Professional Documents

Culture Documents

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Uploaded by

Cipta Rupa PertamaCopyright:

Available Formats

You might also like

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocument31 pagesGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher50% (2)

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- 6.method Statement Steel Erection and CladdingDocument4 pages6.method Statement Steel Erection and Claddingشاز إياسNo ratings yet

- Mechanical GA Drawings - Rev.1Document14 pagesMechanical GA Drawings - Rev.1unnicyriacNo ratings yet

- UntitledDocument10 pagesUntitledROOTH GAMINGNo ratings yet

- Awareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyDocument8 pagesAwareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyIOSRjournalNo ratings yet

- 2 Analysis of Factors Influencing Work Accidents in The Roduction Section at PT Industri Kapal Indonesia (Persero)Document17 pages2 Analysis of Factors Influencing Work Accidents in The Roduction Section at PT Industri Kapal Indonesia (Persero)tutita tari muslimNo ratings yet

- Bab 1Document9 pagesBab 1Kelana FactoryNo ratings yet

- Faktor-Faktor Yang Berhubungan Dengan Perilaku Pekerja Dalam Penggunaan Apd Di Sentra Pengasapan Ikan Kelurahan Bandarharjo Kota SemarangDocument10 pagesFaktor-Faktor Yang Berhubungan Dengan Perilaku Pekerja Dalam Penggunaan Apd Di Sentra Pengasapan Ikan Kelurahan Bandarharjo Kota SemarangFajri AnsyahNo ratings yet

- Journal of Vocational Health StudiesDocument6 pagesJournal of Vocational Health Studiesfaisal mujtamiNo ratings yet

- 551-Article Text-1455-1-10-20230209Document9 pages551-Article Text-1455-1-10-20230209Chandra PratamaNo ratings yet

- 4346 6390 1 SM PDFDocument12 pages4346 6390 1 SM PDFAhmad DikaNo ratings yet

- Jurnal Bpi 2021Document15 pagesJurnal Bpi 2021Izmi DwivasariNo ratings yet

- My ProposalDocument10 pagesMy ProposalNassazi BeatriceNo ratings yet

- Work Accident Risk at Hospital Construction EnvironmentDocument8 pagesWork Accident Risk at Hospital Construction EnvironmentArya DdpNo ratings yet

- Pharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuDocument10 pagesPharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. Kawatukaren.No ratings yet

- 2289-Article Text-5947-1-10-20221202Document8 pages2289-Article Text-5947-1-10-20221202Raditya RaffaNo ratings yet

- Pelaksanaan Serta Pemantauan Evaluasi Kinerja K3 Dan Implikasinya Terhadap Kejadian Kecelakaan Kerja Di PTPN Iii Tebing Tinggi Tahun 2017Document11 pagesPelaksanaan Serta Pemantauan Evaluasi Kinerja K3 Dan Implikasinya Terhadap Kejadian Kecelakaan Kerja Di PTPN Iii Tebing Tinggi Tahun 2017Budiz AlNurNo ratings yet

- Identifikasi Risiko Kecelakan Kerja Terhadap Pekerja Di PT. IKI Makassar Tahun 2020 (Studi Pada Pekerja Proses Marking)Document9 pagesIdentifikasi Risiko Kecelakan Kerja Terhadap Pekerja Di PT. IKI Makassar Tahun 2020 (Studi Pada Pekerja Proses Marking)Rachmat GurnidaNo ratings yet

- Analisa Penerapan Hiradc Di Tempat KerjaDocument7 pagesAnalisa Penerapan Hiradc Di Tempat KerjaBucit SupriadiNo ratings yet

- 1633-Article Text-6645-1-10-20200925Document12 pages1633-Article Text-6645-1-10-20200925Dea Widya HutamiNo ratings yet

- Lensoni 2018Document6 pagesLensoni 2018Kelana FactoryNo ratings yet

- Hubungan Perilaku Dan Sikap Pekerja Pengangkut Sampah Dengan Penggunaan Alat Pelindung Diri Di Kampung Jawa Banda AcehDocument6 pagesHubungan Perilaku Dan Sikap Pekerja Pengangkut Sampah Dengan Penggunaan Alat Pelindung Diri Di Kampung Jawa Banda AcehKelana FactoryNo ratings yet

- Jurnal Penerapan K3 1 PDFDocument5 pagesJurnal Penerapan K3 1 PDFmaulana ichsanNo ratings yet

- JurnalDocument8 pagesJurnalrendysmith098No ratings yet

- 106-Article Text-261-1-10-20181101Document10 pages106-Article Text-261-1-10-20181101Mori Shan24No ratings yet

- Skidujopas258 26585Document8 pagesSkidujopas258 26585Jessymay ZenarosaNo ratings yet

- 57-Article Text-101-1-10-20230315Document7 pages57-Article Text-101-1-10-20230315ozitranscellcomNo ratings yet

- 1 s2.0 S2093791122000439 MainDocument10 pages1 s2.0 S2093791122000439 MainCsanyi EditNo ratings yet

- The Application of The Job Safety Analysis Method in The Identification of Potential Hazards in Pipe Division Workers, West SumatraDocument7 pagesThe Application of The Job Safety Analysis Method in The Identification of Potential Hazards in Pipe Division Workers, West SumatraAndreas SiagianNo ratings yet

- 1 PBDocument15 pages1 PByuelakhbrNo ratings yet

- Trauma Survey Due To Work in The Lumajang District Agriculture AreaDocument12 pagesTrauma Survey Due To Work in The Lumajang District Agriculture AreavinniNo ratings yet

- Public Health Perspectives Journal: Feramida Yuliya Edison, Soesanto Soesanto, Yuni WijayantiDocument12 pagesPublic Health Perspectives Journal: Feramida Yuliya Edison, Soesanto Soesanto, Yuni WijayantiSutrimah KediriNo ratings yet

- Kecelakaan KerjaDocument11 pagesKecelakaan Kerjadata rabiqyNo ratings yet

- Safety and Health Risk MGT On Consruction SiteDocument152 pagesSafety and Health Risk MGT On Consruction SiteSandhya Nundah50% (2)

- Occupational Exposures and Related Health Effects Among Construction WorkersDocument6 pagesOccupational Exposures and Related Health Effects Among Construction WorkersabdishNo ratings yet

- Defining Safety Hazards & Risks in Mining Industry: A Case-Study in United StatesDocument9 pagesDefining Safety Hazards & Risks in Mining Industry: A Case-Study in United StatesJudith MungombeNo ratings yet

- LSMR-19 Vol2010Document12 pagesLSMR-19 Vol2010Vivek SharmaNo ratings yet

- 1 PBDocument11 pages1 PBGumchyyy BubbleNo ratings yet

- Pharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuDocument8 pagesPharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuSandy ElkaNo ratings yet

- ID Analisis Faktor Yang Berpengaruh Terhadap Pelaksanaan Peka Pengamatan KDocument11 pagesID Analisis Faktor Yang Berpengaruh Terhadap Pelaksanaan Peka Pengamatan Knar udinNo ratings yet

- QS 6Document9 pagesQS 6PUTRI NADIA RO PAE INGNo ratings yet

- Safety and Health in Mining: Part 1Document11 pagesSafety and Health in Mining: Part 1Leonel CanoNo ratings yet

- Assessment of Ergonomic Hazards in Workstations and The Effects On Selected Public ServantsDocument6 pagesAssessment of Ergonomic Hazards in Workstations and The Effects On Selected Public ServantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analisis Faktor Yang Berhubungan Dengan Penyakit Akibat Kerja Pada Karyawan Smelter X' Industri Tahun 2020Document12 pagesAnalisis Faktor Yang Berhubungan Dengan Penyakit Akibat Kerja Pada Karyawan Smelter X' Industri Tahun 2020krisma mahendraNo ratings yet

- Occupational Health Safety and Organizational Commitment Evidence From Ghanaian Mining IndustryDocument23 pagesOccupational Health Safety and Organizational Commitment Evidence From Ghanaian Mining IndustryAce Jae BautistaNo ratings yet

- Safety Driving Pada Operator Forklift Di PertambanDocument9 pagesSafety Driving Pada Operator Forklift Di PertambanMuhammad khalid AlhafizhNo ratings yet

- Maxillofacial Trauma With Head Injuries at A Tertiary Care Hospital in Chitwan, Nepal: Clinical, Medico-Legal, and Critical Care..Document9 pagesMaxillofacial Trauma With Head Injuries at A Tertiary Care Hospital in Chitwan, Nepal: Clinical, Medico-Legal, and Critical Care..Muhammad RizqiNo ratings yet

- Occupational Health and Safety of WorkerDocument37 pagesOccupational Health and Safety of Workeraritra sahaNo ratings yet

- IJWC.23 YilmazBurgazogluMan 22.35Document14 pagesIJWC.23 YilmazBurgazogluMan 22.35Joanna KuterNo ratings yet

- 7244 24935 1 SMDocument18 pages7244 24935 1 SMSamantha Meril PandithaNo ratings yet

- Factors Related To Road Accidents in Palembang, South Sumatera, IndonesiDocument8 pagesFactors Related To Road Accidents in Palembang, South Sumatera, IndonesiIJPHSNo ratings yet

- Accident Cost MiningDocument8 pagesAccident Cost MiningAnand sharmaNo ratings yet

- Improving Safety Performance Through Safety Leadership and Safety BehaviorsDocument8 pagesImproving Safety Performance Through Safety Leadership and Safety BehaviorsEverson MurungweniNo ratings yet

- Advances in Occupational Health and Safety ManagementDocument196 pagesAdvances in Occupational Health and Safety Managementdanielelage.advNo ratings yet

- BOSH Module 2Document8 pagesBOSH Module 2Meralie CapangpanganNo ratings yet

- In-Depth Analysis of Workplace Accidents in Food Processing Company in The PhilippinesDocument9 pagesIn-Depth Analysis of Workplace Accidents in Food Processing Company in The PhilippinesJastine AnneNo ratings yet

- Journal of Safety ResearchDocument17 pagesJournal of Safety ResearchJane Eilyza AballaNo ratings yet

- Gambaran Pelaksanaan Program Promosi K3 Pada PT Pertamina Trans Kontinental Jakarta Tahun 2018 Irenia Tennovia Yulius, Siti Rahmah H. LubisDocument13 pagesGambaran Pelaksanaan Program Promosi K3 Pada PT Pertamina Trans Kontinental Jakarta Tahun 2018 Irenia Tennovia Yulius, Siti Rahmah H. LubisArisgaSufanaNo ratings yet

- Assessment of Health, Safety and Environment Procedures in Technical Colleges' Workshops in Rivers StateDocument6 pagesAssessment of Health, Safety and Environment Procedures in Technical Colleges' Workshops in Rivers Statepaul okwelleNo ratings yet

- IMSP Symposium 23Document106 pagesIMSP Symposium 23Sanjeev BhardwajNo ratings yet

- Unmaking the Global Sweatshop: Health and Safety of the World's Garment WorkersFrom EverandUnmaking the Global Sweatshop: Health and Safety of the World's Garment WorkersNo ratings yet

- 20t Tadano Rough Terrain TR 200M - Spec. 00107Document11 pages20t Tadano Rough Terrain TR 200M - Spec. 00107Eugene NortjeNo ratings yet

- QY20B Brand New PDFDocument3 pagesQY20B Brand New PDFDavid GomezNo ratings yet

- F250as 22Document38 pagesF250as 22Денис ЧерныйNo ratings yet

- Critical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)Document4 pagesCritical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)cute1t100% (1)

- Bullivants Rigging Handbook V2Document260 pagesBullivants Rigging Handbook V2Anonymous 2QD5RVWt5100% (5)

- Erection of BoilerDocument40 pagesErection of BoilerSam100% (1)

- SO-0033 SPJ315 A2+inDocument118 pagesSO-0033 SPJ315 A2+inRicardo EspinosaNo ratings yet

- Materials - Handling - & - Storage - 2 - ACADocument25 pagesMaterials - Handling - & - Storage - 2 - ACAJeanlyn Virgo AlmacinNo ratings yet

- Collision Prevention at Ports Terminals Information Paper 2019Document21 pagesCollision Prevention at Ports Terminals Information Paper 2019Casopis Safety100% (1)

- Fushun Yongmao Construction Machinery Co - LTDDocument157 pagesFushun Yongmao Construction Machinery Co - LTDOleksandr YakubetsNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- BASTAIN SOLUTION-250 KG SG EOT CRANE - 316Document10 pagesBASTAIN SOLUTION-250 KG SG EOT CRANE - 316Chandru ChristurajNo ratings yet

- BAUER-Catalogue 7 en WebDocument168 pagesBAUER-Catalogue 7 en Websamudra.gs83No ratings yet

- S393 SPM Lopl Opr MS 2301 - 0Document134 pagesS393 SPM Lopl Opr MS 2301 - 0Barm FuttNo ratings yet

- Fundamentals of Highway Bridge Demolition: Conference PaperDocument10 pagesFundamentals of Highway Bridge Demolition: Conference PaperDenver PlayletsNo ratings yet

- Rate Analysis Programme MorthDocument362 pagesRate Analysis Programme MorthAman SrivastavaNo ratings yet

- Bullivants Fabricated HandbookDocument80 pagesBullivants Fabricated Handbooksebastian9033No ratings yet

- KRA 3.8 Travelling Crane ProcedureDocument11 pagesKRA 3.8 Travelling Crane ProcedureAhsan Farooq100% (1)

- Danger Under Crane BoomsDocument2 pagesDanger Under Crane Boomsابو محمد عليNo ratings yet

- Lifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedDocument23 pagesLifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedGufran ImamNo ratings yet

- Monorail Beam Design Q&ADocument33 pagesMonorail Beam Design Q&Aabdulloh_99No ratings yet

- NORSOK-L-002 (July 2009) - Piping-Layout-&-AnalysisDocument36 pagesNORSOK-L-002 (July 2009) - Piping-Layout-&-AnalysisNils Antoine FreundNo ratings yet

- Method Statement For Construction of Slipform TechnoclogyDocument10 pagesMethod Statement For Construction of Slipform TechnoclogySmart ShivaNo ratings yet

- Factory Rules 1979Document48 pagesFactory Rules 1979Jewel RanaNo ratings yet

- 01 Cital KPW Sea Presentation r3Document31 pages01 Cital KPW Sea Presentation r3daveNo ratings yet

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Uploaded by

Cipta Rupa PertamaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Tasnim349,+46 Article+Text 742 3 11 20210325 - 8.17

Uploaded by

Cipta Rupa PertamaCopyright:

Available Formats

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

Research Article Open Access

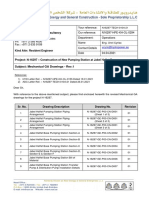

THE APPLICATION OF JOB SAFETY ANALYSIS (JSA)

METHOD IN IDENTIFYING THE RISK OF WORK

ACCIDENTS IN CHARGED MANPOWER IN BUNGKUTOKO

PORT, KENDARI CITY

Muh. Yamin Samma1, Erwin Azizi Jayadipraja2,Azis Harun3

1,2,3

Magister of Public Health Study Program, College of Health Sciences Mandala

Waluya Kendari, Southeast Sulawesi, Indonesia

Corresponding Author : Muh. Yamin Samma

Email : muhyamin0780@gmail.com

Abstract

Background: Data from the Ministry of Manpower of the Republic of Indonesia that the number of

work accidents in Indonesia in 2016 was 101,368, in 2017 there were 123,041 cases, in 2018 there were

173,415 cases. At the end of September 2019 there were 130,923 cases and there were 6 people who

died every day. On September 2019, the sectors that contributed to the relatively large number of work

accidents were the processing industry with 50,358 (38.46%) cases, trade of 9,559 (7.30%) cases,

transportation and warehousing 2,694 (2.06%) cases, and the rest 68,312 (52.18%) cases from other

sectors. The same thing was reported by the Social Security Administration for Employment that there

was an increase in work accidents by 40%, from 157,313 in 2018 to 173,105 cases in 2019.

Methods: This research is quantitative research with a descriptive analytic research design and applied

observational analytic approach. The population of all loading and unloading workers was 150 people

divi ded into 3 teams, where each team consisted of 50 TKBM members of Bungkutoko Port, Kendari

City.

Result: This study found 3 work stages with the highest RPN value, namely, wrong in the lifting

position in the stevedore of work process at the time workers lift goods and put them into the net, as

well as in the cargodore of work process when workers stack goods on the truck with a value of 288,

stumbling (cargo) which occurs in the stevedoring work process where The worker on the truck directs

the crane and the net into the truck body with an RPN value of 192, and pinched by a lifting tool in the

cargodore of work process when workers remove goods from the sling on the truck / remove the sling,

with a value of RPN 144.

Conclusion: There were 3 loading and unloading work processes, namely, stevedoring, cargodoring,

and delivery with each work stage having potential hazards, the impact of hazards, and control efforts,

and the person in charge of control efforts.

Key words: work accident, stevedoring, cargodoring, delivery

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

8

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

INTRODUCTION Sulawesi Province, has a land area of 70,700

Occupational Safety and Health is a m2, 18,236 m2 of landfill, 1200 m2 of

science to anticipate, recognise, evaluate and warehouse, and 388 m2 of office.

control hazards that arise in the workplace Meanwhile, the sea side has a dock area of

which can have an impact on the health and 4,000 m2, -8 Mlws depth, 1,648 m2 Trestle,

well-being of workers, as well as the impacts and 1,200 m2 Causeway. With these

that may be felt by the surrounding facilities, Bungkutoko Port can be berthed by

community and the general environment(1). ships weighing 6,000 DWT. In future

As industrialization and globalization development, Bungkutoko Port is not only a

develop as well as advances in science and container port, but also serves as a

technology, occupational safety and health multipurpose port. The port is also one of the

are also growing. Law Number 1 of 1970 ports that is busy with ships carrying

concerning safety as the legal basis for passengers and shipping goods between

implementing Occupational Safety and islands, the number of loading and unloading

Health in Indonesia has been strengthened by workers is around 150 people, divided into 3

the issuance of Law Number 36 of 2009 teams(5).

concerning Health where in articles 164-165 At a glance, it can be seen that there

concerning occupational health it is stated are many potential hazards of potential

that all workplaces are required to implement hazards that threaten every work process

occupational health efforts both in the sector. carried out by workers that can result in

formal and informal including the State Civil accidents, material loss for workers and the

Apparatus, INA and Police(2). company, death, decreased quality and

Data from the Ministry of Manpower quantity of production, as well as hazards to

of the Republic of Indonesia states that the the surrounding environment(6). The

number of work accidents in Indonesia in operation of lifting and transportation aids

2016 was 101,368, in 2017 there were such as Rubber Tyred Gantry Cranes (TGC)

123,041 cases, in 2018 there were 173,415 and cranes for loading and unloading

cases, and at the end of September 2019 activities at Bungkutoko Port has resulted in

there were 130,923 cases, and there were 6 many workers experiencing injuries, such as

people who died every day. As of September being pinched and hit by tools and cargo.

2019, the sectors that contributed to the Based on an interview with one of the

relatively large number of work accidents managers of the Tunas Bangsa Mandiri

were the processing industry with 50,358 TKBM at Bungkutoko Port, he said that in

(38.46%) cases, trade of 9,559 (7.30%) the last 3 (three) years from 2017 to 2019

cases, transportation and warehousing 2,694 several physical complaints that loading and

(2.06%) cases, and the rest 68,312 (52.18%) unloading workers often complained about

cases from other sectors(3). every day were low back pain, back pain,

The same thing was reported by the pain / neck tension, shoulder pain and

Social Security Administering Body for sprains, hand pain, and other health

Employment that there was an increase in problems, such as coughing and dizziness. In

work accidents by 40%, from 157,313 in 2019 to 2020 there were 3 (three) serious

2018 to 173,105 cases in 2019. BPJS work accidents, namely 1 person was injured

Ketenagakerjaan data from Southeast / scratched by cargo, 5 people tripped over

Sulawesi Province recorded an increase in cargo, 1 person fell from the transport truck

cases from 2017 which only 23 (8.21%) and suffered a fracture. The three cases of

cases, in 2018 84 (30%) cases and in 2019 accidents have been handled well, the

jumped sharply to 173 (61.79%) cases(4). workers received medical care, however,

Bungkutoko Port, which is located in there are also some who only undergo

Abeli District, Kendari City, Southeast traditional healers or massage treatments. It

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

8

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

was further explained that all loading and shows that 14 people aged 21-28 years

unloading workers were provided with health (23.3%), 19 respondents aged 29-36 years

insurance in the form of a Jamsostek card (31.7%), 37 respondents aged -44 years as

and collaborated with BPJS employment. many as 14 people (23.3%), and respondents

Occupational accidents and health problems aged 45-52 years as many as 13 people

are still frequently experienced by workers, (21.7%) (Table 2).

but these incidents are not well documented Table 2

and because workers consider them to be Frequency Distribution Based on the Age

occupational risks for them. of TKBM at the Port Bungkutoko,

Kendari City

METHOD Age n %

This research is a type of quantitative 21-28 years 14 23.3

29-36 years 19 31.7

research, using a cross-sectional design(7).

37-44 years 14 23.3

The research approach used was 45-52 years 13 21.7

observational. The population is all loading Total 60 100

and unloading workers as many as 150

people who are divided into 3 teams, where The frequency distribution of TKBM

each team consists of 50 TKBM members of at Bungkutoko Port, Kendari City based on

Bungkutoko Port, Kendari City. In this tenure shows that 32 respondents with a

study, the researchers took a sample of 20 service period of <2 years (53.3%) and a

people from each team, so that the total service period of> 2 years (46.7%) (Table

sample size was 60 people. The data were 3).

collected by using purposive sampling Table 3

method(8). TKBM Frequency Distribution at

Bungkutoko Port, Kendari City Based on

RESULT the Service Period

Years of n %

The number of lift and transport service

equipment at Bungkutoko Kendari Port, <2 Years 32 53.3

there are 6 lift and transport aircraft used > 2 Years 28 46.7

Total 60 100

including 1 unit of reach stacker, 1 unit of 32

ton forklifts, 2 units of 7 ton forklifts, 1 unit

of 5 ton forklifts, and mobile cranes. 30 tons Worksheet Job Safety Analysis (JSA)

as much as 1 unit (Table 1). The Stevedoring Work Process at

Table 1 Bungkutoko Port, Kendari City, there are 4

Frequency Distribution of the Number of work stages, namely, workers enter the barge

Lift and Transport Equipment at / hold, workers lift goods and enter into the

Bungkutoko Port, Kendari City net, lifting goods in the net using a crane to a

Type of Aircraft and Number of transport truck, and The worker on the truck

Transport Tools (unit) directs the crane and the net into the truck's

Reach Stacker 1 body, with 19 potential hazards that can lead

Forklift 32 tons 1 to work accidents (Table 4).. Efforts to

Forklift 7 tons 2 control are attempted by the person in

Forklift 5 tons 1

charge, in this case the TKBM manager,

Mobile Crane 30 Tons 1

Total 6

field supervisors, port K3 staff and TKBM

foremen to minimize the potential risk of

The frequency distribution of TKBM work accidents.

at Bungkutoko Port, Kendari City by age

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

9

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

Table 4

Job Safety Analysis Worksheet (JSA) Stevedoring Work Process at Bungkutoko Harbor,

Kendari City

Work Stage Potential hazard Potential Risks Control Responsible

1. Workers enter Dropped into the Wounds, fractures Need caution and

the barge / hold hold put up warning

signs

Fall into the sea Drowning, death Need caution and

put up traffic

warning signs

Slip Wounds, injuries Use complete PPE,

namely a helmet,

vest, safety shoes,

and gloves

Stumble Wounds, fractures Use complete PPE,

namely a helmet,

vest, safety shoes,

and gloves

2. Workers lift Sun exposure Dehydration, Using complete

goods and put fatigue PPE, namely

them in the net helmets, vests,

safety shoes and

gloves, as well as

setting rest hours

and providing

drinking water at

work for workers.

Exposure to dust Respiratory Use complete PPE,

disorders, eye namely helmets, TKBM managers,

irritation vests, safety shoes, field supervisors,

and masks. port K3 staff,

Stuck by goods Injuries, broken Use complete PPE, foremen

bones namely a helmet,

vest, safety shoes,

and gloves

Got hit by a tool Wounds, injuries, Use complete PPE,

fractures namely a helmet,

vest, safety shoes,

and gloves

Fatigue Error in lifting Rest hour setting

Wrong lifting Back pain, joint Adjusting the rest

position injuries time, stretching

after working for a

long time,

increasing

knowledge of

ergonomics of

correct lifting

procedures and

positions.

3. Lifting goods Stuck by goods Injuries, broken Use complete PPE,

in the net using bones namely a helmet,

a crane to the vest, safety shoes,

transport truck and gloves

Got hit by a tool Wounds, injuries, Use complete PPE,

fractures namely a helmet,

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

10

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

vest, safety shoes,

and gloves

Exposure to dust Respiratory Use complete PPE,

disorders, eye namely helmets,

irritation vests, safety shoes,

and masks.

The sling broke Injuries, broken Use complete PPE,

bones, death namely a helmet,

vest, safety shoes,

and gloves

4. The worker on The sling broke Injuries, broken Use complete PPE,

the truck bones, death namely a helmet,

directs the vest, safety shoes,

crane and net and gloves

into the truck Stuck by goods Injuries, broken Improve work

body. bones concentration

(focus), wear PPE,

namely helmets,

vests, safety shoes,

gloves

Sandwiched in Wounds, fractures Improve work

the back of a concentration

truck (focus), wear PPE,

namely helmets,

vests, safety shoes,

gloves

Slip Wounds, injuries Improve work

concentration

(focus), wear PPE,

namely helmets,

vests, safety shoes,

gloves

Stumble Wounds, injuries Improve work

concentration

(focus), wear PPE,

namely helmets,

vests, safety shoes,

gloves

Job Safety Analysis Worksheet(JSA) The Cargodoring Work Process at Bungkutoko

Port, Kendari City, there are 2 work stages, namely, Removing goods from the sling on the

truck / removing the slings and arranging the goods on the truck, with 11 potential hazards

that can risk causing work accidents. Efforts to control are attempted by the person in charge,

in this case the TKBM manager, field supervisors, port K3 staff and TKBM foremen to

minimize the potential risk of work accidents (Table 5).

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

11

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

Table 5

Worksheet Job Safety Analysis (JSA) Cargodoring Work Process at Bungkutoko Port, Kendari

City

Potential Potential

Work Stage

hazard Risks

Control Responsible

1. Unload the goods Slip Wounds, Improve work

from the slings on the fractures concentration (focus),

truck / remove the wear PPE, namely

slings helmets, vests, safety

shoes, gloves

Stuck by goods Dead Improve work

concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Clamped in the Wounds, Improve work

lift fractures concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Stumble Wounds, Improve work

injuries concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Sun exposure Dehydration, Using complete PPE,

fatigue namely helmets, vests,

safety shoes and gloves,

as well as setting rest

hours and providing TKBM

drinking water at work managers, field

for workers. supervisors,

Exposure to dust Respiratory Use complete PPE, port K3 staff,

disorders, namely helmets, vests, foremen

eye irritation safety shoes, gloves, and

masks

2. Stacking goods on Dust exposure Respiratory Use complete PPE,

the truck. disorders, namely helmets, vests,

eye irritation safety shoes, gloves, and

masks

Fell Wounds, Improve work

injuries concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Stuck by goods Wounds, Improve work

fractures concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Sun exposure Dehydration, Using complete PPE,

fatigue namely helmets, vests,

safety shoes and gloves,

as well as setting rest

hours and providing

drinking water at work

for workers.

Wrong lifting Back pain, Adjusting the rest time,

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

12

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

position joint injuries stretching after working

for a long time,

increasing knowledge of

ergonomics of correct

lifting procedures and

positions.

Worksheet Job Safety Analysis (JSA) The Delivery Work Process at Bungkutoko

Port, Kendari City, there is 1 work stage, namely, Moving goods from a warehouse or

accumulation field onto trucks, with 5 potential hazards that can risk causing work accidents.

Efforts to control are attempted by the person in charge, in this case the TKBM manager,

field supervisors, port K3 staff and TKBM foremen to minimize the potential risk of work

accidents (Table 6)..

Table 6

Worksheet Job Safety Analysis (JSA) Delivery Work Process at the Port

Bungkutoko, Kendari City

Work Stage Potential hazard Potential Risks Control Responsible

Moving goods Stuck by goods Broken bones, Improve work

from the death concentration (focus),

warehouse or wear PPE, namely

yard onto helmets, vests, safety

trucks shoes, gloves

Stumble Wounds, fractures Improve work

concentration (focus),

wear PPE, namely

helmets, vests, safety

shoes, gloves

Pinched Wounds, injuries Improve work

concentration (focus), TKBM managers,

wear PPE, namely

field supervisors,

helmets, vests, safety

port K3 staff,

shoes, gloves

foremen

Sun exposure Dehydration, Using complete PPE,

fatigue namely helmets,

vests, safety shoes

and gloves, as well as

setting rest hours and

providing drinking

water at work for

workers.

Exposure to dust Respiratory Use complete PPE,

disorders, eye namely helmets,

irrigation vests, safety shoes,

gloves, and masks

Hazard identification during the loading and unloading process shows that the

stevedoring section identified 60 hazards (100%), 60 hazards (100%) identified in the

cargodoring section and 60 hazards (100%) in the delivery section (Table 7)..

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

13

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

Table 7

Hazards Identification During the Loading and Unloading Process at Bungkutoko Port

Kendari City uses the Job Safety Analysis (JSA)method

Loading and Unloading Process

Hazard

Stevedoring Cargodoring Delivery

Identification

n % n % n %

There is 60 100 60 100 60 100

There is no 0 0 0 0 0 0

Total 60 100 60 100 60 100

DISCUSSION unloading activities, both multipurpose ports

Identification of the hazards of work and container ports.

accidents using the JSA method for The following are the stages in making

loading and unloading workers at JSA loading and unloading activities at the

Bungkutoko Port, Kendari City port of Bungkutoko, Kendari City: a)

JSA is a technique that focuses on the Determine the type of job and the name of

stages of work as a way to identify hazards the worker. In this case the loading and

before unwanted events occur(9). This unloading activities carried out by TKBM at

technique focuses more on the interaction Bungkutoko Port consist of 3 types of work

between workers, job tasks, equipment and processes, namely: stevedoring, cargodoring,

the work environment. Once it is known the and delivery; b)Determine the work stages of

hazards present at the work stage, efforts are each work process. In the stevedoring work

made to eliminate or reduce the hazard risk process there are 4 work stages, namely:

to an acceptable level. JSA is very important workers enter the barge / hold, workers lift

to be able to determine and establish work goods and put them into the net, lifting goods

procedures appropriately so that occupational in the net using a crane to the transport truck,

accidents and occupational diseases can be and workers on the truck directing the crane

prevented when workers carry out a good and the net into the truck bag room. In the

work procedure. cargodoring work process, there are 2 work

JSA is a procedure used to review a stages, namely: removing the goods from the

method or way of working and determine sling on the truck / removing the slings and

hazards that may have previously been arranging the goods on the truck. Whereas in

overlooked in the laying of a factory or the delivery work process, there is only a job

building on the design of machines, work of moving goods from the warehouse or

tools, materials, work environment, and storage field onto trucks. c) Determine the

process (10). JSA is an analysis of work potential hazards of each stage of work. In

safety in an activity in the form of safe work this case, the hazard is a potential that can

recommendations based on the potential cause work accidents to TKBM. In general,

hazards that may arise in each sequence of there are types of occupational accident

work steps(11). hazards in the loading and unloading

In the loading and unloading process at activities carried out by TKBM, namely:

Bungkutoko port, there are 3 main activities, falling, slipping, tripping, being hit by

namely stevedoring, cargodoring, and objects, being hit by tools, exposed to

delivery which are carried out for 8 hours sunlight, exposure to dust, fatigue, incorrect

every day. This activity is a loading and lifting positions, broken slings, and being

unloading activity which is generally carried pinched by tools.

out at every seaport that serves loading and In the stevedoring work process, based

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

14

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

on table 4 of the Job Safety Analysis (JSA) include slipping, being hit by objects, being

worksheet, the stevedoring work process at pinched by lifting equipment, tripping,

Bungkutoko Port, Kendari City,there are 19 exposure to sunlight, exposure to dust,

potential hazards. Common potential hazards falling, and wrong lifting positions

that can cause work accidents include falling This is confirmed by research (15),

into a hold, falling into the sea, slipping, against the loading and unloading workers at

tripping, exposure to sunlight, exposure to Teluk Nibung Janjung Balai Asahan Port,

dust, being hit by objects, being hit by tools, stated that in the cargodoring work process

fatigue, incorrect lifting positions, broken there are 9 hazards that can cause accidents

slings, and being caught in the tub. truck. consisting of 5 physical hazards, namely

This is confirmed by research(12), At direct exposure to sunlight, wheelbarrows

the Port of Tanjung Perak, Surabaya, it was sliding without control, scattered piles of

stated that the hazards identified in the goods, fall because they are entangled in

manual loading and unloading work of ropes that are scattered in the warehouse, the

porters at Kalimas Terminal, Tanjung Perak uneven floor of the warehouse can cause

Port, Surabaya were 46 potential hazards, the workers to trip. Workers lift and arrange

highest risk value from the risk analysis was goods repeatedly when arranging goods,

15, namely the danger of falling and being workers often do this by bending so that in

hit. this condition workers are at risk of

The results of this study are in line with experiencing low back pain. The potential

the research(13),regarding the Loading and for these hazards is in line with research

Unloading Workers (TKBM) at the Port of by(16), unnatural work postures and

Tanjung Emas in Semarang, occupational slouching overly cause musculoskeletal

safety and health risks that are often complaints.

experienced by workers at the port include The results of this study are in line with

muscle or musculoskeletal disorders due to the research (17),regarding the Loading and

non-ergonomic conditions, injuries due to Unloading Workers (TKBM) at the Port of

collisions, falls, slips, fractures, and even Tanjung Emas in Semarang, occupational

died from being crushed by a load. Data on safety and health risks that are often

occupational accidents (including deaths) that experienced by workers at the port include

occurred on loading and unloading Workers muscle or musculoskeletal disorders due to

(TKBM) at Tanjung Emas Port Semarang in non-ergonomic conditions, injuries due to

2011 were 14 people, 2012 were 19 people, collisions, falls, slips, fractures, and even

2013 were 22 people, in 2015 were 6 people, died from being crushed by a load.

and in 2016 were January to April as many as In the delivery work process, based on

12 people. table 6, the Worksheet Job Safety Analysis

Other research results, namely research (JSA) for the delivery work process at

(14), shows that most of the workers on the Bungkutoko Port, Kendari City, there is 1

stevedoring and receiving port of Tapaktuan job activity and 5 potential hazards were

Aceh are exhausted. One of the factors that found. Potential hazards that can cause work

can affect fatigue includes the opportunity to accidents, namely falling objects, tripping,

change attitudes or work positions, clothing, pinching, exposure to sunlight, and exposure

shoes, floor conditions and work shifts. to dust.

In the cargodoring work process, based This is confirmed by research(18), on

on table 5, the Job Safety Analysis (JSA) the loading and unloading workers at Teluk

worksheet for the cargodoring work process Nibung Port, Tanjung Balai Asahan, stated

at Bungkutoko Port, Kendari City, there are that in the delivery work process there were 9

11 potential hazards. Common potential potential hazards that could cause accidents

hazards that can cause work accidents consisting of 6 potential physical hazards,

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

15

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

namely, being pinched and the danger of (supervisors), TKBM Foremen. Supervisors

falling goods from goods carried by workers. or workers, both of them work together in

a) Determine the risk of each hazard that has implementing the JSA that has been created.

been identified. Risk is the result of danger if In general, the supervisor is responsible for

it causes an accident. There are various types making the JSA, documenting the JSA form,

of risks from hazards at each stage of the providing training to all TKBM as stated on

loading and unloading process carried out by the JSA form and enforcing safe and efficient

TKBM ranging from minor risks, such as work procedures. d)JSA form that has been

injuries, injuries, dehydration, fatigue, approved by the supervisor with the signature

respiratory problems / irritation, lumbago, and full name of the supervisor. The form is

joint injuries, wounds, fractures to the proof of commitment and guidance in

heaviest risks such as , drowning and wounds ensuring that the form covers all stages of

which can cause death. This is confirmed by work to be carried out in the field. e)The JSA

research(19), regarding the Loading and form then received approval from the Safety

Unloading Workers (TKBM) at the Port of Manager, evidenced by the signature and

Tanjung Emas in Semarang, occupational clear name of the Safety Manager as the party

safety and health risks that are often responsible for ensuring that everything

experienced by workers at the port include written in the JSA form has met the safety

muscle or musculoskeletal disorders due to aspects of the work. f)Each TKBM team

non-ergonomic conditions, injuries due to member puts a signature on the JSA form, so

collisions, falls, slips, fractures, and even that all team members are aware of it and as

died from being crushed by a load. evidence that the JSA form has been

b)Determine the most effective control socialized to all team members. g)The JSA

measures to reduce the risk of each potential Form is complete and must be documented

hazard at the stage of work. There are various and disseminated to related parties.

risk control efforts including: need to be

careful warning and put up warning signs, .

use complete PPE, namely helmets, vests, REFERENCES

safety shoes, gloves, and masks, regulating 1. Van Daele J. The International Labor

rest periods, stretching after working for a Organization (ILO) in past and present

long time, increasing knowledge about research. International Review of Social

ergonomics of proper lifting procedures and History. 2008; 53 (3): 485-511.

positions, as well as increasing concentration 2. Nazirah R, Yuswardi Y. Nurse Behavior

(focus) at work. in the Implementation of Occupational

This is confirmed by research Health and Safety Management (K3) in

(20),states that the design of Aceh. Idea nursing journal. 2017; 8 (3).

recommendations or proposed improvements 3. Khairunnisa K. Report on Field Work

is carried out based on the hazards that occur. Practices (PKL) at the Ministry of

It aims to find a solution for all problems Manpower of the Republic of Indonesia.

from existing hazard sources. With the 2019.

proposed improvement, the Bungkutoko Port 4. BPJS of Employment. BPJS

and TKBM Management can reduce the Ketenagakerjaan Data for Southeast

accident rate and prevent similar accidents Sulawesi Province 2019.

from before. c)Determine the party who is 5. Tunas Bangsa Mandiri Cooperative.

responsible and committed to carrying out Profile of Bungkutoko Port, located in

such control efforts. Some parties who are Abeli District, Kendari City, Southeast

competent in the loading and unloading Sulawesi Province 2019.

process at the port are TKBM Managers, 6. Faniah AM, Suwaji MK. Factors

Field Supervisors, Port K3 staff Related To Compliance With The Use

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

16

Samma, M.Y., E.A. Jayadipraja, & A. Harun.

DOI: 10.36566/ijhsrd/Vol3.Iss1/46

https://ijhsrd.com/index.php/ijhsrd

e- ISSN: 2715-4718

Of Apd Earplugs And Gloves In Repair 15. Saragih¹ WL, Mahyuni EL, Lubis AM.

Unit Workers AT PT. Kai Daop VI Assessment of Work Accident Risk in

Yogyakarta Dipo Solo Racing: Loading and Unloading Workers at

Muhammadiyah University Surakarta; Teluk Nibung Port, Tanjung Balai

2016. Asahan in 2015. University of North

7. Mackey A, Gass SM. Second language Sumatra; 2015.

research: Methodology and design: 16. Utami U, Karimuna SR, Jufri NN.

Routledge; 2015. Relationship of Length of Work, Work

8. Sugiyono. Nonparametric Statistics for Attitude and Workload with

Research. 2015. Musculoskeletal Disorders (MSDs) on

9. Simanjuntak RA, Abdullah R. Overview Rice Farmers in Ahuhu Village, Meluhu

of Systems and Performance District, Konawe Regency in 2017.

Management of Underground Mine (Public Health Student Scientific

Safety & Health CV. Tahiti Coal, Journal). 2017; 2 (6).

Talawi, Sawahlunto, West Sumatra. 17. Prasetio DB, Aryani I, Meikawati W.

Mine Development. 2018; 3 (4): 1536- Risk Assessment of Loading and

45. Unloading Work at Nusantara Tanjung

10. Ilmansyah Y, Mahbubah NA, Emas Port, Semarang. 2016.

Widyaningrum D. Implementation of 18. Ramisdar IO. Analysis of Work

Job Safety Analysis as an Effort to Accident Risk in the Loading and

Prevent Work Accidents and Improve Unloading Process Using the Job Safety

Work Safety at Pt Shell Indonesia. Analysis (JSA) Method and the Hazard

Proficiency. 2020; 8 (1): 15-22. and Operability Study (HAZOPs) at PT

11. Widiantoro O, Kusnan K, Suparji S, Pelindo IV (Persero) Makassar

Rijanto T. Differences in Learning Container Terminal: Alauddin Makassar

Outcomes Using Direct Learning Islamic State University; 2019.

Models Viewed from Spatial Ability: 19. Kurniawan Y, Kurniawan B, Ekawati E.

Study At Basic Survey Working Lesson Knowledge Relationship, Fatigue,

in the Engineering Surveying. Physical Workload, Body Posture at

International Journal for Educational and Work, and Attitudes of Using Apd with

Vocational Studies. 2020; 2 (4). Occupational Accidents (Studies on

12. Husna FA. Compliance with the use of Manual Lifting Activities in the

personal protective equipment for Fertilizer Packaging Unit of Tanjung

loading and unloading workers (TKBM) Emas Port Semarang) Journal of Public

of ships at Belawan Harbor, the working Health (e-Journal). 2018; 6 (4): 393-401.

area of the Class 1 Port Health Office 20. Restuputri DP, Sari RPD. Work accident

(KKP) in Medan. 2019. analysis using the Hazard and

13. Aryani I. Risk assessment on log loading Operability Study (HAZOP) method.

and unloading work (Study at the Deep Industrial Engineering Scientific

Port of Tanjung Emas in Semarang): Journal. 2015; 14 (1): 24-35.

UNIMUS; 2016.

14. Medianto D. Factors Associated with

Work Fatigue in the Loading and

Unloading Workers (TKBM) at the Port

of Tanjung Emas, Semarang (Study on

TKBM Workers in the Fertilizer

Packing Unit): Muhammadiyah

University of Semarang; 2017.

Indonesian Journal Of Health Sciences Research and Development

Vol. 3, No.1, March 2021

17

You might also like

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocument31 pagesGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher50% (2)

- Activity Hazard AnalysisDocument43 pagesActivity Hazard AnalysisShawn James100% (4)

- 6.method Statement Steel Erection and CladdingDocument4 pages6.method Statement Steel Erection and Claddingشاز إياسNo ratings yet

- Mechanical GA Drawings - Rev.1Document14 pagesMechanical GA Drawings - Rev.1unnicyriacNo ratings yet

- UntitledDocument10 pagesUntitledROOTH GAMINGNo ratings yet

- Awareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyDocument8 pagesAwareness of Construction Workers On Occupational Hazards, Illness and Injuries Associated With Construction Industry in Mombasa CountyIOSRjournalNo ratings yet

- 2 Analysis of Factors Influencing Work Accidents in The Roduction Section at PT Industri Kapal Indonesia (Persero)Document17 pages2 Analysis of Factors Influencing Work Accidents in The Roduction Section at PT Industri Kapal Indonesia (Persero)tutita tari muslimNo ratings yet

- Bab 1Document9 pagesBab 1Kelana FactoryNo ratings yet

- Faktor-Faktor Yang Berhubungan Dengan Perilaku Pekerja Dalam Penggunaan Apd Di Sentra Pengasapan Ikan Kelurahan Bandarharjo Kota SemarangDocument10 pagesFaktor-Faktor Yang Berhubungan Dengan Perilaku Pekerja Dalam Penggunaan Apd Di Sentra Pengasapan Ikan Kelurahan Bandarharjo Kota SemarangFajri AnsyahNo ratings yet

- Journal of Vocational Health StudiesDocument6 pagesJournal of Vocational Health Studiesfaisal mujtamiNo ratings yet

- 551-Article Text-1455-1-10-20230209Document9 pages551-Article Text-1455-1-10-20230209Chandra PratamaNo ratings yet

- 4346 6390 1 SM PDFDocument12 pages4346 6390 1 SM PDFAhmad DikaNo ratings yet

- Jurnal Bpi 2021Document15 pagesJurnal Bpi 2021Izmi DwivasariNo ratings yet

- My ProposalDocument10 pagesMy ProposalNassazi BeatriceNo ratings yet

- Work Accident Risk at Hospital Construction EnvironmentDocument8 pagesWork Accident Risk at Hospital Construction EnvironmentArya DdpNo ratings yet

- Pharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuDocument10 pagesPharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. Kawatukaren.No ratings yet

- 2289-Article Text-5947-1-10-20221202Document8 pages2289-Article Text-5947-1-10-20221202Raditya RaffaNo ratings yet

- Pelaksanaan Serta Pemantauan Evaluasi Kinerja K3 Dan Implikasinya Terhadap Kejadian Kecelakaan Kerja Di PTPN Iii Tebing Tinggi Tahun 2017Document11 pagesPelaksanaan Serta Pemantauan Evaluasi Kinerja K3 Dan Implikasinya Terhadap Kejadian Kecelakaan Kerja Di PTPN Iii Tebing Tinggi Tahun 2017Budiz AlNurNo ratings yet

- Identifikasi Risiko Kecelakan Kerja Terhadap Pekerja Di PT. IKI Makassar Tahun 2020 (Studi Pada Pekerja Proses Marking)Document9 pagesIdentifikasi Risiko Kecelakan Kerja Terhadap Pekerja Di PT. IKI Makassar Tahun 2020 (Studi Pada Pekerja Proses Marking)Rachmat GurnidaNo ratings yet

- Analisa Penerapan Hiradc Di Tempat KerjaDocument7 pagesAnalisa Penerapan Hiradc Di Tempat KerjaBucit SupriadiNo ratings yet

- 1633-Article Text-6645-1-10-20200925Document12 pages1633-Article Text-6645-1-10-20200925Dea Widya HutamiNo ratings yet

- Lensoni 2018Document6 pagesLensoni 2018Kelana FactoryNo ratings yet

- Hubungan Perilaku Dan Sikap Pekerja Pengangkut Sampah Dengan Penggunaan Alat Pelindung Diri Di Kampung Jawa Banda AcehDocument6 pagesHubungan Perilaku Dan Sikap Pekerja Pengangkut Sampah Dengan Penggunaan Alat Pelindung Diri Di Kampung Jawa Banda AcehKelana FactoryNo ratings yet

- Jurnal Penerapan K3 1 PDFDocument5 pagesJurnal Penerapan K3 1 PDFmaulana ichsanNo ratings yet

- JurnalDocument8 pagesJurnalrendysmith098No ratings yet

- 106-Article Text-261-1-10-20181101Document10 pages106-Article Text-261-1-10-20181101Mori Shan24No ratings yet

- Skidujopas258 26585Document8 pagesSkidujopas258 26585Jessymay ZenarosaNo ratings yet

- 57-Article Text-101-1-10-20230315Document7 pages57-Article Text-101-1-10-20230315ozitranscellcomNo ratings yet

- 1 s2.0 S2093791122000439 MainDocument10 pages1 s2.0 S2093791122000439 MainCsanyi EditNo ratings yet

- The Application of The Job Safety Analysis Method in The Identification of Potential Hazards in Pipe Division Workers, West SumatraDocument7 pagesThe Application of The Job Safety Analysis Method in The Identification of Potential Hazards in Pipe Division Workers, West SumatraAndreas SiagianNo ratings yet

- 1 PBDocument15 pages1 PByuelakhbrNo ratings yet

- Trauma Survey Due To Work in The Lumajang District Agriculture AreaDocument12 pagesTrauma Survey Due To Work in The Lumajang District Agriculture AreavinniNo ratings yet

- Public Health Perspectives Journal: Feramida Yuliya Edison, Soesanto Soesanto, Yuni WijayantiDocument12 pagesPublic Health Perspectives Journal: Feramida Yuliya Edison, Soesanto Soesanto, Yuni WijayantiSutrimah KediriNo ratings yet

- Kecelakaan KerjaDocument11 pagesKecelakaan Kerjadata rabiqyNo ratings yet

- Safety and Health Risk MGT On Consruction SiteDocument152 pagesSafety and Health Risk MGT On Consruction SiteSandhya Nundah50% (2)

- Occupational Exposures and Related Health Effects Among Construction WorkersDocument6 pagesOccupational Exposures and Related Health Effects Among Construction WorkersabdishNo ratings yet

- Defining Safety Hazards & Risks in Mining Industry: A Case-Study in United StatesDocument9 pagesDefining Safety Hazards & Risks in Mining Industry: A Case-Study in United StatesJudith MungombeNo ratings yet

- LSMR-19 Vol2010Document12 pagesLSMR-19 Vol2010Vivek SharmaNo ratings yet

- 1 PBDocument11 pages1 PBGumchyyy BubbleNo ratings yet

- Pharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuDocument8 pagesPharmacon: Stevanus Yonathan Kalalo, Wulan P.J. Kaunang, Paul A.T. KawatuSandy ElkaNo ratings yet

- ID Analisis Faktor Yang Berpengaruh Terhadap Pelaksanaan Peka Pengamatan KDocument11 pagesID Analisis Faktor Yang Berpengaruh Terhadap Pelaksanaan Peka Pengamatan Knar udinNo ratings yet

- QS 6Document9 pagesQS 6PUTRI NADIA RO PAE INGNo ratings yet

- Safety and Health in Mining: Part 1Document11 pagesSafety and Health in Mining: Part 1Leonel CanoNo ratings yet

- Assessment of Ergonomic Hazards in Workstations and The Effects On Selected Public ServantsDocument6 pagesAssessment of Ergonomic Hazards in Workstations and The Effects On Selected Public ServantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analisis Faktor Yang Berhubungan Dengan Penyakit Akibat Kerja Pada Karyawan Smelter X' Industri Tahun 2020Document12 pagesAnalisis Faktor Yang Berhubungan Dengan Penyakit Akibat Kerja Pada Karyawan Smelter X' Industri Tahun 2020krisma mahendraNo ratings yet

- Occupational Health Safety and Organizational Commitment Evidence From Ghanaian Mining IndustryDocument23 pagesOccupational Health Safety and Organizational Commitment Evidence From Ghanaian Mining IndustryAce Jae BautistaNo ratings yet

- Safety Driving Pada Operator Forklift Di PertambanDocument9 pagesSafety Driving Pada Operator Forklift Di PertambanMuhammad khalid AlhafizhNo ratings yet

- Maxillofacial Trauma With Head Injuries at A Tertiary Care Hospital in Chitwan, Nepal: Clinical, Medico-Legal, and Critical Care..Document9 pagesMaxillofacial Trauma With Head Injuries at A Tertiary Care Hospital in Chitwan, Nepal: Clinical, Medico-Legal, and Critical Care..Muhammad RizqiNo ratings yet

- Occupational Health and Safety of WorkerDocument37 pagesOccupational Health and Safety of Workeraritra sahaNo ratings yet

- IJWC.23 YilmazBurgazogluMan 22.35Document14 pagesIJWC.23 YilmazBurgazogluMan 22.35Joanna KuterNo ratings yet

- 7244 24935 1 SMDocument18 pages7244 24935 1 SMSamantha Meril PandithaNo ratings yet

- Factors Related To Road Accidents in Palembang, South Sumatera, IndonesiDocument8 pagesFactors Related To Road Accidents in Palembang, South Sumatera, IndonesiIJPHSNo ratings yet

- Accident Cost MiningDocument8 pagesAccident Cost MiningAnand sharmaNo ratings yet

- Improving Safety Performance Through Safety Leadership and Safety BehaviorsDocument8 pagesImproving Safety Performance Through Safety Leadership and Safety BehaviorsEverson MurungweniNo ratings yet

- Advances in Occupational Health and Safety ManagementDocument196 pagesAdvances in Occupational Health and Safety Managementdanielelage.advNo ratings yet

- BOSH Module 2Document8 pagesBOSH Module 2Meralie CapangpanganNo ratings yet

- In-Depth Analysis of Workplace Accidents in Food Processing Company in The PhilippinesDocument9 pagesIn-Depth Analysis of Workplace Accidents in Food Processing Company in The PhilippinesJastine AnneNo ratings yet

- Journal of Safety ResearchDocument17 pagesJournal of Safety ResearchJane Eilyza AballaNo ratings yet

- Gambaran Pelaksanaan Program Promosi K3 Pada PT Pertamina Trans Kontinental Jakarta Tahun 2018 Irenia Tennovia Yulius, Siti Rahmah H. LubisDocument13 pagesGambaran Pelaksanaan Program Promosi K3 Pada PT Pertamina Trans Kontinental Jakarta Tahun 2018 Irenia Tennovia Yulius, Siti Rahmah H. LubisArisgaSufanaNo ratings yet

- Assessment of Health, Safety and Environment Procedures in Technical Colleges' Workshops in Rivers StateDocument6 pagesAssessment of Health, Safety and Environment Procedures in Technical Colleges' Workshops in Rivers Statepaul okwelleNo ratings yet

- IMSP Symposium 23Document106 pagesIMSP Symposium 23Sanjeev BhardwajNo ratings yet

- Unmaking the Global Sweatshop: Health and Safety of the World's Garment WorkersFrom EverandUnmaking the Global Sweatshop: Health and Safety of the World's Garment WorkersNo ratings yet

- 20t Tadano Rough Terrain TR 200M - Spec. 00107Document11 pages20t Tadano Rough Terrain TR 200M - Spec. 00107Eugene NortjeNo ratings yet

- QY20B Brand New PDFDocument3 pagesQY20B Brand New PDFDavid GomezNo ratings yet

- F250as 22Document38 pagesF250as 22Денис ЧерныйNo ratings yet

- Critical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)Document4 pagesCritical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)cute1t100% (1)

- Bullivants Rigging Handbook V2Document260 pagesBullivants Rigging Handbook V2Anonymous 2QD5RVWt5100% (5)

- Erection of BoilerDocument40 pagesErection of BoilerSam100% (1)

- SO-0033 SPJ315 A2+inDocument118 pagesSO-0033 SPJ315 A2+inRicardo EspinosaNo ratings yet

- Materials - Handling - & - Storage - 2 - ACADocument25 pagesMaterials - Handling - & - Storage - 2 - ACAJeanlyn Virgo AlmacinNo ratings yet

- Collision Prevention at Ports Terminals Information Paper 2019Document21 pagesCollision Prevention at Ports Terminals Information Paper 2019Casopis Safety100% (1)

- Fushun Yongmao Construction Machinery Co - LTDDocument157 pagesFushun Yongmao Construction Machinery Co - LTDOleksandr YakubetsNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- BASTAIN SOLUTION-250 KG SG EOT CRANE - 316Document10 pagesBASTAIN SOLUTION-250 KG SG EOT CRANE - 316Chandru ChristurajNo ratings yet

- BAUER-Catalogue 7 en WebDocument168 pagesBAUER-Catalogue 7 en Websamudra.gs83No ratings yet

- S393 SPM Lopl Opr MS 2301 - 0Document134 pagesS393 SPM Lopl Opr MS 2301 - 0Barm FuttNo ratings yet

- Fundamentals of Highway Bridge Demolition: Conference PaperDocument10 pagesFundamentals of Highway Bridge Demolition: Conference PaperDenver PlayletsNo ratings yet

- Rate Analysis Programme MorthDocument362 pagesRate Analysis Programme MorthAman SrivastavaNo ratings yet

- Bullivants Fabricated HandbookDocument80 pagesBullivants Fabricated Handbooksebastian9033No ratings yet

- KRA 3.8 Travelling Crane ProcedureDocument11 pagesKRA 3.8 Travelling Crane ProcedureAhsan Farooq100% (1)

- Danger Under Crane BoomsDocument2 pagesDanger Under Crane Boomsابو محمد عليNo ratings yet

- Lifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedDocument23 pagesLifting Plan For Installation of SPACE FRAMES at Ma'aden Facility Security Gate 3-SignedGufran ImamNo ratings yet

- Monorail Beam Design Q&ADocument33 pagesMonorail Beam Design Q&Aabdulloh_99No ratings yet

- NORSOK-L-002 (July 2009) - Piping-Layout-&-AnalysisDocument36 pagesNORSOK-L-002 (July 2009) - Piping-Layout-&-AnalysisNils Antoine FreundNo ratings yet

- Method Statement For Construction of Slipform TechnoclogyDocument10 pagesMethod Statement For Construction of Slipform TechnoclogySmart ShivaNo ratings yet

- Factory Rules 1979Document48 pagesFactory Rules 1979Jewel RanaNo ratings yet

- 01 Cital KPW Sea Presentation r3Document31 pages01 Cital KPW Sea Presentation r3daveNo ratings yet