Professional Documents

Culture Documents

Panwater Counter Flow Film Fill Packing Media-1

Panwater Counter Flow Film Fill Packing Media-1

Uploaded by

danny lohCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Panwater Counter Flow Film Fill Packing Media-1

Panwater Counter Flow Film Fill Packing Media-1

Uploaded by

danny lohCopyright:

Available Formats

Technical Information…

PANWATER Counter Flow Film Fill Packing Media

The fill packing media in a cooling tower offers an expanded surface area for the distribution

of hot water to the induced ambient air to perform the evaporation process and thus, the

circulating hot water is being cooled down. The thermal efficiency and the life span of the fill

packing media are very much depending on the fill packing media design and materials of

construction.

Panwater’s PCF PVC fill packing media offers numerous features and advantages as below:

PANWATER COOLING TOWER

1. The PCF PVC fill packing media can be supplied in any length and of any with to the

maximum width of 1000mm. The width of the media sheets will become the height of the

media module when assembled. However, we always recommend and prefer media module

height of 300mm. With this module height, packing media module can be installed with each

layer perpendicular to the layer above and below. This arrangement of fill packing will

improve the distribution of water through the fills very effectively as the direction of water

distribution changes each time it pass through a new layer of fill packing.

Comparing with the same type of fills and of the similar fill height, say 1.2m, a 600mm module

height will only allow the water direction change once only in the entire film flow process from

the top to the bottom of the fills. While 4 layer of 300mm packing modules will allow 3 times

the water to change its direction. Each time the water changes its direction and flow into a

new layer of packing media, the efficiency of the water to air heat exchange is markedly

enhanced. And thus cooling efficiency is improved. Moreover, with each layer of the fill height

reduced to only 300mm, the overall buckling strength of the module is increased and thus the

media is capable of withstanding higher loading as well and this offer longer life span.

2. The PCF PVC fill packing media are manufactured with the edges on both ends of the sheets folded. These folded edges

will firstly increase the thickness of the sheet size at the edges to double the thickness of the sheet. Secondly, with the edges

being folded instead of just an bare cut edge, the PVC sheet materials is not easily being torn apart. Therefore, the media can

be regularly removed from the cooling tower for cleaning without damages due to handling.

This folded edge is the key design feature to Panwater’s cooling towers which have been well known for its long life span

comparing to most cooling tower in the market. The advantage of this key feature significantly reduced the total maintenance

cost and fill packing replacement cost of the cooling tower through out the entire life span.

3. The PCF PVC fill packing media is manufactured with micro-corrugations on the surface of the major corrugation. The

design is intended to create a maximum total surface area over a constant volume of fill packing to improve the efficiency. The

extra micro-corrugation not only increase the total surface area of the fill packing, it impede film flow velocity to allow a longer

holding time of the hot water in the fill packing section to interact with the induced ambient air for heat exchange process.

4. The PCF PVC fill packing is produced directly from new PVC resin into the PVC film and formed into the finished profile in a

single continuous production process. This type of manufacturing process ensures the quality and consistency of the finished

product is always maintained and controlled. Whereas fill packing media manufactured from standard PVC film need reheating

of the films and thermo forming into various profiles and shapes usually exhibit tendency to brittleness and other manufacturing

defects due to excessive reheating.

Panwater’s PCF PVC fill media has been used to replace fill packing media of cooling towers manufactured by others with

success. It is not limited to be used in Panwater’s cooling tower only.

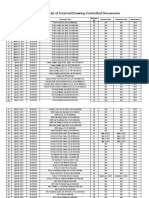

Fill Packing Specification:

Model PCF-12 PCF-19 PCF-27

Materials PVC PVC PVC

Flute Size mm 12 19 27

Surface Of Exchange m2/m3 243 148 112

Minimum Water Loading m3/m2.Hour 8 5 3

Standard Dimensions Length, mm Variable <2000

Width, mm Variable <1000

Height, mm 300 300 300

Distance Of Support mm 1000 Max. 1000 Max. 1000 Max.

Width Of Support mm 50 Min. 50 Min. 50 Min.

Material Thickness mm 0.20 0.25 0.40

Weight Kg/m3 35 27 28

Continuous Operating Temperature o C 50 50 50

Intermittent Operating Temperature o C 55 55 55

Application Clean Indirect Cooling Water

email: panwater@panwater.com Website: www.panwater.com

You might also like

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)From EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)No ratings yet

- Blown Film Extrusion ReportDocument12 pagesBlown Film Extrusion ReportAbdul Razak RahmatNo ratings yet

- Fills For Cooling TowerDocument4 pagesFills For Cooling TowerSurendra ReddyNo ratings yet

- Visqueen PIFA Damp Proof Membranes: DescriptionDocument2 pagesVisqueen PIFA Damp Proof Membranes: DescriptionJNo ratings yet

- Cooling Tower FillDocument13 pagesCooling Tower FillakbarNo ratings yet

- Tritech Water Poramax Brochures 8 en SingleDocument5 pagesTritech Water Poramax Brochures 8 en SingleWendyNo ratings yet

- MBR Membrane BioreactorDocument3 pagesMBR Membrane Bioreactorjpsingh75No ratings yet

- Baement Waterproofing With Integrated Control and Injection Backup SystemDocument128 pagesBaement Waterproofing With Integrated Control and Injection Backup SystemNadeem Hassoon100% (1)

- UntitledDocument1 pageUntitledPerma NCRNo ratings yet

- Technical Paper SiC Ceramic MembranesDocument5 pagesTechnical Paper SiC Ceramic MembranesEman El DsoukyNo ratings yet

- 2020 Upvc MPVC CatalogueDocument10 pages2020 Upvc MPVC Catalogueaviwetangosc01No ratings yet

- Grade 3 Diamond Dotted PresspaperDocument2 pagesGrade 3 Diamond Dotted PresspaperSunil GurubaxaniNo ratings yet

- Benefits of Operating New Thin Membrane Technology PaperDocument11 pagesBenefits of Operating New Thin Membrane Technology Papersahar vahdatifarNo ratings yet

- Visqueen PIFA DPM Handy Packs: Description ApplicationsDocument1 pageVisqueen PIFA DPM Handy Packs: Description ApplicationsJNo ratings yet

- Compact, Self-Closing Vacuum Breakers Protect Against Hazards, Damage and Financial Losses Caused by Vacuum!Document2 pagesCompact, Self-Closing Vacuum Breakers Protect Against Hazards, Damage and Financial Losses Caused by Vacuum!mikeswordsNo ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- Paper 1Document9 pagesPaper 1Jǝ Ǝʌan M CNo ratings yet

- Nafufill KM 250Document2 pagesNafufill KM 250yusak santosoNo ratings yet

- GB 2H Splash Trickle FillsDocument2 pagesGB 2H Splash Trickle FillsRicardo PontesNo ratings yet

- Rocvent Catalogue PDFDocument48 pagesRocvent Catalogue PDFrudarNo ratings yet

- Endura-Joint Treatment Products & ProcedureDocument89 pagesEndura-Joint Treatment Products & ProcedureSrihariKyatamNo ratings yet

- High Pressure Clear PVC Pipe: Submittal Data SheetDocument12 pagesHigh Pressure Clear PVC Pipe: Submittal Data Sheethunain hyderNo ratings yet

- 16 AmrutamDocument2 pages16 AmrutamNikita KadamNo ratings yet

- Fosroc Waterproofing B2R-BOQ (Revised 24th)Document38 pagesFosroc Waterproofing B2R-BOQ (Revised 24th)폴로 쥰 차67% (3)

- Chemical RraghavanDocument60 pagesChemical RraghavanjoekaledaNo ratings yet

- FRP Above Ground Installation ManualDocument32 pagesFRP Above Ground Installation ManualCarlos GutierrezNo ratings yet

- Enexio, 2H NET-150.Document2 pagesEnexio, 2H NET-150.aespinosa_rNo ratings yet

- Lining Material YokogawaDocument4 pagesLining Material YokogawaEfrain Parra QuispeNo ratings yet

- RIL BoppDocument14 pagesRIL BoppSaurabh PariharNo ratings yet

- Penstocks: Figure: Typical Installaion of PenstocksDocument6 pagesPenstocks: Figure: Typical Installaion of PenstocksTharindu Nuwan JayakodyNo ratings yet

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- Nafufill KM 250Document2 pagesNafufill KM 250Richard AmoahNo ratings yet

- Foam TypesDocument12 pagesFoam TypesRolax100% (1)

- PDF 9 (Ecoplate)Document12 pagesPDF 9 (Ecoplate)Iraq 2020No ratings yet

- Lec 11 Pultrusion PrinciplesDocument40 pagesLec 11 Pultrusion Principles201801173No ratings yet

- Cross FluteDocument6 pagesCross FluteAvicena AlbiruniNo ratings yet

- Water Well Packers: Inflatable Packers International Pty LTD © 2014Document5 pagesWater Well Packers: Inflatable Packers International Pty LTD © 2014Viller MontalicoNo ratings yet

- Chiller Tech3 - EIL DelhiDocument3 pagesChiller Tech3 - EIL DelhibmanojNo ratings yet

- Brentwood CT Getting Your Fill Article 2005 enDocument4 pagesBrentwood CT Getting Your Fill Article 2005 enAvicena AlbiruniNo ratings yet

- Wire Jacketing Nylon FirestoneDocument14 pagesWire Jacketing Nylon FirestoneAndres Valencia MiraNo ratings yet

- CFRP Wrap - Build Seal CFFS ExtraDocument10 pagesCFRP Wrap - Build Seal CFFS ExtraMd. Mynul Hossain100% (1)

- Aman Water Tech BrocherDocument5 pagesAman Water Tech BrocheramanwatertechonlineNo ratings yet

- 02 Extrusion of TubularDocument47 pages02 Extrusion of TubularNguyên CátNo ratings yet

- Water StopsDocument3 pagesWater StopsHussein BeqaiNo ratings yet

- EDI FlexAir-SSM-spec Sheet PDFDocument2 pagesEDI FlexAir-SSM-spec Sheet PDFomega AlfaNo ratings yet

- CEMswell Swelling RubberWaterproofDocument1 pageCEMswell Swelling RubberWaterproofTung Doan ThanhNo ratings yet

- Lamella For SettlersDocument4 pagesLamella For Settlersaev65No ratings yet

- Strainer Type 305Document5 pagesStrainer Type 305alexiel1806No ratings yet

- Extrusion of Blown Film: Josip MauričDocument47 pagesExtrusion of Blown Film: Josip MauričnamNo ratings yet

- Extrusion of Blown Film: Josip MauričDocument47 pagesExtrusion of Blown Film: Josip MauričnamNo ratings yet

- CembraneDocument13 pagesCembraneGöksel VATANNo ratings yet

- +1 646 360 1656 Request A QuoteDocument12 pages+1 646 360 1656 Request A QuoteInnovation 4uNo ratings yet

- 1 High Fibre Index Sept 14Document4 pages1 High Fibre Index Sept 14Abdul SabirNo ratings yet

- The Melt Blowing Process NonwovensDocument10 pagesThe Melt Blowing Process NonwovensFlorin DamaroiuNo ratings yet

- Meltblown TechnologyDocument7 pagesMeltblown TechnologyRonik J100% (1)

- Brett FillersDocument2 pagesBrett Fillerslokomoko1No ratings yet

- Rocvent CatalogueDocument48 pagesRocvent CatalogueJuan AlarcónNo ratings yet

- 1.deepseal PVC WaterstopsDocument4 pages1.deepseal PVC WaterstopsTimothy HughesNo ratings yet

- Elias Alemayehu LeanDocument57 pagesElias Alemayehu LeanTedla BekeleNo ratings yet

- BST Gen Cns Mos Aip 10003 10003 00 Pin Brazing Method StatementDocument42 pagesBST Gen Cns Mos Aip 10003 10003 00 Pin Brazing Method StatementRao DharmaNo ratings yet

- VeneersDocument8 pagesVeneersBob CalebNo ratings yet

- FMDS0117Document7 pagesFMDS0117Samuel Granados MejíaNo ratings yet

- MahadevDocument36 pagesMahadevquality fluconNo ratings yet

- How Are Steel Coils Loaded On ShipsDocument4 pagesHow Are Steel Coils Loaded On Shipstruongthaotran201819No ratings yet

- ASTM B982-14e1Document6 pagesASTM B982-14e1Lokesh HNo ratings yet

- Fast Turn PCB Profile-V3.0Document18 pagesFast Turn PCB Profile-V3.0ada.jerewlryNo ratings yet

- Guroflex Installation GuideDocument2 pagesGuroflex Installation GuideAditya270791No ratings yet

- Master List of Internal DrawingDocument26 pagesMaster List of Internal DrawingMaria Katherine Cruz PantojaNo ratings yet

- Shearing ToolsDocument21 pagesShearing Toolsメルヴリッ クズルエタNo ratings yet

- IREGA - Chei Reglabile 2018Document32 pagesIREGA - Chei Reglabile 2018Popp Laurentiu LiviuNo ratings yet

- Assignment 1 BMFS 4613Document12 pagesAssignment 1 BMFS 4613Shafi AbdullahNo ratings yet

- FinexBond SBR TDS REV 00Document2 pagesFinexBond SBR TDS REV 00Mahesh PriyadarshanaNo ratings yet

- Mechanized Separation of Mixed Solid Waste and Recovery of Recyclable Products Using Optical SorterDocument17 pagesMechanized Separation of Mixed Solid Waste and Recovery of Recyclable Products Using Optical Sorterbartlomiej.jacek.urbanskiNo ratings yet

- Short Problem#1: No Lost Units, Pure EUPDocument3 pagesShort Problem#1: No Lost Units, Pure EUPDerick FigueroaNo ratings yet

- Material Astm A283 Grade CDocument1 pageMaterial Astm A283 Grade CramdikaNo ratings yet

- BTEC Assignment BriefDocument3 pagesBTEC Assignment Briefmahmoud ahmedNo ratings yet

- ACSINDO - Plastic Bottles & Jars CatalogueDocument31 pagesACSINDO - Plastic Bottles & Jars Cataloguerakhalazuardi08No ratings yet

- 44.15 in (1121.5 MM) 6.72 in (170.6 MM) 31.34 in (796.1 MM)Document1 page44.15 in (1121.5 MM) 6.72 in (170.6 MM) 31.34 in (796.1 MM)Jorge LNo ratings yet

- Ppce Unit - I Process Planning and Cost EstimationDocument14 pagesPpce Unit - I Process Planning and Cost EstimationJacob RubasinghNo ratings yet

- Cavalida - ME137L-2 - Drill PressDocument8 pagesCavalida - ME137L-2 - Drill PressEman CavalidaNo ratings yet

- HQ091EN Balinit® ALNOVADocument2 pagesHQ091EN Balinit® ALNOVAMari BraatzNo ratings yet

- CEMA Technical Report 2014 01 Design Considerations For High Temperature Screw Conveyor Applications Mz30smDocument9 pagesCEMA Technical Report 2014 01 Design Considerations For High Temperature Screw Conveyor Applications Mz30smLeonardo LimaNo ratings yet

- Inventions of The Industrial RevolutionDocument10 pagesInventions of The Industrial RevolutionQuinton Matsuo-ChunNo ratings yet

- Low Temperature Cure Strategies For Powder Coatings - IndiaDocument12 pagesLow Temperature Cure Strategies For Powder Coatings - IndiawolfkynNo ratings yet

- Daily Design Team Status 18-01-2024 UpdatedDocument3 pagesDaily Design Team Status 18-01-2024 Updatedvenkatesh kollisettiNo ratings yet

- T 899-1988-Double End StudsDocument6 pagesT 899-1988-Double End StudsdadanjunkmailNo ratings yet

- Lmi Bending Machine Stand Alone HintsDocument2 pagesLmi Bending Machine Stand Alone Hintsfarzan pardakhtNo ratings yet

- Factory Profile FlossyDocument17 pagesFactory Profile FlossyK.M. Abedur Rahman ShuvroNo ratings yet