Professional Documents

Culture Documents

翔貝製氧機原廠維修手冊

翔貝製氧機原廠維修手冊

Uploaded by

bbn88hg21Copyright:

Available Formats

You might also like

- EC-Certificate - 263168 - Carl Zeiss Meditec AG - Valid Until 2024-03-07 MR2Document5 pagesEC-Certificate - 263168 - Carl Zeiss Meditec AG - Valid Until 2024-03-07 MR2יוסי קונסטנטיניסNo ratings yet

- Spare Parts List: Gendex Dental SystemsDocument140 pagesSpare Parts List: Gendex Dental SystemsTony100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Inventory ChecklistDocument7 pagesInventory ChecklistAnonymous D8ay3BMJ5No ratings yet

- VX-351PMR446 SM EC083U90C With Spares LDocument32 pagesVX-351PMR446 SM EC083U90C With Spares Lvjt.radioNo ratings yet

- CE2A-11G0042-1-listDocument2 pagesCE2A-11G0042-1-listerminhusagic2308No ratings yet

- Inventaris Alat Medis 2020Document9 pagesInventaris Alat Medis 2020wahyuwiarsoNo ratings yet

- Ozosteril: Spare PartsDocument14 pagesOzosteril: Spare PartsReza KühnNo ratings yet

- Inventaris 2022 AGUSTUSDocument44 pagesInventaris 2022 AGUSTUSYuni Syalawiyah IINo ratings yet

- Inspecciones Pendientes PNC0243Document1 pageInspecciones Pendientes PNC0243Cesar Castro DeviaNo ratings yet

- No Nama Alat Merk/Spesifikasi Jumlah KetDocument2 pagesNo Nama Alat Merk/Spesifikasi Jumlah KetHanazwa SalsabillahNo ratings yet

- 1.2020-030-Valve and Fittings TracDocument1 page1.2020-030-Valve and Fittings TracvinuNo ratings yet

- Inventaris Alkes 2017 NDBS 2Document49 pagesInventaris Alkes 2017 NDBS 2bimarsalNo ratings yet

- Ap1000837-Cct, Cne Rev. BDocument18 pagesAp1000837-Cct, Cne Rev. BJader RuizNo ratings yet

- Parts MRP7000Document324 pagesParts MRP7000Bashir AhmedNo ratings yet

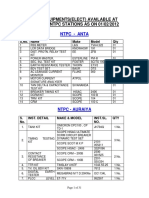

- Test Equipt at NTPC StationsDocument31 pagesTest Equipt at NTPC StationsvenkateshbitraNo ratings yet

- GALILEO Gold 510 (K) Submission Hamilton Mevicalag Doc.-No2 E35103 Par 2 GALILEO Gold Ventilator Modification Part 10 - 510 (K) Summary 1.1Document9 pagesGALILEO Gold 510 (K) Submission Hamilton Mevicalag Doc.-No2 E35103 Par 2 GALILEO Gold Ventilator Modification Part 10 - 510 (K) Summary 1.1Syarif AlfathNo ratings yet

- Air Conditioner GroupsDocument3 pagesAir Conditioner GroupsNidya Wardah JuhanaNo ratings yet

- Avvolgitubo Portotecnica Del CazzoDocument2 pagesAvvolgitubo Portotecnica Del Cazzomagnavacchi serviceNo ratings yet

- DGS Replacement Procedure 28KA3122A&BDocument20 pagesDGS Replacement Procedure 28KA3122A&Bofon OML102No ratings yet

- 13-2021مواصفات الفنية لقطع غيار المكيفاتDocument4 pages13-2021مواصفات الفنية لقطع غيار المكيفاتTawfeeq Al-HababbiNo ratings yet

- Pcil Gimmf1dDocument26 pagesPcil Gimmf1dWilliam LozadaNo ratings yet

- NO Nama Alkes SAT Jumlah Merk /Type/Model No - Seri Ruangan KETDocument31 pagesNO Nama Alkes SAT Jumlah Merk /Type/Model No - Seri Ruangan KETfebriNo ratings yet

- Datex-Ohmeda S/5™ Compact Anesthesia Monitor S/5™ Compact Critical Care Monitor Technical Reference ManualDocument58 pagesDatex-Ohmeda S/5™ Compact Anesthesia Monitor S/5™ Compact Critical Care Monitor Technical Reference ManualAnwar QahtanNo ratings yet

- Lista de Repuestos Recomendada (LRR)Document12 pagesLista de Repuestos Recomendada (LRR)Javier PérezNo ratings yet

- Spare Parts List: Ref: LPTB01418Document18 pagesSpare Parts List: Ref: LPTB01418Aleksey MalakhovNo ratings yet

- 9822/1065 C340-10-1 HEATER/AIR CON ASSEMBLY AUTOMATIC Temperature Control AssemblyDocument20 pages9822/1065 C340-10-1 HEATER/AIR CON ASSEMBLY AUTOMATIC Temperature Control AssemblyDean mark rey luzonNo ratings yet

- Inbound 6373724171176570885Document19 pagesInbound 6373724171176570885Diácono Rui Cunha CamposNo ratings yet

- Cfa 901Document70 pagesCfa 901chatahomoNo ratings yet

- NN ST756 - NN ST786 - NN SD786Document8 pagesNN ST756 - NN ST786 - NN SD786Patrice PaulNo ratings yet

- DIS-201 Publications Summary ListDocument2 pagesDIS-201 Publications Summary ListRICHAR MORENONo ratings yet

- Ceklist Evaluasi INVENTARIS 2022Document293 pagesCeklist Evaluasi INVENTARIS 2022lab rsutebetNo ratings yet

- Register Material DensoDocument138 pagesRegister Material DensoAbdurrohman Ahmad RofiqNo ratings yet

- Lista de Peças Vta-28Document2 pagesLista de Peças Vta-28Mauricio TorresNo ratings yet

- CRG-FO-008 Surgery Expense SheetDocument4 pagesCRG-FO-008 Surgery Expense SheetScribdTranslationsNo ratings yet

- Monthly Requirement Oct 19 HalolDocument23 pagesMonthly Requirement Oct 19 HalolAmit ParwaniNo ratings yet

- Daftar Harga e Catalog Electromedic Onemed Groups 2021Document21 pagesDaftar Harga e Catalog Electromedic Onemed Groups 2021PRABANTORO AHMAD AFIANNo ratings yet

- Rec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01Document1 pageRec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01olinda.controlNo ratings yet

- Service Bulletin: AB Volvo PentaDocument4 pagesService Bulletin: AB Volvo PentaDan LiamNo ratings yet

- Utl 001 002 PDFDocument2 pagesUtl 001 002 PDFfreeman11072000No ratings yet

- Packing ListDocument1 pagePacking ListLuis EsbaNo ratings yet

- Mechanical Thrombectomy Devices For Acute Ischaemic Stroke PDF 2285963514951109Document30 pagesMechanical Thrombectomy Devices For Acute Ischaemic Stroke PDF 2285963514951109Dinner OutNo ratings yet

- Cooling Gas Compressor: DP07J1-FE21-E3020-RS504Document5 pagesCooling Gas Compressor: DP07J1-FE21-E3020-RS504Haitham AbdEl-TawabNo ratings yet

- Spairpart RequirementDocument2 pagesSpairpart RequirementmrlaeluNo ratings yet

- Daftar Inventaris Alat MedisDocument16 pagesDaftar Inventaris Alat MedisElfrida MooNo ratings yet

- Set Rs Type CDocument14 pagesSet Rs Type CHera Oktria ElnisNo ratings yet

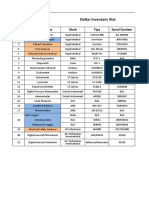

- No. Device Name Merk Tipe Serial Number: Daftar Inventaris AlatDocument6 pagesNo. Device Name Merk Tipe Serial Number: Daftar Inventaris AlatLevi AliciaNo ratings yet

- 13-EG-LB-019 Consumables Balance On 03-02-2014Document1 page13-EG-LB-019 Consumables Balance On 03-02-2014hellfire8No ratings yet

- CCR Equipment ListDocument1 pageCCR Equipment Listbehzad parsiNo ratings yet

- Jadwal Preventive Maintenance Dan Kalibrasi External Peralatan Medik 2017Document100 pagesJadwal Preventive Maintenance Dan Kalibrasi External Peralatan Medik 2017Ari RandaNo ratings yet

- LPU - D PNET Spare Parts PDFDocument7 pagesLPU - D PNET Spare Parts PDFИван ПарлапановNo ratings yet

- Daftar Alat Yg DikalibrasiDocument2 pagesDaftar Alat Yg DikalibrasiAgustina TriNo ratings yet

- F4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07Document12 pagesF4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07a.n.87711990No ratings yet

- Prostheses List February 2010Document865 pagesProstheses List February 2010Edgar KlerksNo ratings yet

- PPM 2023-2024Document6 pagesPPM 2023-2024mrlaeluNo ratings yet

- Safety Data Sheet: SDS: E6010, E6011, E6013, E7014, E7018, E7018-1, 80T-AC March 29, 2017Document8 pagesSafety Data Sheet: SDS: E6010, E6011, E6013, E7014, E7018, E7018-1, 80T-AC March 29, 2017Mr.HYCONo ratings yet

- List Alat Kesehatan Yang Perlu Di KalibrasiDocument1 pageList Alat Kesehatan Yang Perlu Di KalibrasiRiawati NazarudinNo ratings yet

- Fortuna Akd PricelistDocument6 pagesFortuna Akd Pricelistmeldyana dwi fransiscaNo ratings yet

- What Are The Different Types of Sequential CircuitsDocument10 pagesWhat Are The Different Types of Sequential Circuitsalvin castroNo ratings yet

- STP40N20-STF40N20: STB40N20 - STW40N20Document14 pagesSTP40N20-STF40N20: STB40N20 - STW40N20Rodrigo GarceteNo ratings yet

- 46TMSS07R0 DC-DC ConvertorsDocument18 pages46TMSS07R0 DC-DC ConvertorsMohamed NasrNo ratings yet

- Panasonic Toyota Cq-js6880g SMDocument28 pagesPanasonic Toyota Cq-js6880g SMdumberNo ratings yet

- Application of Out of Step Relays PDFDocument10 pagesApplication of Out of Step Relays PDFViraj Viduranga MuthugalaNo ratings yet

- ME345 Lecture 25Document9 pagesME345 Lecture 25Sivasankar PoovaragavanNo ratings yet

- Power Electronics Lab: ObjectivesDocument8 pagesPower Electronics Lab: ObjectivesRafeyNo ratings yet

- dlp3806 400bmDocument2 pagesdlp3806 400bmWindu SeptianNo ratings yet

- EXP5 3-Phase Uncontrolled RectifierDocument6 pagesEXP5 3-Phase Uncontrolled RectifierMohammad alhaboob2030No ratings yet

- DJ-3A TR Unit ManualDocument21 pagesDJ-3A TR Unit Manualsoltani aliNo ratings yet

- Siem Acx32 000Document4 pagesSiem Acx32 000hugo YangNo ratings yet

- SIH 2023 Final ResultsDocument58 pagesSIH 2023 Final ResultsKunal singh RajpurohitNo ratings yet

- 323Dz/D & 323Dz/4D: Engineering and Technical DataDocument2 pages323Dz/D & 323Dz/4D: Engineering and Technical Datasebastian garciaNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- SemiconductorsDocument5 pagesSemiconductorsManoj KhandelwalNo ratings yet

- WRD MP - 08 Amendment UCSR 2017 Gate & Allied WorksDocument3 pagesWRD MP - 08 Amendment UCSR 2017 Gate & Allied WorksMurali GawandeNo ratings yet

- Life Support System DetailDocument2 pagesLife Support System DetailOki purnama susiloNo ratings yet

- 2164 Dual Vca ElectrosmithDocument6 pages2164 Dual Vca Electrosmithjustin joolsNo ratings yet

- Lowara Hidrovar HV2,1Document72 pagesLowara Hidrovar HV2,1pastilhasNo ratings yet

- AVAXP 006 Rev3 AXP340 - 322Document19 pagesAVAXP 006 Rev3 AXP340 - 322jesus francoNo ratings yet

- Bipolar Junction Transistors (BJTS)Document28 pagesBipolar Junction Transistors (BJTS)Musa MagaulaNo ratings yet

- A&D MGMU End Sem Exam Paper (2022-23) Part-IDocument5 pagesA&D MGMU End Sem Exam Paper (2022-23) Part-IAzar BargirNo ratings yet

- EEE225 - Pre-Final Exam Section 1 - Google FormsDocument11 pagesEEE225 - Pre-Final Exam Section 1 - Google FormsDavid Louie BediaNo ratings yet

- The Constructability Review Process: Keys To Maximizing The BenefitsDocument41 pagesThe Constructability Review Process: Keys To Maximizing The BenefitsChristian SesoNo ratings yet

- Catalogue - 40.5kV T Type OVCB PDFDocument20 pagesCatalogue - 40.5kV T Type OVCB PDFGanesh Duraisamy0% (1)

- U1560 Diode Datasheet PDFDocument8 pagesU1560 Diode Datasheet PDFDemóstenes Moraes OlintoNo ratings yet

- SP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesDocument5 pagesSP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesFrancisco RochaNo ratings yet

- Ad-S 30175 PDFDocument33 pagesAd-S 30175 PDFJulian AlvarezNo ratings yet

- Irradiance-Adaptive PV Module Integrated Converter For High Efficiency and Power Quality in Standalone and DC Microgrid ApplicationsDocument11 pagesIrradiance-Adaptive PV Module Integrated Converter For High Efficiency and Power Quality in Standalone and DC Microgrid ApplicationsTRIAD TECHNO SERVICESNo ratings yet

- Switchgear and Transformer Maintenance: Compiled by P.Murugesan Dy - Director M.Ravichandrababu Asst - DirectorDocument104 pagesSwitchgear and Transformer Maintenance: Compiled by P.Murugesan Dy - Director M.Ravichandrababu Asst - DirectorGnanavel GNo ratings yet

翔貝製氧機原廠維修手冊

翔貝製氧機原廠維修手冊

Uploaded by

bbn88hg21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

翔貝製氧機原廠維修手冊

翔貝製氧機原廠維修手冊

Uploaded by

bbn88hg21Copyright:

Available Formats

Doc.

No RD41006436C Page no 1 21

Prepared by Approved by

Name Chaushu Nir Chaushu Gershon

OXYTEC-5S – RD41006436C Signature

OXYTEC-5S ASSEMBLY INSTRUCTIONS

Date: 10/03/2019 Rev:0

.1Objective:

1.1 Early preparations

1.1.1 Pcb board preparation

1.1.2 Compressor preparation

1.1.3 Cover bottom preparation

1.1.4 Oxygen sieve beds preparation

1.2 Front cover assembly

1.3 Compressor case assembly

1.4 Pipe system and filters assembly

1.5 Wiring system

1.6 Open system test

1.7 Closing system

1.8 Final Test

1.9 Final packing

1.10 Final Q.A test

2 Applicable documents:

2.1 RD41003437C – OXYTEC-5S TEST PROCEDURE ,Rev03

2.2 RD41006438C – OXYTEC-5S FINAL TEST REPORT ,Rev02

2.3 RD41006439C – OXYTE-5S PACKING INSTRUCTIONS ,Rev01

2.4 RD410064XXC – OXYTE-5S ROUTE CARD ,Rev01

.3 Accessories attached

3.1 Long Philip's screwdriver.

3.2 Short Philip's screwdriver.

3.3 Short Flat screwdriver.

3.4 Small locomotive (for cutting cable ties).

3.5 Ruler 30 c"m

3.6 Sharp scissors.

3.7 Calibrated concentrator test equipment .

3.8 External power cord.

3.9 Concentrator connector origin.

21 מתוך1 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

4. Rectangle diagram Oxygen concentrator system:

21 מתוך2 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

5. Part List:

C

Vendor part

Part Number Vendor M PARRT LIST PICTURE

No.

D

1.Dynmed

Medical A FILTER R030 CUT

1 36003089C HM2003

2. Russcll M 70X50mm

Kussner

1.Dynmed

Medical M INLET – INTAKE

2 19001332C SL2004

2.Air O FILTER(purchase)

safety

BACTERIAL

1.Dynmed FILTER(Bacteria Filter

M

3 19001294C Medical SL2007

O Straight Barb 1/4"

x1/4" ) (purchase)

1.Dynmed M

4 19003292C P07001 SOUND REDUCER

Medical O

1.Dynmed COMPRESSOR( GSE:

M

5 19003293C Medical A01001 ZW280F-67/1.5A-

O

GD084) (purchase)

CAPACITOR( CBB60

1.Dynmed

M 6Uf+5% 450VAC

6 19003294C Medical A01001

O 50/60Hz 40/70/21)

(purchase)

1.Dynmed

M

7 19003297C Medical P08001 MUFFLER (purchase)

O

21 מתוך3 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.Dynmed

FAN (MUTUAL

Medical

M MOTORS - AC AXIAL

8 19001298C 2. רפק E08001

O FANS – M115BA2H)

אלקטרוניקה

(purchase)

1.Dynmed

M MAGNETIC VALVE

9 19003296C Medical E10001

O MANIFOLD (purchase)

1.Dynmed OXYTEC_5S OXYGEN

M

10 19003226C Medical ZJ1001 FILTER(Manifold/Tank/

O

Valve)

1.Dynmed

M OXYGEN TANK

11 19003298C Medical P11001

O (purchase)

1.Dynmed PRESSURE

M

12 19003299C Medical C08001 ADJUSTMENT VALVE

O

(purchase)

1.Dynmed

Medical

M FLOWMETER 0-5LPM

13 19001296C 2.Key SL2011

O (purchase) REV 04

Instrument

M

O

AP19CV0025 DIAPHRAGM CHECK

14 19004327C 1.Conlog

SN VALVES 1/4"

PCB BOARD

1.Dynmed EO1043 W/STRONG

M

15 19004469C Medical (MODE:5220 BUZZER+LOW&HIGH

O

ES) FLOW ALERT REV 02

21 מתוך4 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.Dynmed

M ROUND STRONG

16 19004386C Medical EO9004

O BUZZER

1.Dynmed

M Residual Current Device

17 19003301C Medical E05001

O 4 AMP (purchase)

1.Dynmed

M LCD DISPLAY (purchase

18 19003302C Medical E01003

O )

Gas Flow & Oxygen

1.Dynmed M Sensor (without

19 19003355C E03001

Medical O oscillator) and with J1

connector assembled

1.Dynmed M 4 wires with 4 pin

20 19003370C E01014

Medical O connector

1.Dynmed M 2 wires with 3-2 pin

21 19003371C E01013

Medical O connector

1.Dynmed

Medical

M 2 PINS CAST ISRAELI

22 19004389C

O CABLE 2.3M 220V

CONN RECEPT 3POS

P

23 21003046C MOLEX 39-01-4030 VERT SINGLE

O

(FEMALE)

MOLEX

P CONN TERM FEMALE

24 21003047C 39-00-0078

O 16AWG TIN CRIMP

21 מתוך5 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

MOLEX

P CONN PLUG 3POS

25 21003048C 39-01-4036

O VERT SINGLE (MALE)

MOLEX

P CONN TERM MALE

26 21003049C 39-00-0082

O 16AWG TIN CRIMP

1.Dynmed COMPRESSOR

OXYTEC 5S M

27 19004468C Medical SYSTEM 5L DO2-5AM

VER05 O

VERSION 05

1.Dynmed

SL2009 + M

28 19001398C Medical HUMIDIFIER (purchase)

SL2002 O

1.Dynmed M OVER THE EAR

29 19004388C SL2022

Medical O CHNNULA 2.5M

1.Dynmed P BOX + PADDING +

30 43000096C -

Medical K PLASTIC BAG

1.Dynmed Y

31 34000066C - KRAFT TAPE

Medical R

21 מתוך6 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.1 Early preparations

1.1.1 Pcb board preparation :

1.1.1.1 Attached 8 mm pipe (HM40001379C) in 36.5 cm length to gas flow & oxygen sensor

entrance (MO19003355C) which located nearby J2 connector , in the right side of

the gas flow & oxygen sensor and compress with cable tie (VW31000054C).

1.1.1.2 Attached 8 mm pipe (HM40001379C) in 12 cm length to gas flow & oxygen sensor

exit (MO19003355C) which located nearby J5 connector , in the left side of the gas

flow & oxygen sensor and compress with cable tie (VW31000054C)

1.1.1.3 Using 2 M3x30mm screws (HO35000655C) , assemble of gas flow & oxygen sensor

(MO19003355C) on top of pcb board (MO19003300C) .Make sure that Free

movement of gas flow & oxygen sensor (MO19003355C) doesn’t exist

Pic no 1 – pcb board assembly

1.1.2 Compressor preparation:

1.1.2.1 Attached flexible 10 mm pipe (HM40001375C) in 21.5 cm length to air entrance

connector of the compressor (MO19003293C) and compress with metal cable tie

(HM40001376C)

Pic no 2 – pipe connecting to compressor entrance

21 מתוך7 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.1.2.2 Attached flexible 10 mm pipe (HM40001375C) in 31.5 cm length to air exit

connector of the compressor (MO19003293C) an compress with metal cable tie

(HM40001376C)

Pic no 3 – pipe connecting to compressor exit

1.1.2.3 Using 4 M6x12mm screws (HO35000691C) , screw 4 shock absorber of the

compressor (MO19003385C) to 4 compressor leg’s.

Pic no 4 – shock absorber connecting

Pic no 5 – compressor system formation assembly

1.1.3 Cover bottom preparation:

1.1.3.1 Place 35 mm elastic band (HM40001377C) in the compressor wiring path hole ,

which located In the center of the compressor case cover.

1.1.3.2 Make sure that elastic band placed properly from both sides of compressor case

cover

1.1.3.3 Place protection elastic band (HM40001380C) in the compressor air entrance pipe

path hole which located in the bottom right side of compressor case cover

1.1.3.4 Make sure that elastic band placed properly from both sides of compressor case

cover

21 מתוך8 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.1.3.5 Using 3 screws M4x12mm (HO35000458C) connect muffler (MO19003297C) to

compressor case front cover , while screwing them from the compressor case rear

cover

Pic no 6 - muffler connecting

1.1.3.6 Attached 10 mm elastic pipe (HM40001375C) in 23 cm length to air entrance

connector of the muffler (MO19003297C) and compress with cable tie

(VW31000054C)

1.1.3.7 Move muffler pipe (MO19003297C) through the V passageway which located on top

of compressor case front cover , so that it will exit from the front of the other side of

compressor case cover

Pic no 7 – pipe muffler formation assembly

1.1.3.8 Place air entrance sound reducer (MO19003292C) on top of related socket which

located in the right side of compressor case cover and compress with 2 cable ties

(VW3100054C)

1.1.3.9 Make sure that the exit of sound reducer (MO19003292C) placed in front of air

entrance path to the compressor

Pic no 8 - . sound reducer assembly

21 מתוך9 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.1.3.10 Attached flexible 10 mm pipe (HM40001375CC) in 21.5 cm length to air entrance

connector of the sound reducer (MO19003292C) which located upwards and

compress using metal cable tie (HM40001376C)

.

Pc no 9 – sound reducer entrance pipe assembly

1.1.3.11 Attached compressor air entrance edge connector (MO19003387C) to flexible 10

mm pipe (HM40001375C) in 21.5 cm length which connected to sound reducer air

entrance connector (MO19003292C) and compress using metal cable tie

(HM40001376C)

Pic no 10 – air entrance edge connector assembly

1.1.3.12 Using 1 screw 4Mx12mm (HO35000458C) connect capacitor (MO1903294C) to

exact place in the bottom right compressor case cover

Pic no 11 - capacitor assembly

21 מתוך10 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

Pic no 12 – compressor case cover formation assembly

1.1.4 oxygen sieve beds preparation:

1.1.4.1 Attached 3 mm silicon pipe (HM4001378C) in 37.5 cm length to 3 mm edge

connector which located on top of oxygen tank (MO19003298C) an compress using

cable tie (VW3100054C)

1.1.4.2 Attached 8 mm silicon pipe (HM4001379C) in 45.5 cm length to 8 mm edge

connector which located in the exit of the pressure adjustment valve

(MO19003299C) on top of oxygen tank (MO19003298C) an compress using cable

tie (VW3100054C)

Pic no 13 – oxygen sieve beds formation preparation

21 מתוך11 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.2 Front cover assembly:

1.2.1 Using small Philip's screwdriver assemble system formation on top of its 4 screws

M3x8mm (HO35000453C) in the back of front cover

Pic no 14 – system formation assembly

1.2.2 Using 2 screws M4x12mm (HO35000458C) screw the system exit edge connector

Pic no 15 – system exit edge connector

1.2.3 Press on the power switch (MO19003386C) . make sure that the “on” caption located

upward

Pic no 16 – power switch assembly

1.2.4 Assemble flow meter (MO19001296C) to the exact socket which located on the external

side of the external cover and compress while screwing it’s legs on flow meter clips from

the inside of external cover

21 מתוך12 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

Pic no 17 – system flow meter assembly

1.2.5 Press on the residual current device 4 AMP (MO19003301C) to the exact socket at the

front cover front. Make sure that the “4AMP” caption located at the right side of the device

(written top down)

pic no 18 – protection assembly of CB

1.2.6 Using 4 M3x8mm screws (HO35000453C) assemble pcb board (MO19003300C) to exact

seating located at the back center of front cover. Make sure that card transformer located

downward

Pic no 19 – pcb board assembly

21 מתוך13 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.2.7 Place 2 fans (MO19001298) in the exact socket on the back of front cover. Make sure fans

cables faces towards pcb board (MO19003300C) as well as upwards

1.2.8 Attached fans cables using cable tie (VW31000054C)

Pic no 20 – fans system placing.

1.2.9 Using 4 M6x12mm screws (HO35000691C) assemble system compressor (MO19003293)

while screwing compressor 4 shock absorbers (MO19003385C) to front cover (from

external side)

Pic no 21 – system compressor assembly to front cover

1.2.10 Make sure capacitor faces towards inside the system

1.2.11 Stabilize system compressor (MO19003293C) using 2 CT-500 500x4.8mm cable ties

(VW31000378)

1.3 Compressor case assembly:

Assemble compressor case cover on top of front cover. Make sure :

1.3.1 Wiring path elastic band (HO40001377C) located on top of compressor case

1.3.2 Exiting power cable through wiring path elastic band (HO40001377C) on top of compressor

case

Pic no 22 – capacitor elastic band placing

21 מתוך14 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.3.3 Exiting compressor electricity cables (MO19003293C) and their attachment (2 red wires)

Pic no 23 – compressor electricity cable assembly

1.3.4 Exiting compressor ejection pipe through compressor pipe path to the oxygen sieve beds.

Make sure entrance elastic band (HM40001380C) located properly after carrying out pipes

transfer

1.3.5 Exiting compressor entrance pipe through pipe path from sound reducer to compressor.

Make sure entrance elastic band (M40001380C) located properly after carrying out pipes

transfer

.

Pi no 24 – compressor entrance elastic band placing

1.3.6 Assemble compressor entrance pipe (MO19003293C) to sound reducer exit

(MO19003292C) using metal cable tie (MO4001376C)

Pic no 25 - compressor entrance pipe assembly

21 מתוך15 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.3.7 Using 4 4Mx12mm screws (HO35000458C) assemble compressor case cover

Pic no 26 – assembly formation of compressor case cover to system front cover

1.4 Pipe system and filters assembly:

1.4.1 Attached compressor exit pipe (MO19003293C) to magnetic valve manifold (MO19003296C)

using metal cable tie (HM40001376C)

1.4.2 Attached muffler pipe (MO19003297C) to magnetic valve manifold (MO19003296C) using

metal cable tie (HM40001376C)

1.4.3 Place oxygen sieve beds (MO19003226C) so that manifold valves will be located upwards ,

then insert oxygen sieve beds to rail fixation which located on top of compressor case cover.

Make sure foam insulation located in the bottom of oxygen sieve beds, before It’s entry to

rail fixation

Pic no 27 – oxygen sieve beds assembly formation

21 מתוך16 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.4.4 Attached 3 mm pipe (HM40001378C) in 37.5 cm length , which connected to oxygen tank

(MO19003298C) , to pressure sensor located on top of pcb board (MO19003300C) and

compress using cable tie (VW31000054C)

Pic no 28 – sensor oxygen assembly

1.4.5 Attached 8 mm pipe (HM40001379C) in 45.5 cm length , which connected to pressure

adjustment valve (MO19003299C) exit , to flow meter air entrance (MO19001296C) ,

therefor it is the entrance , facing him appears zero line of flow meter (bottom entrance) ,

then compress using cable tie (VW3100054C)

1.4.6 Attached 8 mm pipe (HM4001379C) in 21 cm length to flow meter air exit entrance

(MO19001296C) , therefore it is the entrance , facing him appears 5LPM flow line of flow

meter (top entrance) , then compress using cable tie (VW3100054C)

Pic no 29 – flow meter assembly

21 מתוך17 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.4.7 One way check valve placing , in 8 mm pipe (HM40001379C) ,in 12 cm length

***Comment: make sure to cut the pipe straight and in the exact position. Also, make sure

that the airflow in the valve is towards the outlet of the oxygen concentrator.

To place the valve without bending in the pipe, measure 3 cm from the outlet of the oxygen

concentrator and cut 4 cm. The valve should be positioned so that the airflow will be

towards the outlet of the oxygen concentrator.

1.4.8 Attached 8 mm pipe (HM40001379C) in 12 cm length , which connected to gas flow &

oxygen sensor exit entrance (MO19003355C) and located nearby J5 connector on left side

of gas flow & oxygen sensor , to oxygen concentrator exit spout. Then compress using

cable tie (VW3100054C)

Pic no 30 – gas flow & oxygen sensor assembly formation

1.5 Wiring system:

1.5.1 Power switch wiring:

1.5.1.1 Attached red power switch cable to 2 left legs of power switch (MO19003386C) (closest

to flow meter) , using pressing . from the opposite side , attached cable connector to

KEY connector on top of pcb board (MO19003300C)

1.5.1.2 Make sure connections are secure properly

Pic no 31 – power switch wiring

1.5.1.3 Attached short cable between top right leg of power switch (MO19003386C) to bottom

leg of the residual current device 4 AMP switch (MO19003301C)

1.5.1.4 Attached double supply cable between bottom right leg of power switch (MO19003386C)

to top leg of the residual current device 4 AMP switch (MO19003301C) . from the other

side , attached to POWER connector which located on top of pcb board

(MO19003300C)

1.5.1.5 Attached LCD display (MO19003302C) cable to cable base on top of pcb board

(MO19003300C)

21 מתוך18 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץRD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.5.1.6 Attached 2 fans (MO19001298C) to 2 connectors marked with FAN on top of pcb

board (MO19003300C)

1.5.1.7 Attached solenoid cable to ELECT-VLVE connector on top of pcb board

(MO19003300C)

1.5.1.8 Attached gas flow & oxygen sensor data cable , which contains 4 wires with 4 pin

connenctor (MO19003370C) , to the exact MOLEX connector on top of oxygen card .

from the other side , attached to 4 PIN MOLEX connector on top of pcb board

(MO19003300C)

1.5.1.9 Attached gas flow & oxygen sensor power feeder cable (MO19003371C) to exact

MOLEX connector on top of oxygen card (right 3 pins connector). From the other side ,

attached to 2 PINS MOLEX connector on top of pcb board (MO19003300C)

Pic no 34 –Final wiring assembly

1.5.1.10 Attached supply cable to system compressor (MO19003293C)

21 מתוך19 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.6 Open system test:

1.6.1 Attached 8 mm pipe (HM40001379C) in 21 cm length to bacterial filter (MO19001294C)

1.6.2 Attached 8 mm pipe (HM4001379C) in 36.5 cm length to bacterial filter (MO19001294C)

1.6.3 Attached air entrance filter (MO19001322C) to air entrance filter spout (MO19003387C)

1.6.4 Attached power cable (MO19003409C) to supply cable

1.6.5 Execute system tests as defined in oxygen concentrator test procedure (RD41006437C) .

1.6.6 Disconnect 8 mm pipe (HM40001379C) in 21 cm length from bacterial filter (MO19001294C)

1.6.7 Disconnect 8 mm pipe (HM40001379C) in 36.5 cm length from bacterial filter (MO19001294C)

1.6.8 Disconnect bacterial inlet filter intake filter (MO19001332C) from air entrance filter spout

(MO19003387C)

1.7 Closing system:

1.7.1 Attached system back panel on top of front panel , and before closing :

1.7.1.1 Transfer 8 mm pipe (HM40001379C) in 21 cm length from flow meter exit

(MO19001296C) through filters left window path of filters window cell , which located on

top of system back panel (MOxxxxxxxc)

1.7.1.2 Attached 8 mm pipe (HM40001379C) in 21 cm length o bacterial filter (MO19001294C)

1.7.1.3 Transfer 8 mm pipe (HM40001379C) in 36.5 cm length from gas flow & oxygen sensor

entrance (MO19003355C) though filters right window path of filters window cell , which

located on top of system back panel (MOxxxxxxxc)

1.7.1.4 Attached 8 mm pipe (HM40001379C) in 36.5 cm length to bacterial filter

(MO19001294C)

1.7.1.5 Attached air entrance filter spout (MO19003387C) through round filters window of filters

cell window , which located on top of system back panel. Make sure that it’s placed

properly

1.7.1.6 Attached bacterial inlet filter intake filter (MO19001332C) to air entrance filter spout

(MO19003387C)

1.7.1.7 Attached power cable (MO19003409C) to supply cable

1.7.2 Close system back panel using 9 package screws

1.7.3 Close filters cell window

21 מתוך20 עמוד

OXYTEC-5S ASSEMBLY INSTRUCTIONS : קובץ RD41006436C בע"מ CHABAN MEICAL 10/03/2019 : תאריך

1.8 FINAL TEST:

1.8.1 Execute final test procedure OXYTEC-5S TEST PROCEDURE ACCORDING TO

RD41006437C (VISUAL , OPERATIONAL TEST AND TEST RUN)

COMMENT : thermal ATP test is required for all test run systems and continuous test for one

system from 20

1.8.2 .Fill the tests results in pressure tests table an in the exact generic report OXYTEC-5S FINAL

TEST REPORT - RO41006438C

1.8.3 Approve tests execution in the appropriate section (6) in the rout card

(RD410066443C name + signature)

1.8.4 Add a copy of final tests report of each device to delivery note that sends out to

customer

1.9 FINAL Q.A – quality assurance testing

1.9.1 Execute QA test to all closed concentrators packages including labels origin country

verifying

1.9.2 Make sure that rout card is signed properly - RD41006443C (name + signature)

1.9.3 Approve test execution in the appropriate section (17) in the rout card RD41006443C

( name + signature)

1.9.4 Approve test execution (second inspector) in test report RD41006438C (name + signature)

21 מתוך21 עמוד

You might also like

- EC-Certificate - 263168 - Carl Zeiss Meditec AG - Valid Until 2024-03-07 MR2Document5 pagesEC-Certificate - 263168 - Carl Zeiss Meditec AG - Valid Until 2024-03-07 MR2יוסי קונסטנטיניסNo ratings yet

- Spare Parts List: Gendex Dental SystemsDocument140 pagesSpare Parts List: Gendex Dental SystemsTony100% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Inventory ChecklistDocument7 pagesInventory ChecklistAnonymous D8ay3BMJ5No ratings yet

- VX-351PMR446 SM EC083U90C With Spares LDocument32 pagesVX-351PMR446 SM EC083U90C With Spares Lvjt.radioNo ratings yet

- CE2A-11G0042-1-listDocument2 pagesCE2A-11G0042-1-listerminhusagic2308No ratings yet

- Inventaris Alat Medis 2020Document9 pagesInventaris Alat Medis 2020wahyuwiarsoNo ratings yet

- Ozosteril: Spare PartsDocument14 pagesOzosteril: Spare PartsReza KühnNo ratings yet

- Inventaris 2022 AGUSTUSDocument44 pagesInventaris 2022 AGUSTUSYuni Syalawiyah IINo ratings yet

- Inspecciones Pendientes PNC0243Document1 pageInspecciones Pendientes PNC0243Cesar Castro DeviaNo ratings yet

- No Nama Alat Merk/Spesifikasi Jumlah KetDocument2 pagesNo Nama Alat Merk/Spesifikasi Jumlah KetHanazwa SalsabillahNo ratings yet

- 1.2020-030-Valve and Fittings TracDocument1 page1.2020-030-Valve and Fittings TracvinuNo ratings yet

- Inventaris Alkes 2017 NDBS 2Document49 pagesInventaris Alkes 2017 NDBS 2bimarsalNo ratings yet

- Ap1000837-Cct, Cne Rev. BDocument18 pagesAp1000837-Cct, Cne Rev. BJader RuizNo ratings yet

- Parts MRP7000Document324 pagesParts MRP7000Bashir AhmedNo ratings yet

- Test Equipt at NTPC StationsDocument31 pagesTest Equipt at NTPC StationsvenkateshbitraNo ratings yet

- GALILEO Gold 510 (K) Submission Hamilton Mevicalag Doc.-No2 E35103 Par 2 GALILEO Gold Ventilator Modification Part 10 - 510 (K) Summary 1.1Document9 pagesGALILEO Gold 510 (K) Submission Hamilton Mevicalag Doc.-No2 E35103 Par 2 GALILEO Gold Ventilator Modification Part 10 - 510 (K) Summary 1.1Syarif AlfathNo ratings yet

- Air Conditioner GroupsDocument3 pagesAir Conditioner GroupsNidya Wardah JuhanaNo ratings yet

- Avvolgitubo Portotecnica Del CazzoDocument2 pagesAvvolgitubo Portotecnica Del Cazzomagnavacchi serviceNo ratings yet

- DGS Replacement Procedure 28KA3122A&BDocument20 pagesDGS Replacement Procedure 28KA3122A&Bofon OML102No ratings yet

- 13-2021مواصفات الفنية لقطع غيار المكيفاتDocument4 pages13-2021مواصفات الفنية لقطع غيار المكيفاتTawfeeq Al-HababbiNo ratings yet

- Pcil Gimmf1dDocument26 pagesPcil Gimmf1dWilliam LozadaNo ratings yet

- NO Nama Alkes SAT Jumlah Merk /Type/Model No - Seri Ruangan KETDocument31 pagesNO Nama Alkes SAT Jumlah Merk /Type/Model No - Seri Ruangan KETfebriNo ratings yet

- Datex-Ohmeda S/5™ Compact Anesthesia Monitor S/5™ Compact Critical Care Monitor Technical Reference ManualDocument58 pagesDatex-Ohmeda S/5™ Compact Anesthesia Monitor S/5™ Compact Critical Care Monitor Technical Reference ManualAnwar QahtanNo ratings yet

- Lista de Repuestos Recomendada (LRR)Document12 pagesLista de Repuestos Recomendada (LRR)Javier PérezNo ratings yet

- Spare Parts List: Ref: LPTB01418Document18 pagesSpare Parts List: Ref: LPTB01418Aleksey MalakhovNo ratings yet

- 9822/1065 C340-10-1 HEATER/AIR CON ASSEMBLY AUTOMATIC Temperature Control AssemblyDocument20 pages9822/1065 C340-10-1 HEATER/AIR CON ASSEMBLY AUTOMATIC Temperature Control AssemblyDean mark rey luzonNo ratings yet

- Inbound 6373724171176570885Document19 pagesInbound 6373724171176570885Diácono Rui Cunha CamposNo ratings yet

- Cfa 901Document70 pagesCfa 901chatahomoNo ratings yet

- NN ST756 - NN ST786 - NN SD786Document8 pagesNN ST756 - NN ST786 - NN SD786Patrice PaulNo ratings yet

- DIS-201 Publications Summary ListDocument2 pagesDIS-201 Publications Summary ListRICHAR MORENONo ratings yet

- Ceklist Evaluasi INVENTARIS 2022Document293 pagesCeklist Evaluasi INVENTARIS 2022lab rsutebetNo ratings yet

- Register Material DensoDocument138 pagesRegister Material DensoAbdurrohman Ahmad RofiqNo ratings yet

- Lista de Peças Vta-28Document2 pagesLista de Peças Vta-28Mauricio TorresNo ratings yet

- CRG-FO-008 Surgery Expense SheetDocument4 pagesCRG-FO-008 Surgery Expense SheetScribdTranslationsNo ratings yet

- Monthly Requirement Oct 19 HalolDocument23 pagesMonthly Requirement Oct 19 HalolAmit ParwaniNo ratings yet

- Daftar Harga e Catalog Electromedic Onemed Groups 2021Document21 pagesDaftar Harga e Catalog Electromedic Onemed Groups 2021PRABANTORO AHMAD AFIANNo ratings yet

- Rec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01Document1 pageRec. Spare Parts - EWWQ970B-XS - Promar 09 - List Price - R-01olinda.controlNo ratings yet

- Service Bulletin: AB Volvo PentaDocument4 pagesService Bulletin: AB Volvo PentaDan LiamNo ratings yet

- Utl 001 002 PDFDocument2 pagesUtl 001 002 PDFfreeman11072000No ratings yet

- Packing ListDocument1 pagePacking ListLuis EsbaNo ratings yet

- Mechanical Thrombectomy Devices For Acute Ischaemic Stroke PDF 2285963514951109Document30 pagesMechanical Thrombectomy Devices For Acute Ischaemic Stroke PDF 2285963514951109Dinner OutNo ratings yet

- Cooling Gas Compressor: DP07J1-FE21-E3020-RS504Document5 pagesCooling Gas Compressor: DP07J1-FE21-E3020-RS504Haitham AbdEl-TawabNo ratings yet

- Spairpart RequirementDocument2 pagesSpairpart RequirementmrlaeluNo ratings yet

- Daftar Inventaris Alat MedisDocument16 pagesDaftar Inventaris Alat MedisElfrida MooNo ratings yet

- Set Rs Type CDocument14 pagesSet Rs Type CHera Oktria ElnisNo ratings yet

- No. Device Name Merk Tipe Serial Number: Daftar Inventaris AlatDocument6 pagesNo. Device Name Merk Tipe Serial Number: Daftar Inventaris AlatLevi AliciaNo ratings yet

- 13-EG-LB-019 Consumables Balance On 03-02-2014Document1 page13-EG-LB-019 Consumables Balance On 03-02-2014hellfire8No ratings yet

- CCR Equipment ListDocument1 pageCCR Equipment Listbehzad parsiNo ratings yet

- Jadwal Preventive Maintenance Dan Kalibrasi External Peralatan Medik 2017Document100 pagesJadwal Preventive Maintenance Dan Kalibrasi External Peralatan Medik 2017Ari RandaNo ratings yet

- LPU - D PNET Spare Parts PDFDocument7 pagesLPU - D PNET Spare Parts PDFИван ПарлапановNo ratings yet

- Daftar Alat Yg DikalibrasiDocument2 pagesDaftar Alat Yg DikalibrasiAgustina TriNo ratings yet

- F4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07Document12 pagesF4-VB Spray Gun Plasma Spraying: Parts List PL 40333 EN 07a.n.87711990No ratings yet

- Prostheses List February 2010Document865 pagesProstheses List February 2010Edgar KlerksNo ratings yet

- PPM 2023-2024Document6 pagesPPM 2023-2024mrlaeluNo ratings yet

- Safety Data Sheet: SDS: E6010, E6011, E6013, E7014, E7018, E7018-1, 80T-AC March 29, 2017Document8 pagesSafety Data Sheet: SDS: E6010, E6011, E6013, E7014, E7018, E7018-1, 80T-AC March 29, 2017Mr.HYCONo ratings yet

- List Alat Kesehatan Yang Perlu Di KalibrasiDocument1 pageList Alat Kesehatan Yang Perlu Di KalibrasiRiawati NazarudinNo ratings yet

- Fortuna Akd PricelistDocument6 pagesFortuna Akd Pricelistmeldyana dwi fransiscaNo ratings yet

- What Are The Different Types of Sequential CircuitsDocument10 pagesWhat Are The Different Types of Sequential Circuitsalvin castroNo ratings yet

- STP40N20-STF40N20: STB40N20 - STW40N20Document14 pagesSTP40N20-STF40N20: STB40N20 - STW40N20Rodrigo GarceteNo ratings yet

- 46TMSS07R0 DC-DC ConvertorsDocument18 pages46TMSS07R0 DC-DC ConvertorsMohamed NasrNo ratings yet

- Panasonic Toyota Cq-js6880g SMDocument28 pagesPanasonic Toyota Cq-js6880g SMdumberNo ratings yet

- Application of Out of Step Relays PDFDocument10 pagesApplication of Out of Step Relays PDFViraj Viduranga MuthugalaNo ratings yet

- ME345 Lecture 25Document9 pagesME345 Lecture 25Sivasankar PoovaragavanNo ratings yet

- Power Electronics Lab: ObjectivesDocument8 pagesPower Electronics Lab: ObjectivesRafeyNo ratings yet

- dlp3806 400bmDocument2 pagesdlp3806 400bmWindu SeptianNo ratings yet

- EXP5 3-Phase Uncontrolled RectifierDocument6 pagesEXP5 3-Phase Uncontrolled RectifierMohammad alhaboob2030No ratings yet

- DJ-3A TR Unit ManualDocument21 pagesDJ-3A TR Unit Manualsoltani aliNo ratings yet

- Siem Acx32 000Document4 pagesSiem Acx32 000hugo YangNo ratings yet

- SIH 2023 Final ResultsDocument58 pagesSIH 2023 Final ResultsKunal singh RajpurohitNo ratings yet

- 323Dz/D & 323Dz/4D: Engineering and Technical DataDocument2 pages323Dz/D & 323Dz/4D: Engineering and Technical Datasebastian garciaNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- SemiconductorsDocument5 pagesSemiconductorsManoj KhandelwalNo ratings yet

- WRD MP - 08 Amendment UCSR 2017 Gate & Allied WorksDocument3 pagesWRD MP - 08 Amendment UCSR 2017 Gate & Allied WorksMurali GawandeNo ratings yet

- Life Support System DetailDocument2 pagesLife Support System DetailOki purnama susiloNo ratings yet

- 2164 Dual Vca ElectrosmithDocument6 pages2164 Dual Vca Electrosmithjustin joolsNo ratings yet

- Lowara Hidrovar HV2,1Document72 pagesLowara Hidrovar HV2,1pastilhasNo ratings yet

- AVAXP 006 Rev3 AXP340 - 322Document19 pagesAVAXP 006 Rev3 AXP340 - 322jesus francoNo ratings yet

- Bipolar Junction Transistors (BJTS)Document28 pagesBipolar Junction Transistors (BJTS)Musa MagaulaNo ratings yet

- A&D MGMU End Sem Exam Paper (2022-23) Part-IDocument5 pagesA&D MGMU End Sem Exam Paper (2022-23) Part-IAzar BargirNo ratings yet

- EEE225 - Pre-Final Exam Section 1 - Google FormsDocument11 pagesEEE225 - Pre-Final Exam Section 1 - Google FormsDavid Louie BediaNo ratings yet

- The Constructability Review Process: Keys To Maximizing The BenefitsDocument41 pagesThe Constructability Review Process: Keys To Maximizing The BenefitsChristian SesoNo ratings yet

- Catalogue - 40.5kV T Type OVCB PDFDocument20 pagesCatalogue - 40.5kV T Type OVCB PDFGanesh Duraisamy0% (1)

- U1560 Diode Datasheet PDFDocument8 pagesU1560 Diode Datasheet PDFDemóstenes Moraes OlintoNo ratings yet

- SP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesDocument5 pagesSP 100 EC: Data Sheet Eccentric Diaphragm Pumps For GasesFrancisco RochaNo ratings yet

- Ad-S 30175 PDFDocument33 pagesAd-S 30175 PDFJulian AlvarezNo ratings yet

- Irradiance-Adaptive PV Module Integrated Converter For High Efficiency and Power Quality in Standalone and DC Microgrid ApplicationsDocument11 pagesIrradiance-Adaptive PV Module Integrated Converter For High Efficiency and Power Quality in Standalone and DC Microgrid ApplicationsTRIAD TECHNO SERVICESNo ratings yet

- Switchgear and Transformer Maintenance: Compiled by P.Murugesan Dy - Director M.Ravichandrababu Asst - DirectorDocument104 pagesSwitchgear and Transformer Maintenance: Compiled by P.Murugesan Dy - Director M.Ravichandrababu Asst - DirectorGnanavel GNo ratings yet