Professional Documents

Culture Documents

52 Series: Tee-Type Filters (10K, 20K)

52 Series: Tee-Type Filters (10K, 20K)

Uploaded by

enseven3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

52 Series: Tee-Type Filters (10K, 20K)

52 Series: Tee-Type Filters (10K, 20K)

Uploaded by

enseven3Copyright:

Available Formats

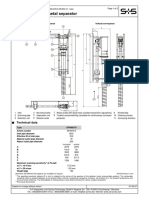

52 Series Tee-Type Filters (10K, 20K)

Available in 303, 316 Stainless (10K) and 17-4 PH

Stainless (20K)

Flows up to 24 GPM or 1,200 SCFM

Various Micron Ratings Ranging from .1 to 150

Available in Stainless Steel, Micro Glass and Porous

Sintered Stainless Steel

Port Sizes Range from 1/4” to 3/4” FNPT (10K only)

and 1/4” to 3/4” MP Port and HP Ports

TEE-TYPE FILTERS

Optional Accessories

Visual Indicator Setting: 40 PSID

Relief Valve Setting: 50 PSID

Bowl Drain: 1/8” and 1/4” FNPT (10K only)

1/4“ MP Ports

Gauge Ports: 1/8” and 1/4” FNPT (10K only)

1/4“ MP Ports

Pressure Ratings Temperature Ratings

303 and 316 Stainless (10K) Elements

Operating: 10,000 PSI Micro Glass -65�F to +325�F

Proof: 15,000 PSI Stainless -425�F to +1000�F

Burst: 40,000 PSI Sintered -425�F to +1000�F

O-Rings

17-4 PH Stainless (20K)

Buna -40�F to +250�F

Operating: 20,000 PSI

Viton -20�F to +400�F

Proof: 30,000 PSI

EPR -60�F to +400�F

Burst: 80,000 PSI

Kalrez -40�F to +550�F

Teflon Encapsulated Viton -4�F to +400�F

307 E Street, Hampton, VA 23661

(PH) 757-327-0036 • (F) 757-327-0552

www.chasefiltercompany.com

info@chasefiltercompany.com

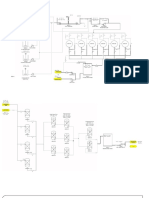

Flow Data (Pressure Drop vs. Flow)

51E - Flow Data - 10 GPM Size

Filter Housing Less Element 51E Series Micro Glass Elements 51E Series Stainless Elements

D

I

10 D

I

10 D

I

10

FDID 10 FDID 10 FDID 10

FFI 9 FFI 9 FFI 9

EF 9 EF 9 EF 9

REFF 8 RFEF 8 REFF 8

EE EE EE

NRER 78 NRER 78 NRER 78

CC C

11MM 1M

TE TE TE

N IN 76 --MMP-MP N IN 76 D

N IN 76

ATIT ATIT ATIT

11//44 1/4

P 6M D

LAI

A 56

LAI

A 56 66MMD LAI

A 56

PLL PLL C PLL

RP 5 RP 5 3M C C RP 5

ERP 4 ERP 4 33MMC 6MC 12M C ERP 4

SER

SE

43 SER

SE

43 66MMCC 1122MMC SER

SE

43

USSS 3 USSS 3 USSS 3 105

RUS

ERU

2 RUS

ERU

2 RUS

ERU

2 112005555

2 MP 2 2

9/16- MPP

R R R

PEE 1 PEE 1 PEE 1 405221550505

5

99/ M

1 6 -

- 3/4-MP

01 01 01

SP / 1 6 SP SP

IP -MPP

3/4-M

3/4 IP IP 4400551000055

DSIS DSIS DSIS 1

I 00 2 4 6 8 10 I 00 2 4 6 8 20 I 00 2 4 6 8 10

DD 0 2FLOW (GPM),

4 1006SSU OIL 8 10 DD 0 2 FLOW (GPM),

4 6 SSU OIL8

100 20 DD 0 2 FLOW (GPM),

4 1006 SSU OIL8 10

FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL

D 10

52E - 10Flow Data - 16 GPM Size

D 10 D

I Filter Housing Less Element I 52E Series Micro Glass Elements I 52E Series Stainless Elements

FDID 10 FDID 10 FDID 10

FFI 9 FFI 9 FFI 9

EF 9 EF 9 EF 9

DD D

REFF 8 RFEF 8 66MM 6M REFF

EE

8

EE EE

NRER 78 NRER 78 NRER 78

CC C

33MM 3M

TE TE TE

N IN 76 N IN 76 C

N IN 76

ATIT ATIT ATIT

12M CC

-MMPP MP

C 5

56

LAI

56 56

LAI LAI

6M C 1122MM 10 5

11//44-1/4-

A A A

PLL

5 P PLL

5 66 C

M

M PLL

5 11 5

0

0

RP

4 6-M P RP

4 RP

4 5

ERP

SER 43 9/1 66--MMP ERP

SER 43

ERP

SER 43 255

SE 99//11 SE SE 22555

USSS 3 USSS 3 USSS 3 4 0 5

RUS 2 RUS 2 RUS 2

ERU ERU ERU 440055

R 2 R 2 R 2 1005

PEE 1 3/4-MP PEE 1 PEE 1 5

-MPP 1100005

01 /4-M

33/4

01 01

SP SP SP

IP IP IP

DSIS 12 16 20 DSIS 12 16 20 DSIS 00 12 16 20

I 00 4 8 I 00 4 8 I 4 8

DD 0 8 10012SSU OIL16

4 FLOW (GPM), 20 DD 0 4 FLOW (GPM),

8 12SSU OIL16

100 20 DD 0 4 FLOW (GPM),

8 12SSU OIL16

100 20

FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL

D 10

53E - 10Flow Data - 24 GPM Size

D 10 D

I Filter Housing Less Element I 53E Series Micro Glass Elements I 53E Series Stainless Elements

FDID 10 FDID 10 FDID 10

FFI 9 FFI 9 FFI 9

EF 9 EF 9 C EF 9

REFF 8 REFF 8 3M CC RFEF 8

11005105

EE EE EE

33MM

NRER 78 NRER 78 NRER 78

5

TE TE TE

N IN 76 N IN 76 D N IN 76

MPP P

ATIT ATIT 6M DD ATIT

11//44-1-M/4-M

22555 255

56 56 56

LAI LAI LAI

66MM

6MC

5

A A A

PLL PLL CC PLL

5 P 5 5

RP

ERP 4 6-M PP

RP

ERP 4 C 66MM RP

ERP 4 5

40 5

9/1 66--MM 12M CC

SER 43 SER 43

1122MM

SER 43 44 5

0

0

SE

USSS 99//11 SE

USSS

SE

USSS

RUS

3 3 3

ERU

2 RUS

ERU

2 RUS

ERU

2

R 2 3/4-MP R 2 R 2

PEE 1 -MPP

/4-M

33/4 PEE 1 PEE 1

01 01 01

SP SP SP

IP IP IP

DSIS 00 5 10 15 20 25 DSIS 00 5 10 15 20 25 DSIS 00 5 10 15 20 25

I I I

DD 0 10 10015SSU OIL 20

5FLOW (GPM), 25 DD 0 5 FLOW (GPM),

10 10015SSU OIL20 25 DD 0 5 FLOW (GPM),

10 10015SSU OIL20 25

FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL FLOW (GPM), 100 SSU OIL

NOTE: Add pressure drop of the housing to that of the element to obtain total initial clean pressure drop of the assembly.

NOTE: Add pressure drop

To determine of thedrop

pressure housing to that ofviscosity

for a different the element to obtainfluid,

and density totaluse

initial clean pressure

the following drop offactor:

conversion the assembly.

To determine pressure drop for a different viscosity and density fluid, use the following conversion factor:

new viscosity, SSU new spec. gravity

New ∆ P = ∆ @ 100 SSU x new viscosity, SSU x new spec. gravity

New ∆ P = ∆ @ 100 SSU x 100 SSU x 0.9

100 SSU 0.9

307 E Street, Hampton, VA 23661 • (PH) 757-327-0036 • (F) 757-327-0552

www.chasefiltercompany.com • info@chasefiltercompany.com

52 Series How to Order

Optional

51 Series How to Order 10,000 PSI and 20,000 PSI Example Part Number

A B C D E F G H I J K

51 P - 10 4 MP - 10S E N - V B2 B25

Section A Description Code

Filter Series Tee-Type Filters up to 20,000 PSI 51 51

Section B

303 Stainless 10,000 PSI S S

Housing Material

316 Stainless 10,000 PSI T T

& Pressure

17-4PH Stainless 20,000 PSI P P

Section C Element Size

10 GPM / 300 SCFM 51E 10 10

Flow - GPM/SCFM 16 GPM / 600 SCFM 52E 16 16

24 GPM / 1200 SCFM 53E 24 24

Section D

1/4" 4 4

3/8" 6 6

Port Size 1/2" 8 8

9/16" *Medium Pressure Only 9 9

3/4" 12 12

Section E

Medium Pressure MP MP

Inlet/Outlet Type

NPT *10,000 PSI Only P P

Section F Material Micron/Nom Micron/Abs

316 Sintered SSTL 0.2 .2P .2P

316 Sintered SSTL 0.7 .7P .7P

316 Sintered SSTL 2 2P 2P

316 Sintered SSTL 5 5P 5P

Microglass 3250 PSID 1 1M 1M

Microglass 3250 PSID 3 3M 3M

Microglass 3250 PSID 5 5M 5M

Micron Rating/ Microglass 3250 PSID 10 10M 10M

Material Microglass 3250 PSID 25 25M 25M

304 SSTL 2 10 10S 10S

304 SSTL 5 18 18S 18S

304 SSTL 10 25 25S 25S

304 SSTL 20 40 40S 40S

304 SSTL 40 75 75S 75S

304 SSTL 75 100 100S 100S

304 SSTL 100 150 150S 150S

Section G

300 PSID Microglass C C

3250 PSID Microglass D D

Collapse Rating

4500 PSID Stainless Wire E E

2000 PSID 316 Sintered F F

Section H

Buna -40°F to +250°F N N

O-Ring Material

®

Viton -20°F to +400°F

EPR -60°F to 400°F

V

E

V

E

®

Kalrez -40°F to +550°F

Teflon Encapsulated Viton -4°F to +400°F

K

S

K

S

Section I

Visual Indicator V V

Electrical Indicator E E

Optional

1/8" NPT ΔP Ports *10,000 PSI Only D1 D1

Accessories

1/4" NPT ΔP Ports *10,000 PSI Only D2 D2

1/4" MP ΔP Ports MP4 MP4

Section J

1/8" NPT *10,000 PSI Only B1 B1

Optional Bowl

1/4" NPT *10,000 PSI Only B2 B2

Drain

1/4" MP MP4 MP4

Section K

Insert Pressure Setting B** ** Indicates Pressure Setting B**

Optional Bypass **Default Setting is 50 PSID**

Tested without leakage to 60,000 PSI

1 2 3 4 5

Replacement Element 51 E - 10S E N

Section C Description

Element Size See Section C for Element Size 51

Element E

Section F

Micron/Material See Section F for Micron Rating 10S

Section G

Collapse Rating See Section G for Collapse Rating E

Section H

O-Ring Material See Section H for O'Ring Material N

Form No. 5200 307 E Street, Hampton, VA 23661 • (PH) 757-327-0036 • (F) 757-327-0552

Rev 4/14 www.chasefiltercompany.com • info@chasefiltercompany.com

250

You might also like

- BSI Standards Publication: Welding - Recommendations For Welding of Metallic MaterialsDocument28 pagesBSI Standards Publication: Welding - Recommendations For Welding of Metallic MaterialsAli Mojtabaei100% (1)

- Valvula Proporcional Norgren Vp60Document1 pageValvula Proporcional Norgren Vp60Base SistemasNo ratings yet

- Sockets and Accessories For Auxiliary Relays: User ManualDocument41 pagesSockets and Accessories For Auxiliary Relays: User ManualHuy Truong GiaNo ratings yet

- Bulk HP FiltrosDocument4 pagesBulk HP FiltrosrolexxNo ratings yet

- PPG-Filtration Product-Matrix 0820Document1 pagePPG-Filtration Product-Matrix 0820dtgpandNo ratings yet

- 1.9.4.7 RBT 100 Data Sheet - 2021Document2 pages1.9.4.7 RBT 100 Data Sheet - 2021CésarNo ratings yet

- Fi750 Inline Flow Indicators - enDocument2 pagesFi750 Inline Flow Indicators - enMIGUELNo ratings yet

- Filtrec F040 SeriesDocument8 pagesFiltrec F040 Serieshkhan10No ratings yet

- Gfps-Datasheet-Type 2250 For Level and Depth Control-159001248Document1 pageGfps-Datasheet-Type 2250 For Level and Depth Control-159001248VIHIKA ENGINEERINGNo ratings yet

- Aa Manejadora Split Central Ciac 5TRDocument1 pageAa Manejadora Split Central Ciac 5TRPipe ValenciaNo ratings yet

- OPTIFLUX 4300 HPrec (Rango Caudalimetros)Document19 pagesOPTIFLUX 4300 HPrec (Rango Caudalimetros)Leandro AlanNo ratings yet

- Catalogo LefooDocument72 pagesCatalogo LefooOscar MontañezNo ratings yet

- Ampl 15 WDocument1 pageAmpl 15 WmplennaNo ratings yet

- Power Cable and Motor Winding Insulation Resistance Tests: BWC 20Mld Phase 1Document32 pagesPower Cable and Motor Winding Insulation Resistance Tests: BWC 20Mld Phase 1Jose Mari BarrogaNo ratings yet

- Sema Atx SmpsDocument1 pageSema Atx SmpsDeepak AnandNo ratings yet

- Alfa Laval Alfa Laval LKRK Product Leaflet enDocument3 pagesAlfa Laval Alfa Laval LKRK Product Leaflet enfmahieuNo ratings yet

- Nice Neotech - BC 565Document1 pageNice Neotech - BC 565David Gnana DuraiNo ratings yet

- IOL Series Filter Housings: Design RatingsDocument2 pagesIOL Series Filter Housings: Design RatingsDaniel HernándezNo ratings yet

- Miniature Aluminum Electrolytic Capacitors: SpecificationsDocument4 pagesMiniature Aluminum Electrolytic Capacitors: SpecificationsManikandan GurunathanNo ratings yet

- ECE 4670 Spring 2014 Lab 4 Radio Receivers For Analog and Digital ModulationDocument16 pagesECE 4670 Spring 2014 Lab 4 Radio Receivers For Analog and Digital ModulationVanidevi ManiNo ratings yet

- Livewire - Professional Edition - Circuito TransmisorDocument1 pageLivewire - Professional Edition - Circuito TransmisorRey TiburonNo ratings yet

- Proteus Data Sheet - 2022Document8 pagesProteus Data Sheet - 2022Rubel AguilarNo ratings yet

- Indicators Series: Max 420 BarDocument6 pagesIndicators Series: Max 420 BarЫфтнфNo ratings yet

- Operating Conditions: Model Output Pole Dimensions (MM) Capacity Flow SpeedDocument1 pageOperating Conditions: Model Output Pole Dimensions (MM) Capacity Flow SpeedJavierNo ratings yet

- GRM Catalogue 2021 Model F FC 1fmcDocument10 pagesGRM Catalogue 2021 Model F FC 1fmcVELUCKIESTNo ratings yet

- RS-13 5-8-5m Annular BOP Operaion ManualDocument6 pagesRS-13 5-8-5m Annular BOP Operaion ManualAlexsandro Cordeiro75% (4)

- En7501 DF DFFDocument10 pagesEn7501 DF DFFHadi AlizadehNo ratings yet

- Dewatering Submersible Pumps FlyerDocument16 pagesDewatering Submersible Pumps Flyerhendryanur97No ratings yet

- GF4000 070 0 TB en V1.1Document2 pagesGF4000 070 0 TB en V1.1Supriyanto yantoNo ratings yet

- FUS 3D Flanges FZF, FUFDocument1 pageFUS 3D Flanges FZF, FUFArunKumar RajendranNo ratings yet

- Ball Valves: DIN Full Bore, Floa! NG Ball, 2-Piece BodyDocument12 pagesBall Valves: DIN Full Bore, Floa! NG Ball, 2-Piece BodyErcan YilmazNo ratings yet

- TempDocument1 pageTempgrwgNo ratings yet

- Piggyback Design R 01Document4 pagesPiggyback Design R 01Manu GowdaNo ratings yet

- HHO - DL Phase Lock Loop Parts PDFDocument3 pagesHHO - DL Phase Lock Loop Parts PDFМарко Сајић0% (1)

- FI750 User ManualDocument36 pagesFI750 User ManualEnrrique Vega MecatronicNo ratings yet

- Medidor Digital B&W-4Document2 pagesMedidor Digital B&W-4Aaron Quispe PinedaNo ratings yet

- Cabur Solar MC4Document1 pageCabur Solar MC4Global NewsNo ratings yet

- Pompa HCP 2Document8 pagesPompa HCP 2Amarizal UMSNo ratings yet

- Ebara Pump Brochure - Fsa, - 50 - HZ Terbaru 10092021Document6 pagesEbara Pump Brochure - Fsa, - 50 - HZ Terbaru 10092021Firdaus ArifiyantoNo ratings yet

- Alum Dosing PumpDocument2 pagesAlum Dosing PumpBassamNo ratings yet

- Pllone BuildDocument10 pagesPllone BuildsamhainnNo ratings yet

- HydropompeDocument4 pagesHydropompeReggie TopsNo ratings yet

- Filtro Hidráulico Pi340 MahleDocument7 pagesFiltro Hidráulico Pi340 MahleHIDRAFLUIDNo ratings yet

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- SMPS Half Bridge IR2153 2.0 - Esquema-1Document1 pageSMPS Half Bridge IR2153 2.0 - Esquema-1BanePartonjicNo ratings yet

- SMPS Half Bridge IR2153 2.0 - Esquema PDFDocument1 pageSMPS Half Bridge IR2153 2.0 - Esquema PDFleosedfNo ratings yet

- Flygt DX: Submersible Drainage & Waste Water Pumps, 50 HZDocument4 pagesFlygt DX: Submersible Drainage & Waste Water Pumps, 50 HZAndrey GyrychNo ratings yet

- 安全与截止阀 Saf DsvDocument22 pages安全与截止阀 Saf DsvpeterNo ratings yet

- DFBN FilterDocument10 pagesDFBN FilterPutut SuprihartonoNo ratings yet

- SL3488D-Plus Multipath Ultrasonic Flowmeter BrochureDocument10 pagesSL3488D-Plus Multipath Ultrasonic Flowmeter BrochureNaji OmarNo ratings yet

- FLOWTRON Glass Tube Rotameters Rotameters GC-TECHNOTRADINGDocument6 pagesFLOWTRON Glass Tube Rotameters Rotameters GC-TECHNOTRADINGDaniel Sandoval RodriguezNo ratings yet

- Tda7292 DatasheetDocument22 pagesTda7292 DatasheetandrezeppelimNo ratings yet

- Alat ElektronikaDocument69 pagesAlat ElektronikaRSUD KK IPSRSNo ratings yet

- Electrical Feedthroughs DN40 CF-F ENDocument4 pagesElectrical Feedthroughs DN40 CF-F ENjagajack33No ratings yet

- DataBook LPC4Document35 pagesDataBook LPC4Anonymous 9vF9XUU2ZKNo ratings yet

- ITT Standard Gould SpecDocument12 pagesITT Standard Gould SpecDendi DenisNo ratings yet

- 4WE10 Series - Tech SpecificationsDocument6 pages4WE10 Series - Tech Specificationsargo_arjieantoNo ratings yet

- C. LAMPIRAN Flowsheet UtilityDocument12 pagesC. LAMPIRAN Flowsheet UtilityNorsyam H DaniNo ratings yet

- Catalog Casting and Forging ProductsDocument7 pagesCatalog Casting and Forging ProductsanggitNo ratings yet

- DBL 8451pDocument16 pagesDBL 8451pSimone CorrêaNo ratings yet

- Hifit Industries-ProfileDocument6 pagesHifit Industries-Profileprakash 3No ratings yet

- Catiofast VMP TI. enDocument3 pagesCatiofast VMP TI. enmostafizur rahmanNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- Brosur Baja Gunung Raja Paksi Wire RodDocument1 pageBrosur Baja Gunung Raja Paksi Wire RodRobbi Shobri RakhmanNo ratings yet

- Bucket Inspection & MaintenanceDocument12 pagesBucket Inspection & MaintenanceVictor Marcos BautistaNo ratings yet

- Price List Hong Tomas Trading 2022-02-02Document4 pagesPrice List Hong Tomas Trading 2022-02-02Neil Patrick OrdoñezNo ratings yet

- Homemade Bandsaw Plans - YouTubeDocument3 pagesHomemade Bandsaw Plans - YouTubeStaroth Gonz Rodr100% (4)

- Nickel in Ferritic & Martensitic Stainless Steel PDFDocument23 pagesNickel in Ferritic & Martensitic Stainless Steel PDFhimanshu17121990No ratings yet

- Ote Floodaf Microflotation System enDocument2 pagesOte Floodaf Microflotation System enENNYMRNo ratings yet

- 2021 P2 AAB30903 Lay Up CuringDocument5 pages2021 P2 AAB30903 Lay Up CuringReza HusainiNo ratings yet

- Liftoff TechniquesDocument4 pagesLiftoff TechniquesSwarnava SanyalNo ratings yet

- Precautionary Measures To Avoid Cracks in PlasteringDocument2 pagesPrecautionary Measures To Avoid Cracks in PlasteringsmartkhazanchiNo ratings yet

- Transolac Aluminium HR: Product DescriptionDocument3 pagesTransolac Aluminium HR: Product Descriptionshady yehiaNo ratings yet

- Daftar Tubes Manajemen EnergiDocument1 pageDaftar Tubes Manajemen EnergiSyifaprilia NNo ratings yet

- DIY Bed Frame Plans - Queen Size: Minwax Clear Semi-Gloss PolyurethaneDocument17 pagesDIY Bed Frame Plans - Queen Size: Minwax Clear Semi-Gloss PolyurethaneJareth KoltynNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- TDS PEEK Filament 1Document2 pagesTDS PEEK Filament 1Krzysztof KardachNo ratings yet

- DS - 752-Rev01 - Epilux 485 HB IntermediateDocument2 pagesDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainNo ratings yet

- Countersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Document10 pagesCountersunk Screw With Hexagon Socket Head ISO 10642 Steel 10.9Alex DeschevogNo ratings yet

- 2C-03-01 Rev 0Document2 pages2C-03-01 Rev 0Christian Martínez G.No ratings yet

- HDPE FinalDocument15 pagesHDPE Finalsaha92No ratings yet

- MSS SP-65 (1999)Document11 pagesMSS SP-65 (1999)Islam SolimanNo ratings yet

- Barrels & Actions by Harold HoffmanDocument238 pagesBarrels & Actions by Harold HoffmanNorm71% (7)

- Wood Processes: Product DesignDocument26 pagesWood Processes: Product Design809945No ratings yet

- PROPOSED TRAINING-Sequoia Safety Products PVT LTD - 230711 - 210151Document5 pagesPROPOSED TRAINING-Sequoia Safety Products PVT LTD - 230711 - 210151Nikunj SinghNo ratings yet

- Ut Pumps & Systems Pvt. LTDDocument2 pagesUt Pumps & Systems Pvt. LTDSravan DasariNo ratings yet

- Workshop Practice Series 08 - Sheet Metal WorkDocument53 pagesWorkshop Practice Series 08 - Sheet Metal WorkDiego Romero100% (1)