Professional Documents

Culture Documents

MDESIGN Reductor

MDESIGN Reductor

Uploaded by

Petru RonceaCopyright:

Available Formats

You might also like

- Raducanu MdesignDocument35 pagesRaducanu MdesignMada 230No ratings yet

- C4M Bar Bending Schedule BBS FormatDocument8 pagesC4M Bar Bending Schedule BBS FormatRaja VarshneyNo ratings yet

- RSB CalogcogDocument11 pagesRSB CalogcogMoamar TaratinganNo ratings yet

- As3 - Sailau Dinara - ColaboratoryDocument6 pagesAs3 - Sailau Dinara - ColaboratoryFarukh IskalinovNo ratings yet

- Tensile TestDocument1 pageTensile TestA. ΒρατσισταNo ratings yet

- Slab Quantity EstimateDocument8 pagesSlab Quantity EstimateDeepak Kumar SinghNo ratings yet

- Scheda Tecnica 6050 Composito UltraDocument1 pageScheda Tecnica 6050 Composito UltraJulioCarrascoSNo ratings yet

- Bar Bending Schedule BBS FormatDocument8 pagesBar Bending Schedule BBS FormatKundan SinghNo ratings yet

- Predict-Sw 3.0 For Usd Units: Multipoint Analysis Template MetricDocument23 pagesPredict-Sw 3.0 For Usd Units: Multipoint Analysis Template MetricMohammad NadimNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Metrados: Obra: Fabrica Ubicación: Propietario: Fecha: Hecho Por: Aepd Pag NoDocument10 pagesMetrados: Obra: Fabrica Ubicación: Propietario: Fecha: Hecho Por: Aepd Pag NoRonald Guevara AliagaNo ratings yet

- Field Leak Estimator en v1.3Document41 pagesField Leak Estimator en v1.3Nicola SorbiNo ratings yet

- Lecture # 40: Creation of A File On NTFSDocument6 pagesLecture # 40: Creation of A File On NTFSapi-3812413No ratings yet

- BR-WR Snap RingsDocument9 pagesBR-WR Snap RingsPhilNo ratings yet

- Pierszcienie Lozyskowe IdcDocument9 pagesPierszcienie Lozyskowe Idcaku2505kamuNo ratings yet

- DC-Motor M28x20/S Id.-Nr. 220518 (12V) 220531 (24V)Document2 pagesDC-Motor M28x20/S Id.-Nr. 220518 (12V) 220531 (24V)Adriano R. OrtizNo ratings yet

- Sondir S3 - BrondongDocument3 pagesSondir S3 - BrondongAl MasagalaNo ratings yet

- Lucsoon National High School Lucsoon, Naval, Biliran: 8-AristotleDocument18 pagesLucsoon National High School Lucsoon, Naval, Biliran: 8-Aristotleサビーネ ジェイNo ratings yet

- Hook 2DIA16mm ReportDocument30 pagesHook 2DIA16mm ReportYahia OsamaNo ratings yet

- Beam DesignDocument29 pagesBeam DesignMwengei MutetiNo ratings yet

- Contoh Analisis Hasil PTS: PG Isian 3.1 3.2 3.1 3.2Document9 pagesContoh Analisis Hasil PTS: PG Isian 3.1 3.2 3.1 3.2Ilham PratamaNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Cutting ListDocument10 pagesCutting ListCandido VeneracionNo ratings yet

- Adobe Scan 12 Sep 2023Document1 pageAdobe Scan 12 Sep 2023salebratoNo ratings yet

- Push Over Portico de 2 PisosDocument2 pagesPush Over Portico de 2 PisosAlexis MasamiNo ratings yet

- Phast CFD - Pool FiresDocument20 pagesPhast CFD - Pool FiresPeddy NesaNo ratings yet

- Sgim 1Document16 pagesSgim 1Liced RoblesNo ratings yet

- Bar Bending Schedule BBSDocument8 pagesBar Bending Schedule BBSsandip santpalNo ratings yet

- Bar Bending Schedule BBSDocument8 pagesBar Bending Schedule BBSEr HarishNo ratings yet

- Bar Bending Schedule BBS FormatDocument8 pagesBar Bending Schedule BBS FormatgirumNo ratings yet

- Government of Andhra Pradesh C.T.Department: Form of Way Bill Form X or Form 600Document3 pagesGovernment of Andhra Pradesh C.T.Department: Form of Way Bill Form X or Form 600ChakrNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Tugas 1 Cs SoketDocument1 pageTugas 1 Cs Soketilham dwi putraNo ratings yet

- Hot Rolled Steel Section Sets: No Data To Print ..Document2 pagesHot Rolled Steel Section Sets: No Data To Print ..9082888lcNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- SasaDocument2 pagesSasaAsh DizonNo ratings yet

- Wiremesh FormatDocument3 pagesWiremesh FormatRajat SharmaNo ratings yet

- 16.12.2022 208510Document6 pages16.12.2022 208510THE SHAYARI HOUSENo ratings yet

- 07 SMR JULI - Daily Report SolarDocument11 pages07 SMR JULI - Daily Report Solarzhy1493No ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- CE 411 - Lecture 5Document14 pagesCE 411 - Lecture 5Israel PopeNo ratings yet

- Touch Off: Yakusoku No Neverland OP Arranged by Steve HansenDocument5 pagesTouch Off: Yakusoku No Neverland OP Arranged by Steve HansenKevinNo ratings yet

- Daftar Nilai Pjok Kelas 1 Semester 1Document17 pagesDaftar Nilai Pjok Kelas 1 Semester 1Rustan Spdi100% (2)

- Planilla Conversiones UnidadesDocument5 pagesPlanilla Conversiones UnidadesLissette Karina Moncada SalinasNo ratings yet

- Usulan TUK TBSM DAN TKRO 2020Document9 pagesUsulan TUK TBSM DAN TKRO 2020Robby AnwarNo ratings yet

- Axial Ultimate Single Pile Capacity Using CPT / Sondir Data (Schmertman and Nottingham, 1975)Document3 pagesAxial Ultimate Single Pile Capacity Using CPT / Sondir Data (Schmertman and Nottingham, 1975)Ahmad AkbarNo ratings yet

- Champs Elys2ees AccordsDocument1 pageChamps Elys2ees AccordsC-Lee-O -No ratings yet

- Blackbird p4 - The Beatles - Guitar Tab PDF - BlackbirdDocument1 pageBlackbird p4 - The Beatles - Guitar Tab PDF - BlackbirdLe Roi KandaNo ratings yet

- Laporan Dokumentasi AntaraDocument68 pagesLaporan Dokumentasi AntaraBudi FikriNo ratings yet

- Laporan Dokumentasi Paparan AkhirDocument70 pagesLaporan Dokumentasi Paparan AkhirBudi FikriNo ratings yet

- Programación de CortesDocument28 pagesProgramación de Cortescesar89278No ratings yet

- JEE Main Test Series - Paper - 2Document13 pagesJEE Main Test Series - Paper - 2Ammar AdilNo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- FINAL Exam - Answer SheetDocument1 pageFINAL Exam - Answer SheetViggo VillanuevaNo ratings yet

- Tools NameDocument4 pagesTools NameManohar Paul Praveen MNo ratings yet

- 5D - Richmon PribadiDocument124 pages5D - Richmon PribadiRichmon PribadiNo ratings yet

- Cataleg PSCDocument151 pagesCataleg PSCAntônio Cesar de OliveiraNo ratings yet

- OI MARI' Partitura BatteriaDocument3 pagesOI MARI' Partitura BatteriapqbqpnzbqgNo ratings yet

- The Promise: Secret GardenDocument3 pagesThe Promise: Secret GardenYun Kwan ChongNo ratings yet

- Angle Section PropertiesDocument9 pagesAngle Section PropertiesDaniyal AhmadNo ratings yet

- Metals AluminumDocument22 pagesMetals AluminumSantosh KumarNo ratings yet

- Assignment Fencing and Gate ConstechDocument24 pagesAssignment Fencing and Gate Constechillya amyraNo ratings yet

- Lab 1Document25 pagesLab 1Self McNo ratings yet

- Only Questions HTDocument2 pagesOnly Questions HTrkiran05No ratings yet

- CTCDocument3 pagesCTCnaveenpnaidu1No ratings yet

- Mechanical and Thermal Properties of Lightweight Concretes With Vermiculite and EPS Using Air-Entraining AgentDocument8 pagesMechanical and Thermal Properties of Lightweight Concretes With Vermiculite and EPS Using Air-Entraining AgentAbner SantosNo ratings yet

- Split Charge InstructionsDocument4 pagesSplit Charge InstructionsAugusto ZanlungoNo ratings yet

- SJVNL Junior Field Engineer 23 October 2021 Paper WatermarkedDocument26 pagesSJVNL Junior Field Engineer 23 October 2021 Paper Watermarkedsantosh singhNo ratings yet

- Building Construction4Document473 pagesBuilding Construction4Jett Soriano100% (2)

- ABET Laminati Tech Data HPL Horizontal Post Forming 0.9mm R-110Document4 pagesABET Laminati Tech Data HPL Horizontal Post Forming 0.9mm R-110Ronaldino MacatangayNo ratings yet

- Difficulty in Sinking Well FoundationDocument22 pagesDifficulty in Sinking Well Foundationhussain9000100% (1)

- Mag General Business: Certificate of QualityDocument1 pageMag General Business: Certificate of QualityErik Jhonattan Jara YpanaqueNo ratings yet

- Essar Steels PPT b2bDocument14 pagesEssar Steels PPT b2bSaravanan SnrNo ratings yet

- Calentador Rheem de 250000 BtuhrDocument6 pagesCalentador Rheem de 250000 BtuhrAJM Controles y QNo ratings yet

- CTV Chiller WeightsDocument5 pagesCTV Chiller WeightsNoushad P HamsaNo ratings yet

- Colt VentilationDocument7 pagesColt VentilationRamkrishna MahatoNo ratings yet

- Triplexed Conductors in Air: Ampacity TablesDocument2 pagesTriplexed Conductors in Air: Ampacity TablesalbertoNo ratings yet

- Data Sheet - Wilden AODD Pump PDFDocument28 pagesData Sheet - Wilden AODD Pump PDFFirdaus NawiNo ratings yet

- Ficha Oleo Termico - UnlockedDocument2 pagesFicha Oleo Termico - UnlockedWisard MagalhãesNo ratings yet

- Chem 110, Chapter 9 UDLDocument50 pagesChem 110, Chapter 9 UDL5fyqv62kytNo ratings yet

- Thesis Po Ya Chuang PDFDocument271 pagesThesis Po Ya Chuang PDFMilan VachhaniNo ratings yet

- Chapter - Forces and Matter PDFDocument17 pagesChapter - Forces and Matter PDFasiyaNo ratings yet

- V O Nanofibre Sheet Actuators: LettersDocument4 pagesV O Nanofibre Sheet Actuators: Letters俞俊No ratings yet

- A Study On Creep and Drying Shrinkage of High Performance ConcreteDocument4 pagesA Study On Creep and Drying Shrinkage of High Performance Concreteit does not exist for the [mpossibleNo ratings yet

- SBW-RFMA-005R1 - Engineer's ApprovalDocument40 pagesSBW-RFMA-005R1 - Engineer's ApprovalChamux skalNo ratings yet

- ValvesDocument82 pagesValvespuru55980No ratings yet

- Glass ClassificationDocument4 pagesGlass ClassificationHAN HANNo ratings yet

- Equipos Fan & Coil YgfcDocument26 pagesEquipos Fan & Coil YgfcRoberto Reyes LaraNo ratings yet

- Characteristic Study of Geopolymer Fly Ash Sand As A Replacement To Natural River SandDocument8 pagesCharacteristic Study of Geopolymer Fly Ash Sand As A Replacement To Natural River SandLuis Fernando Tonholo DomingosNo ratings yet

MDESIGN Reductor

MDESIGN Reductor

Uploaded by

Petru RonceaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDESIGN Reductor

MDESIGN Reductor

Uploaded by

Petru RonceaCopyright:

Available Formats

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

This program allows to prove the bearing ability for shafts and axles. The calculation base is provided by DIN 743, edition of December

2012.

The proof of the bearing ability for shafts an axles is produced by defining a calculated safety. This safety is divided in the safety against

fatigue fracture and the residual deformation (and flaw or forced break).

When calculating the avoidance of fatigue fracture, constant stress amplitudes being equivalent to damaging loads are taken as a basis.

These ones are resulting from the predetermined loads. When proving against the residual deformation or forced break, designated as a

safety against yielding, only the maximum occurring load is determinant. This one is resulting from the predetermined loads, too.

The calculation of factors of safety is related only to the point of a clear notch effect. For it, 9 calculable notches are at your disposal due

to the graphical selection, principally.

The scope is limited to steels. Welded members should be calculated separately. But the utilized standard or the present program is

ineffective for this purpose!

The calculation base for the module Shaft Calculation is provided by DIN 743, edition of December 2012, part 1-4 “

Tragfähigkeitsberechnung von Wellen and Achsen” (“Calculation of bearing capacity of shafts and axles”).

Input data:

Shaft calculation in accordance with DIN 743 - extended version

Geometry scheme General shaft geometry

Calculation process Dynamic and static

strength proof

Geometry

Shaft geometry

Shaft geometry

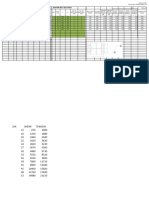

Nr. Da l Di l Da r Di r L Rz r d: t: b t: n n n d

mm mm mm mm mm µm mm mm mm zd : : zd b t zddBK bdBK

dBK: BK

: : : :

: :

m

m

1 50 0 50 0 20 1,6 0,8 49,4 0 0 0 0 0 0 0 0 0 0 0

2 58 0 58 0 42 6,3 1 0 0 0 0 0 0 0 0 0 0 0 0

3 70 0 70 0 8 6,3 1 0 0 0 0 0 0 0 0 0 0 0 0

4 93,75 0 93,75 0 60 3,2 1 0 0 0 0 0 0 0 0 0 0 0 0

5 70 0 70 0 8 6,3 0,8 57,5 0 0 0 0 0 0 0 0 0 0 0

6 58 0 58 0 79 1,6 1 0 0 0 0 0 0 0 0 0 0 0 0

7 50 0 50 0 42 1,6 0 0 0 0 0 0 0 0 0 0 0 0 0

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:16 Page 1/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Notch

Nr. Type = x d: t: r 2r m L zd b : t: n n n dBK d

mm mm mm mm mm mm mm : zd b zddBK bdBK: : BK

t:

: : : :

m

m

1 Feather 144 0 0 0 0 0 70 0 0 0 0 0 0 0 0 0 0

key joint,

1 groove

2 Toothed 70 93 0 0 0 0 60 0 0 0 0 0 0 0 0 0 0

shaft

(evolvent)

Predetermine the diameter determinant for the heat treatment ? no

Calculation of the deflection for point x = 150 mm

Shaft speed n : 697,67 1/min

Considering weight - horizontal or vertical horizontal shaft

Consider gyroscope effect? No

Consider bearing stiffness? No

Bearing

Nr. Type = Position x = Radial bearing Torsional bearing Bending bearing

mm stiffness cr = stiffness c = stiffness c =

N/m N*m N*m

1 Locating bearing -> 19 1e+015 0 0

2 Locating bearing <- 240 1e+015 0 0

Masses

N Position x = Mass moment of inertia Jxx = Mass moment of inertia Jy y = Additional masses

r. mm kg*m² kg*m² m=

kg

1 150 0 0 1,622

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 2/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Loading Data

Type of loading: tension-pressure Dynamically pure cyclic

Type of loading: bending Dynamically pure cyclic

Type of loading: torsion Dynamically pure cyclic

Factor for maximum loading (tension-pressure) 1

Factor for maximum loading (bending) 1

Factor for maximum loading (torsion) 1

Axial forces Fax

Nr. Position x = Amount = Radius = Angle =

mm N mm °

1 70 -5761,32 44 90

Radial forces Fr

Nr. Position x = Amount = Angle =

mm N °

1 70 -8687,19 90

2 70 -21501,56 180

3 150 -504,33 270

4 150 -6117,66 180

Bending moments Mb

Nr. Position x = Amount = Angle =

mm N·mm °

1 150 -114129,879 270

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 3/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Torsion

Nr. Position x = Torsion moments Mt: Power P: Transition part =

mm N*mm kW

1 150 765047,28 0 drive

2 70 765047,28 0 takeoff

Specifications about the load/loadings

Loading case Constant mean stress

(loading case 1)

Calculation of finite-life fatique strength ? no

Minimum safety against fatigue fracture SDmin = 1,2

Minimum safety against residual deformation SFmin = 1,2

Material Data

Strength values according to MDESIGN database

Material designation 1C50

Material number 1.0540

Gage diameter dB = 16 mm

For the gage diameter

Tensile strength B (Rm) = 750 N/mm²

Yield stress S (Re) = 520 N/mm²

Cyclic fatigue strength under bending stress bW = 375 N/mm²

Cyclic tension and pressure fatigue strength zdW = 300 N/mm²

Cyclic torsional fatigue strength tW = 220 N/mm²

Young's modulus E = 215000 N/mm²

Shear modulus G = 83000 N/mm²

Density = 7850 kg/m³

Apply surface hardening to Total shaft

Material group Quenched and

tempered steel

Heat treatment quenched and

tempered

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 4/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Surface hardening no

Output data:

Calculation process: Dynamic and static strength proof

Geometry

Total shaft length L = 259 mm

Total shaft mass m = 7,2 kg

Mass moment of inertia of the shaft J = 0,00522 kg*m²

Geometrical moment of inertia of the shaft I = 787,365 cm4

Position of the centre of gravity xs = 119,053 mm

in the X-axis

Angle of torsion = -0,012 °

Additional shaft data:

Shaft fillet number l Ip Wt m J I Wb

mm cm4 cm³ kg kg*m² cm4 cm³

1 20 61,359 24,544 0,308 0,0001 30,68 12,272

2 42 111,099 38,31 0,871 0,0004 55,55 19,155

3 8 235,718 67,348 0,242 0,0001 117,859 33,674

4 60 758,377 161,787 3,251 0,0036 379,188 80,894

5 8 235,718 67,348 0,242 0,0001 117,859 33,674

6 79 111,099 38,31 1,638 0,0007 55,55 19,155

7 42 61,359 24,544 0,647 0,0002 30,68 12,272

Loading Data

Calculation results for point x = 150 mm

Trend of curve of the transverse force Qx = 8566,89 N

deflection yx = 0,020192 mm

Angle of deflection = 0,002062 °

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 5/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Supporting forces:

No. Type Positio Radial Radial Result. Axial force Tilting Tilting Result.

n force force radial in the moment moment tilting

x in the in the force X-axis in the in the moment

mm Y-axis Z-axis R Rax Y-axis Z-axis N*m

Ry Rz N N N*m N*m

N N

1 Locating 19 -18985,89 8140,546 20657,51 5761,32 0 0 0

bearing -> 8 2

2 Locating 240 -8546,809 42,314 8546,91 0 0 0 0

bearing <- 4

Resulting maximum bending moment:

Position x = 70 mm

Amount Mbmax = 1053,936 N*m

Resulting maximum torsional moment:

Position x = 70 mm

Amount Mtmax = 765,047 N*m

Resulting maximum tension-pressure-force:

Position x = 19 mm

Amount Fzdmax = -5761,32 N

Resulting maximum tension-pressure-stress:

Position x = 19 mm

Amount zdmax = -2,934 N/mm²

Resulting maximum bending stress:

Position x = 62 mm

Amount bmax = 46,389 N/mm²

Resulting maximum torsional stress:

Position x = 150 mm

Amount tmax = 19,97 N/mm²

Resulting maximum equivalent stress:

Position x = 138,01 mm

Amount v max = 56,046 N/mm²

Resulting maximum deflection:

Position x = 145,78 mm

Amount ymax = 0,020258 mm

Angle of the maximum deflection:

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 6/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Position x = 252,34 mm

Amount = 0,019103 °

Minimum safety against yielding:

Position x = 138 mm

Amount SF = 9,198

Minimum safety against fatigue fracture:

Position x = 138 mm

Amount SD = 2,186

Parameter of cross-sections:

Tension-pressure force Fzd and tension/pressure stress zd

No. Type Position Result. Amplitude Mean Maximum Amplitude Mean Maximum

x Fzdx Fzda Fzdm Fzdmax zda zdm zdmax

mm N N N N N/mm² N/mm² N/mm²

1 Fillet with recess 20 -5761,32 -5761,32 0 -5761,32 -3,006 0 -3,006

2 Shaft fillet 62 -5761,32 -5761,32 0 -5761,32 -2,181 0 -2,181

3 Shaft fillet 70 0 0 0 0 0 0 0

4 Toothed shaft 70 0 0 0 0 0 0 0

(evolvent)

5 Shaft fillet 130 0 0 0 0 0 0 0

6 Fillet with recess 138 0 0 0 0 0 0 0

7 Feather key joint, 1 144 0 0 0 0 0 0 0

groove

8 Shaft fillet 217 0 0 0 0 0 0 0

9 Calculation results 150 0 0 0 0 0 0 0

for point x

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 7/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Bending moment Mb and bending stress b

No. Type Position Result. Amplitude Mean Maximum Amplitude Mean Maximum

x Mbx Mba Mbm Mbmax ba bm bmax

mm N*m N*m N*m N*m N/mm² N/mm² N/mm²

1 Fillet with recess 20 20,685 20,685 0 20,685 1,748 0 1,748

2 Shaft fillet 62 888,582 888,58 0 888,58 46,389 0 46,389

2 2

3 Shaft fillet 70 1053,93 1053,93 0 1053,93 31,298 0 31,298

6 6 6

4 Toothed shaft 70 1053,93 1053,93 0 1053,93 13,346 0 13,346

(evolvent) 6 6 6

5 Shaft fillet 130 829,642 829,64 0 829,64 24,638 0 24,638

2 2

6 Fillet with recess 138 809,455 809,45 0 809,45 43,37 0 43,37

5 5

7 Feather key joint, 1 144 794,326 794,32 0 794,32 41,468 0 41,468

groove 6 6

8 Shaft fillet 217 196,712 196,71 0 196,71 16,03 0 16,03

2 2

9 Calculation results 150 779,205 779,20 0 779,20 40,679 0 40,679

for point x 5 5

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 8/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Torsional moment Mt und Torsional stress t

No. Type Position Result. Amplitude Mean Maximum Amplitude Mean Maximum

x Mtx Mta Mtm Mtmax ta tm tmax

mm N*m N*m N*m N*m N/mm² N/mm² N/mm²

1 Fillet with recess 20 0 0 0 0 0 0 0

2 Shaft fillet 62 0 0 0 0 0 0 0

3 Shaft fillet 70 765,047 765,04 0 765,04 11,36 0 11,36

7 7

4 Toothed shaft 70 765,047 765,04 0 765,04 4,844 0 4,844

(evolvent) 7 7

5 Shaft fillet 130 765,047 765,04 0 765,04 11,36 0 11,36

7 7

6 Fillet with recess 138 765,047 765,04 0 765,04 20,495 0 20,495

7 7

7 Feather key joint, 1 144 765,047 765,04 0 765,04 19,97 0 19,97

groove 7 7

8 Shaft fillet 217 0 0 0 0 0 0 0

9 Calculation results 150 765,047 765,04 0 765,04 19,97 0 19,97

for point x 7 7

Critical shaft speed values:

Critical bending shaft speed values

No. Critical shaft speed values Eigenfrequencies

nb

1/min rad/s

1 112821,84 11814,68

2 432767,67 45319,32

3 784405,73 82142,78

4 1120991,08 117389,91

5 1415548,31 148235,87

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 9/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Critical torsional shaft speed values

No. Critical shaft speed values Eigenfrequencies

nb

1/min rad/s

1 470795,79 49301,62

2 837899 87744,58

3 1151819,95 120618,3

4 1527937,61 160005,25

5 1928154,61 201915,88

Material Data

Material parameter for dmax = 93,75 mm

Material designation 1C50

Material number 1.0540

Tensile strength B = 600,269 N/mm²

Yield stress S = 384,244 N/mm²

Cyclic tension and pressure fatigue zdW = 240,108 N/mm²

strength

Cyclic fatigue strength under bending bW = 300,134 N/mm²

stress

Cyclic torsional fatigue strength tW = 176,079 N/mm²

Technological dimension factor K1B(dmax) = 0,8

(tensile strength)

Technological dimension factor K1S (dmax) = 0,739

(yield stress)

Proof of Strength

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 10/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

K1(d) - Technological dimension factor

K2(d) - Geometrical dimension factor

KF - Influence factor of surface roughness

, - Form factors

No. Type Position K1B(d) K1S (d) Tensio Bending Tension Torsion Tensio Bending Torsion

x n- and - KF n- b

mm pressur torsion pressure pressur

e K2(d) , e

K2(d) bending zd

KF

1 Fillet with recess 20 0,85 0,81 1 0,87 0,98 0,99 3,06 2,78 1,87

2 Shaft fillet 62 0,83 0,78 1 0,86 0,91 0,95 3,07 2,77 1,88

3 Shaft fillet 70 0,8 0,74 1 0,85 0,92 0,95 3,52 3,1 2,07

4 Toothed shaft 70 0,8 0,74 1 0,83 1 1 - - -

(evolvent)

5 Shaft fillet 130 0,8 0,74 1 0,85 0,92 0,95 3,52 3,1 2,07

6 Fillet with recess 138 0,83 0,78 1 0,86 0,98 0,99 3,34 3 2

7 Feather key joint, 1 144 0,85 0,81 1 0,86 1 1 - - -

groove

8 Shaft fillet 217 0,85 0,81 1 0,87 0,98 0,99 2,81 2,56 1,76

9 Calculation results 150 0,85 0,81 1 0,86 1 1 - - -

for point x

G - Relative stress drop

n, - Bearing factor

No. Type Position Tension- Bending Torsion Tension- Bending Torsion

x pressure G b G t pressure nb n

mm G zd 1/mm 1/mm nzd

1/mm

1 Fillet with recess 20 3,13 3,13 1,44 1,21 1,21 1,14

2 Shaft fillet 62 2,49 2,49 1,15 1,2 1,2 1,13

3 Shaft fillet 70 2,45 2,45 1,15 1,21 1,21 1,14

4 Toothed shaft (evolvent) 70 - - - - - -

5 Shaft fillet 130 2,45 2,45 1,15 1,21 1,21 1,14

6 Fillet with recess 138 3,09 3,09 1,44 1,22 1,22 1,15

7 Feather key joint, 1 groove 144 - - - - - -

8 Shaft fillet 217 2,53 2,53 1,15 1,19 1,19 1,13

9 Calculation results 150 - - - - - -

for point x

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 11/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

zddBK, bdBK, dBK - Stress concentration factor at dBK

zd , b , - Stress concentration factors

Kv - Influence factor of surface hardening

No. Type Position Tension Bending Torsion Tension Bending Torsion Tension Bendin Torsio

x - bdBK dBK - b - g n

mm pressur pressur pressur Kvb Kv

e e e

zd Kv zd

zddBK

1 Fillet with recess 20 - - - 2,52 2,29 1,64 1 1 1

2 Shaft fillet 62 - - - 2,57 2,31 1,66 1 1 1

3 Shaft fillet 70 - - - 2,9 2,56 1,81 1 1 1

4 Toothed shaft 70 1,08 1,08 1,12 1,08 1,08 1,13 1 1 1

(evolvent)

5 Shaft fillet 130 - - - 2,9 2,56 1,81 1 1 1

6 Fillet with recess 138 - - - 2,74 2,46 1,74 1 1 1

7 Feather key joint, 1 144 2,53 2,53 1,52 2,56 2,56 1,53 1 1 1

groove

8 Shaft fillet 217 - - - 2,36 2,15 1,56 1 1 1

9 Calculation results 150 2,53 2,53 1,52 2,56 2,56 1,53 1 1 1

for point x

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 12/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

K, K - Total influence factor

zdW K, bW K, tW K - Cyclic fatigue strength of the notched part

K2F - Static bearing effect

No. Type Position Tension Bending Torsion Tension Bending Torsion Tension Bendin Torsio

x - K K - bW K s - g n

mm pressur pressur N/mm² pressur K2Fb K2Ft

tW K

e e N/mm² e

K zdW K K2Fzd

N/mm²

1 Fillet with recess 20 2,55 2,64 1,88 100,6 121,1 99,7 1 1,2 1,2

9 9 5

2 Shaft fillet 62 2,66 2,78 1,97 93,9 112,6 92,9 1 1,2 1,2

7 8

3 Shaft fillet 70 2,99 3,1 2,18 80,1 96,94 80,7 1 1,2 1,2

8 5

4 Toothed shaft 70 1,08 1,3 1,35 221,7 230,5 129,9 1 1,2 1,2

(evolvent) 3 7 8

5 Shaft fillet 130 2,99 3,1 2,18 80,1 96,94 80,7 1 1,2 1,2

8 5

6 Fillet with recess 138 2,76 2,87 2,02 90,5 109,0 90,7 1 1,2 1,2

6 3

7 Feather key joint, 1 144 2,56 2,96 1,77 100,1 108,0 106,4 1 1,2 1,2

groove 5 9

8 Shaft fillet 217 2,38 2,49 1,8 107,7 128,7 104,4 1 1,2 1,2

3 4

9 Calculation results 150 2,56 2,96 1,77 100,1 108,0 106,4 1 1,2 1,2

for point x 5 9

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 13/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

F - Yield point rise

zdFK, bFK, tFK - Yield point of the part

No. Type Position Tension- Bending Torsion Tension- Bending Torsion

x pressure Fb Ft pressure bFK tFK

mm Fzd zdFK N/mm² N/mm²

N/mm²

1 Fillet with recess 20 1,15 1,1 1 484,28 555,87 291,76

2 Shaft fillet 62 1,15 1,1 1 467,68 536,81 281,75

3 Shaft fillet 70 1,15 1,15 1 441,88 530,26 266,21

4 Toothed shaft (evolvent) 70 1 1 1 384,24 461,09 266,21

5 Shaft fillet 130 1,15 1,15 1 441,88 530,26 266,21

6 Fillet with recess 138 1,15 1,1 1 467,68 536,81 281,75

7 Feather key joint, 1 groove 144 1 1 1 421,11 505,34 291,76

8 Shaft fillet 217 1,1 1,1 1 463,23 555,87 291,76

9 Calculation results 150 1 1 1 421,11 505,34 291,76

for point x

Static safety

No. Type Position SF In in

x Point1 Point2

mm SF1 SF2

1 Fillet with recess 20 106,94 - -

2 Shaft fillet 62 10,98 - -

3 Shaft fillet 70 13,73 - -

4 Toothed shaft (evolvent) 70 - 29,25 34,29

5 Shaft fillet 130 15,85 - -

6 Fillet with recess 138 9,2 - -

7 Feather key joint, 1 groove 144 - 9,36 43,53

8 Shaft fillet 217 34,68 - -

9 Calculation results 150 9,46 - -

for point x

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 14/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

- Influence factor of the mean stress sensitivitz

mv , mv - Comparative mean stress

No. Type Position Tension Bending Torsion mv mv mv 1 mv 1 mv 2 mv 2

x - b K K N/mm N/mm N/mm² N/mm N/mm² N/mm

mm pressur ² ² ² ²

e

zd K

1 Fillet with recess 20 0,09 0,1 - 0 0 - - - -

2 Shaft fillet 62 0,08 0,1 - 0 0 - - - -

3 Shaft fillet 70 - 0,09 0,07 0 0 - - - -

4 Toothed shaft 70 - 0,24 0,12 - - 0 0 0 0

(evolvent)

5 Shaft fillet 130 - 0,09 0,07 0 0 - - - -

6 Fillet with recess 138 - 0,1 0,08 0 0 - - - -

7 Feather key joint, 1 144 - 0,09 - - - 0 0 0 0

groove

8 Shaft fillet 217 - 0,11 - 0 0 - - - -

9 Calculation results 150 - 0,09 0,09 0 0 - - - -

for point x

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 15/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Alternating fatigue strength of the part (rated fatigue limit)

No. Type Position Tension Bending Torsion Tensio Bending Torsion Tensio Bending Torsion

x - bA DK tA DK n- in in n- in in

mm pressur N/mm² N/mm² pressur Point1 Point1 pressur Point2 Point2

e e bA DK1 tA DK1 e bA DK2 tA DK2

zdA DK in N/mm² N/mm² in N/mm² N/mm²

N/mm² Point1 Point2

zdA DK1 zdA DK2

N/mm² N/mm²

1 Fillet with recess 20 100,6 121,1 - - - - - - -

9 9

2 Shaft fillet 62 93,9 112,6 - - - - - - -

7

3 Shaft fillet 70 - 96,9 80,7 - - - - - -

4 5

4 Toothed shaft 70 - - - - 230,5 129,9 - 230,5 129,9

(evolvent) 7 8 7 8

5 Shaft fillet 130 - 96,9 80,7 - - - - - -

4 5

6 Fillet with recess 138 - 109,0 90,7 - - - - - -

3

7 Feather key joint, 1 144 - - - - 108,0 106,4 - 108,0 -

groove 9 9

8 Shaft fillet 217 - 128,7 - - - - - - -

3

9 Calculation results 150 - 108,0 106,4 - - - - - -

for point x 9

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 16/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Dynamic safety

No. Type Position SD in in

x Point1 Point2

mm SD1 SD2

1 Fillet with recess 20 22,59 - -

2 Shaft fillet 62 2,3 - -

3 Shaft fillet 70 2,84 - -

4 Toothed shaft (evolvent) 70 - 14,53 16,99

5 Shaft fillet 130 3,44 - -

6 Fillet with recess 138 2,19 - -

7 Feather key joint, 1 groove 144 - 2,34 9,31

8 Shaft fillet 217 8,03 - -

9 Calculation results 150 2,38 - -

for point x

Unnotched (part dimension) for point x

N/mm²

650 Material = 1C50

Number = 1.0540

B (d eff ) = 600 N/mm²

520

zdF = 384 N/mm²

bF = 461 N/mm²

tF = 266 N/mm²

390

zdW = 240 N/mm²

bW = 300 N/mm²

tW = 176 N/mm²

260

Tension-pressure

Bending

130 Torsion

-130

-260

-390 N/mm²

130 260 390 520 650

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 17/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Notched (part dimension) for point x

N/mm²

650 Material = 1C 50

Number = 1.0540

B (d eff ) = 600 N/mm²

520

zdFK = 421 N/mm²

bFK = 505 N/mm²

tFK = 292 N/mm²

390

zdWK = 100 N/mm²

bWK = 108 N/mm²

tWK = 106 N/mm²

260

Tension-pressure

Bending

130 Torsion

-130 N/mm²

130 260 390 520 650

Trend of curve of the transverse force in the Y-X-plane

Q y ,N

19000

12666

6333

-6333

-12666

-19000

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 18/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Trend of curve of the transverse force in the Z-X-plane

Q z,N

8141

5427

2714

-2714

-5427

-8141

0 50 100 150 200 250

L, mm

Trend of curve of the transverse force (combined characteristic)

Q, N

20670

13780

6890

-6890

-13780

-20670

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 19/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Bending moment in the Y-X-plane

M b y , Nm

968,7

645,8

322,9

0,0

-322,9

-645,8

-968,7

0 50 100 150 200 250

L, mm

Trend of curve of the bending moment curve in the Z-X plane

M b z , Nm

415,2

276,8

138,4

0,0

-138,4

-276,8

-415,2

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 20/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Trend of curve of the bending moment (combined characteristic)

M b , Nm

1054

703

351

- 351

- 703

-1054

0 50 100 150 200 250

L, mm

Trend of curve of the torsional moment

M t , Nm

765,0

510,0

255,0

0,0

-255,0

-510,0

-765,0

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 21/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Trend of curve of the tension-pressure forces

F zd ,N

5761

3841

1920

-1920

-3841

-5761

0 50 100 150 200 250

L, mm

Deflection and angle of deflection in the Y-X-plane

Angle

Deflection

y, mm

6,04e- 2 1,91e- 2

4,03e- 2 1,27e- 2

2,01e- 2 6,35e- 3

0.00 0.00

- 2,01e- 2 - 6,35e- 3

- 4,03e- 2 - 1,27e- 2

- 6,04e- 2 - 1,91e- 2

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 22/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Deflection and angle of deflection in the Z-X-plane

Angle

Deflection

y, mm

7,80e- 3 4,52e- 3

5,20e- 3 3,01e- 3

2,60e- 3 1,51e- 3

0.00 0.00

- 2,60e- 3 - 1,51e- 3

- 5,20e- 3 - 3,01e- 3

- 7,80e- 3 - 4,52e- 3

0 50 100 150 200 250

L, mm

Deflection and angle of deflection (combined characteristic)

Angle

Deflection

y, mm

6,08e- 2 1,91e- 2

4,05e- 2 1,27e- 2

2,03e- 2 6,37e- 3

0.00 0.00

- 2,03e- 2 - 6,37e- 3

- 4,05e- 2 - 1,27e- 2

- 6,08e- 2 - 1,91e- 2

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 23/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Equivalent mean stress (normal stress)

sm v , N/mm²

0,000

0,000

0,000

0,000

-0,000

-0,000

-0,000

0 50 100 150 200 250

L, mm

Equivalent mean stress (shear stress)

tm v , N/mm²

0,000

0,000

0,000

0,000

-0,000

-0,000

-0,000

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 24/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Safety factor against yielding

(diagram section up to 5*minimum safety)

S F

46,0

38,3

30,7

23,0

15,3

7,7

0,0

0 50 100 150 200 250

L, mm

Safety against fatigue fracture

(diagram section up to 5*minimum safety)

S D

10,93

9,11

S D 7 =9,3

S D 8 =8,0 7,29

5,46

3,64

S D 5 =3,4

SD 3 =2,8

S D 9 =2,4 1,82

S D 2 =2,3 S D 6 =2,2

S D 7 =2,3

0,00

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 25/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Maximum value of the tension-pressure stress (combined characteristic)

sm a x , N/mm²

3,01

2,00

1,00

0,00

-1,00

-2,00

-3,01

0 50 100 150 200 250

L, mm

Maximum value of the bending stress (combined characteristic)

sm a x , N/mm²

46,4

30,9

15,5

0,0

-15,5

-30,9

-46,4

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 26/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Maximum value of the torsional stress (combined characteristic)

tm a x , N/mm²

20,5

13,7

6,8

0,0

- 6,8

-13,7

-20,5

0 50 100 150 200 250

L, mm

Equivalent stress development (resultant)

sv , N/mm²

56,0

46,7

37,4

28,0

18,7

9,3

0,0

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 27/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Amplitude value of the tension-pressure stress (combined characteristic)

sz d a , N/mm²

3,01

2,00

1,00

0,00

-1,00

-2,00

-3,01

0 50 100 150 200 250

L, mm

Amplitude value of the bending stress (combined characteristic)

sb a , N/mm²

46,4

30,9

15,5

0,0

-15,5

-30,9

-46,4

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 28/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Amplitude value of the torsional stress (combined characteristic)

tt a , N/mm²

20,5

13,7

6,8

0,0

- 6,8

-13,7

-20,5

0 50 100 150 200 250

L, mm

Mean value of the tension-pressure stress (combined characteristic)

sz d m , N/mm²

0,000

0,000

0,000

0,000

-0,000

-0,000

-0,000

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 29/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Mean value of the bending stress (combined characteristic)

sb m , N/mm²

0,000

0,000

0,000

0,000

-0,000

-0,000

-0,000

0 50 100 150 200 250

L, mm

Mean value of the torsional stress (combined characteristic)

tt m , N/mm²

0,000

0,000

0,000

0,000

-0,000

-0,000

-0,000

0 50 100 150 200 250

L, mm

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 30/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

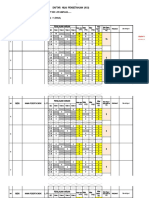

Safety factor against yielding

L1 L2

> 1,20

Safety against fatigue fracture

L1 L2

> 1,20

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 31/32

Educational version

Program : MDESIGN 2020 - User : Customer : TEO

Module version : 18.0.13e Date : 08.08.2023 Proj. Nr :

Shaft

Calculation graphic Y-X-plane

Fr2

y

Fr4

T2 T1

Fax1

m1*g

L1 L2

x, mm

0 25,900 51,800 77,700 103,600 129,500 155,400 181,300 207,200 233,100 259,000

Calculation graphic Z-X-plane

Fr1

z

Fr3

Fax1

M b1

T2 T1

m1*g

L1 L2

x, mm

0 25,900 51,800 77,700 103,600 129,500 155,400 181,300 207,200 233,100 259,000

MDESIGN RONCEA PETRU.MDP 01/08/2024 10:20:23 Page 32/32

You might also like

- Raducanu MdesignDocument35 pagesRaducanu MdesignMada 230No ratings yet

- C4M Bar Bending Schedule BBS FormatDocument8 pagesC4M Bar Bending Schedule BBS FormatRaja VarshneyNo ratings yet

- RSB CalogcogDocument11 pagesRSB CalogcogMoamar TaratinganNo ratings yet

- As3 - Sailau Dinara - ColaboratoryDocument6 pagesAs3 - Sailau Dinara - ColaboratoryFarukh IskalinovNo ratings yet

- Tensile TestDocument1 pageTensile TestA. ΒρατσισταNo ratings yet

- Slab Quantity EstimateDocument8 pagesSlab Quantity EstimateDeepak Kumar SinghNo ratings yet

- Scheda Tecnica 6050 Composito UltraDocument1 pageScheda Tecnica 6050 Composito UltraJulioCarrascoSNo ratings yet

- Bar Bending Schedule BBS FormatDocument8 pagesBar Bending Schedule BBS FormatKundan SinghNo ratings yet

- Predict-Sw 3.0 For Usd Units: Multipoint Analysis Template MetricDocument23 pagesPredict-Sw 3.0 For Usd Units: Multipoint Analysis Template MetricMohammad NadimNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Metrados: Obra: Fabrica Ubicación: Propietario: Fecha: Hecho Por: Aepd Pag NoDocument10 pagesMetrados: Obra: Fabrica Ubicación: Propietario: Fecha: Hecho Por: Aepd Pag NoRonald Guevara AliagaNo ratings yet

- Field Leak Estimator en v1.3Document41 pagesField Leak Estimator en v1.3Nicola SorbiNo ratings yet

- Lecture # 40: Creation of A File On NTFSDocument6 pagesLecture # 40: Creation of A File On NTFSapi-3812413No ratings yet

- BR-WR Snap RingsDocument9 pagesBR-WR Snap RingsPhilNo ratings yet

- Pierszcienie Lozyskowe IdcDocument9 pagesPierszcienie Lozyskowe Idcaku2505kamuNo ratings yet

- DC-Motor M28x20/S Id.-Nr. 220518 (12V) 220531 (24V)Document2 pagesDC-Motor M28x20/S Id.-Nr. 220518 (12V) 220531 (24V)Adriano R. OrtizNo ratings yet

- Sondir S3 - BrondongDocument3 pagesSondir S3 - BrondongAl MasagalaNo ratings yet

- Lucsoon National High School Lucsoon, Naval, Biliran: 8-AristotleDocument18 pagesLucsoon National High School Lucsoon, Naval, Biliran: 8-Aristotleサビーネ ジェイNo ratings yet

- Hook 2DIA16mm ReportDocument30 pagesHook 2DIA16mm ReportYahia OsamaNo ratings yet

- Beam DesignDocument29 pagesBeam DesignMwengei MutetiNo ratings yet

- Contoh Analisis Hasil PTS: PG Isian 3.1 3.2 3.1 3.2Document9 pagesContoh Analisis Hasil PTS: PG Isian 3.1 3.2 3.1 3.2Ilham PratamaNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Cutting ListDocument10 pagesCutting ListCandido VeneracionNo ratings yet

- Adobe Scan 12 Sep 2023Document1 pageAdobe Scan 12 Sep 2023salebratoNo ratings yet

- Push Over Portico de 2 PisosDocument2 pagesPush Over Portico de 2 PisosAlexis MasamiNo ratings yet

- Phast CFD - Pool FiresDocument20 pagesPhast CFD - Pool FiresPeddy NesaNo ratings yet

- Sgim 1Document16 pagesSgim 1Liced RoblesNo ratings yet

- Bar Bending Schedule BBSDocument8 pagesBar Bending Schedule BBSsandip santpalNo ratings yet

- Bar Bending Schedule BBSDocument8 pagesBar Bending Schedule BBSEr HarishNo ratings yet

- Bar Bending Schedule BBS FormatDocument8 pagesBar Bending Schedule BBS FormatgirumNo ratings yet

- Government of Andhra Pradesh C.T.Department: Form of Way Bill Form X or Form 600Document3 pagesGovernment of Andhra Pradesh C.T.Department: Form of Way Bill Form X or Form 600ChakrNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- Tugas 1 Cs SoketDocument1 pageTugas 1 Cs Soketilham dwi putraNo ratings yet

- Hot Rolled Steel Section Sets: No Data To Print ..Document2 pagesHot Rolled Steel Section Sets: No Data To Print ..9082888lcNo ratings yet

- Anchor Bolt Dia CheckDocument2 pagesAnchor Bolt Dia CheckSaravanan SNo ratings yet

- SasaDocument2 pagesSasaAsh DizonNo ratings yet

- Wiremesh FormatDocument3 pagesWiremesh FormatRajat SharmaNo ratings yet

- 16.12.2022 208510Document6 pages16.12.2022 208510THE SHAYARI HOUSENo ratings yet

- 07 SMR JULI - Daily Report SolarDocument11 pages07 SMR JULI - Daily Report Solarzhy1493No ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- CE 411 - Lecture 5Document14 pagesCE 411 - Lecture 5Israel PopeNo ratings yet

- Touch Off: Yakusoku No Neverland OP Arranged by Steve HansenDocument5 pagesTouch Off: Yakusoku No Neverland OP Arranged by Steve HansenKevinNo ratings yet

- Daftar Nilai Pjok Kelas 1 Semester 1Document17 pagesDaftar Nilai Pjok Kelas 1 Semester 1Rustan Spdi100% (2)

- Planilla Conversiones UnidadesDocument5 pagesPlanilla Conversiones UnidadesLissette Karina Moncada SalinasNo ratings yet

- Usulan TUK TBSM DAN TKRO 2020Document9 pagesUsulan TUK TBSM DAN TKRO 2020Robby AnwarNo ratings yet

- Axial Ultimate Single Pile Capacity Using CPT / Sondir Data (Schmertman and Nottingham, 1975)Document3 pagesAxial Ultimate Single Pile Capacity Using CPT / Sondir Data (Schmertman and Nottingham, 1975)Ahmad AkbarNo ratings yet

- Champs Elys2ees AccordsDocument1 pageChamps Elys2ees AccordsC-Lee-O -No ratings yet

- Blackbird p4 - The Beatles - Guitar Tab PDF - BlackbirdDocument1 pageBlackbird p4 - The Beatles - Guitar Tab PDF - BlackbirdLe Roi KandaNo ratings yet

- Laporan Dokumentasi AntaraDocument68 pagesLaporan Dokumentasi AntaraBudi FikriNo ratings yet

- Laporan Dokumentasi Paparan AkhirDocument70 pagesLaporan Dokumentasi Paparan AkhirBudi FikriNo ratings yet

- Programación de CortesDocument28 pagesProgramación de Cortescesar89278No ratings yet

- JEE Main Test Series - Paper - 2Document13 pagesJEE Main Test Series - Paper - 2Ammar AdilNo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- FINAL Exam - Answer SheetDocument1 pageFINAL Exam - Answer SheetViggo VillanuevaNo ratings yet

- Tools NameDocument4 pagesTools NameManohar Paul Praveen MNo ratings yet

- 5D - Richmon PribadiDocument124 pages5D - Richmon PribadiRichmon PribadiNo ratings yet

- Cataleg PSCDocument151 pagesCataleg PSCAntônio Cesar de OliveiraNo ratings yet

- OI MARI' Partitura BatteriaDocument3 pagesOI MARI' Partitura BatteriapqbqpnzbqgNo ratings yet

- The Promise: Secret GardenDocument3 pagesThe Promise: Secret GardenYun Kwan ChongNo ratings yet

- Angle Section PropertiesDocument9 pagesAngle Section PropertiesDaniyal AhmadNo ratings yet

- Metals AluminumDocument22 pagesMetals AluminumSantosh KumarNo ratings yet

- Assignment Fencing and Gate ConstechDocument24 pagesAssignment Fencing and Gate Constechillya amyraNo ratings yet

- Lab 1Document25 pagesLab 1Self McNo ratings yet

- Only Questions HTDocument2 pagesOnly Questions HTrkiran05No ratings yet

- CTCDocument3 pagesCTCnaveenpnaidu1No ratings yet

- Mechanical and Thermal Properties of Lightweight Concretes With Vermiculite and EPS Using Air-Entraining AgentDocument8 pagesMechanical and Thermal Properties of Lightweight Concretes With Vermiculite and EPS Using Air-Entraining AgentAbner SantosNo ratings yet

- Split Charge InstructionsDocument4 pagesSplit Charge InstructionsAugusto ZanlungoNo ratings yet

- SJVNL Junior Field Engineer 23 October 2021 Paper WatermarkedDocument26 pagesSJVNL Junior Field Engineer 23 October 2021 Paper Watermarkedsantosh singhNo ratings yet

- Building Construction4Document473 pagesBuilding Construction4Jett Soriano100% (2)

- ABET Laminati Tech Data HPL Horizontal Post Forming 0.9mm R-110Document4 pagesABET Laminati Tech Data HPL Horizontal Post Forming 0.9mm R-110Ronaldino MacatangayNo ratings yet

- Difficulty in Sinking Well FoundationDocument22 pagesDifficulty in Sinking Well Foundationhussain9000100% (1)

- Mag General Business: Certificate of QualityDocument1 pageMag General Business: Certificate of QualityErik Jhonattan Jara YpanaqueNo ratings yet

- Essar Steels PPT b2bDocument14 pagesEssar Steels PPT b2bSaravanan SnrNo ratings yet

- Calentador Rheem de 250000 BtuhrDocument6 pagesCalentador Rheem de 250000 BtuhrAJM Controles y QNo ratings yet

- CTV Chiller WeightsDocument5 pagesCTV Chiller WeightsNoushad P HamsaNo ratings yet

- Colt VentilationDocument7 pagesColt VentilationRamkrishna MahatoNo ratings yet

- Triplexed Conductors in Air: Ampacity TablesDocument2 pagesTriplexed Conductors in Air: Ampacity TablesalbertoNo ratings yet

- Data Sheet - Wilden AODD Pump PDFDocument28 pagesData Sheet - Wilden AODD Pump PDFFirdaus NawiNo ratings yet

- Ficha Oleo Termico - UnlockedDocument2 pagesFicha Oleo Termico - UnlockedWisard MagalhãesNo ratings yet

- Chem 110, Chapter 9 UDLDocument50 pagesChem 110, Chapter 9 UDL5fyqv62kytNo ratings yet

- Thesis Po Ya Chuang PDFDocument271 pagesThesis Po Ya Chuang PDFMilan VachhaniNo ratings yet

- Chapter - Forces and Matter PDFDocument17 pagesChapter - Forces and Matter PDFasiyaNo ratings yet

- V O Nanofibre Sheet Actuators: LettersDocument4 pagesV O Nanofibre Sheet Actuators: Letters俞俊No ratings yet

- A Study On Creep and Drying Shrinkage of High Performance ConcreteDocument4 pagesA Study On Creep and Drying Shrinkage of High Performance Concreteit does not exist for the [mpossibleNo ratings yet

- SBW-RFMA-005R1 - Engineer's ApprovalDocument40 pagesSBW-RFMA-005R1 - Engineer's ApprovalChamux skalNo ratings yet

- ValvesDocument82 pagesValvespuru55980No ratings yet

- Glass ClassificationDocument4 pagesGlass ClassificationHAN HANNo ratings yet

- Equipos Fan & Coil YgfcDocument26 pagesEquipos Fan & Coil YgfcRoberto Reyes LaraNo ratings yet

- Characteristic Study of Geopolymer Fly Ash Sand As A Replacement To Natural River SandDocument8 pagesCharacteristic Study of Geopolymer Fly Ash Sand As A Replacement To Natural River SandLuis Fernando Tonholo DomingosNo ratings yet