Professional Documents

Culture Documents

PIB1100 A1 KT166 275 Actuator To Bosch MV Pump

PIB1100 A1 KT166 275 Actuator To Bosch MV Pump

Uploaded by

milad miriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIB1100 A1 KT166 275 Actuator To Bosch MV Pump

PIB1100 A1 KT166 275 Actuator To Bosch MV Pump

Uploaded by

milad miriCopyright:

Available Formats

ACB275H Actuator Installation

on a Bosch MW Fuel Injection Pump

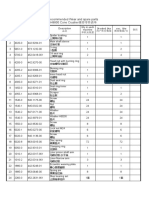

1 INTRODUCTION 2 Kt166 - parts list

Adding the GAC ACB275H actuator to a Bosch MW fuel injection pump enables direc-

ITEM

tor access to the actuator. NUMBER

PART NUMBER QTY DESCRIPTION:

1 PL283 1 Mounting Plate

2 GA176 1 Mounting Plate Gasket

M6x30 Flat Head - Mounting Plate

3 HW05-629 6

Retaining Screws

4 PL365 1 Actuator Mounting Bar

5 HW05-535 2 M6x45 Socket Head Cap Screws

6 HW06-627 2 M6 Lock Washers

7 HW06-601 2 M6 Flat Washers

8 HW05-566 1 M6x16 Actuator Retaining Screw

9 HW04-405 1 Linkage - M5x115 Threaded Rod

10 PL276 1 Stop Plate - Linkage Assembly

11 HW07-701 4 M5 Hex Nuts

12 HW06-609 1 M5 Flat Washer

13 HW07-704 1 M5 Castle Nut w/ Plastic Insert

14 HW05-521 1 M5x20 Button Head Cap Screw

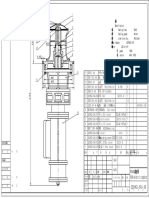

3 component description

KT166 Installation Kit for Bosch MW Pump 12.9.2019 PIB1100_A1

1

Governors America Corp. © 2019 Copyright All Rights Reserved

4 fuel pump preparation

Remove the back governor cover and all internal parts from the exist- 1. Remove the top cover (15) of the ACB275H actuator and remove the

ing RS/RSV mechanical governor per Bosch service instructions. existing linkage (16) from the actuator operating lever (17) by removing

screw (18) and nut (19).

2. Remove the two ball links (20) from the existing linkage.

3. Install one ball link (20) onto the fuel control rack with screw (12), wash-

er (13) and hex nut (14) from KT166. Tighten nut (14) to 30-40 in-lbs

(3.5-4.5 Nm). Check to make sure the ball link can move freely without

binding.

4. Screw the threaded linkage rod (4) into this ball link until bottomed and

secure with M5 hex nut (5) torqued to 30-40 in-lbs (3.5-4.5 Nm). Recheck

the ball link for freedom of movement.

KT166 Installation Kit for Bosch MW Pump 12.9.2019 PIB1100_A1

2

Governors America Corp. © 2019 Copyright All Rights Reserved

5. Apply Loctite 5999 or equivalent sealing compound to gasket (1) and

position the gasket onto the RSV housing. Slide the mounting plate (2)

with its counter-bored side facing the RSV housing, over the linkage

rod and install the 6 flat-head retaining screws (3). Torque the retaining

screws equally to 70-80 in-lbs (8-9 Nm)

6. Place the stop plate (6) with two retaining nuts onto the linkage rod.

Pull the rod completely out and adjust the stop plate position to 2.560”

+/- 0.020” (65 +/- 0.5mm) as shown. Tighten the locknuts (5) to 30-40

in-lbs (3.5-4.5 Nm). Be sure the stop plate is in the vertical position and

that the rod moves freely in both radial direction.

7. Screw on the outer ball link with its locknut and adjust its position to

4.450” +/- 0.020” (113 +/- 0.5mm). Position the ball link horizontally and

tighten the lock nut to 30-40 in-lbs (3.5-4.5 Nm).

Check to be sure the linkage moves freely for about 6° from horizontal

centerline in each direction.

8. Pull the linkage to its full outward position. Apply a coating of Loctite

5999 or equivalent sealant to the actuator face gasket (21) and place it

onto the actuators mounting surface.

9. Place the actuator onto the mounting plate and screw in the top two

retaining screws (22) hand tight. The two bottom retaining screws can

be installed with a ball end hex wrench.

NOTE: The shorter M6x16 cap screw (7), supplied with KT166, must

be installed in the lower right hand position. This is important, otherwise

the fuel rack will not move to the no-fuel position!

10. Install the lower mounting block (8) with two M6x45mm socket head cap

screws (11), lockwasher (10) and flat washer (9) and torque to 70-80 14. Pull the linkage all the way out of the pump, then move it in toward the

in-lbs (8-9 Nm). pump 0.020” (0.5mm). Hold it in this position and tighten the operating

lever stop nut to 30-40 in-lbs (3.5-4.5 Nm). Make sure the linkage can

11. Check to be sure the cam on the manual shut-off lever shaft can push still be moved radially approximately 6° in either direction. Move the

the linkage all the way to the zero fuel position. operating lever manually to the extreme forward position and release

12. Tighten all four actuator retaining screws to (22 & 7) to 70-80 in-lbs it. It must snap back without binding or friction.

(8-9 Nm) 15. The maximum fuel stop screw can be set for full power. Refer to the

13. Install linkage retaining screw (12) through the ball link. Place the engine manufacturers specifications for the proper setting.

washer (13) between the ball link and operating lever and install locknut 16. Re-install the actuator top cover (15) and tighten the for cover screws

(14). Install loosely so the linkage can still be adjusted. to 4-9 in-lbs (0.5-1.0 Nm)

KT166 Installation Kit for Bosch MW Pump 12.9.2019 PIB1100_A1

3

Governors America Corp. © 2019 Copyright All Rights Reserved

You might also like

- Business Plan Security CompanyDocument27 pagesBusiness Plan Security CompanyJiji100% (3)

- XL100 BS4 BS6Document47 pagesXL100 BS4 BS6karthi v keyan88% (8)

- Part ListDocument9 pagesPart ListMuhammad GaneshaNo ratings yet

- SAT3series Parts Section-June2014Document72 pagesSAT3series Parts Section-June2014Heidi Cuevas Venegas100% (2)

- Jenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EDocument6 pagesJenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EArîf100% (2)

- Family ResourcesDocument33 pagesFamily ResourcesJackie S LaymanNo ratings yet

- BV 12 H PDFDocument35 pagesBV 12 H PDFAbdolhak PDM reliabilityNo ratings yet

- Manual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFDocument27 pagesManual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFmuahdibNo ratings yet

- Dellorto PHBHDocument4 pagesDellorto PHBHv0rtex77No ratings yet

- Portable Planer: GHO 6500 - 3 601 E96 0F0Document3 pagesPortable Planer: GHO 6500 - 3 601 E96 0F0Manmohan SharmaNo ratings yet

- Hammer Kit For Lifting ArmDocument2 pagesHammer Kit For Lifting ArmAbelardo PinaNo ratings yet

- Portable Planer: GHO 6500 - 3 601 E96 0F0Document7 pagesPortable Planer: GHO 6500 - 3 601 E96 0F0Manmohan SharmaNo ratings yet

- Recommended Wear and spare parts H8800 Cone Crusher推荐零件清单Document3 pagesRecommended Wear and spare parts H8800 Cone Crusher推荐零件清单Lmf DanielNo ratings yet

- List of Ais Spare Parts 2008: Issue Date: 13.02.08 Valid Until: 31.12.08Document14 pagesList of Ais Spare Parts 2008: Issue Date: 13.02.08 Valid Until: 31.12.08Kushtrim MalaNo ratings yet

- 5eecf65e9fe6013c4283e691 - 175 Series Installation KitsDocument11 pages5eecf65e9fe6013c4283e691 - 175 Series Installation Kitsdaniel armando ardila martinez100% (1)

- Picture Book Index/Checklist For Pipe Handler PH-60 and PH-85Document17 pagesPicture Book Index/Checklist For Pipe Handler PH-60 and PH-85HayLenLeeNo ratings yet

- Vdocuments - MX - Sinotruk Howo Truck Parts CatalogueDocument252 pagesVdocuments - MX - Sinotruk Howo Truck Parts CatalogueCLEMENT KUNDANo ratings yet

- RTR 160 4V Bsvi Parts CatalogueDocument56 pagesRTR 160 4V Bsvi Parts Catalogueforwardktm100% (2)

- Replace Valve Stem Seals With Cylinder Head InstalledDocument4 pagesReplace Valve Stem Seals With Cylinder Head InstalledRendy MechanicNo ratings yet

- DOC1304647Document11 pagesDOC1304647mediacampaigncc24No ratings yet

- ALOJAMIENTOS SUPER ESTRUCTURA - 2017-10-noCPI-GSI-EM028161-01-6060-oversized Bushings For MainframeDocument3 pagesALOJAMIENTOS SUPER ESTRUCTURA - 2017-10-noCPI-GSI-EM028161-01-6060-oversized Bushings For MainframeCesar G. AhureNo ratings yet

- 8x10 NH 5 UnitsDocument3 pages8x10 NH 5 UnitsMantenimiento ElectroPlastNo ratings yet

- Nation Parts Guide PG 29Document1 pageNation Parts Guide PG 29ramsi17No ratings yet

- Westerbeke 4,5bcgtc Part ListDocument77 pagesWesterbeke 4,5bcgtc Part Listcengiz kutukcu100% (1)

- HLK-31000 Manual (Rev 0)Document6 pagesHLK-31000 Manual (Rev 0)Thanh NghiemNo ratings yet

- 50KN Electric Capstan AS BUILD DWGDocument1 page50KN Electric Capstan AS BUILD DWGBudiarta CassaNo ratings yet

- Appendix E-Parts Details For Sliding VanepumpDocument5 pagesAppendix E-Parts Details For Sliding VanepumpAgistaNo ratings yet

- Tvs Motor Company: Parts CatalogueDocument57 pagesTvs Motor Company: Parts Cataloguetvsparavattani100% (7)

- Lista de Partes de Suspension HendricsonDocument4 pagesLista de Partes de Suspension HendricsonLEO100% (1)

- Installation Instructions For Blade Guide (04602, 04603) To Saw It Pneumatic SawDocument2 pagesInstallation Instructions For Blade Guide (04602, 04603) To Saw It Pneumatic SawAndres NavarroNo ratings yet

- AudiDocument2 pagesAudioctizipNo ratings yet

- Ford TSG-416 Service Parts Manual (April, 2008)Document17 pagesFord TSG-416 Service Parts Manual (April, 2008)MárcioNo ratings yet

- VXN155 Vixion R Electrical 1Document1 pageVXN155 Vixion R Electrical 1smksteknologiNo ratings yet

- RTR 200 Bs6parts CatalogueDocument54 pagesRTR 200 Bs6parts CatalogueforwardktmNo ratings yet

- B Ackmer PompaDocument2 pagesB Ackmer PompaGrzegorzNo ratings yet

- CAT Fuel Priming Pump Parts List r1Document2 pagesCAT Fuel Priming Pump Parts List r1gunawanNo ratings yet

- L - HRF2F40401 - Hose & Pulley Block (M, METRIC)Document4 pagesL - HRF2F40401 - Hose & Pulley Block (M, METRIC)Gustavo RodriguezNo ratings yet

- Manual Peças 935HDocument143 pagesManual Peças 935HWeverton PereiraNo ratings yet

- Print PAFDocument2 pagesPrint PAFSonaina KhanNo ratings yet

- Sr30je E01Document3 pagesSr30je E01freddy1115No ratings yet

- Slk6750 Part Catalog SunlongDocument34 pagesSlk6750 Part Catalog Sunlongreurri100% (2)

- Gestionnaire Pièces de Rechange HAWE - HK. 4..-H Single Circuit PumpDocument3 pagesGestionnaire Pièces de Rechange HAWE - HK. 4..-H Single Circuit PumpGERALD SIMON100% (1)

- LNP125 Gear 125 Electrical 3Document1 pageLNP125 Gear 125 Electrical 3gsalak40No ratings yet

- Hendrickson - Airtek Parts List For Volvo Vehicles (Sp174f)Document8 pagesHendrickson - Airtek Parts List For Volvo Vehicles (Sp174f)Eli RochaNo ratings yet

- NEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Document8 pagesNEXT GEN HEX - SERVICE PARTS REFERENCE GUIDE - 2017 - revised10OCT2017Aldo MaranonNo ratings yet

- Mounting Kits For Wide Panel Antennas (Installation Instruction)Document4 pagesMounting Kits For Wide Panel Antennas (Installation Instruction)you are awesomeNo ratings yet

- Part Diagram - M1901B - MakitaDocument4 pagesPart Diagram - M1901B - MakitaRenhard GultomNo ratings yet

- Eaton V Series 3520v Standard Double Pump Parts Data I 3202 S en UsDocument4 pagesEaton V Series 3520v Standard Double Pump Parts Data I 3202 S en UskieshutoNo ratings yet

- HT-101 Parts BookDocument190 pagesHT-101 Parts Booktranphu.vttbNo ratings yet

- Part Diagram - N1900B - MakitaDocument4 pagesPart Diagram - N1900B - MakitaRenhard GultomNo ratings yet

- Assembly: Usinage X-Spec IncDocument1 pageAssembly: Usinage X-Spec IncFedericoButronNo ratings yet

- Part Diagram - UB1103 - MakitaDocument3 pagesPart Diagram - UB1103 - MakitaRenhard GultomNo ratings yet

- SacrifierDocument14 pagesSacrifierIhsanNo ratings yet

- M20 Clutch-3Document42 pagesM20 Clutch-3Max NeitesNo ratings yet

- UPower140 1P56FMJDocument18 pagesUPower140 1P56FMJF TsNo ratings yet

- 14-P-220 Mud Pump & Parts SouthwestDocument8 pages14-P-220 Mud Pump & Parts SouthwestLuis Manuel Montoya RiveraNo ratings yet

- Group 3 Pump DeviceDocument24 pagesGroup 3 Pump DeviceTaha RdmanNo ratings yet

- V Series Vickers 4520v Standard Double Pump Parts DataDocument4 pagesV Series Vickers 4520v Standard Double Pump Parts DataNick OchoaNo ratings yet

- GDR155 All New Aerox 155 Connected Electrical 1Document2 pagesGDR155 All New Aerox 155 Connected Electrical 1Sat AkbarNo ratings yet

- Del 5Document8 pagesDel 5Владислав ДяченкоNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- B3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementDocument10 pagesB3-201-2018 - Developing and Using Justifiable Asset Health Indices For Tactical and Strategic Risk ManagementNamLeNo ratings yet

- Random-Access Memory - WikipediaDocument14 pagesRandom-Access Memory - WikipediaHeera SinghNo ratings yet

- Add and Subtract Fractions With Unlike Denominators 7 +Document5 pagesAdd and Subtract Fractions With Unlike Denominators 7 +Priyanka JawaherNo ratings yet

- Lampiran PQ - CSMS Questionnaires Pertamina WiriagarDocument29 pagesLampiran PQ - CSMS Questionnaires Pertamina WiriagarYogi Anggawan100% (3)

- Mac Formatting ElCapDocument7 pagesMac Formatting ElCapJC SardiniaNo ratings yet

- Mcdonald'S History ListingDocument9 pagesMcdonald'S History Listinghimanshu-guntewar-4431No ratings yet

- 2019 - International Trade Policy PDFDocument17 pages2019 - International Trade Policy PDFJuana FernandezNo ratings yet

- FBI Special Agent in Charge Eric W. Sporre Request Criminal Prosecution Foreclosure FRAUDDocument101 pagesFBI Special Agent in Charge Eric W. Sporre Request Criminal Prosecution Foreclosure FRAUDNeil GillespieNo ratings yet

- HRM Notes A2Document114 pagesHRM Notes A2Hari Prasad AnupojuNo ratings yet

- PLC Transmit Instruction Mov Smov Cmov Bmov FmovDocument2 pagesPLC Transmit Instruction Mov Smov Cmov Bmov FmovNatKThNo ratings yet

- Bai Thu Hoach Kinh Te Chinh TriDocument28 pagesBai Thu Hoach Kinh Te Chinh TriHai TranNo ratings yet

- Property Law Conso Digested Cases 1st Sem 2019 2020Document487 pagesProperty Law Conso Digested Cases 1st Sem 2019 2020Mik ZeidNo ratings yet

- Tax Structure in IndiaDocument33 pagesTax Structure in IndiaVinayak Saxena100% (1)

- INF1520 May 2012 Exam Answers DoneDocument7 pagesINF1520 May 2012 Exam Answers DoneNthabiseng MahlasiNo ratings yet

- A4064-2 Datasheet en - 201003Document1 pageA4064-2 Datasheet en - 201003Khalid ElfiqyNo ratings yet

- Enhancement of InfotypesDocument8 pagesEnhancement of InfotypesAshok KancharlaNo ratings yet

- Summaryof StandardsDocument2 pagesSummaryof Standardsroman_maximoNo ratings yet

- Japan AwardsDocument3 pagesJapan AwardsLeonard LyonsNo ratings yet

- 24 Micro-Cap Multibagger Stocks To Buy Now PDFDocument11 pages24 Micro-Cap Multibagger Stocks To Buy Now PDFPravin YeluriNo ratings yet

- P2 Forces and Terminal Velocity HigherDocument12 pagesP2 Forces and Terminal Velocity HigherdownendscienceNo ratings yet

- ISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020Document69 pagesISAE 3000 ICI-Pakistan-Sustainability-Report-2019-2020saqlain khanNo ratings yet

- Chapter 9: FOREX MARKET Key PointsDocument6 pagesChapter 9: FOREX MARKET Key PointsDanica AbelardoNo ratings yet

- Handbook TNSTC CbeDocument25 pagesHandbook TNSTC CbeAnonymous SEDun6PWNo ratings yet

- Godrej AdharDocument11 pagesGodrej Adharsaxena100% (4)

- Top 42 Electrical Machines Interview Questions (2023) - JavatpointDocument15 pagesTop 42 Electrical Machines Interview Questions (2023) - JavatpointeeeshijaNo ratings yet

- NEW - Brochure Villas DAOS ENG LowDocument30 pagesNEW - Brochure Villas DAOS ENG Lowsean golarNo ratings yet

- CIO VP Director IT in Detroit MI Resume Remi DiesbourgDocument2 pagesCIO VP Director IT in Detroit MI Resume Remi DiesbourgRemi DiesbourgNo ratings yet