve FEMGino TironiNo ratings yet

- c19 Catia v5 6r2018 Free DWDDocument76 pagesc19 Catia v5 6r2018 Free DWDUriel CasiqueNo ratings yet

- AR203Document1 pageAR203Harshita MittalNo ratings yet

- Poster Group 7Document1 pagePoster Group 7api-392769552No ratings yet

- Punching Shear and One Way Shear Check.Document2 pagesPunching Shear and One Way Shear Check.ElancheliyanNo ratings yet

- Unit 1 PDFDocument30 pagesUnit 1 PDFpankajNo ratings yet

- 6.6 Moments and Centers of MassDocument8 pages6.6 Moments and Centers of MassHamed MemarianNo ratings yet

- Ideal Gas ProcessesDocument9 pagesIdeal Gas ProcessesOrley G Fadriquel33% (3)

- Simulation of Two Phase Flow in FLUENTDocument10 pagesSimulation of Two Phase Flow in FLUENTfaisal58650No ratings yet

- 10 1016/j Matdes 2016 05 055Document27 pages10 1016/j Matdes 2016 05 055Jufri ArdiNo ratings yet

- GME Mech Questions 3 PDFDocument109 pagesGME Mech Questions 3 PDFshakeer100% (1)

- Cooling of A Cake.: List of Proposed Problems Applied MathematicsDocument2 pagesCooling of A Cake.: List of Proposed Problems Applied MathematicsEstrella M Correa VertizNo ratings yet

- Forging and Extrusion: M Jamil Ms/IeDocument51 pagesForging and Extrusion: M Jamil Ms/IeM. RazaNo ratings yet

- Grillage Analysis For Slab & Pseudo-Slab Bridge DecksDocument52 pagesGrillage Analysis For Slab & Pseudo-Slab Bridge DecksChhandak BiswasNo ratings yet

- 07 Chapter 5 Aktuell Page SetupDocument33 pages07 Chapter 5 Aktuell Page SetupHO Vinh-QuynhNo ratings yet

- 93 Sample ChapterDocument23 pages93 Sample ChapterSamuel GaétanNo ratings yet

- GravityDocument2 pagesGravitySebastian EcheverriaNo ratings yet

- Structural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSDocument4 pagesStructural Analysis of Turbine Blade Disc Fir-Tree Root Using ANSYSRahul VermaNo ratings yet

- Lecture Notes 12Document21 pagesLecture Notes 12Mannu BhattacharyaNo ratings yet

- The Determination of Stefan's Constant.Document4 pagesThe Determination of Stefan's Constant.usman67% (3)