Professional Documents

Culture Documents

QIP For P22 Small Bore Green List Jobs

QIP For P22 Small Bore Green List Jobs

Uploaded by

JabranYounas0 ratings0% found this document useful (0 votes)

2 views1 pageOriginal Title

QIP for P22 Small Bore Green List Jobs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views1 pageQIP For P22 Small Bore Green List Jobs

QIP For P22 Small Bore Green List Jobs

Uploaded by

JabranYounasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

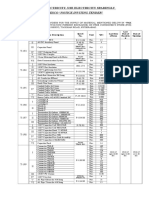

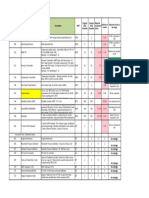

Job Description- QIP for P22 Small Bore Piping Valve Replacement

Drawing No.: Sheet No. Rev.

EFERT EFERT WELD # WELD # WELD #

S# Activity Criteria Kamcon

FM Insp EFERT EFERT

Value Kamcon FM Insp Value Kamcon FM Insp Value Kamcon EFERT FM Insp

Material Varification /

1 Consumables SA335 GR P22 W - P

Randomly

Tacking material /

2 P22 H W H

welding check

3 Before Bevel Fitup check as per WPS H H -

start of

4 welding Welder I.D for Root P22-Qualified H R R

Welding consumables

5 as per WPS ER-90S-B3 W W W

(root+2Hot)

6 DPT of both Bevels No defects H - H

Pre-Heat Prior To

7 250 ℃ min. W - W

Root

8 DPT of Root Not Required

Interpass temp

9 During Max 300 ℃ W W W

control

welding

Welding finishing: VI

Final (No cleat mark,

no under cut, No Capping should not

10 H W H

spatter, No Arc strike, >2.5mm

no other pit at weld

and HAZ area)

11 Final Pass DPT No defects W - P

After Post Weld Heat

12 650℃ for 15 min H - R

Welding Treatment

13 Hardness test < 225BHN H - H,P

100% of Butt Joints

14 RT R - P

& Golden Joint

15 Repairs (if any) H - H

You might also like

- Welder Qualification Test RecordDocument75 pagesWelder Qualification Test RecordVenkatesh Sundarrajan100% (1)

- Laptek Form CB 11KV MVDocument1 pageLaptek Form CB 11KV MVDian PermanaNo ratings yet

- Air CompressorDocument139 pagesAir CompressorPraveen KumarNo ratings yet

- Motor Certification SampleDocument1 pageMotor Certification Sampleyasseralwasabi2016No ratings yet

- PSV-1100B Rev 3Document6 pagesPSV-1100B Rev 3einhaw1985No ratings yet

- MURB1020CT - MURB1060CT: PB FeaturesDocument4 pagesMURB1020CT - MURB1060CT: PB FeaturesJOHN BRICCO A. MATACSILNo ratings yet

- 11KV VCB With PF Panel PDFDocument2 pages11KV VCB With PF Panel PDFprojects spdclNo ratings yet

- 45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchDocument2 pages45-5C AVK Gate Valve OS&Y-ANSI FF - Opt. SwitchImtiyaz KhanNo ratings yet

- FM-02 Consumable Material Feb 16 Stock RecordDocument6 pagesFM-02 Consumable Material Feb 16 Stock RecordyogoNo ratings yet

- Hesco103 293Document2 pagesHesco103 293muhammad nazirNo ratings yet

- StrainerDocument2 pagesStrainerRanjithNo ratings yet

- sv08-20 27feb2022 16-50Document5 pagessv08-20 27feb2022 16-50Cesar LimaNo ratings yet

- VLECP83771T 4 InfoPacketDocument13 pagesVLECP83771T 4 InfoPacketmaricruolivarNo ratings yet

- 45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Document2 pages45-5C AVK Gate Valve O&SY-Non-UL - ANSI FF - Blue Epoxy - Dated 28-07-2019Imtiyaz KhanNo ratings yet

- CAD Drawing - 184TTFB6003 - Cert - Data - A - 4224537 - 192Document1 pageCAD Drawing - 184TTFB6003 - Cert - Data - A - 4224537 - 192archivofacilitiesNo ratings yet

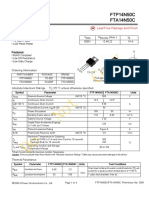

- FTP04N60D Fta04n60dDocument9 pagesFTP04N60D Fta04n60dgigiNo ratings yet

- R4V UkDocument6 pagesR4V UkNelsitonNo ratings yet

- sv98-t40 ГидрофорсDocument3 pagessv98-t40 ГидрофорсMMM-MMMNo ratings yet

- Must Change Non Ac LHBDocument2 pagesMust Change Non Ac LHBsaurav chetiaNo ratings yet

- 300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesDocument12 pages300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesPierpaolo GustinNo ratings yet

- 45-BC AVK Gate Valve OSYDocument2 pages45-BC AVK Gate Valve OSYAnonymous X3PnFL6No ratings yet

- LCS 2Document1 pageLCS 2nutral powertechNo ratings yet

- SERIE T, TP, 50HzDocument5 pagesSERIE T, TP, 50HzFrancisco Meza GonzalezNo ratings yet

- VERSATI II UputstvoDocument31 pagesVERSATI II UputstvoMiljanNo ratings yet

- Rih - Esp Diagram Report 19-03-2014Document2 pagesRih - Esp Diagram Report 19-03-2014fauzan kartiyasaNo ratings yet

- Vt-Vrpa2-5 - 1XRTPDocument8 pagesVt-Vrpa2-5 - 1XRTPPanca AriefNo ratings yet

- Ph-In-Pms Line BDocument61 pagesPh-In-Pms Line BHarkynollar HarkyntehyeNo ratings yet

- List WPS Piping New 2023Document1 pageList WPS Piping New 2023YUDI IRMAWANTONo ratings yet

- C2C-1254-NSD-612-R6 Manual Valve With Limit SwitchDocument13 pagesC2C-1254-NSD-612-R6 Manual Valve With Limit Switchpraveen kumar vengadasamyNo ratings yet

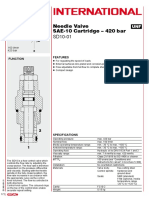

- Needle Valve SAE-10 Cartridge - 420 Bar SD10-01: Features FunctionDocument2 pagesNeedle Valve SAE-10 Cartridge - 420 Bar SD10-01: Features FunctionOmkar TerkhedkarNo ratings yet

- Pending Supply InstrumentationDocument1 pagePending Supply InstrumentationSachin VermaNo ratings yet

- Drawing For Final: 45, Namhannam-Ro, Yeongdo-Gu, Busan, Korea Tel: +82 51 412 5551, Fax: +82 51 412 6660Document84 pagesDrawing For Final: 45, Namhannam-Ro, Yeongdo-Gu, Busan, Korea Tel: +82 51 412 5551, Fax: +82 51 412 6660FILIN VLADIMIRNo ratings yet

- GD300 Manual EnglishDocument298 pagesGD300 Manual Englishnhu@nhuNo ratings yet

- VMR L M OE (I)Document14 pagesVMR L M OE (I)miguelmiargentinaNo ratings yet

- ACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance ScheduleDocument4 pagesACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance Scheduleafadsfd asfadfNo ratings yet

- Mano StarDocument3 pagesMano StarImam Syafi'iNo ratings yet

- Irfr6215Pbf Irfu6215Pbf: V - 150V R 0.295 I - 13ADocument11 pagesIrfr6215Pbf Irfu6215Pbf: V - 150V R 0.295 I - 13AMiswantoNo ratings yet

- 100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXDL15D-dsDocument2 pages100V-Line 15 Watt Horn Speaker With Series Blocking Capacitor For Use in Hazardous areasBEXDL15D-dsEufemiano Noble JrNo ratings yet

- Do Not Copy: FTP14N50 C FTA14N50 CDocument4 pagesDo Not Copy: FTP14N50 C FTA14N50 CListenNo ratings yet

- SDV 08-30 Cartucho HydraforceDocument5 pagesSDV 08-30 Cartucho HydraforceErika MendezNo ratings yet

- BTL 08Document1 pageBTL 08Firdaus YasinNo ratings yet

- Control Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Document2 pagesControl Valve Data Sheet: (Printed 2007-01-16 9:46 AM) K2 - 2006 (A1.3)Mateus EliasNo ratings yet

- C65P1 Spec Sheet - E - A4Document3 pagesC65P1 Spec Sheet - E - A4Chandru ChristurajNo ratings yet

- Re18139 05 - 2022 01 28Document16 pagesRe18139 05 - 2022 01 28Jeff RedingtonNo ratings yet

- Rev. Status: Customer Drawing ListDocument9 pagesRev. Status: Customer Drawing ListDebesh ChaudharyNo ratings yet

- Socla Katalog CZ - 3Document28 pagesSocla Katalog CZ - 3Anugrah Prihantoro Amd TNo ratings yet

- GD300 Operation Manual PDFDocument299 pagesGD300 Operation Manual PDFBalaram pattanayak100% (1)

- BomDocument2 pagesBomsalesgoaNo ratings yet

- Itp Ec14epDocument1 pageItp Ec14epRavi ShankarNo ratings yet

- Phase Y Uncontrolled Phase R/B Controlled: Motor Data Product CodeDocument8 pagesPhase Y Uncontrolled Phase R/B Controlled: Motor Data Product CodeWaleed AlzoudNo ratings yet

- Antenna Direction ToDocument2 pagesAntenna Direction ToCV SINAR GEMILANG UTAMANo ratings yet

- RT9293Document13 pagesRT9293Bijan AmiriNo ratings yet

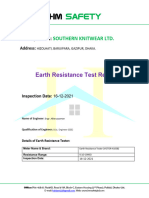

- ER Report SKL 18.12.21Document7 pagesER Report SKL 18.12.21Siam HarunNo ratings yet

- Draft Tube GateDocument23 pagesDraft Tube GateAnonymous sfkedkymNo ratings yet

- C65MS1-L5 Spec Sheet - A - A4Document3 pagesC65MS1-L5 Spec Sheet - A - A4Chandru ChristurajNo ratings yet

- Eatfit Kurla Kitchen Equipment Technical Details: PulverizerDocument5 pagesEatfit Kurla Kitchen Equipment Technical Details: PulverizerRaviKant PalNo ratings yet

- 300ma, Low Noise, Ultra-Fast CMOS LDO Regulator: General Description Ordering InformationDocument18 pages300ma, Low Noise, Ultra-Fast CMOS LDO Regulator: General Description Ordering Informationmarino246No ratings yet

- Datasheet PS PHE ONWJDocument3 pagesDatasheet PS PHE ONWJTjhin VinceNo ratings yet

- 3010-PS003 - 3 Valve ScheduleDocument61 pages3010-PS003 - 3 Valve ScheduleMichael adu-boahenNo ratings yet

- Thermal Imaging For Your Manintenace ProgramDocument38 pagesThermal Imaging For Your Manintenace ProgramJabranYounas100% (1)

- A Guide To Steam Trap Testing - TLVDocument6 pagesA Guide To Steam Trap Testing - TLVJabranYounasNo ratings yet

- Application of IR - ITCDocument23 pagesApplication of IR - ITCJabranYounasNo ratings yet

- Akpanyung 2019 J. Phys. Conf. Ser. 1378 022088Document17 pagesAkpanyung 2019 J. Phys. Conf. Ser. 1378 022088JabranYounasNo ratings yet

- Flir Technical GuideDocument54 pagesFlir Technical GuideJabranYounasNo ratings yet

- EC Declaration of Conformity HighDocument2 pagesEC Declaration of Conformity HighJabranYounasNo ratings yet

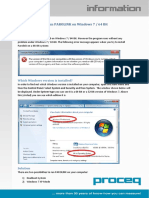

- How To Install Parolink On Windows 7 64 Bit Version 1Document3 pagesHow To Install Parolink On Windows 7 64 Bit Version 1JabranYounasNo ratings yet

- SilverSchmidt - Sales Flyer - English - HighDocument4 pagesSilverSchmidt - Sales Flyer - English - HighJabranYounasNo ratings yet

- Product Certificates: Swiss MadeDocument32 pagesProduct Certificates: Swiss MadeJabranYounasNo ratings yet

- Schmidt Family - Sales Flyer - English - HighDocument6 pagesSchmidt Family - Sales Flyer - English - HighJabranYounasNo ratings yet

- Accurate and Dependable Roll Hardness TestingDocument2 pagesAccurate and Dependable Roll Hardness TestingJabranYounasNo ratings yet

- SilverSchmidt - Operating Instructions - English - HighDocument32 pagesSilverSchmidt - Operating Instructions - English - HighJabranYounasNo ratings yet

- Pundit Lab Adds Site Functionality To The Leading Ultrasonic Test Instrument For ConcreteDocument4 pagesPundit Lab Adds Site Functionality To The Leading Ultrasonic Test Instrument For ConcreteJabranYounasNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- The Smartest and Most Accurate Ultrasonic Thickness GaugeDocument4 pagesThe Smartest and Most Accurate Ultrasonic Thickness GaugeJabranYounasNo ratings yet

- Profoscope - Operating Instructions - English - HighDocument36 pagesProfoscope - Operating Instructions - English - HighJabranYounasNo ratings yet

- Parotester - Operating Instructions - English - HighDocument35 pagesParotester - Operating Instructions - English - HighJabranYounasNo ratings yet

- AWS D-1.1 Acceptance CriteriaDocument12 pagesAWS D-1.1 Acceptance CriteriaJabranYounasNo ratings yet

- API 1104 Exams STDocument38 pagesAPI 1104 Exams STJabranYounasNo ratings yet

- Certified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIADocument6 pagesCertified Reference Materials (CRM) : Csir-National Metallurgical Laboratory JAMSHEDPUR-831007, INDIAShiv PandeyNo ratings yet

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument13 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipesandrea assanelliNo ratings yet

- Ferrous MetalDocument26 pagesFerrous MetalEdbert TulipasNo ratings yet

- Astm A106-02Document13 pagesAstm A106-02Quang-derer83% (6)

- Jotun Jotamastic Smart Pack TDSDocument5 pagesJotun Jotamastic Smart Pack TDSAbeer HarisNo ratings yet

- Billet Defects: Off-Corner Formation, Prevention and EvolutionDocument15 pagesBillet Defects: Off-Corner Formation, Prevention and Evolutionamit gajbhiyeNo ratings yet

- Buletinul Ipt Iasi - 2005Document308 pagesBuletinul Ipt Iasi - 2005danmertzNo ratings yet

- Year Abstract Donal GildeaDocument4 pagesYear Abstract Donal GildeadhareeshNo ratings yet

- GB8410 2006 enDocument46 pagesGB8410 2006 enDiego Camargo100% (1)

- Syllabus For B.Tech Manufacturing TechnologyDocument74 pagesSyllabus For B.Tech Manufacturing TechnologyJuhi SinghNo ratings yet

- Application of Internal Linings - Sample - PIPDocument15 pagesApplication of Internal Linings - Sample - PIPgbuckley9630100% (1)

- MG2Document81 pagesMG2jasimabdNo ratings yet

- BPDocument36 pagesBPThiruvenkatasamy Elangovan100% (2)

- Standard BoltsDocument7 pagesStandard BoltsPablo GalindosNo ratings yet

- NormalizingDocument4 pagesNormalizingAbd.ul.RahmanNo ratings yet

- Materials Varieties and ApplicationsDocument2 pagesMaterials Varieties and ApplicationsHossein GhazinezhadNo ratings yet

- Fracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanDocument33 pagesFracture and Fracture Toughness of Cast Irons: W. L. Bradley and M. N. SrinivasanNarasimha Murthy InampudiNo ratings yet

- 5.1. 402020-01391-08-PI-SPC-0001 Rev0Document58 pages5.1. 402020-01391-08-PI-SPC-0001 Rev0sumit kumarNo ratings yet

- Nickel and Cobalt MaterialsDocument2 pagesNickel and Cobalt MaterialsshamsNo ratings yet

- Modified 2 1-4CrDocument45 pagesModified 2 1-4CrandreahankNo ratings yet

- WM - TK Hi Integrity Trunnion Mounted Ball ValvesDocument28 pagesWM - TK Hi Integrity Trunnion Mounted Ball ValvesLuis Eduardo PerillaNo ratings yet

- 1 Leser-459Document19 pages1 Leser-459Saravanan ThangamalaiNo ratings yet

- Chemical Composition: ASTM A36 Mild/Low Carbon SteelDocument2 pagesChemical Composition: ASTM A36 Mild/Low Carbon SteelrekyNo ratings yet

- Ok 83.28Document1 pageOk 83.28joe_frangiehNo ratings yet

- Corrosion Control by Modern Weld Overlay TechnologyDocument3 pagesCorrosion Control by Modern Weld Overlay TechnologyAmanda Ariesta ApriliaNo ratings yet

- Engr 3Document3 pagesEngr 3శ్రీనివాస బాబ్జి జోస్యులNo ratings yet

- SimulationDocument143 pagesSimulationnilesh_erusNo ratings yet

- Steel Weight CalculatorDocument4 pagesSteel Weight CalculatorMujjo Sahb0% (1)

- Piping Interview Question Part 4Document2 pagesPiping Interview Question Part 4mithunjobs80% (5)

- Broiler Plant Processing 2000 BPH ManualDocument5 pagesBroiler Plant Processing 2000 BPH ManualBolivar MorelNo ratings yet