Professional Documents

Culture Documents

PFD - Go - U2 - 2

PFD - Go - U2 - 2

Uploaded by

das_joydebCopyright:

Available Formats

You might also like

- In Line Fuel InjectionDocument146 pagesIn Line Fuel InjectionRaphael Lomonaco97% (33)

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: Projectbecpavan100% (1)

- Mass Media in EducationDocument26 pagesMass Media in EducationNavpreet Singh50% (2)

- PFD - Go - U1 - 1Document1 pagePFD - Go - U1 - 1das_joydebNo ratings yet

- Accumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerDocument5 pagesAccumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerBenyamin heidariNo ratings yet

- Masons Industrial MSW 65-220P 50HzDocument8 pagesMasons Industrial MSW 65-220P 50HzGogaNo ratings yet

- Test Report CertificateDocument2 pagesTest Report CertificateBùi Việt100% (2)

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- CompressedDocument1 pageCompressedPAul JoHn MeNdozaNo ratings yet

- Power Rating Motor Siemens SGE HM56Document1 pagePower Rating Motor Siemens SGE HM56santiagovillanueva91No ratings yet

- Gas Engine Site Specific Technical DataDocument4 pagesGas Engine Site Specific Technical Datavlcmstne04No ratings yet

- Spu 1253Document1 pageSpu 1253Josemir MarquesNo ratings yet

- Masons - Industrial - MBW - 18-45W - 50HzDocument4 pagesMasons - Industrial - MBW - 18-45W - 50HzGogaNo ratings yet

- ULMA SMART 300 SETARI Matrita 15x23Document1 pageULMA SMART 300 SETARI Matrita 15x23Voicu PetreNo ratings yet

- SFGLD 480 1800: Gas Ic-G-B-48-033 IcDocument1 pageSFGLD 480 1800: Gas Ic-G-B-48-033 IccihanNo ratings yet

- Utility Machineries (NG)Document1 pageUtility Machineries (NG)Md. Rayhan TalukderNo ratings yet

- Utilities Table 696Document2 pagesUtilities Table 696yseffoNo ratings yet

- Gas Engine Technical Data: Rating Notes Load 100% 75% 50%Document4 pagesGas Engine Technical Data: Rating Notes Load 100% 75% 50%Isaac MuñozNo ratings yet

- Rev2 3.0bpmg Technical ManDocument58 pagesRev2 3.0bpmg Technical ManLalo LopezNo ratings yet

- Main Function of EspDocument6 pagesMain Function of EspcmcNo ratings yet

- Book 1Document19 pagesBook 1dans putraNo ratings yet

- Bima - MP10 GearboxesDocument99 pagesBima - MP10 GearboxesronNo ratings yet

- Zamil 250Document13 pagesZamil 250Zaid Samha100% (1)

- 6hym WetDocument169 pages6hym WetMichell Quinteros GilerNo ratings yet

- Main Af Form 1458 Daily Steam Plant Operating LogDocument2 pagesMain Af Form 1458 Daily Steam Plant Operating LogRitche Lim BragaisNo ratings yet

- YZ-Systems - Crude Oil Sampling System - Datasheet - HiResDocument2 pagesYZ-Systems - Crude Oil Sampling System - Datasheet - HiResCuong TranHungNo ratings yet

- Utility Table 868Document1 pageUtility Table 868yseffoNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Engine Unit: ComponentsDocument9 pagesEngine Unit: ComponentsUmar ShamsudinNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- Gas DM8811 07 GS Epg M 10069210 1Document5 pagesGas DM8811 07 GS Epg M 10069210 1coolcaryyanNo ratings yet

- Area 200 PFD. in Proforma v2Document2 pagesArea 200 PFD. in Proforma v2Derek DennisNo ratings yet

- Service Operating - Model 8329 ALEMITEDocument19 pagesService Operating - Model 8329 ALEMITEMorales EduardoNo ratings yet

- ATA30 Fed ExDocument59 pagesATA30 Fed Exprzytul2007No ratings yet

- 4.2 - RB FGC Sootblower Data SheetDocument1 page4.2 - RB FGC Sootblower Data SheetAuilias DiasNo ratings yet

- CHN628 - Truspec Liquid Autosampler 209-218-003Document2 pagesCHN628 - Truspec Liquid Autosampler 209-218-003Alfredo MarcanoNo ratings yet

- WHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Document13 pagesWHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Amelia Van KallenNo ratings yet

- API 610 Vertical Centrifugal PumpDocument7 pagesAPI 610 Vertical Centrifugal PumpNAHASALI11100% (1)

- DYNACO A10VSO18 140 SeriesDocument10 pagesDYNACO A10VSO18 140 SeriesDani bastaraNo ratings yet

- DS58 FLC 120Document2 pagesDS58 FLC 120Arpit BafnaNo ratings yet

- Catalog Sludge Centrifuge CNCDocument2 pagesCatalog Sludge Centrifuge CNCIrwan Harahap0% (1)

- Cat G3512H - 1500 KW 1Document5 pagesCat G3512H - 1500 KW 1Yousuf AliNo ratings yet

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrNo ratings yet

- S2111-600-005JS Ele - Load Analysis A0Document10 pagesS2111-600-005JS Ele - Load Analysis A0Cornea IonutNo ratings yet

- IC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural GasDocument1 pageIC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural Gasz018125No ratings yet

- Weekly Preventive Maintenance Inspection: Suction Filter Differential PressureDocument1 pageWeekly Preventive Maintenance Inspection: Suction Filter Differential PressureAdam CabarrubiasNo ratings yet

- Cessna 172M CHECKLISTDocument3 pagesCessna 172M CHECKLISTDev ShahNo ratings yet

- 8 - Technical - SpecificationDocument1 page8 - Technical - SpecificationHadad KarimiNo ratings yet

- Erosional Velocity CalcDocument2 pagesErosional Velocity CalcJay SadNo ratings yet

- Fujitsu Arg45alc3 Aog45apa3l Arg45rlc3 Aog45rpa3l Ary45alc3 Aoy45apa3l Ary45rlc3 Aoy45rpa3l Art45rlc3 Aot45rpa3l PDFDocument26 pagesFujitsu Arg45alc3 Aog45apa3l Arg45rlc3 Aog45rpa3l Ary45alc3 Aoy45apa3l Ary45rlc3 Aoy45rpa3l Art45rlc3 Aot45rpa3l PDFNaser NaserNo ratings yet

- Engineering Details Reliance 5E TRSCSSVDocument4 pagesEngineering Details Reliance 5E TRSCSSVAmbroise RICHARDNo ratings yet

- Performance Demar Offshore HOKA 800 KWDocument3 pagesPerformance Demar Offshore HOKA 800 KWJuan Almanza MosquedaNo ratings yet

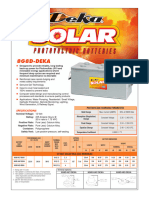

- 8G8D-DEKA MK Solar Rev 1-21Document2 pages8G8D-DEKA MK Solar Rev 1-21Fenner Tovar RojasNo ratings yet

- TAG Radiator P1500P3 - P1875E1 (0811) (GB)Document2 pagesTAG Radiator P1500P3 - P1875E1 (0811) (GB)hakim HANo ratings yet

- Single Packaged Air Conditioner: Service ManualDocument83 pagesSingle Packaged Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- MVWFWDocument1 pageMVWFWparthasutradharNo ratings yet

- Wall Mounted: Split Type Room Air ConditionerDocument18 pagesWall Mounted: Split Type Room Air ConditionerCristian AlexeNo ratings yet

- Gas Engine Site Specific Technical Data Non-CurrentDocument4 pagesGas Engine Site Specific Technical Data Non-CurrentDanny PalaceNo ratings yet

- RDSDocument1 pageRDSsantosh yadavNo ratings yet

- 696 Customer ConnectionsDocument2 pages696 Customer ConnectionsyseffoNo ratings yet

- One Pack (Virichem) PFDDocument1 pageOne Pack (Virichem) PFDdas_joydebNo ratings yet

- Nuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and ChecklistsDocument227 pagesNuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and Checklistsdas_joydebNo ratings yet

- Piping Handbook - 7th Edition 400Document1 pagePiping Handbook - 7th Edition 400das_joydebNo ratings yet

- MSIHC Rules 1989Document50 pagesMSIHC Rules 1989das_joydebNo ratings yet

- The Regional Municipality of York: RecommendationDocument9 pagesThe Regional Municipality of York: Recommendationdas_joydebNo ratings yet

- ENGIE IMS Broschuere EnglischDocument12 pagesENGIE IMS Broschuere Englischdas_joydebNo ratings yet

- Proform Laser Services LTD QP01 Integrated Management System ManualDocument32 pagesProform Laser Services LTD QP01 Integrated Management System Manualdas_joydeb100% (1)

- Qhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012Document43 pagesQhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012das_joydebNo ratings yet

- ES Integrated Management System Manual - MA - IMS - .00001Document45 pagesES Integrated Management System Manual - MA - IMS - .00001das_joydeb100% (1)

- Sys Pros 08 IMS ManualDocument81 pagesSys Pros 08 IMS Manualdas_joydebNo ratings yet

- Integrated Management Systems ManualDocument26 pagesIntegrated Management Systems Manualdas_joydeb100% (1)

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Schneider CCTVDocument41 pagesSchneider CCTVdas_joydebNo ratings yet

- Fire Risk Assessment PAS79 ExampleDocument15 pagesFire Risk Assessment PAS79 Exampledas_joydebNo ratings yet

- Is 13115 B 1991Document10 pagesIs 13115 B 1991das_joydeb100% (1)

- Spec Fire Fighting Vehicle EquipmentDocument208 pagesSpec Fire Fighting Vehicle Equipmentdas_joydebNo ratings yet

- Klueber Summit HySyn FG 15-100 050015 PI GB enDocument4 pagesKlueber Summit HySyn FG 15-100 050015 PI GB enOMiD QahqaieNo ratings yet

- Bu2506df 1Document8 pagesBu2506df 1pepo1974No ratings yet

- RFID Based Attendance SystemDocument3 pagesRFID Based Attendance SystemKulbir GodaraNo ratings yet

- Programming Interface For Bus Master IDE ControllerDocument6 pagesProgramming Interface For Bus Master IDE Controllerd_olexNo ratings yet

- WSMDocument4 pagesWSMWaseem MughalNo ratings yet

- Updated Cbe Confidentiality Agreement 2016Document3 pagesUpdated Cbe Confidentiality Agreement 2016api-444978327No ratings yet

- CH 34Document8 pagesCH 34Qassem MohaidatNo ratings yet

- UnicalDocument4 pagesUnicalAan StiawanNo ratings yet

- Lecture 1. What Is ICTEDocument8 pagesLecture 1. What Is ICTENoli ResterioNo ratings yet

- Epson m2140Document3 pagesEpson m2140Ahmad CikalNo ratings yet

- Information Technology in BusinessDocument5 pagesInformation Technology in Businesslidia zNo ratings yet

- Industrial Process ProblemsDocument1 pageIndustrial Process ProblemsJustine SomentacNo ratings yet

- Fiber Optic Connectors PDFDocument3 pagesFiber Optic Connectors PDFPaBenavidesNo ratings yet

- H-Series BrochureDocument5 pagesH-Series BrochuremartinNo ratings yet

- SIRIUS IC10 Complete English 2018 201712111415265308Document1,440 pagesSIRIUS IC10 Complete English 2018 201712111415265308Catarina ContenteNo ratings yet

- Handbook For Presiding OfficersDocument216 pagesHandbook For Presiding OfficersAbhi NavNo ratings yet

- Geared Drive Mixer: Mobile: +91 9820268595Document1 pageGeared Drive Mixer: Mobile: +91 9820268595Anil SharmaNo ratings yet

- NonlinearAnalysis of StructuresDocument30 pagesNonlinearAnalysis of StructuresUmut Akın100% (1)

- All-Time FPM/CCPM For Selected Machines: Order by FrequencyDocument19 pagesAll-Time FPM/CCPM For Selected Machines: Order by FrequencybensonmechanicalNo ratings yet

- DLL g6 q3 Week 4 All Subjects (Mam Inkay Peralta)Document66 pagesDLL g6 q3 Week 4 All Subjects (Mam Inkay Peralta)Jocelyn Flores-JunioNo ratings yet

- 1 Production ControlDocument25 pages1 Production ControlSweetu NancyNo ratings yet

- ARTCAM PRO9.0 InglésDocument466 pagesARTCAM PRO9.0 InglésYamen Issa100% (2)

- Comeleak 2016Document16 pagesComeleak 2016Anonymous r1cRm7FNo ratings yet

- John Abercrombie - SidekicksDocument1 pageJohn Abercrombie - SidekicksСергей ЕгоровNo ratings yet

- 21 Structural Conceptual Design ReportDocument12 pages21 Structural Conceptual Design Reportsofianina05No ratings yet

- NASA 122367main M-1588 SealsDocument1 pageNASA 122367main M-1588 SealsNASAdocumentsNo ratings yet

- A1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304Document24 pagesA1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304sanjay poudelNo ratings yet

- Grove RT600E PDFDocument20 pagesGrove RT600E PDFEsteban Ignacio SandovalNo ratings yet

PFD - Go - U2 - 2

PFD - Go - U2 - 2

Uploaded by

das_joydebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFD - Go - U2 - 2

PFD - Go - U2 - 2

Uploaded by

das_joydebCopyright:

Available Formats

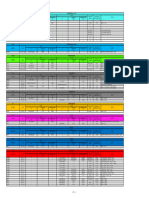

PROCESS FLOW DIAGRAM FOR GRAY OXIDE MANUFACTURING PROCESS FOR (UNIT-2)

AUTO FEEDING

(2) LEAD ELECTRICAL PANEL

MELTING POT BOARD

CAPACITY: 8 (3) LEAD BALL CASTING M/C MCC 250 AMPS

MT. CAPACITY: 1.5 MT./HR.

(1) RAW OIL

MATERIAL BURNER

99.97%

WITH (4) MATERIAL

PUMP STORAGE AREA

AIR COMPRESSOR

MANUAL

FEEDING

PRESSURE: 15 KG

OIL STORAGE WATER

TANK STORAGE TANK

STEAM

OUTLET

STEAM OUTLET

(5) BALL MILL (5A) BALL MILL

CONTROLLED FROM ELECTRICAL PANNEL BOARD.

PROCESS FLOW DIRECTION

REQD. TEMP.: 120°C REQD. TEMP.: 120°C

RPM: 35 - 38 RPM: 35 - 38

BALL MILL DRIVING BALL MILL DRIVING

MOTOR AMP.: (100- MOTOR AMP.: (100-

120)A. 120)A.

THERMOCOUPLE

THERMOCOUPLE

TEMP.: 120°C

TEMP.: 120°C

8 NOS SOLENOID VALVE 8 NOS SOLENOID VALVE

(7) BAG HOUSE (7A) BAG HOUSE

(64 NOS. BAG) (64 NOS. BAG)

(8) CONVEYOR (8A) CONVEYOR

(9) MATERIAL FOR PACKING (9A) MATERIAL FOR PACKING

DISPLAYED AT SITE

ID FAN (10)SAMPLE COLLECTION FOR QC CHECK ID FAN

RPM: RPM:

1200 1200

SCRUBBER

SCRUBBER

You might also like

- In Line Fuel InjectionDocument146 pagesIn Line Fuel InjectionRaphael Lomonaco97% (33)

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: Projectbecpavan100% (1)

- Mass Media in EducationDocument26 pagesMass Media in EducationNavpreet Singh50% (2)

- PFD - Go - U1 - 1Document1 pagePFD - Go - U1 - 1das_joydebNo ratings yet

- Accumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerDocument5 pagesAccumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerBenyamin heidariNo ratings yet

- Masons Industrial MSW 65-220P 50HzDocument8 pagesMasons Industrial MSW 65-220P 50HzGogaNo ratings yet

- Test Report CertificateDocument2 pagesTest Report CertificateBùi Việt100% (2)

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- CompressedDocument1 pageCompressedPAul JoHn MeNdozaNo ratings yet

- Power Rating Motor Siemens SGE HM56Document1 pagePower Rating Motor Siemens SGE HM56santiagovillanueva91No ratings yet

- Gas Engine Site Specific Technical DataDocument4 pagesGas Engine Site Specific Technical Datavlcmstne04No ratings yet

- Spu 1253Document1 pageSpu 1253Josemir MarquesNo ratings yet

- Masons - Industrial - MBW - 18-45W - 50HzDocument4 pagesMasons - Industrial - MBW - 18-45W - 50HzGogaNo ratings yet

- ULMA SMART 300 SETARI Matrita 15x23Document1 pageULMA SMART 300 SETARI Matrita 15x23Voicu PetreNo ratings yet

- SFGLD 480 1800: Gas Ic-G-B-48-033 IcDocument1 pageSFGLD 480 1800: Gas Ic-G-B-48-033 IccihanNo ratings yet

- Utility Machineries (NG)Document1 pageUtility Machineries (NG)Md. Rayhan TalukderNo ratings yet

- Utilities Table 696Document2 pagesUtilities Table 696yseffoNo ratings yet

- Gas Engine Technical Data: Rating Notes Load 100% 75% 50%Document4 pagesGas Engine Technical Data: Rating Notes Load 100% 75% 50%Isaac MuñozNo ratings yet

- Rev2 3.0bpmg Technical ManDocument58 pagesRev2 3.0bpmg Technical ManLalo LopezNo ratings yet

- Main Function of EspDocument6 pagesMain Function of EspcmcNo ratings yet

- Book 1Document19 pagesBook 1dans putraNo ratings yet

- Bima - MP10 GearboxesDocument99 pagesBima - MP10 GearboxesronNo ratings yet

- Zamil 250Document13 pagesZamil 250Zaid Samha100% (1)

- 6hym WetDocument169 pages6hym WetMichell Quinteros GilerNo ratings yet

- Main Af Form 1458 Daily Steam Plant Operating LogDocument2 pagesMain Af Form 1458 Daily Steam Plant Operating LogRitche Lim BragaisNo ratings yet

- YZ-Systems - Crude Oil Sampling System - Datasheet - HiResDocument2 pagesYZ-Systems - Crude Oil Sampling System - Datasheet - HiResCuong TranHungNo ratings yet

- Utility Table 868Document1 pageUtility Table 868yseffoNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Engine Unit: ComponentsDocument9 pagesEngine Unit: ComponentsUmar ShamsudinNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- Gas DM8811 07 GS Epg M 10069210 1Document5 pagesGas DM8811 07 GS Epg M 10069210 1coolcaryyanNo ratings yet

- Area 200 PFD. in Proforma v2Document2 pagesArea 200 PFD. in Proforma v2Derek DennisNo ratings yet

- Service Operating - Model 8329 ALEMITEDocument19 pagesService Operating - Model 8329 ALEMITEMorales EduardoNo ratings yet

- ATA30 Fed ExDocument59 pagesATA30 Fed Exprzytul2007No ratings yet

- 4.2 - RB FGC Sootblower Data SheetDocument1 page4.2 - RB FGC Sootblower Data SheetAuilias DiasNo ratings yet

- CHN628 - Truspec Liquid Autosampler 209-218-003Document2 pagesCHN628 - Truspec Liquid Autosampler 209-218-003Alfredo MarcanoNo ratings yet

- WHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Document13 pagesWHOC 2019, H, Salimi, EOR Strategy For A Heavy-Oil Field Development in South America, A Case Study, ID 747Amelia Van KallenNo ratings yet

- API 610 Vertical Centrifugal PumpDocument7 pagesAPI 610 Vertical Centrifugal PumpNAHASALI11100% (1)

- DYNACO A10VSO18 140 SeriesDocument10 pagesDYNACO A10VSO18 140 SeriesDani bastaraNo ratings yet

- DS58 FLC 120Document2 pagesDS58 FLC 120Arpit BafnaNo ratings yet

- Catalog Sludge Centrifuge CNCDocument2 pagesCatalog Sludge Centrifuge CNCIrwan Harahap0% (1)

- Cat G3512H - 1500 KW 1Document5 pagesCat G3512H - 1500 KW 1Yousuf AliNo ratings yet

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrNo ratings yet

- S2111-600-005JS Ele - Load Analysis A0Document10 pagesS2111-600-005JS Ele - Load Analysis A0Cornea IonutNo ratings yet

- IC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural GasDocument1 pageIC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural Gasz018125No ratings yet

- Weekly Preventive Maintenance Inspection: Suction Filter Differential PressureDocument1 pageWeekly Preventive Maintenance Inspection: Suction Filter Differential PressureAdam CabarrubiasNo ratings yet

- Cessna 172M CHECKLISTDocument3 pagesCessna 172M CHECKLISTDev ShahNo ratings yet

- 8 - Technical - SpecificationDocument1 page8 - Technical - SpecificationHadad KarimiNo ratings yet

- Erosional Velocity CalcDocument2 pagesErosional Velocity CalcJay SadNo ratings yet

- Fujitsu Arg45alc3 Aog45apa3l Arg45rlc3 Aog45rpa3l Ary45alc3 Aoy45apa3l Ary45rlc3 Aoy45rpa3l Art45rlc3 Aot45rpa3l PDFDocument26 pagesFujitsu Arg45alc3 Aog45apa3l Arg45rlc3 Aog45rpa3l Ary45alc3 Aoy45apa3l Ary45rlc3 Aoy45rpa3l Art45rlc3 Aot45rpa3l PDFNaser NaserNo ratings yet

- Engineering Details Reliance 5E TRSCSSVDocument4 pagesEngineering Details Reliance 5E TRSCSSVAmbroise RICHARDNo ratings yet

- Performance Demar Offshore HOKA 800 KWDocument3 pagesPerformance Demar Offshore HOKA 800 KWJuan Almanza MosquedaNo ratings yet

- 8G8D-DEKA MK Solar Rev 1-21Document2 pages8G8D-DEKA MK Solar Rev 1-21Fenner Tovar RojasNo ratings yet

- TAG Radiator P1500P3 - P1875E1 (0811) (GB)Document2 pagesTAG Radiator P1500P3 - P1875E1 (0811) (GB)hakim HANo ratings yet

- Single Packaged Air Conditioner: Service ManualDocument83 pagesSingle Packaged Air Conditioner: Service ManualCesar Calderon GrNo ratings yet

- MVWFWDocument1 pageMVWFWparthasutradharNo ratings yet

- Wall Mounted: Split Type Room Air ConditionerDocument18 pagesWall Mounted: Split Type Room Air ConditionerCristian AlexeNo ratings yet

- Gas Engine Site Specific Technical Data Non-CurrentDocument4 pagesGas Engine Site Specific Technical Data Non-CurrentDanny PalaceNo ratings yet

- RDSDocument1 pageRDSsantosh yadavNo ratings yet

- 696 Customer ConnectionsDocument2 pages696 Customer ConnectionsyseffoNo ratings yet

- One Pack (Virichem) PFDDocument1 pageOne Pack (Virichem) PFDdas_joydebNo ratings yet

- Nuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and ChecklistsDocument227 pagesNuclear Geo-Hazards Group Core Integrated Management System Procedures, Work Instructions, Forms and Checklistsdas_joydebNo ratings yet

- Piping Handbook - 7th Edition 400Document1 pagePiping Handbook - 7th Edition 400das_joydebNo ratings yet

- MSIHC Rules 1989Document50 pagesMSIHC Rules 1989das_joydebNo ratings yet

- The Regional Municipality of York: RecommendationDocument9 pagesThe Regional Municipality of York: Recommendationdas_joydebNo ratings yet

- ENGIE IMS Broschuere EnglischDocument12 pagesENGIE IMS Broschuere Englischdas_joydebNo ratings yet

- Proform Laser Services LTD QP01 Integrated Management System ManualDocument32 pagesProform Laser Services LTD QP01 Integrated Management System Manualdas_joydeb100% (1)

- Qhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012Document43 pagesQhse Management System Manual: UNI EN ISO 9001:2015 UNI EN ISO 14001:2015 BS OHSAS 18001:2007 EN ISO/IEC 80079-34:2012das_joydebNo ratings yet

- ES Integrated Management System Manual - MA - IMS - .00001Document45 pagesES Integrated Management System Manual - MA - IMS - .00001das_joydeb100% (1)

- Sys Pros 08 IMS ManualDocument81 pagesSys Pros 08 IMS Manualdas_joydebNo ratings yet

- Integrated Management Systems ManualDocument26 pagesIntegrated Management Systems Manualdas_joydeb100% (1)

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Is 3844 1989 PDFDocument25 pagesIs 3844 1989 PDFdas_joydebNo ratings yet

- Schneider CCTVDocument41 pagesSchneider CCTVdas_joydebNo ratings yet

- Fire Risk Assessment PAS79 ExampleDocument15 pagesFire Risk Assessment PAS79 Exampledas_joydebNo ratings yet

- Is 13115 B 1991Document10 pagesIs 13115 B 1991das_joydeb100% (1)

- Spec Fire Fighting Vehicle EquipmentDocument208 pagesSpec Fire Fighting Vehicle Equipmentdas_joydebNo ratings yet

- Klueber Summit HySyn FG 15-100 050015 PI GB enDocument4 pagesKlueber Summit HySyn FG 15-100 050015 PI GB enOMiD QahqaieNo ratings yet

- Bu2506df 1Document8 pagesBu2506df 1pepo1974No ratings yet

- RFID Based Attendance SystemDocument3 pagesRFID Based Attendance SystemKulbir GodaraNo ratings yet

- Programming Interface For Bus Master IDE ControllerDocument6 pagesProgramming Interface For Bus Master IDE Controllerd_olexNo ratings yet

- WSMDocument4 pagesWSMWaseem MughalNo ratings yet

- Updated Cbe Confidentiality Agreement 2016Document3 pagesUpdated Cbe Confidentiality Agreement 2016api-444978327No ratings yet

- CH 34Document8 pagesCH 34Qassem MohaidatNo ratings yet

- UnicalDocument4 pagesUnicalAan StiawanNo ratings yet

- Lecture 1. What Is ICTEDocument8 pagesLecture 1. What Is ICTENoli ResterioNo ratings yet

- Epson m2140Document3 pagesEpson m2140Ahmad CikalNo ratings yet

- Information Technology in BusinessDocument5 pagesInformation Technology in Businesslidia zNo ratings yet

- Industrial Process ProblemsDocument1 pageIndustrial Process ProblemsJustine SomentacNo ratings yet

- Fiber Optic Connectors PDFDocument3 pagesFiber Optic Connectors PDFPaBenavidesNo ratings yet

- H-Series BrochureDocument5 pagesH-Series BrochuremartinNo ratings yet

- SIRIUS IC10 Complete English 2018 201712111415265308Document1,440 pagesSIRIUS IC10 Complete English 2018 201712111415265308Catarina ContenteNo ratings yet

- Handbook For Presiding OfficersDocument216 pagesHandbook For Presiding OfficersAbhi NavNo ratings yet

- Geared Drive Mixer: Mobile: +91 9820268595Document1 pageGeared Drive Mixer: Mobile: +91 9820268595Anil SharmaNo ratings yet

- NonlinearAnalysis of StructuresDocument30 pagesNonlinearAnalysis of StructuresUmut Akın100% (1)

- All-Time FPM/CCPM For Selected Machines: Order by FrequencyDocument19 pagesAll-Time FPM/CCPM For Selected Machines: Order by FrequencybensonmechanicalNo ratings yet

- DLL g6 q3 Week 4 All Subjects (Mam Inkay Peralta)Document66 pagesDLL g6 q3 Week 4 All Subjects (Mam Inkay Peralta)Jocelyn Flores-JunioNo ratings yet

- 1 Production ControlDocument25 pages1 Production ControlSweetu NancyNo ratings yet

- ARTCAM PRO9.0 InglésDocument466 pagesARTCAM PRO9.0 InglésYamen Issa100% (2)

- Comeleak 2016Document16 pagesComeleak 2016Anonymous r1cRm7FNo ratings yet

- John Abercrombie - SidekicksDocument1 pageJohn Abercrombie - SidekicksСергей ЕгоровNo ratings yet

- 21 Structural Conceptual Design ReportDocument12 pages21 Structural Conceptual Design Reportsofianina05No ratings yet

- NASA 122367main M-1588 SealsDocument1 pageNASA 122367main M-1588 SealsNASAdocumentsNo ratings yet

- A1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304Document24 pagesA1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304sanjay poudelNo ratings yet

- Grove RT600E PDFDocument20 pagesGrove RT600E PDFEsteban Ignacio SandovalNo ratings yet