Professional Documents

Culture Documents

Guide Scaffold Stadium

Guide Scaffold Stadium

Uploaded by

nazulailawitra95Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide Scaffold Stadium

Guide Scaffold Stadium

Uploaded by

nazulailawitra95Copyright:

Available Formats

GUIDE TO SCAFFOLD INSPECTION

AND MAINTENANCE

This Guide provides information on scaffold inspection and maintenance including information on

certification that a scaffold is safe to use.

It is part of a series of guidance material and should be read and used together with the General

guide for scaffolds and scaffolding work which includes information on risk management as well

as advice on planning, erecting, altering, dismantling, and working with scaffolds and the following

material:

Guide to scaffolds and scaffolding

Guide to suspended (swing stage) scaffolds, and

Information Sheet: Tower and mobile scaffolds.

Further information for scaffolding work near overhead electric lines is also available in the Information

Sheet: Scaffolding work near overhead electric lines.

Inspecting scaffolds

Procedures should be developed for inspecting and maintaining the scaffold and scaffolding to ensure

the scaffold is safe to use and remains in a safe condition.

For suspended, cantilevered, spur and hung scaffolds and any other scaffold from which a person or

thing could fall more than 4 metres:

the scaffold must not be used unless there is written confirmation from a competent person that they

have inspected the scaffold and construction of the scaffold is complete

the scaffold and its supporting structure must be inspected by a competent person:

o before the scaffold is used after an incident has occurred that might affect the stability of the

scaffold

o before the scaffold is used after repairs

o at least every 30 days

if an inspection indicates that a scaffold or its supporting structure creates a risk to health or safety:

o any necessary repairs, alterations and additions must be made, and

o the scaffold and its supporting structure are inspected by a competent person before the

scaffold is used, and

unauthorised access to the scaffold is prevented while the scaffold is incomplete or unattended.

Scaffolds with a fall risk of less than 4 metres should also be inspected before use and after any

incident, repair, alteration or addition.

Inspecting scaffolds and scaffolding at a workplace is particularly important when the scaffold is in

place for a long period of time. An example of a scaffold inspection checklist is at Appendix A.

Handover inspections

Once a scaffold has been erected a handover inspection should be completed to check that the

scaffold is safe to use. Where written confirmation from a competent person is required this usually

takes the form of a handover certificate. An example is at Appendix B.

If alterations, repairs or additions to the scaffold are required a further inspection should be completed

and a new handover certificate provided.

The handover certificate should be kept at the workplace until the scaffold has been dismantled.

Guide to scaffold inspection and maintenance July 2014 Page 1 of 4

Post-handover inspections

wind loading on containment sheeting?

Has the retention of rainwater and its effect on increasing weight been considered?

Are the fixing ties secure?

Are there rips or tears?

Are the overlap joints satisfactory?

1. Mobile scaffolds

Is the supporting surface hard and flat?

Is the area of operation free of overhead electric lines and other hazards?

Are floor penetrations covered?

Are the castor wheel locks in working order? They should be locked at all times,

except during movement of the scaffold.

2. General fitness for purpose

Is there provision for material handling?

Are the clearances between the scaffold and adjacent structures correct?

Is there protection from falling debris?

Has the scaffold been safely designed to support attachments?

Are approaches and platforms effectively lit?

Guide to scaffold inspection and maintenance July 2014 Page 2 of 4

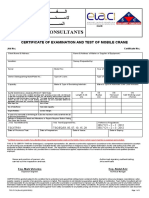

APPENDIX B – EXAMPLE SCAFFOLD HANDOVER OR INSPECTION

CERTIFICATE

A person with management or control of a suspended, cantilevered, spur, hung or other

scaffold from which a person or thing could fall more than 4 metres must receive written

confirmation from a competent person that the scaffold has been inspected, completed

and is safe for use.

This example handover or inspection certificate may also be used for minor scaffolds.

Scaffold supplier/erector Client

Certificate No: Client Name:

Company Name:

Address: Address:

Site Address:

Contact Phone: Contact Phone:

Fax: Fax:

Project Details

Project/Reference Number:

Description of area handed over:

Drawings attached:

Intended use of scaffold:

Duty Classification:

Number of working decks:

Top working platform height:

3 m Bays: 2.4 m Bays: 1.8 m Bays:

1.3 m Bays: 0.8 m Bays: Access Bays:

Plant Design Registration Number: Additional Details:

Guide to scaffold inspection and maintenance July 2014 Page 3 of 4

Handover Inspection of Scaffold

The scaffold detailed above has been erected in accordance with the attached drawings,

the WHS Regulations and the General guide for scaffolds and scaffolding work; is

informed by relevant technical standards and is suitable for its intended purpose.

Note: A completed scaffold inspection checklist should be provided and attached to this

handover certificate stating every aspect of the inspected scaffold which meets the

required standards. Subsequent inspections should be recorded on an inspection checklist

and provided to the relevant person.

Name: Signature:

High risk work licence No:

Time: Date:

Acceptance – on behalf of the client

Name: Signature:

Date:

Arrange for scaffold to be inspected at intervals not exceeding 30 days or immediately

following an incident which may affect the adequacy of the scaffold. The design

registration number for prefabricated scaffolding must be kept readily accessible at all

times, for example near the scaffold.

Guide to scaffold inspection and maintenance July 2014 Page 4 of 4

You might also like

- Load Test ProcedureDocument70 pagesLoad Test ProcedureMohammed Rizwan Ahmed80% (5)

- Scaffold HandbookDocument175 pagesScaffold HandbookNizar Mohamed100% (3)

- Book - SA Advanced ScaffoldingDocument37 pagesBook - SA Advanced ScaffoldingdiyamoniNo ratings yet

- Installation Procedure For Pressure Vessel - EnglishDocument8 pagesInstallation Procedure For Pressure Vessel - EnglishApri Dianto92% (13)

- Book - SB Basic ScaffoldingDocument62 pagesBook - SB Basic ScaffoldingMichael Peter DentonNo ratings yet

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerNo ratings yet

- Birdcage Scaffold Plan & Method StatementDocument9 pagesBirdcage Scaffold Plan & Method StatementTeodoro EsquilloNo ratings yet

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- Method Statement DPE GL1 Cooling Water Line CleaningDocument15 pagesMethod Statement DPE GL1 Cooling Water Line CleaningDheeraj Chowdary DhanekulaNo ratings yet

- Guide Scaffold StadiumDocument2 pagesGuide Scaffold Stadiumnazulailawitra95No ratings yet

- Guide Scaffold Inspection MaintenanceDocument7 pagesGuide Scaffold Inspection MaintenanceMalahati HashinaNo ratings yet

- Guide To Scaffold Inspection and Maintenance: General Guide For S Caffolds and Scaffolding WorkDocument6 pagesGuide To Scaffold Inspection and Maintenance: General Guide For S Caffolds and Scaffolding WorkSandeep KumarNo ratings yet

- Sample Scaffold Erecting and Dismantling Procedure 1 PurposeDocument4 pagesSample Scaffold Erecting and Dismantling Procedure 1 PurposegrandeNo ratings yet

- Working at Height Day 2Document48 pagesWorking at Height Day 2OsamaAlaasamNo ratings yet

- Working at Height Day 2Document46 pagesWorking at Height Day 2OsamaAlaasam67% (3)

- Saf 076Document11 pagesSaf 076celsocarvalhNo ratings yet

- Scaffolding: Safe Erection and USE: Jerus V. Lucine 5-BSCE-BDocument103 pagesScaffolding: Safe Erection and USE: Jerus V. Lucine 5-BSCE-Bjerus lucineNo ratings yet

- Saes B 054Document14 pagesSaes B 054Tarek Mustafa100% (1)

- Guide To Inspecting and Maintaining CranesDocument7 pagesGuide To Inspecting and Maintaining CranesBerk TekinNo ratings yet

- Mos-Replacement Gasket For PP Piping - 2024Document6 pagesMos-Replacement Gasket For PP Piping - 2024habibullah.centroironNo ratings yet

- ScaffoldingDocument2 pagesScaffoldingBSFNo ratings yet

- Method Statement For Backfilling and Compaction ProcedureDocument22 pagesMethod Statement For Backfilling and Compaction ProcedureAlbertyNo ratings yet

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerNo ratings yet

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- Tca Safety Guidelines Version13-1Document11 pagesTca Safety Guidelines Version13-1engdireccionNo ratings yet

- EscalatorDocument9 pagesEscalatorHarris ShehzadNo ratings yet

- ASPEC Safe Operation of Camera CranesDocument28 pagesASPEC Safe Operation of Camera CranesM. GuidoNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- Regulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Document18 pagesRegulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Revankar B R ShetNo ratings yet

- TD MPI Inspection StandardDocument97 pagesTD MPI Inspection StandardMohamed BadranNo ratings yet

- Guide To Inspecting and Maintaining CranesDocument8 pagesGuide To Inspecting and Maintaining CranesMohammed MujahidNo ratings yet

- Mobile CraneDocument18 pagesMobile CraneHarris Shehzad100% (1)

- Mobile CraneDocument2 pagesMobile CraneSHARAFUDHEEN TKNo ratings yet

- Prosedur ScaffoldingDocument38 pagesProsedur ScaffoldingFafa seyza100% (4)

- ABC Guide To Dropped ObjectDocument108 pagesABC Guide To Dropped ObjectLes Donaldson100% (5)

- SC Bulk Hose Handling Guidance DocumentDocument24 pagesSC Bulk Hose Handling Guidance DocumentLeonardo AlvarezNo ratings yet

- Construction - Scaffold Checklist - HSEDocument6 pagesConstruction - Scaffold Checklist - HSEroldskiNo ratings yet

- Window CradleDocument10 pagesWindow CradleHarris ShehzadNo ratings yet

- Checklist Design Review TechnicalDocument14 pagesChecklist Design Review Technicaldsahmed100% (1)

- Construction Method Statement: Fabrication & Erection of Piping SystemDocument24 pagesConstruction Method Statement: Fabrication & Erection of Piping SystemHarun Akkaya100% (2)

- Work InstructionsDocument32 pagesWork InstructionshainguyenbkvhvNo ratings yet

- Scaffold Erecting and Dismantling Procedure 1 PurposeDocument4 pagesScaffold Erecting and Dismantling Procedure 1 PurposeHu Hin AngNo ratings yet

- Method Statement For DuctworksDocument4 pagesMethod Statement For DuctworksJAY ROD AWITNo ratings yet

- DOC0142874Document10 pagesDOC0142874DeivisNo ratings yet

- Maz - PRJ - Hse - PRC 10 - Lifting Operations Procedures 001Document8 pagesMaz - PRJ - Hse - PRC 10 - Lifting Operations Procedures 001ghazi kallelNo ratings yet

- ScaffoldingDocument7 pagesScaffoldingFreshop SurabayaNo ratings yet

- scaffoldProcedErectDismant PDFDocument4 pagesscaffoldProcedErectDismant PDFresaNo ratings yet

- Form WorkDocument37 pagesForm WorkDavid SeowNo ratings yet

- ScaffoldDocument8 pagesScaffoldSAYED100% (1)

- Scaffolding ProcedureDocument22 pagesScaffolding ProcedureMuhammad Saqib Asif100% (2)

- 8.0 Annexure VIII - Safety RequirementDocument17 pages8.0 Annexure VIII - Safety RequirementRabi Sankar MohantyNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3From EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3No ratings yet

- SCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGEFrom EverandSCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGENo ratings yet

- Construction Methodologies & Procedures for Civil Engineers - Part -1From EverandConstruction Methodologies & Procedures for Civil Engineers - Part -1No ratings yet

- POB Revision Questions (Paper 2)Document4 pagesPOB Revision Questions (Paper 2)Khalil WeirNo ratings yet

- Predictive AnalyticsDocument9 pagesPredictive Analyticsjayanth jNo ratings yet

- Co Cat List PFPL 2020 Published 1Document908 pagesCo Cat List PFPL 2020 Published 1SUDHA RANJITHNo ratings yet

- Overcoming Behavioral Biases Morgan StanleyDocument7 pagesOvercoming Behavioral Biases Morgan StanleySiddharthNo ratings yet

- Macroeconomics Canadian 5th Edition Williamson Test BankDocument35 pagesMacroeconomics Canadian 5th Edition Williamson Test Banksinapateprear4k100% (17)

- Chapter 1: IntroductionDocument143 pagesChapter 1: IntroductionmarieieiemNo ratings yet

- Britannia - 2Document3 pagesBritannia - 2tejaNo ratings yet

- Ujala Co ProjctDocument36 pagesUjala Co ProjctShamseer Ummalil0% (2)

- Weight SteelDocument128 pagesWeight SteelMark Philip BaliwisNo ratings yet

- Design Program Logic NewDocument111 pagesDesign Program Logic NewAyansa ErgibaNo ratings yet

- Manufacturing 4 PagerDocument4 pagesManufacturing 4 PagerPradeep SinghNo ratings yet

- Company ProfileDocument6 pagesCompany Profilekiran Engineering FabricationNo ratings yet

- Business Plan OutlineDocument7 pagesBusiness Plan OutlineNayre JunmarNo ratings yet

- Company Law Memorial-RespondentDocument20 pagesCompany Law Memorial-RespondentAnsh GulatiNo ratings yet

- Airolink Profile 05112022 - CapabilitiesDocument93 pagesAirolink Profile 05112022 - CapabilitiesHasanNo ratings yet

- 9 Ways To Increase Sewing Operator EfficiencyDocument47 pages9 Ways To Increase Sewing Operator EfficiencyNitta MallikNo ratings yet

- Test Bank For Essentials of Investments 11th by BodieDocument36 pagesTest Bank For Essentials of Investments 11th by Bodiepotassicdaywomanslqia100% (27)

- Ahmed Ezz I.T MGR PDFDocument4 pagesAhmed Ezz I.T MGR PDFAhmed Ezz EldinNo ratings yet

- Conceputal Framework-On Campus Task-SolvedDocument3 pagesConceputal Framework-On Campus Task-SolvedPacific Hunter JohnnyNo ratings yet

- Financial Leasing RegulationsDocument30 pagesFinancial Leasing RegulationsZaminNo ratings yet

- PDF Ims Manual 2019 FinalDocument102 pagesPDF Ims Manual 2019 FinalThulasi RamNo ratings yet

- Survey FormDocument1 pageSurvey FormMohit KumarNo ratings yet

- Impact of Credit Card On Buying BehaviourDocument21 pagesImpact of Credit Card On Buying BehaviourNoor OsamaNo ratings yet

- Reusable Verification Environment For Verification of Ethernet PDFDocument4 pagesReusable Verification Environment For Verification of Ethernet PDFRachel GreenNo ratings yet

- Problems Identified by The Narasimham CommitteeDocument3 pagesProblems Identified by The Narasimham Committeeshaikhaamir21No ratings yet

- DNV-OSS-305 Rules For Certification and Verification of Diving Systems October2011Document85 pagesDNV-OSS-305 Rules For Certification and Verification of Diving Systems October2011Rumi Kai RekaNo ratings yet

- BUNTONG ES Sampling TemplateDocument148 pagesBUNTONG ES Sampling TemplateMea GuillerNo ratings yet

- Extended Essay EconomicsDocument18 pagesExtended Essay EconomicsJamie LiuNo ratings yet

- Innovative Lolwe Hybrid Solar 600kWp Minigrid Inaugurated in UgandaDocument9 pagesInnovative Lolwe Hybrid Solar 600kWp Minigrid Inaugurated in UgandaNassimba FlorenceNo ratings yet

- Better Cotton Suppliers 09.11.2021Document258 pagesBetter Cotton Suppliers 09.11.2021Jai PatelNo ratings yet