Professional Documents

Culture Documents

PGI BarriAire Gold Hoods Inspection Guide

PGI BarriAire Gold Hoods Inspection Guide

Uploaded by

uzer4oCopyright:

Available Formats

You might also like

- Colace (Docusate Sodium)Document1 pageColace (Docusate Sodium)E100% (1)

- Hazard and Risk Assessment PDFDocument99 pagesHazard and Risk Assessment PDFjanisha11No ratings yet

- Materials and Jacketing TechniqueDocument5 pagesMaterials and Jacketing TechniqueHoussam Al MoussawiNo ratings yet

- AlembicDocument3 pagesAlembicΜένιος ΚουστράβαςNo ratings yet

- Pyroplex Fire Rated Foam Datasheet - NWDocument4 pagesPyroplex Fire Rated Foam Datasheet - NWAhmed AssafNo ratings yet

- Ac 0071Document4 pagesAc 0071umn_mlkNo ratings yet

- RaiDocument2 pagesRaiuptc1985No ratings yet

- Isp Article 8-17-15Document1 pageIsp Article 8-17-15api-312462673No ratings yet

- Makeup and Hairdressing: Guideline 20Document2 pagesMakeup and Hairdressing: Guideline 20Elma McGouganNo ratings yet

- Bomb Blanket Defense TechsDocument1 pageBomb Blanket Defense TechsdefensetechsNo ratings yet

- VIKING Protective Garment Structual FF (1066626 0318)Document16 pagesVIKING Protective Garment Structual FF (1066626 0318)Sebastián GómezNo ratings yet

- BS en 1869 Fire Blankets VersionDocument12 pagesBS en 1869 Fire Blankets VersionCameronNo ratings yet

- Welding Plant ManualDocument80 pagesWelding Plant ManualDwaine ParrisNo ratings yet

- Washer DryerDocument44 pagesWasher DryerJohn LincolnNo ratings yet

- Molykote G 4000 FGDocument2 pagesMolykote G 4000 FGRicardo ZuimNo ratings yet

- Lincoln Air Vantage 566 Manual Del OperadorDocument64 pagesLincoln Air Vantage 566 Manual Del OperadorAlfonso VidalNo ratings yet

- Poly ZincDocument2 pagesPoly ZincMahinda GamageNo ratings yet

- 327 - Mil-C-15074Document2 pages327 - Mil-C-15074Bianca MoraisNo ratings yet

- Handbook Aerated Concrete ProductsDocument2 pagesHandbook Aerated Concrete ProductsIrahad AhmadNo ratings yet

- Polycure W Polycure W: Water Based Curing CompoundDocument2 pagesPolycure W Polycure W: Water Based Curing CompoundMuhsin KhanNo ratings yet

- Service Manual Welder Machine Air Vantage 600-IDocument65 pagesService Manual Welder Machine Air Vantage 600-IDercio CostaNo ratings yet

- JC-556 Type 5610 IOM - Final - LoResDocument15 pagesJC-556 Type 5610 IOM - Final - LoResjosfwangNo ratings yet

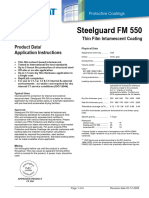

- SG 0550Document4 pagesSG 0550Safdar JNo ratings yet

- Traditions - Cap and Ball Revolver Shooting InformationDocument2 pagesTraditions - Cap and Ball Revolver Shooting InformationtcrummNo ratings yet

- IM Gauge HatchesDocument2 pagesIM Gauge HatchesqwertyNo ratings yet

- TractorDocument6 pagesTractorthartzog30No ratings yet

- Molykote: Information About G-5008 Dielectric GreaseDocument2 pagesMolykote: Information About G-5008 Dielectric GreaseMohamed MahrousNo ratings yet

- Imt 237Document37 pagesImt 237miguelNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaNo ratings yet

- Pure Guardian Humidifier H5225 Manual 0618Document14 pagesPure Guardian Humidifier H5225 Manual 0618Dave BestonNo ratings yet

- Washer-Dryer : 2820527803 - EN/ Document NumberDocument44 pagesWasher-Dryer : 2820527803 - EN/ Document NumberMagdomkakNo ratings yet

- Molykote SuperglissDocument2 pagesMolykote SuperglissMaciekNo ratings yet

- Im10179 221219 093458Document69 pagesIm10179 221219 093458Kevin SaldanaNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Molykote PU3 Grease NEW 15612856484Document1 pageMolykote PU3 Grease NEW 15612856484tsmvikasojhaNo ratings yet

- Technical Data Sheet: Antilux® 654Document2 pagesTechnical Data Sheet: Antilux® 654simbua72100% (1)

- Flextec 500XDocument46 pagesFlextec 500XArturo CiaNo ratings yet

- Abe. Flex: Polymer Bonded E-Glass YarnDocument1 pageAbe. Flex: Polymer Bonded E-Glass Yarncremildo maetinhoNo ratings yet

- Im10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IDocument60 pagesIm10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IKevin SaldanaNo ratings yet

- AAA Manufacturing Instructions - START HEREDocument1 pageAAA Manufacturing Instructions - START HEREPutra SaheriNo ratings yet

- CONNECTING LANYARD BROChureDocument2 pagesCONNECTING LANYARD BROChureSritheran MenonNo ratings yet

- STT LincolnDocument32 pagesSTT LincolnedwinNo ratings yet

- Ranger 330 MPX Manual de OperacionDocument56 pagesRanger 330 MPX Manual de OperacionEduardo Lopez100% (1)

- Tweezle 9 Gal 000082 enDocument16 pagesTweezle 9 Gal 000082 enClaudio LopesNo ratings yet

- Utdrag Dunstabzug AnleitungDocument52 pagesUtdrag Dunstabzug AnleitungdjokanomcaNo ratings yet

- Broan Qtxe110 Instalation ManualDocument8 pagesBroan Qtxe110 Instalation Manualyoshdog@gmail.comNo ratings yet

- Ford Figo b517 2010 25 wrm68Document1 pageFord Figo b517 2010 25 wrm68sandeepNo ratings yet

- VpCI 309 PouchDocument2 pagesVpCI 309 PouchREHITH RAJNo ratings yet

- Instructions For The Safe Use Of: Roundslings: Storing and Handling RoundslingsDocument2 pagesInstructions For The Safe Use Of: Roundslings: Storing and Handling Roundslingsreda mesbahNo ratings yet

- Molykote G 4000 FMDocument2 pagesMolykote G 4000 FMRicardo ZuimNo ratings yet

- Dispercoll U 54Document3 pagesDispercoll U 54ID ICVONo ratings yet

- Magnum Pro Curve 200Document22 pagesMagnum Pro Curve 200Nico Natanael SNo ratings yet

- Big Red 500: Operator's ManualDocument68 pagesBig Red 500: Operator's ManualJuan Carlos Torres MartinezNo ratings yet

- Lincoln Ranger® 250 GXT Engine Driven Welder (Kohler®) (Electric Fuel Pump) - K2923-1-User Operating ManualDocument52 pagesLincoln Ranger® 250 GXT Engine Driven Welder (Kohler®) (Electric Fuel Pump) - K2923-1-User Operating ManualfilturcotteNo ratings yet

- Imt 10640Document78 pagesImt 10640miguelNo ratings yet

- Ldee5bgs153tw01Document17 pagesLdee5bgs153tw01levuthien2902No ratings yet

- MagMate TIG 150 200 OP ManualDocument16 pagesMagMate TIG 150 200 OP ManualAlan AnastasiNo ratings yet

- 13GR - 059 Bituthene HB Web PDFDocument141 pages13GR - 059 Bituthene HB Web PDFWendel MeloNo ratings yet

- Scott Bader Gelcoat Handling Guide EnglishDocument6 pagesScott Bader Gelcoat Handling Guide EnglishALEXANDER FRANCO CASTRILLONNo ratings yet

- Scott Bader Gelcoat Handling Guide EnglishDocument6 pagesScott Bader Gelcoat Handling Guide EnglishALEXANDER FRANCO CASTRILLONNo ratings yet

- Shell and Tube Heat Exchangers: Installation, Operation, & Maintenance Manual 0120 1Document21 pagesShell and Tube Heat Exchangers: Installation, Operation, & Maintenance Manual 0120 1Danny BoysieNo ratings yet

- Technical Data Sheet: Antilux® 500Document2 pagesTechnical Data Sheet: Antilux® 500simbua72No ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- PM Schedule Unit-3 2018Document144 pagesPM Schedule Unit-3 2018Anonymous q8EusUCNo ratings yet

- Building A PolypeptideDocument2 pagesBuilding A PolypeptideDiana RomeroNo ratings yet

- Performance Task 1: DNA Extraction From Fruits: BIO02 - General Biology 02Document8 pagesPerformance Task 1: DNA Extraction From Fruits: BIO02 - General Biology 02John Lemuel U. LolaNo ratings yet

- Astm C 356-87Document3 pagesAstm C 356-87Manivasagan VasuNo ratings yet

- Hazard Communication ProcedureDocument3 pagesHazard Communication ProcedurevladNo ratings yet

- Chem100 - ThermochemDocument12 pagesChem100 - ThermochemEdrick RamoranNo ratings yet

- Zuhriyyah Ratih Ardyani Seminar Online JermanDocument21 pagesZuhriyyah Ratih Ardyani Seminar Online JermanYusuf Seto PradanaNo ratings yet

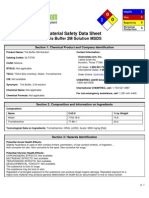

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Proton Nuclear Magnetic Resonance Spectroscopy H - NMRDocument61 pagesProton Nuclear Magnetic Resonance Spectroscopy H - NMRchemist100% (2)

- II Housing and Family Economics: Choosing An Ideal HouseDocument20 pagesII Housing and Family Economics: Choosing An Ideal HouseMary Joy GantuanNo ratings yet

- Desalination and Water TreatmentDocument10 pagesDesalination and Water Treatmentl209No ratings yet

- Fire Fighting Drill and InstructionDocument12 pagesFire Fighting Drill and InstructionAsif HussainNo ratings yet

- Lecture 10. Analytical Chemistry (Presentation) Author Medical University of LublinDocument137 pagesLecture 10. Analytical Chemistry (Presentation) Author Medical University of Lublinguadie workuNo ratings yet

- Petronas Carigali Sdn. Bhd. Inspection Test Report Itr-C Firewater/Foam System S10-CDocument3 pagesPetronas Carigali Sdn. Bhd. Inspection Test Report Itr-C Firewater/Foam System S10-CWael ChouchaniNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- Trays PDFDocument18 pagesTrays PDFBilal Hasan100% (1)

- Design Optimisation of Spur Gear - Review1Document14 pagesDesign Optimisation of Spur Gear - Review1Aritra Guha RayNo ratings yet

- Nomenclature of Organic Compounds (I.U.P.A.C SYSTEM) : Chemistry-XIIDocument12 pagesNomenclature of Organic Compounds (I.U.P.A.C SYSTEM) : Chemistry-XIIZia RathoreNo ratings yet

- Laboratory Safety Rules: WWW - Yale.edu/trainingDocument11 pagesLaboratory Safety Rules: WWW - Yale.edu/trainingSergi Davis Quispe ChainaNo ratings yet

- Meth Orange Post LabDocument4 pagesMeth Orange Post LabConnor LaBellaNo ratings yet

- History & Humanities: Shamanistic Hallucinogen To The Search For AcetylcholineDocument7 pagesHistory & Humanities: Shamanistic Hallucinogen To The Search For Acetylcholinemocoloco1No ratings yet

- Metabolic WorksheetDocument3 pagesMetabolic Worksheetjamaica46No ratings yet

- Cell Organelles - Biology Class 11 - NEETDocument18 pagesCell Organelles - Biology Class 11 - NEETsanjNo ratings yet

- Activity 6 Hydrogen Peroxide-RevisedDocument2 pagesActivity 6 Hydrogen Peroxide-RevisedQuenneeNo ratings yet

- D 4787 - 93 R99 - Rdq3odcDocument4 pagesD 4787 - 93 R99 - Rdq3odcmorchedtounsiNo ratings yet

- Manufacture of Solid Soap Based On Crude Papain Enzyme and Antioxidant From PapayaDocument8 pagesManufacture of Solid Soap Based On Crude Papain Enzyme and Antioxidant From PapayaAde HerdiansyahNo ratings yet

PGI BarriAire Gold Hoods Inspection Guide

PGI BarriAire Gold Hoods Inspection Guide

Uploaded by

uzer4oCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PGI BarriAire Gold Hoods Inspection Guide

PGI BarriAire Gold Hoods Inspection Guide

Uploaded by

uzer4oCopyright:

Available Formats

INSPECTION OF YOUR PROTECTIVE HOOD

Though most performance properties of the protective hood

FIREFIGHTING HOOD cannot be tested adequately in the field, OSHA regulations require

your department or employer to regularly inspect your protective

INSPECTION, CARE &

ensemble and other safety equipment. Your fire department should

have a systematic, routine and regularly scheduled inspection of

MAINTENANCE GUIDE

your protective ensemble and equipment. Full documentation of

these inspections should be kept.

CLEANING AND MAINTENANCE OF YOUR

PROTECTIVE HOOD — WARNING!

• You must keep your hoods clean and maintain them as set forth

in their labels and the manufacturer’s instructions.

• Clean your hood as soon as possible after an incident where it has

been soiled or exposed to blood or body fluids, tars, fuels, resins,

paints, acids, by-products of combustion or other hazardous

materials. Do not wear your hood again until it has been properly

cleaned. If hood cannot be properly cleaned, you must retire and

dispose of the hood.

• Hoods should be washed in regular detergent in warm water not

to exceed 105°F / 40°C, rinsed with cold water.

• Use a liquid detergent such as Tide vs a powder detergent to

minimize pilling.

• Do not use chlorine bleach or detergents containing chlorine

bleach. Chlorine bleach will compromise the protective qualities

provided by the fabrics used in the manufacturing of this hood.

• Hoods should be laundered with like products, i.e. other flame-

resistant knits such as other FR hoods, knit FR shirts, etc.

• FR apparel should never be laundered with non-FR fabrics due to

lint from the non-FR fabrics potentially contaminating the FR fabrics.

• Do not wring hoods to dry, squeeze hood to remove excess water.

• For maximum wear life, shape and lay flat in a dry, shaded location

to dry. If machine drying is required, use “gentle cycle with low

heat” and remove from dryer while still damp and finish with air

dry. Do not over dry hood.

• Do not commercially dry clean.

• Before and after every fire ground use or training exercise, your

hoods should be inspected. All damaged protective hoods must

be retired and disposed. Any physical change in any component

should be immediately referred to personnel to determine if your

hood’s protective qualities have been in any way compromised.

• In the event of either questionable appearance or characteristics,

caution should prevail and the protective hood should be replaced.

MAINTENANCE AND REPAIRS

Repair is generally not practical (or recommended) considering the

cost of new hoods. If repair is desired, refer to the manufacturer or

to a facility capable of making repairs consistent with the original

manufacturer. PGI does not warranty any hood in which repairs

have been made without the specific written permission or

inclusion of PGI, Inc.

WARRANTY INFORMATION

Your protective hood is warranted by the manufacturer to be free

from defects in material and workmanship. This warranty does

not cover normal wear or unusual exposures. This warranty is

in lieu of all other warranties, express or implied, including but

not limited to, implied warranties of marketability and/or fitness

for a particular purpose. The manufacturer shall not be liable for

incidental or consequential damages.

PGI, Inc. Corporate Office PGI Safety Limited

550 Commercial Avenue Unit 5, Albert Edward House,

Green Lake, WI 54941 The Pavilions

800-558-8290 Preston PR2 2YB

mail@pgi-inc.com info@pgi-safety.com

pgi-inc.com +44 (0)1772 842115

YOUR FIRE HOOD IS AN After completing the NFPA 1851 – Current

Edition guidelines for advanced inspection of

INVESTMENT IN YOUR hood elements, PGI recommends the following

HEALTH & SAFETY for particulate barrier inspection.

1. The 3-ply composite fabric, Nomex® Nano Flex

STEP 2

particulate barrier quilted between jersey knit

BarriAire Gold fabrics, can be easily inspected

with a flashlight for structural integrity to identify

rips, tears, and cuts.

2. Please be advised that the quilting holes you

see are not detrimental to particulate barrier

performance, Nomex® Nano Flex fabric with our

quilting blocks on average 96% of particulate

In an effort to aid fire departments with the as submitted and washed. PGI quilted BarriAire

composite fabric recently achieved Viral Filtration

inspection of their firefighting hoods as well Efficiency (VFE) Rating of 96.8% and Bacterial

as the Nomex® Nano Flex particulate barrier, Filtration Efficiency (BFE) Rating of 97.9%*.

the following two-step process is recommended. 3. Any necessary advanced evaluations of Cobra

BarriAire Gold hoods shall be conducted by PGI

Begin by following NFPA 1851 – Current

STEP 1

through the return authorization process in

Edition Guidelines for Firefighting Hoods:

accordance with PGI’s ISO 9001 certification.

6.3.5.2 Hood elements shall be inspected Please call Customer Service at 800-558-8290

for the following: for all return inquiries.

1. Soiling

2. Contamination

3. Physical damage such as follows:

a. Rips, tears, and cuts

b. Thermal damage (charring, burn holes,

melting, discoloration of any layer)

4. Shrinkage

Barrier Intact Barrier Intact

5. Loss of material elasticity or

stretching out of shape

Nomex® Nano Flex Nomex® Nano Flex

6. Loss of seam integrity and Good Condition Overlapped Good Condition

broken or missing stitches

7. Loss of face-opening adjustment

8. Label integrity and legibility

8.1.1 All repairs shall be performed by the original

manufacturer, a verified ISP who has received

training, or a member of the organization who

has received training.

Return for Additional Evaluation

Tear in Nomex® Nano Flex

DuPont™ and Nomex® are trademarks or registered trademarks of

E.I. du Pont de Nemours and Company or its affiliates.

PPE REDEFINED 800.558.8290

barriaire.com

You might also like

- Colace (Docusate Sodium)Document1 pageColace (Docusate Sodium)E100% (1)

- Hazard and Risk Assessment PDFDocument99 pagesHazard and Risk Assessment PDFjanisha11No ratings yet

- Materials and Jacketing TechniqueDocument5 pagesMaterials and Jacketing TechniqueHoussam Al MoussawiNo ratings yet

- AlembicDocument3 pagesAlembicΜένιος ΚουστράβαςNo ratings yet

- Pyroplex Fire Rated Foam Datasheet - NWDocument4 pagesPyroplex Fire Rated Foam Datasheet - NWAhmed AssafNo ratings yet

- Ac 0071Document4 pagesAc 0071umn_mlkNo ratings yet

- RaiDocument2 pagesRaiuptc1985No ratings yet

- Isp Article 8-17-15Document1 pageIsp Article 8-17-15api-312462673No ratings yet

- Makeup and Hairdressing: Guideline 20Document2 pagesMakeup and Hairdressing: Guideline 20Elma McGouganNo ratings yet

- Bomb Blanket Defense TechsDocument1 pageBomb Blanket Defense TechsdefensetechsNo ratings yet

- VIKING Protective Garment Structual FF (1066626 0318)Document16 pagesVIKING Protective Garment Structual FF (1066626 0318)Sebastián GómezNo ratings yet

- BS en 1869 Fire Blankets VersionDocument12 pagesBS en 1869 Fire Blankets VersionCameronNo ratings yet

- Welding Plant ManualDocument80 pagesWelding Plant ManualDwaine ParrisNo ratings yet

- Washer DryerDocument44 pagesWasher DryerJohn LincolnNo ratings yet

- Molykote G 4000 FGDocument2 pagesMolykote G 4000 FGRicardo ZuimNo ratings yet

- Lincoln Air Vantage 566 Manual Del OperadorDocument64 pagesLincoln Air Vantage 566 Manual Del OperadorAlfonso VidalNo ratings yet

- Poly ZincDocument2 pagesPoly ZincMahinda GamageNo ratings yet

- 327 - Mil-C-15074Document2 pages327 - Mil-C-15074Bianca MoraisNo ratings yet

- Handbook Aerated Concrete ProductsDocument2 pagesHandbook Aerated Concrete ProductsIrahad AhmadNo ratings yet

- Polycure W Polycure W: Water Based Curing CompoundDocument2 pagesPolycure W Polycure W: Water Based Curing CompoundMuhsin KhanNo ratings yet

- Service Manual Welder Machine Air Vantage 600-IDocument65 pagesService Manual Welder Machine Air Vantage 600-IDercio CostaNo ratings yet

- JC-556 Type 5610 IOM - Final - LoResDocument15 pagesJC-556 Type 5610 IOM - Final - LoResjosfwangNo ratings yet

- SG 0550Document4 pagesSG 0550Safdar JNo ratings yet

- Traditions - Cap and Ball Revolver Shooting InformationDocument2 pagesTraditions - Cap and Ball Revolver Shooting InformationtcrummNo ratings yet

- IM Gauge HatchesDocument2 pagesIM Gauge HatchesqwertyNo ratings yet

- TractorDocument6 pagesTractorthartzog30No ratings yet

- Molykote: Information About G-5008 Dielectric GreaseDocument2 pagesMolykote: Information About G-5008 Dielectric GreaseMohamed MahrousNo ratings yet

- Imt 237Document37 pagesImt 237miguelNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaNo ratings yet

- Pure Guardian Humidifier H5225 Manual 0618Document14 pagesPure Guardian Humidifier H5225 Manual 0618Dave BestonNo ratings yet

- Washer-Dryer : 2820527803 - EN/ Document NumberDocument44 pagesWasher-Dryer : 2820527803 - EN/ Document NumberMagdomkakNo ratings yet

- Molykote SuperglissDocument2 pagesMolykote SuperglissMaciekNo ratings yet

- Im10179 221219 093458Document69 pagesIm10179 221219 093458Kevin SaldanaNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Molykote PU3 Grease NEW 15612856484Document1 pageMolykote PU3 Grease NEW 15612856484tsmvikasojhaNo ratings yet

- Technical Data Sheet: Antilux® 654Document2 pagesTechnical Data Sheet: Antilux® 654simbua72100% (1)

- Flextec 500XDocument46 pagesFlextec 500XArturo CiaNo ratings yet

- Abe. Flex: Polymer Bonded E-Glass YarnDocument1 pageAbe. Flex: Polymer Bonded E-Glass Yarncremildo maetinhoNo ratings yet

- Im10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IDocument60 pagesIm10568 MANUAL OPERADOR LINCOLN ELECTRIC 600-IKevin SaldanaNo ratings yet

- AAA Manufacturing Instructions - START HEREDocument1 pageAAA Manufacturing Instructions - START HEREPutra SaheriNo ratings yet

- CONNECTING LANYARD BROChureDocument2 pagesCONNECTING LANYARD BROChureSritheran MenonNo ratings yet

- STT LincolnDocument32 pagesSTT LincolnedwinNo ratings yet

- Ranger 330 MPX Manual de OperacionDocument56 pagesRanger 330 MPX Manual de OperacionEduardo Lopez100% (1)

- Tweezle 9 Gal 000082 enDocument16 pagesTweezle 9 Gal 000082 enClaudio LopesNo ratings yet

- Utdrag Dunstabzug AnleitungDocument52 pagesUtdrag Dunstabzug AnleitungdjokanomcaNo ratings yet

- Broan Qtxe110 Instalation ManualDocument8 pagesBroan Qtxe110 Instalation Manualyoshdog@gmail.comNo ratings yet

- Ford Figo b517 2010 25 wrm68Document1 pageFord Figo b517 2010 25 wrm68sandeepNo ratings yet

- VpCI 309 PouchDocument2 pagesVpCI 309 PouchREHITH RAJNo ratings yet

- Instructions For The Safe Use Of: Roundslings: Storing and Handling RoundslingsDocument2 pagesInstructions For The Safe Use Of: Roundslings: Storing and Handling Roundslingsreda mesbahNo ratings yet

- Molykote G 4000 FMDocument2 pagesMolykote G 4000 FMRicardo ZuimNo ratings yet

- Dispercoll U 54Document3 pagesDispercoll U 54ID ICVONo ratings yet

- Magnum Pro Curve 200Document22 pagesMagnum Pro Curve 200Nico Natanael SNo ratings yet

- Big Red 500: Operator's ManualDocument68 pagesBig Red 500: Operator's ManualJuan Carlos Torres MartinezNo ratings yet

- Lincoln Ranger® 250 GXT Engine Driven Welder (Kohler®) (Electric Fuel Pump) - K2923-1-User Operating ManualDocument52 pagesLincoln Ranger® 250 GXT Engine Driven Welder (Kohler®) (Electric Fuel Pump) - K2923-1-User Operating ManualfilturcotteNo ratings yet

- Imt 10640Document78 pagesImt 10640miguelNo ratings yet

- Ldee5bgs153tw01Document17 pagesLdee5bgs153tw01levuthien2902No ratings yet

- MagMate TIG 150 200 OP ManualDocument16 pagesMagMate TIG 150 200 OP ManualAlan AnastasiNo ratings yet

- 13GR - 059 Bituthene HB Web PDFDocument141 pages13GR - 059 Bituthene HB Web PDFWendel MeloNo ratings yet

- Scott Bader Gelcoat Handling Guide EnglishDocument6 pagesScott Bader Gelcoat Handling Guide EnglishALEXANDER FRANCO CASTRILLONNo ratings yet

- Scott Bader Gelcoat Handling Guide EnglishDocument6 pagesScott Bader Gelcoat Handling Guide EnglishALEXANDER FRANCO CASTRILLONNo ratings yet

- Shell and Tube Heat Exchangers: Installation, Operation, & Maintenance Manual 0120 1Document21 pagesShell and Tube Heat Exchangers: Installation, Operation, & Maintenance Manual 0120 1Danny BoysieNo ratings yet

- Technical Data Sheet: Antilux® 500Document2 pagesTechnical Data Sheet: Antilux® 500simbua72No ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- PM Schedule Unit-3 2018Document144 pagesPM Schedule Unit-3 2018Anonymous q8EusUCNo ratings yet

- Building A PolypeptideDocument2 pagesBuilding A PolypeptideDiana RomeroNo ratings yet

- Performance Task 1: DNA Extraction From Fruits: BIO02 - General Biology 02Document8 pagesPerformance Task 1: DNA Extraction From Fruits: BIO02 - General Biology 02John Lemuel U. LolaNo ratings yet

- Astm C 356-87Document3 pagesAstm C 356-87Manivasagan VasuNo ratings yet

- Hazard Communication ProcedureDocument3 pagesHazard Communication ProcedurevladNo ratings yet

- Chem100 - ThermochemDocument12 pagesChem100 - ThermochemEdrick RamoranNo ratings yet

- Zuhriyyah Ratih Ardyani Seminar Online JermanDocument21 pagesZuhriyyah Ratih Ardyani Seminar Online JermanYusuf Seto PradanaNo ratings yet

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Proton Nuclear Magnetic Resonance Spectroscopy H - NMRDocument61 pagesProton Nuclear Magnetic Resonance Spectroscopy H - NMRchemist100% (2)

- II Housing and Family Economics: Choosing An Ideal HouseDocument20 pagesII Housing and Family Economics: Choosing An Ideal HouseMary Joy GantuanNo ratings yet

- Desalination and Water TreatmentDocument10 pagesDesalination and Water Treatmentl209No ratings yet

- Fire Fighting Drill and InstructionDocument12 pagesFire Fighting Drill and InstructionAsif HussainNo ratings yet

- Lecture 10. Analytical Chemistry (Presentation) Author Medical University of LublinDocument137 pagesLecture 10. Analytical Chemistry (Presentation) Author Medical University of Lublinguadie workuNo ratings yet

- Petronas Carigali Sdn. Bhd. Inspection Test Report Itr-C Firewater/Foam System S10-CDocument3 pagesPetronas Carigali Sdn. Bhd. Inspection Test Report Itr-C Firewater/Foam System S10-CWael ChouchaniNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- Trays PDFDocument18 pagesTrays PDFBilal Hasan100% (1)

- Design Optimisation of Spur Gear - Review1Document14 pagesDesign Optimisation of Spur Gear - Review1Aritra Guha RayNo ratings yet

- Nomenclature of Organic Compounds (I.U.P.A.C SYSTEM) : Chemistry-XIIDocument12 pagesNomenclature of Organic Compounds (I.U.P.A.C SYSTEM) : Chemistry-XIIZia RathoreNo ratings yet

- Laboratory Safety Rules: WWW - Yale.edu/trainingDocument11 pagesLaboratory Safety Rules: WWW - Yale.edu/trainingSergi Davis Quispe ChainaNo ratings yet

- Meth Orange Post LabDocument4 pagesMeth Orange Post LabConnor LaBellaNo ratings yet

- History & Humanities: Shamanistic Hallucinogen To The Search For AcetylcholineDocument7 pagesHistory & Humanities: Shamanistic Hallucinogen To The Search For Acetylcholinemocoloco1No ratings yet

- Metabolic WorksheetDocument3 pagesMetabolic Worksheetjamaica46No ratings yet

- Cell Organelles - Biology Class 11 - NEETDocument18 pagesCell Organelles - Biology Class 11 - NEETsanjNo ratings yet

- Activity 6 Hydrogen Peroxide-RevisedDocument2 pagesActivity 6 Hydrogen Peroxide-RevisedQuenneeNo ratings yet

- D 4787 - 93 R99 - Rdq3odcDocument4 pagesD 4787 - 93 R99 - Rdq3odcmorchedtounsiNo ratings yet

- Manufacture of Solid Soap Based On Crude Papain Enzyme and Antioxidant From PapayaDocument8 pagesManufacture of Solid Soap Based On Crude Papain Enzyme and Antioxidant From PapayaAde HerdiansyahNo ratings yet