Professional Documents

Culture Documents

GIW WI-HQ1-039 - Hydraulic Press Operation

GIW WI-HQ1-039 - Hydraulic Press Operation

Uploaded by

Mohamed RashidCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GIW WI-HQ1-039 - Hydraulic Press Operation

GIW WI-HQ1-039 - Hydraulic Press Operation

Uploaded by

Mohamed RashidCopyright:

Available Formats

GEOSYNTHETIC INDUSTRIAL WORKS DOCUMENT

NO: WI-HQ1-039-1

WORK INSTRUCTION PAGE: 1 OF 3

TITLE: HYDRAULIC PRESS OPERATION DATE: 01/05

DEPARTMENT: Quality Control Laboratory

AUTHOR: MM

1. PURPOSE

1.1. To document the procedure for safely operating the hydraulic presses located in the

Quality Control Laboratory.

2. SCOPE

2.1. This document applies to Quality Control personnel.

3. EQUIPMENT

3.1. Steel dies of various dimensions

3.2. Polypropylene cutting board

3.3. China marker

4. BACKGROUND

4.1. The hydraulic press or “clicker press” is used in conjunction with steel dies to cut test

samples of known dimensions.

4.2. The steel die is positioned on the material to be cut into samples for testing. The

hydraulic press drives a rectangular “hammer” onto the steel die. The hammer

presses the die through the material and on to a soft polypropylene cutting board. The

resulting specimen is removed from the die by hand and tested.

4.3. There are two (2) hydraulic presses in the Quality Control Lab, identified as QC-DC-1

and QC-DC-2.

4.3.1. QC-DC-1 can be adjusted for stroke depth and initial distance between

hammer and table.

4.3.2. QC-DC-2 can be adjusted for hammer height and impact force.

5. HEALTH AND SAFETY

5.1. The clicker press can only be operated when the two (2) engagement buttons are

pressed with both hands simultaneously.

5.1.1. DO NOT insert any objects into either button to make the clicker press

operational by one (1) hand.

5.2. The clicker presses generate sufficient force to CRUSH BONES. Ensure that all

extremities are clear of the hammer’s path before engaging the press.

5.3. The depth of the hammer’s stroke should be just sufficient to cut the specimens.

UNCONTROLLED IF PRINTED ON PAPER

GEOSYNTHETIC INDUSTRIAL WORKS DOCUMENT

NO: WI-HQ1-039-1

WORK INSTRUCTION PAGE: 2 OF 3

TITLE: HYDRAULIC PRESS OPERATION DATE: 01/05

5.3.1. CAUTION: A deeper stroke will drive the die into the cutting board, which may

cause the die to become embedded and possibly shatter the board, which

could result in serious injuries from sharp shards of the board.

5.4. Exercise caution when handling the cutting dies. They are extremely sharp and can

cause severe lacerations.

5.5. ALL personnel are required to wear safety glasses and safety shoes while operating

the clicker presses.

6. PROCEDURES

6.1. Energize the clicker press.

6.1.1. QC-DC-1: Press the green start button

6.1.2. QC-DC-2: Turn the switch on the right side of the machine CLOCKWISE.

6.2. Lay the sample in the middle of the cutting board.

6.2.1. Samples longer than the cutting board should be draped over the sides of the

machine.

6.3. Place the cutting die on the sample.

6.3. Move the hammer over top of the die.

6.4. Engage the hammer by pressing the buttons on both hand controls simultaneously.

This will drive the hammer onto the die, cutting the sample.

6.5. Pick up the die and carefully remove the specimen.

6.6. Using a china marker, label the specimen with the Zone and the direction (machine or

cross).

6.7. Move the die to another location on the sample and repeat the steps from 6.3 to 6.5.

7. TROUBLESHOOTING

7.1. QC-DC-1:

7.1.1. If the stroke of the hammer was NOT sufficient to cut the sample, adjust the

depth of the stroke by rotating the three-spoke wheel on top of the hammer in

the INCREASE direction (CLOCKWISE).

7.1.2. If the stroke of the hammer WAS sufficient to cut the sample, but used too

much force (ie. the die is embedded in the cutting board), adjust the depth of

the stroke by rotating the three-spoke wheel on top of the hammer in the

DECREASE direction (COUNTER-CLOCKWISE).

7.2. QC-DC-2:

UNCONTROLLED IF PRINTED ON PAPER

GEOSYNTHETIC INDUSTRIAL WORKS DOCUMENT

NO: WI-HQ1-039-1

WORK INSTRUCTION PAGE: 3 OF 3

TITLE: HYDRAULIC PRESS OPERATION DATE: 01/05

7.2.1. If the stroke of the hammer was NOT sufficient to cut the sample, adjust the

impact force using the right-hand dial (has red button underneath) on the front

of the hammer by turning the dial CLOCKWISE. This will INCREASE the

impact force.

7.2.2. If the stroke of the hammer WAS sufficient to cut the sample, but used too

much force (ie. the die is embedded in the cutting board), adjust the impact

force using the right-hand dial (has red button underneath) on the front of the

hammer by turning the dial COUNTER-CLOCKWISE. This will DECREASE the

impact force.

UNCONTROLLED IF PRINTED ON PAPER

You might also like

- DX68 Hose Crimping Machine User Manual (Introductions)Document4 pagesDX68 Hose Crimping Machine User Manual (Introductions)Leanne GeermanNo ratings yet

- Thin Cyclinder Student Guide (A)Document27 pagesThin Cyclinder Student Guide (A)Daniel MabengoNo ratings yet

- Thin Cylinder StressDocument16 pagesThin Cylinder StressMihir Ashar0% (2)

- S A C M IDocument26 pagesS A C M IEdwinNo ratings yet

- Manual Tecnico Micros 60 PDFDocument269 pagesManual Tecnico Micros 60 PDFsirlena guillenNo ratings yet

- GIW WI-HQ1-026 - ASTM D5885 HPOIT TestingDocument9 pagesGIW WI-HQ1-026 - ASTM D5885 HPOIT TestingMohamed RashidNo ratings yet

- GIW WI-HQ1-056 - FTMS 101C, Method 2031 PunctureDocument4 pagesGIW WI-HQ1-056 - FTMS 101C, Method 2031 PunctureMohamed RashidNo ratings yet

- To Study The Operation of Hydraulic Press: ObjectiveDocument3 pagesTo Study The Operation of Hydraulic Press: ObjectiveMuhammad Abdullah ButtNo ratings yet

- Die Attach Dispensing MethodsDocument3 pagesDie Attach Dispensing Methodsquinn akaneNo ratings yet

- Double Shear TestDocument4 pagesDouble Shear TestHarit Bala50% (2)

- GIW WI-HQ1-051 - Grab751Document3 pagesGIW WI-HQ1-051 - Grab751Mohamed RashidNo ratings yet

- GIW WI-HQ1-019 - ASTM D5994 Tx. Sheet ThicknessDocument3 pagesGIW WI-HQ1-019 - ASTM D5994 Tx. Sheet ThicknessMohamed RashidNo ratings yet

- GIW WI-HQ1-022 - ASTM D751 Method B, Tongue TearDocument4 pagesGIW WI-HQ1-022 - ASTM D751 Method B, Tongue TearMohamed RashidNo ratings yet

- GIW WI-HQ1-038 - FTMS 101C 2065 Puncture ResistanceDocument3 pagesGIW WI-HQ1-038 - FTMS 101C 2065 Puncture ResistanceMohamed RashidNo ratings yet

- Procedure For Stimating Basic Friction Angle From A Tilt TestDocument7 pagesProcedure For Stimating Basic Friction Angle From A Tilt TestBen AguilarNo ratings yet

- MKS-L Side Feed ApplicatorDocument27 pagesMKS-L Side Feed ApplicatorThuy MaiNo ratings yet

- Dental Turbine Handpiece Instruction Manual: Guilin Woodpecker Medical Instrument Co., LTDDocument40 pagesDental Turbine Handpiece Instruction Manual: Guilin Woodpecker Medical Instrument Co., LTDSukla SarmaNo ratings yet

- Hand Book Part 3Document7 pagesHand Book Part 3Michał JabłońskiNo ratings yet

- URIT-660 Service Manual PDFDocument15 pagesURIT-660 Service Manual PDFCharlys RajaobelinaNo ratings yet

- MANUAL016Document8 pagesMANUAL016kim johnNo ratings yet

- Film Slitting Tool - UB5enDocument7 pagesFilm Slitting Tool - UB5enLepa PekarkaNo ratings yet

- Metramax 2 Ba GBDocument20 pagesMetramax 2 Ba GBwalter.ad.huacasiNo ratings yet

- GIW WI-HQ1-034 - ASTM D5199 Nominal ThicknessDocument2 pagesGIW WI-HQ1-034 - ASTM D5199 Nominal ThicknessMohamed RashidNo ratings yet

- VCS User's Guide 2016-04Document24 pagesVCS User's Guide 2016-04aulia haniefNo ratings yet

- Department of Civil Engineneering Geotechnical Engineering IIIDocument13 pagesDepartment of Civil Engineneering Geotechnical Engineering IIInyashaNo ratings yet

- M2010051in-Mcb - Rolling Suggestions PDFDocument42 pagesM2010051in-Mcb - Rolling Suggestions PDFthaivinhtuyNo ratings yet

- Unsticking Presses Jammed at BDC - D. SmithDocument18 pagesUnsticking Presses Jammed at BDC - D. Smithwulfgang66No ratings yet

- GIW WI-HQ1-059 - ASTM D5596 CB DispersionDocument5 pagesGIW WI-HQ1-059 - ASTM D5596 CB DispersionMohamed RashidNo ratings yet

- Digital CTM Plate Type Manual Pace Rate Controller (2000Kn) - 4-19Document16 pagesDigital CTM Plate Type Manual Pace Rate Controller (2000Kn) - 4-19Shaik Asif Ali civil0% (1)

- Micros 60 TekmDocument280 pagesMicros 60 Tekmwins0946No ratings yet

- V2DManual Version1 0Document28 pagesV2DManual Version1 0Tibor TiborNo ratings yet

- CCB PDFDocument101 pagesCCB PDFbruce lian100% (1)

- FCP Eng Ver3.01Document15 pagesFCP Eng Ver3.01frankNo ratings yet

- Manual E4ccDocument28 pagesManual E4cc张淼No ratings yet

- Experiment No. 2: Title Group MembersDocument5 pagesExperiment No. 2: Title Group MembersMansoob BukhariNo ratings yet

- 5312010-5312011-5312012 AG-200 Orbital Shaker Instructions ManualDocument14 pages5312010-5312011-5312012 AG-200 Orbital Shaker Instructions Manualbme.engineer.issa.mansourNo ratings yet

- Matest C380Document8 pagesMatest C380Sokha Run100% (1)

- Instruction Manual FOR Hose Reel Type: LB4080-520 GR1-2": Sandvik TamrockDocument14 pagesInstruction Manual FOR Hose Reel Type: LB4080-520 GR1-2": Sandvik TamrockFer NuñezNo ratings yet

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDocument12 pagesProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- Angle DekkorDocument15 pagesAngle Dekkorarun elshaddaiNo ratings yet

- 3-Dimensional Experimental and Finite Element Stress Analysis of C.I.Document4 pages3-Dimensional Experimental and Finite Element Stress Analysis of C.I.msk4mechNo ratings yet

- Bobcat Vinyl Cutter Man Rev1npsDocument26 pagesBobcat Vinyl Cutter Man Rev1npsSoporte ScadcamNo ratings yet

- Coldwork Puller Tooling Manual: For WCI-1700, WCI-1800 and WCI-1900 Puller Guns and AccessoriesDocument21 pagesColdwork Puller Tooling Manual: For WCI-1700, WCI-1800 and WCI-1900 Puller Guns and AccessoriesWattsonDiazRuizNo ratings yet

- Installation, Operating, & Maintenance Instructions: Model 8392-02 Sidewinder (Brass) Model 8492-02 Sidewinder (Aluminum)Document6 pagesInstallation, Operating, & Maintenance Instructions: Model 8392-02 Sidewinder (Brass) Model 8492-02 Sidewinder (Aluminum)Jean Jacques ouandaNo ratings yet

- LG Lx-U250a Lxs-U250Document55 pagesLG Lx-U250a Lxs-U250remanuel18No ratings yet

- Planed Recision Planed American ToolingDocument44 pagesPlaned Recision Planed American ToolingmeiyappannNo ratings yet

- User Manual T Model: V.1.2 MAYDocument35 pagesUser Manual T Model: V.1.2 MAYAndrés MorenoNo ratings yet

- Betty Cutter Operation ManualDocument24 pagesBetty Cutter Operation ManualJaffer AftabNo ratings yet

- Tablet Machine ManualDocument27 pagesTablet Machine ManualRafeek Shaikh100% (1)

- 119118-General 09 Tool GrindersDocument217 pages119118-General 09 Tool GrindersNathan RittenhouseNo ratings yet

- Tidland SlittingSeries 1Document15 pagesTidland SlittingSeries 1rodrigo9bessim9rochaNo ratings yet

- Tablet Compression Operation: Industrial PharmacyDocument49 pagesTablet Compression Operation: Industrial PharmacyHenry BarriosNo ratings yet

- Demec Operating InstructionsDocument7 pagesDemec Operating InstructionsKudzai MushunjeNo ratings yet

- Design and Fabrication of Semi-Automated Punching MachineDocument5 pagesDesign and Fabrication of Semi-Automated Punching MachineLEELEE NWISEREDUMNo ratings yet

- Swaging Machine OPDocument40 pagesSwaging Machine OPOsvaldo Urzua Castillo100% (1)

- Rheo Meter Training ManualDocument11 pagesRheo Meter Training ManualRossamirah KhairiNo ratings yet

- Etm 2 ManualDocument13 pagesEtm 2 ManualMark K50% (2)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Why Static ExcitationDocument15 pagesWhy Static ExcitationMohamed RashidNo ratings yet

- Highćcapacity Rotary Valves For General or Fibrous Slurry ServiceDocument20 pagesHighćcapacity Rotary Valves For General or Fibrous Slurry ServiceMohamed RashidNo ratings yet

- Generator BasicsDocument21 pagesGenerator BasicsMohamed RashidNo ratings yet

- Motor ProtectionDocument33 pagesMotor ProtectionMohamed RashidNo ratings yet

- Digital Excitation TechnologyDocument11 pagesDigital Excitation TechnologyMohamed RashidNo ratings yet

- Intro SynchDocument21 pagesIntro SynchMohamed RashidNo ratings yet

- Basic GoverningDocument24 pagesBasic GoverningMohamed RashidNo ratings yet

- Terra-et-Aqua nr64 01Document7 pagesTerra-et-Aqua nr64 01Mohamed RashidNo ratings yet

- ThyristorDocument19 pagesThyristorMohamed RashidNo ratings yet

- Ansi CodesDocument43 pagesAnsi CodesMohamed RashidNo ratings yet

- Distributed GenerationDocument14 pagesDistributed GenerationMohamed RashidNo ratings yet

- Closed Loop SystemsDocument11 pagesClosed Loop SystemsMohamed RashidNo ratings yet

- Terra-et-Aqua nr86 03Document10 pagesTerra-et-Aqua nr86 03Mohamed RashidNo ratings yet

- Dredgeand SpoilDocument4 pagesDredgeand SpoilMohamed RashidNo ratings yet

- Clearwaters PCBarticleDocument4 pagesClearwaters PCBarticleMohamed RashidNo ratings yet

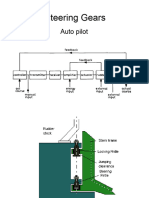

- Steering GearsDocument34 pagesSteering GearsMohamed RashidNo ratings yet

- الموتوسيكلDocument192 pagesالموتوسيكلMohamed RashidNo ratings yet

- Swimming Pool Heat Pump Specifications 50hz 2020Document1 pageSwimming Pool Heat Pump Specifications 50hz 2020Mohamed RashidNo ratings yet

- MaxChill Water Chillers WarrantyDocument3 pagesMaxChill Water Chillers WarrantyMohamed RashidNo ratings yet

- Butterfly CircusDocument2 pagesButterfly CircusSalma BenjellounNo ratings yet

- Part4-Object Oriented ProgrammingDocument151 pagesPart4-Object Oriented Programminganhtrang_181289No ratings yet

- HSCode Master BPSDocument1,262 pagesHSCode Master BPSsumber jayaNo ratings yet

- Basic Concepts On Integrating Technology in InstructionDocument19 pagesBasic Concepts On Integrating Technology in InstructionAries PerezNo ratings yet

- 001drawing Fathul Ma'ArifDocument8 pages001drawing Fathul Ma'ArifParman YantiNo ratings yet

- 1700 Kva Rab Panel SinkronDocument2 pages1700 Kva Rab Panel SinkronIqbal KomengNo ratings yet

- Chapter 2-6 - Structured Cabling OverviewDocument16 pagesChapter 2-6 - Structured Cabling OverviewAfendey ArthurNo ratings yet

- Project Report On Indian Stock Market - DBFSDocument100 pagesProject Report On Indian Stock Market - DBFSkartikNo ratings yet

- Entrepreneurship: Entrepreneurship According To Onuoha (2007) Is The Practice of Starting New Organizations orDocument5 pagesEntrepreneurship: Entrepreneurship According To Onuoha (2007) Is The Practice of Starting New Organizations orDeogratias LaurentNo ratings yet

- Blue Pelican Java Textbook by Charles E. CookDocument543 pagesBlue Pelican Java Textbook by Charles E. CookAlex PopaNo ratings yet

- Hydroxy ZineDocument2 pagesHydroxy ZineSharmaine Grace FlorigNo ratings yet

- JD Asistent Manager - ENDocument4 pagesJD Asistent Manager - ENMihaela RaduNo ratings yet

- Tarang Hearing Aids To MoH Thru DEIT - 3Document9 pagesTarang Hearing Aids To MoH Thru DEIT - 3Ravindra KumarNo ratings yet

- Notice: Meetings: California Independent System Operator Corp. Post-Technical Conference Comments Period RescindedDocument1 pageNotice: Meetings: California Independent System Operator Corp. Post-Technical Conference Comments Period RescindedJustia.comNo ratings yet

- تقرير الانجليزيDocument2 pagesتقرير الانجليزيbasel.khashashneh.44No ratings yet

- An Analysis of The FIBA Governing Council in The Czech RepublicDocument17 pagesAn Analysis of The FIBA Governing Council in The Czech RepublicAbbie AyorindeNo ratings yet

- 775G90V1ESXMDocument3 pages775G90V1ESXMfaapctba2913No ratings yet

- Krishnan - Soliton Interview ExperienceDocument4 pagesKrishnan - Soliton Interview ExperiencePoorna Saai MNo ratings yet

- Install LogDocument36 pagesInstall Logfrans parulianNo ratings yet

- Chico Resume 2015 For WebsiteDocument2 pagesChico Resume 2015 For Websiteapi-87866586No ratings yet

- TSQL Coding Standards ChecklistDocument5 pagesTSQL Coding Standards ChecklistSaman AzeemNo ratings yet

- Transaxle Part No'sDocument9 pagesTransaxle Part No'sRon BonnevilleNo ratings yet

- Part R Price ListDocument88 pagesPart R Price Listpwills1234No ratings yet

- MC145106PDocument8 pagesMC145106PzerokappaNo ratings yet

- SJ Mepla Manual Program EngDocument57 pagesSJ Mepla Manual Program EngCuong HoNo ratings yet

- Distributed Control SystemsDocument2 pagesDistributed Control SystemssukanyagggNo ratings yet

- Reading 3Document5 pagesReading 3Aileen Mae E. MarcelinoNo ratings yet

- Wlupg PDFDocument130 pagesWlupg PDFmraza30No ratings yet

- Course Javascript Es6Document82 pagesCourse Javascript Es6AIT SALAH MassinissaNo ratings yet

- Fifi SpeechDocument2 pagesFifi SpeechDesi NovitaNo ratings yet