Professional Documents

Culture Documents

PFD NRL

PFD NRL

Uploaded by

das_joydebCopyright:

Available Formats

You might also like

- S12A2-Y1PTA-1 Mitsubishi Diesel Generator EngineDocument3 pagesS12A2-Y1PTA-1 Mitsubishi Diesel Generator Enginejabed habib100% (1)

- Honda X4 Wiring Diagram El Schema FINAL LaikaDocument1 pageHonda X4 Wiring Diagram El Schema FINAL LaikaErlan Burdani50% (2)

- Viking - Pre-Action SystemDocument80 pagesViking - Pre-Action SystemHang Tran100% (2)

- Electrical Design ConceptDocument54 pagesElectrical Design ConceptNazeeruddin Mohammed100% (1)

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Load Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromDocument1 pageLoad Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromJohn BuntalesNo ratings yet

- Location Key Plan: Kids ParadiseDocument1 pageLocation Key Plan: Kids ParadiseClynne Jay DespiNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- V121411002X00F2 CCSDocument1 pageV121411002X00F2 CCSEr M M KazimNo ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- 20M Shallow Draft Tug - General ArrangementDocument1 page20M Shallow Draft Tug - General ArrangementEdi sonNo ratings yet

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Document1 pageSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonNo ratings yet

- Feet MeterDocument1 pageFeet MeterThomas MathewNo ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Su Japanese Restaurant: Date: 2023.09.08 18:14:53 - 04'00'Document1 pageSu Japanese Restaurant: Date: 2023.09.08 18:14:53 - 04'00'Engr Mohammad AbdullahNo ratings yet

- A C D B: LegendDocument1 pageA C D B: LegendjanelleNo ratings yet

- 46a93 Arc Series ManualDocument8 pages46a93 Arc Series Manualranjanspur3381No ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- A B C A B C: Ground Floor Sewer & Storm Drainage System Layout Second Floor Sewer & Storm Drainage System LayoutDocument1 pageA B C A B C: Ground Floor Sewer & Storm Drainage System Layout Second Floor Sewer & Storm Drainage System Layoutvinmar28No ratings yet

- General Notes and Specifications: Hanger Rod Locknut & 10mmøDocument1 pageGeneral Notes and Specifications: Hanger Rod Locknut & 10mmøLhewiz BrionesNo ratings yet

- Direct-Hit - Search Diagrama 4Document1 pageDirect-Hit - Search Diagrama 4CharleXs ChanNo ratings yet

- Audiometric BoothDocument1 pageAudiometric BoothIdayuNo ratings yet

- From Drawing: No. M-U-PW-01Document1 pageFrom Drawing: No. M-U-PW-01Tôn Huỳnh ĐoànNo ratings yet

- CCT Tunnel Option #1 Elm ST Portal - PlanDocument1 pageCCT Tunnel Option #1 Elm ST Portal - PlanAJ MetcalfNo ratings yet

- Door List: P/J:P-618 (HULL21) / P-718 (HULL22)Document12 pagesDoor List: P/J:P-618 (HULL21) / P-718 (HULL22)harimecNo ratings yet

- Conductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsDocument1 pageConductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsJohn Philip BuntalesNo ratings yet

- 1 - Fire ProtectionDocument1 page1 - Fire Protectionamal_postNo ratings yet

- Deyu Cai: General NotesDocument1 pageDeyu Cai: General NotesskyNo ratings yet

- Main Deck PlanDocument1 pageMain Deck PlanElmer HabloNo ratings yet

- Wfi PidDocument1 pageWfi Pidu273673No ratings yet

- A320 Ata 21 (2) CattsDocument1 pageA320 Ata 21 (2) CattsabmedhussNo ratings yet

- High Mast ElectricalDocument1 pageHigh Mast ElectricalTomas Casillas-GerenaNo ratings yet

- Steel Pipe VesselDocument133 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- Pressure Plate Frame Plate Frame Plate Pressure PlateDocument6 pagesPressure Plate Frame Plate Frame Plate Pressure PlateTung Bui ThanhNo ratings yet

- A320 Ata 36 CattsDocument1 pageA320 Ata 36 CattsabmedhussNo ratings yet

- 208418M506-Smoke Extra FanDocument1 page208418M506-Smoke Extra FanFuji Electric SMBENo ratings yet

- Steel Pipe VesselDocument122 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Learjet 55: Eng Fire Pull Eng Fire PullDocument2 pagesLearjet 55: Eng Fire Pull Eng Fire PullFelipe Ponce De LeónNo ratings yet

- CP - VISTA HUB BGC - 08112017-ModelDocument1 pageCP - VISTA HUB BGC - 08112017-ModelAngelo AguinaldoNo ratings yet

- Ges-18 Mkii DC - Ga - Ges-18 Mkii DC - 23-08-2019Document1 pageGes-18 Mkii DC - Ga - Ges-18 Mkii DC - 23-08-2019mustafasenbagci3693No ratings yet

- Steel PipeDocument175 pagesSteel Pipellc3nd3rllNo ratings yet

- Symbols Descriptions: This SiteDocument1 pageSymbols Descriptions: This SiteVincent FilomenaNo ratings yet

- Site Development Plan: Dirty Kitchen Laundry T&BDocument1 pageSite Development Plan: Dirty Kitchen Laundry T&BEphrem Marx AparicioNo ratings yet

- Bridge-A Lobby: Middle East Australia Asia Europe North AmericaDocument1 pageBridge-A Lobby: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- A2 Vetrinary 6 4 23Document1 pageA2 Vetrinary 6 4 23Rajab SalhubNo ratings yet

- Female Male: Middle East Australia Asia Europe North AmericaDocument1 pageFemale Male: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- Bridge-A Lobby: Middle East Australia Asia Europe North AmericaDocument1 pageBridge-A Lobby: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- CCS - FA Schematic - NorthDocument1 pageCCS - FA Schematic - NorthQaiserNo ratings yet

- Manhole Detail. Proposal 2Document1 pageManhole Detail. Proposal 2Mohammed BasheeruddinNo ratings yet

- Electrical Plan: LegendDocument1 pageElectrical Plan: LegendDaryl Jay YubalNo ratings yet

- Marpol, Ows, Incinerator, Sewage - Br.31Document43 pagesMarpol, Ows, Incinerator, Sewage - Br.31Muhammad FadliNo ratings yet

- New Piping DesignDocument277 pagesNew Piping DesignSurya Kiran KNo ratings yet

- ODC ModelDocument1 pageODC ModelASAP AUCNo ratings yet

- Tabela Completa Especificação de TubulaçãoDocument240 pagesTabela Completa Especificação de TubulaçãojuliermeribeiroNo ratings yet

- Electrical Plan - Bo, Roselyn - Bsee 1aDocument1 pageElectrical Plan - Bo, Roselyn - Bsee 1aRoselyn BoNo ratings yet

- Spinneys, KSA - Joinery DrawingDocument17 pagesSpinneys, KSA - Joinery DrawingjoshanderiaNo ratings yet

- BarışDocument4 pagesBarışMehmed the BoringNo ratings yet

- SDP (A3)Document1 pageSDP (A3)Fleight VandollinNo ratings yet

- Steel Pipe VesselDocument185 pagesSteel Pipe VesselAlberto VerdezotoNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Proform Laser Services LTD QP01 Integrated Management System ManualDocument32 pagesProform Laser Services LTD QP01 Integrated Management System Manualdas_joydeb100% (1)

- One Pack (Virichem) PFDDocument1 pageOne Pack (Virichem) PFDdas_joydebNo ratings yet

- Piping Handbook - 7th Edition 400Document1 pagePiping Handbook - 7th Edition 400das_joydebNo ratings yet

- ES Integrated Management System Manual - MA - IMS - .00001Document45 pagesES Integrated Management System Manual - MA - IMS - .00001das_joydeb100% (1)

- MSIHC Rules 1989Document50 pagesMSIHC Rules 1989das_joydebNo ratings yet

- The Regional Municipality of York: RecommendationDocument9 pagesThe Regional Municipality of York: Recommendationdas_joydebNo ratings yet

- Qhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012Document43 pagesQhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012das_joydebNo ratings yet

- Nuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and ChecklistsDocument227 pagesNuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and Checklistsdas_joydebNo ratings yet

- ENGIE IMS Broschuere EnglischDocument12 pagesENGIE IMS Broschuere Englischdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Integrated Management Systems ManualDocument26 pagesIntegrated Management Systems Manualdas_joydeb100% (1)

- Sys Pros 08 IMS ManualDocument81 pagesSys Pros 08 IMS Manualdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Fire Risk Assessment PAS79 ExampleDocument15 pagesFire Risk Assessment PAS79 Exampledas_joydebNo ratings yet

- Schneider CCTVDocument41 pagesSchneider CCTVdas_joydebNo ratings yet

- Spec Fire Fighting Vehicle EquipmentDocument208 pagesSpec Fire Fighting Vehicle Equipmentdas_joydebNo ratings yet

- Is 13115 B 1991Document10 pagesIs 13115 B 1991das_joydeb100% (1)

- Offshore Standard DNV-OS-A101, October 2010Document2 pagesOffshore Standard DNV-OS-A101, October 2010Arshavin Watashi WaNo ratings yet

- Baxi Luna DUOTEC E (Februarie 2019)Document11 pagesBaxi Luna DUOTEC E (Februarie 2019)Ustea CalinNo ratings yet

- SOLAR ChimneyDocument14 pagesSOLAR ChimneyJayan VijayanNo ratings yet

- Chapter 3:first Law of Thermodynamics and Its ProcessesDocument24 pagesChapter 3:first Law of Thermodynamics and Its ProcessesDaneal FikriNo ratings yet

- Condensate Stabilizer English A4Document2 pagesCondensate Stabilizer English A4wisnu_bayusaktiNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W ReversingDocument1 pageMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W ReversingArun SNo ratings yet

- Rhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYDocument3 pagesRhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYplcuserNo ratings yet

- Venturi Tubes PDFDocument2 pagesVenturi Tubes PDFJericho Paulo RosalesNo ratings yet

- L2 TB KHMER PrintDocument214 pagesL2 TB KHMER PrintPonleuFCG ChhunNo ratings yet

- Revisi Pekerjaan ME LOTT LamonganDocument32 pagesRevisi Pekerjaan ME LOTT LamonganJunta BuwanaNo ratings yet

- 860LTB BrochureDocument4 pages860LTB BrochureMachani OmkarNo ratings yet

- C30 PerformanceDocument14 pagesC30 PerformanceLoy RiveroNo ratings yet

- 3048 - Forecasting H2 Cost Decreases - Whitepaper - 20231128Document32 pages3048 - Forecasting H2 Cost Decreases - Whitepaper - 20231128hopnip449No ratings yet

- ESSC2014Document499 pagesESSC2014Aurangzaib ArshadNo ratings yet

- Prextherm RSH EngDocument8 pagesPrextherm RSH EngPeter HristovNo ratings yet

- 2023 Beacon New Machine CatalogueDocument51 pages2023 Beacon New Machine CatalogueJair OmarNo ratings yet

- Howden Compressor Division Brochure PDFDocument7 pagesHowden Compressor Division Brochure PDFdigecaNo ratings yet

- Heater OperationDocument8 pagesHeater OperationAakashNo ratings yet

- 102 Na04529a IlzheDocument12 pages102 Na04529a IlzheIstvan MadacsyNo ratings yet

- Overview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumDocument4 pagesOverview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumAdemola RabiuNo ratings yet

- Turbine Rolling Procedure Pre Rolling ActivitiesDocument7 pagesTurbine Rolling Procedure Pre Rolling ActivitiesPrakash Choudhary100% (2)

- Generator ProtectionDocument24 pagesGenerator ProtectionSantoshkumar Gupta100% (2)

- Mode of Heat Input: - Unfired - Supplementary Fired - Fully/Fresh Air FiredDocument26 pagesMode of Heat Input: - Unfired - Supplementary Fired - Fully/Fresh Air FiredrajanNo ratings yet

- Ramagundam Power PlantDocument38 pagesRamagundam Power PlantMadhu KamshettyNo ratings yet

- Chapter 78 - Exhaust: Section 78-10 - CollectorDocument6 pagesChapter 78 - Exhaust: Section 78-10 - Collectorvanmorrison69No ratings yet

- Efel Installation Harmony 3Document11 pagesEfel Installation Harmony 3Raffaele Di MaioNo ratings yet

- Screw CompressorDocument2 pagesScrew CompressorsaeidNo ratings yet

- MECE 4240U Practice Final W15Document15 pagesMECE 4240U Practice Final W15Foisal Ahmed MirzaNo ratings yet

PFD NRL

PFD NRL

Uploaded by

das_joydebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFD NRL

PFD NRL

Uploaded by

das_joydebCopyright:

Available Formats

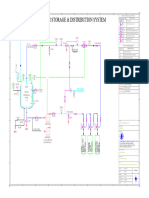

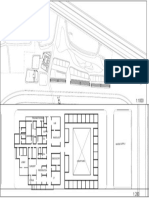

PROCESS FLOW DIAGRAM FOR RED LEAD MANUFACTURING PROCESS

5 NOS SOLENOID VALVE

N

BAG HOUSE Amps

AIR E

ID FAN (25 NOS. BAG) Pulsing

COMPRESSOR

W

C PRESSURE: 10

STARTER KG.

H

I STARTER S

M

N MAIN DUCT LINE

E

Y Quantity

Amps

Pulsing LOAD CELL WITH ID ID

ID FAN ID

DISPLAY FAN FAN

SILO ROTARY VALVE FAN

E (13)

L 5 NOS 5 NOS

Amps

PACKING

PADDLE VALVE

14 NOS SOLENOID SOLENOID

E VALVE VALVE Pulsing

E HOPPER

SOLENOID VALVE

V (6) STORAGE HOPPER

5 NOS L CAPACITY:

SOLENOID

A CAPACITY: 25 MT. (7A) BAG (8A) BAG E 6 MT

VALVE

HOUSE HOUSE V

(5) BAG HOUSE T (25 NOS. BAG) (25 NOS. BAG)

(12) BAG A

(98 NOS. BAG) O

Quantity HOUSE T

R O

(25 NOS.

BAG) R

CYCLONE

CYCLONE

CONVEYOR PADDLE

THERMOCOUPLE

VALVE

(9)

PADDLE VALVE

Quantity CONVEYOR

STORAGE

HOPPER PACKING

CONVEYOR E

AMPS L

CAPACITY:

E 20 MT

DISPLAY (1) RAW

MATERIAL V MP BP

(8) RED A

99.97% (7) RED Temperature Temperature

LEAD BAR Amps LEAD T Lead feeding Amps

(2). MELTING LEAD FURNACE-2

OIL OIL Temp. O rate A.D. of

POT FURNACE-1 CAPACITY: (10) Barton oxide

(3) BARTON POT BURNER BURNER % PbO2 R Cleaning of

WITH WITH CAPACITY: 3.5 MT DISINTEGRATOR dross as % of Fe of

CAPACITY: 10MT/DAY PUMP PUMP 3.5 MT required. Barton oxide

START

Amps Cleaning of Colour of

molten lead Barton oxide

from feeding

point

STARTER

OIL CONVEYOR

STORAGE

OIL SUPPLY LINE

TANK FLUE GAS LINE

ELECTRICAL PANEL BOARD ELECTRICAL PANEL BOARD

MCC-1 (250 AMPS) PROCESS FLOW

MCC-2 (250 AMPS)

IDENTIFICATION

ELECTRIC SUPPLY LINE

You might also like

- S12A2-Y1PTA-1 Mitsubishi Diesel Generator EngineDocument3 pagesS12A2-Y1PTA-1 Mitsubishi Diesel Generator Enginejabed habib100% (1)

- Honda X4 Wiring Diagram El Schema FINAL LaikaDocument1 pageHonda X4 Wiring Diagram El Schema FINAL LaikaErlan Burdani50% (2)

- Viking - Pre-Action SystemDocument80 pagesViking - Pre-Action SystemHang Tran100% (2)

- Electrical Design ConceptDocument54 pagesElectrical Design ConceptNazeeruddin Mohammed100% (1)

- Digital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGDocument1 pageDigital F13-MB-007 Xlpe 170: Esd Auxilliary 12PRX18AWGJohn BuntalesNo ratings yet

- Load Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromDocument1 pageLoad Conduits Conductors Service Gland Type RUN Total QTY HP OR KVA Volts "FROM" END " TO " END FromJohn BuntalesNo ratings yet

- Location Key Plan: Kids ParadiseDocument1 pageLocation Key Plan: Kids ParadiseClynne Jay DespiNo ratings yet

- RD-139767-013-0F1 (J) IC-4941 Through IC-4960Document1 pageRD-139767-013-0F1 (J) IC-4941 Through IC-4960John BuntalesNo ratings yet

- V121411002X00F2 CCSDocument1 pageV121411002X00F2 CCSEr M M KazimNo ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- 20M Shallow Draft Tug - General ArrangementDocument1 page20M Shallow Draft Tug - General ArrangementEdi sonNo ratings yet

- Sh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Document1 pageSh1 Dhi p0100 M m01 Pid 5301 - Symbol and Legend 1 of 4Thanh SonNo ratings yet

- Feet MeterDocument1 pageFeet MeterThomas MathewNo ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- Su Japanese Restaurant: Date: 2023.09.08 18:14:53 - 04'00'Document1 pageSu Japanese Restaurant: Date: 2023.09.08 18:14:53 - 04'00'Engr Mohammad AbdullahNo ratings yet

- A C D B: LegendDocument1 pageA C D B: LegendjanelleNo ratings yet

- 46a93 Arc Series ManualDocument8 pages46a93 Arc Series Manualranjanspur3381No ratings yet

- Feet Meter: Saudi Arabian Oil CompanyDocument1 pageFeet Meter: Saudi Arabian Oil CompanyJohn BuntalesNo ratings yet

- A B C A B C: Ground Floor Sewer & Storm Drainage System Layout Second Floor Sewer & Storm Drainage System LayoutDocument1 pageA B C A B C: Ground Floor Sewer & Storm Drainage System Layout Second Floor Sewer & Storm Drainage System Layoutvinmar28No ratings yet

- General Notes and Specifications: Hanger Rod Locknut & 10mmøDocument1 pageGeneral Notes and Specifications: Hanger Rod Locknut & 10mmøLhewiz BrionesNo ratings yet

- Direct-Hit - Search Diagrama 4Document1 pageDirect-Hit - Search Diagrama 4CharleXs ChanNo ratings yet

- Audiometric BoothDocument1 pageAudiometric BoothIdayuNo ratings yet

- From Drawing: No. M-U-PW-01Document1 pageFrom Drawing: No. M-U-PW-01Tôn Huỳnh ĐoànNo ratings yet

- CCT Tunnel Option #1 Elm ST Portal - PlanDocument1 pageCCT Tunnel Option #1 Elm ST Portal - PlanAJ MetcalfNo ratings yet

- Door List: P/J:P-618 (HULL21) / P-718 (HULL22)Document12 pagesDoor List: P/J:P-618 (HULL21) / P-718 (HULL22)harimecNo ratings yet

- Conductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsDocument1 pageConductors Total QTY Remarks HP OR KVA Volts "FROM" END " TO " END From TO Load Gland Type RUN ConduitsJohn Philip BuntalesNo ratings yet

- 1 - Fire ProtectionDocument1 page1 - Fire Protectionamal_postNo ratings yet

- Deyu Cai: General NotesDocument1 pageDeyu Cai: General NotesskyNo ratings yet

- Main Deck PlanDocument1 pageMain Deck PlanElmer HabloNo ratings yet

- Wfi PidDocument1 pageWfi Pidu273673No ratings yet

- A320 Ata 21 (2) CattsDocument1 pageA320 Ata 21 (2) CattsabmedhussNo ratings yet

- High Mast ElectricalDocument1 pageHigh Mast ElectricalTomas Casillas-GerenaNo ratings yet

- Steel Pipe VesselDocument133 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Steel PipeDocument186 pagesSteel PipeMarti H JNo ratings yet

- Pressure Plate Frame Plate Frame Plate Pressure PlateDocument6 pagesPressure Plate Frame Plate Frame Plate Pressure PlateTung Bui ThanhNo ratings yet

- A320 Ata 36 CattsDocument1 pageA320 Ata 36 CattsabmedhussNo ratings yet

- 208418M506-Smoke Extra FanDocument1 page208418M506-Smoke Extra FanFuji Electric SMBENo ratings yet

- Steel Pipe VesselDocument122 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Learjet 55: Eng Fire Pull Eng Fire PullDocument2 pagesLearjet 55: Eng Fire Pull Eng Fire PullFelipe Ponce De LeónNo ratings yet

- CP - VISTA HUB BGC - 08112017-ModelDocument1 pageCP - VISTA HUB BGC - 08112017-ModelAngelo AguinaldoNo ratings yet

- Ges-18 Mkii DC - Ga - Ges-18 Mkii DC - 23-08-2019Document1 pageGes-18 Mkii DC - Ga - Ges-18 Mkii DC - 23-08-2019mustafasenbagci3693No ratings yet

- Steel PipeDocument175 pagesSteel Pipellc3nd3rllNo ratings yet

- Symbols Descriptions: This SiteDocument1 pageSymbols Descriptions: This SiteVincent FilomenaNo ratings yet

- Site Development Plan: Dirty Kitchen Laundry T&BDocument1 pageSite Development Plan: Dirty Kitchen Laundry T&BEphrem Marx AparicioNo ratings yet

- Bridge-A Lobby: Middle East Australia Asia Europe North AmericaDocument1 pageBridge-A Lobby: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- A2 Vetrinary 6 4 23Document1 pageA2 Vetrinary 6 4 23Rajab SalhubNo ratings yet

- Female Male: Middle East Australia Asia Europe North AmericaDocument1 pageFemale Male: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- Bridge-A Lobby: Middle East Australia Asia Europe North AmericaDocument1 pageBridge-A Lobby: Middle East Australia Asia Europe North AmericaAslam YaseenNo ratings yet

- CCS - FA Schematic - NorthDocument1 pageCCS - FA Schematic - NorthQaiserNo ratings yet

- Manhole Detail. Proposal 2Document1 pageManhole Detail. Proposal 2Mohammed BasheeruddinNo ratings yet

- Electrical Plan: LegendDocument1 pageElectrical Plan: LegendDaryl Jay YubalNo ratings yet

- Marpol, Ows, Incinerator, Sewage - Br.31Document43 pagesMarpol, Ows, Incinerator, Sewage - Br.31Muhammad FadliNo ratings yet

- New Piping DesignDocument277 pagesNew Piping DesignSurya Kiran KNo ratings yet

- ODC ModelDocument1 pageODC ModelASAP AUCNo ratings yet

- Tabela Completa Especificação de TubulaçãoDocument240 pagesTabela Completa Especificação de TubulaçãojuliermeribeiroNo ratings yet

- Electrical Plan - Bo, Roselyn - Bsee 1aDocument1 pageElectrical Plan - Bo, Roselyn - Bsee 1aRoselyn BoNo ratings yet

- Spinneys, KSA - Joinery DrawingDocument17 pagesSpinneys, KSA - Joinery DrawingjoshanderiaNo ratings yet

- BarışDocument4 pagesBarışMehmed the BoringNo ratings yet

- SDP (A3)Document1 pageSDP (A3)Fleight VandollinNo ratings yet

- Steel Pipe VesselDocument185 pagesSteel Pipe VesselAlberto VerdezotoNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Proform Laser Services LTD QP01 Integrated Management System ManualDocument32 pagesProform Laser Services LTD QP01 Integrated Management System Manualdas_joydeb100% (1)

- One Pack (Virichem) PFDDocument1 pageOne Pack (Virichem) PFDdas_joydebNo ratings yet

- Piping Handbook - 7th Edition 400Document1 pagePiping Handbook - 7th Edition 400das_joydebNo ratings yet

- ES Integrated Management System Manual - MA - IMS - .00001Document45 pagesES Integrated Management System Manual - MA - IMS - .00001das_joydeb100% (1)

- MSIHC Rules 1989Document50 pagesMSIHC Rules 1989das_joydebNo ratings yet

- The Regional Municipality of York: RecommendationDocument9 pagesThe Regional Municipality of York: Recommendationdas_joydebNo ratings yet

- Qhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012Document43 pagesQhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012das_joydebNo ratings yet

- Nuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and ChecklistsDocument227 pagesNuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and Checklistsdas_joydebNo ratings yet

- ENGIE IMS Broschuere EnglischDocument12 pagesENGIE IMS Broschuere Englischdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Integrated Management Systems ManualDocument26 pagesIntegrated Management Systems Manualdas_joydeb100% (1)

- Sys Pros 08 IMS ManualDocument81 pagesSys Pros 08 IMS Manualdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Fire Risk Assessment PAS79 ExampleDocument15 pagesFire Risk Assessment PAS79 Exampledas_joydebNo ratings yet

- Schneider CCTVDocument41 pagesSchneider CCTVdas_joydebNo ratings yet

- Spec Fire Fighting Vehicle EquipmentDocument208 pagesSpec Fire Fighting Vehicle Equipmentdas_joydebNo ratings yet

- Is 13115 B 1991Document10 pagesIs 13115 B 1991das_joydeb100% (1)

- Offshore Standard DNV-OS-A101, October 2010Document2 pagesOffshore Standard DNV-OS-A101, October 2010Arshavin Watashi WaNo ratings yet

- Baxi Luna DUOTEC E (Februarie 2019)Document11 pagesBaxi Luna DUOTEC E (Februarie 2019)Ustea CalinNo ratings yet

- SOLAR ChimneyDocument14 pagesSOLAR ChimneyJayan VijayanNo ratings yet

- Chapter 3:first Law of Thermodynamics and Its ProcessesDocument24 pagesChapter 3:first Law of Thermodynamics and Its ProcessesDaneal FikriNo ratings yet

- Condensate Stabilizer English A4Document2 pagesCondensate Stabilizer English A4wisnu_bayusaktiNo ratings yet

- Marinediesels - Co.uk - Members Section Starting and Reversing MAN B&W ReversingDocument1 pageMarinediesels - Co.uk - Members Section Starting and Reversing MAN B&W ReversingArun SNo ratings yet

- Rhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYDocument3 pagesRhgs4biomass StovesA TWO-BURNER CONTINUOUS-TYPE RICE HUSK GAS STOVE DEVELOPED FOR HOUSEHOLD/SMALL COTTAGE INDUSTRYplcuserNo ratings yet

- Venturi Tubes PDFDocument2 pagesVenturi Tubes PDFJericho Paulo RosalesNo ratings yet

- L2 TB KHMER PrintDocument214 pagesL2 TB KHMER PrintPonleuFCG ChhunNo ratings yet

- Revisi Pekerjaan ME LOTT LamonganDocument32 pagesRevisi Pekerjaan ME LOTT LamonganJunta BuwanaNo ratings yet

- 860LTB BrochureDocument4 pages860LTB BrochureMachani OmkarNo ratings yet

- C30 PerformanceDocument14 pagesC30 PerformanceLoy RiveroNo ratings yet

- 3048 - Forecasting H2 Cost Decreases - Whitepaper - 20231128Document32 pages3048 - Forecasting H2 Cost Decreases - Whitepaper - 20231128hopnip449No ratings yet

- ESSC2014Document499 pagesESSC2014Aurangzaib ArshadNo ratings yet

- Prextherm RSH EngDocument8 pagesPrextherm RSH EngPeter HristovNo ratings yet

- 2023 Beacon New Machine CatalogueDocument51 pages2023 Beacon New Machine CatalogueJair OmarNo ratings yet

- Howden Compressor Division Brochure PDFDocument7 pagesHowden Compressor Division Brochure PDFdigecaNo ratings yet

- Heater OperationDocument8 pagesHeater OperationAakashNo ratings yet

- 102 Na04529a IlzheDocument12 pages102 Na04529a IlzheIstvan MadacsyNo ratings yet

- Overview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumDocument4 pagesOverview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumAdemola RabiuNo ratings yet

- Turbine Rolling Procedure Pre Rolling ActivitiesDocument7 pagesTurbine Rolling Procedure Pre Rolling ActivitiesPrakash Choudhary100% (2)

- Generator ProtectionDocument24 pagesGenerator ProtectionSantoshkumar Gupta100% (2)

- Mode of Heat Input: - Unfired - Supplementary Fired - Fully/Fresh Air FiredDocument26 pagesMode of Heat Input: - Unfired - Supplementary Fired - Fully/Fresh Air FiredrajanNo ratings yet

- Ramagundam Power PlantDocument38 pagesRamagundam Power PlantMadhu KamshettyNo ratings yet

- Chapter 78 - Exhaust: Section 78-10 - CollectorDocument6 pagesChapter 78 - Exhaust: Section 78-10 - Collectorvanmorrison69No ratings yet

- Efel Installation Harmony 3Document11 pagesEfel Installation Harmony 3Raffaele Di MaioNo ratings yet

- Screw CompressorDocument2 pagesScrew CompressorsaeidNo ratings yet

- MECE 4240U Practice Final W15Document15 pagesMECE 4240U Practice Final W15Foisal Ahmed MirzaNo ratings yet