Professional Documents

Culture Documents

323直管 批检 Review

323直管 批检 Review

Uploaded by

Panneer Selvam0 ratings0% found this document useful (0 votes)

16 views27 pagesOriginal Title

323直管 批检 Review

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

16 views27 pages323直管 批检 Review

323直管 批检 Review

Uploaded by

Panneer SelvamCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 27

YON Be as i TPS A IR]

Cangzhou Longtaidi Pipe Technology Co., Ltd

323.8*(9.53+3)mm ASTM A106 GR.B (NACE) + N08825

Siihh: USGL CK ST Aw 33 S —A: 061000

Address: No 33, Huanghe East Road, Cangzhou Economic Development Zone, Hebei Postal

Codes: 061000

if: 0317-2179602 fH: 0317-5296185 _ HikAl:Itdzjb@longtaidi.com

Tel: 0317-2179602 Fax:0317-5296185 Email: Itdzjb@longtaidi.com

Bx

Content

x = ITP No.

No. Title

1 OPRAH GEE 7

Raw Material Mill Test Certificate (Copy)

PAL RE

> Material Re-test Report 42-45

2 REA E ROME A,

‘Welding material quality certificate and reinspection report M

4 6.1~6.2

5 6.3/6.7

2 64

7 65

. Dimension Inspection Report 6.6168

SERA

° PMI Test Report 69

10 ATER BRE =

Surface Hardness ‘Test Report

un URGE on

Utasonic Test Report

SRE

B PT Inspection Report 6.12

Pyaar

8 Hydrostatic Test Report 6.13

HEE SRNR

“ Performance Test Report 6.14-6.16

AA

8 Hardness Test Record 6.17

AT RAR

re Metallographic Test Report 6.18

ayaa

" Bending Test Report 6.19

i RN

7 Flattening Test Report 620

Waa Re

» Bond Strength Test Report 621

20 BA Ie PRIA cn

Intergranular Corrosion of Feric Sulfate Test Report

21 A RRA in

Pitting Corrosion Test Report

‘6j{h4e38 RF ATRL] HENG YANG VALIN STEEL TUBE CO.LTD e & pilodaeaion

ae Kaoiiled a5 30486

ogcases EE aa 7 AS

S INSPECTION CERTIFICATE

Tao a“ aT (ezrwas ==

aa TET: caro awa] PoE

SS ae “sees = |

Jrsno| wee resriorie | women, | mooi | snes

| asoroase aS z z

BATE Licence No.

$5444 SA] HENG YANG VALIN STEEL TUBE CO.,LTD ._182710686-2004

: faghtihg ss 30487

Pee EHS _"

a 108 ae 101

as: Aisin revang iyi. 42101

a INSPECTION CERTIFICATE Fea

feepnnsicnss SF Ai:

7S 2 ee ee

: +

TE

‘Wispre BODY = = 7 =n — ——

ee SS See

SS

foie ete Mureee Gener. Sif een

oe Page 22

he tania

wy Ae

we SB wR OB

Material Verification Report

LTDIQRZL-01-01

MEA Ld BS Pe eS RES

Material Name Speciation Material Grade Heat Number Pipe Plts)No. Report Na

iw 0323.89.53 A068 23300075, l | urprs230212-001

Ye % mf [Chemical Composition % CAMARA Test Standards ASTM.A751)

= c si | mm | s P [| to) ce v w | ot B Al nN | cee

SN

et ae | oases | 0300 | 11s | oon | oorse | ones | corse | corre | cots | coos | —- | = | = | = | = | or

ait ; ; ' / 1 /

neni y y v v vfiy y y v vj=—-[-|=-[- |] - q

$L BR te fE / Mechanical Properties (SRERHYE Test Standards ASTM A370)

‘eae MPa | VARESE MPa | ICA ANG a 34H Impoct Testing KV)

TS.Rm YS. RtO.5, Elongation RRR aeC 7 2 SE An

Test piece Size_| Temperature SI Ne

Vise in 490 as 455 ! 246 200 2 2

at sroess oc

ee v y y 1 y v q q

BO Nowe

ER aR RRR

Surface Quality - ur. Mill Test Certificate Review

tie ete at

Qualified Qualified Qualified

eae eA ah

Basis OF Evaluation Inspection Conclusion Qualified

AMA Date: 2023.02.12

SHER Inspectors 6 a phe Curved det Review: WER

5

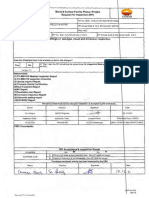

CERTIFICATE OF QUALITY

neem We, LAT RUNERME SRA

amae ‘No. Jntonghuang Road Shipl acheng Town Kunshan Ci

iL cme FAH mA Wee

Kunshan Gintune Welding Go..LTD. Tecosiesree7T7 __ Fax 051287087776

Hen amos TR] tam | ae | 20220507

WS 75-14 i zi

tos sem mm] (ASMESFAS.14/5 14M-2021_ ERNICrMo-3)

Lot No. FeNeoay ‘Specification (GBYT 15620-2008 _SNi6625)

{80 18274-2010 5 NL6626)

a

Eestoioe

xD

Elomenis_| © | S| Mn] P

kit | wax. | Max | Max. | Max.

Requirement | 0:90 | 0.80 | 0,80 | 008

8 8. Toca 008 | 002 [oon

a mh

ct ie SUE ee ‘Weta Impact Test

rt oan

22988 | ven (remeron | Sommer [eal wf gRARRTS] BERR

aa eee | EO] BEER,

ze A : z

oes e Z

wt i ia ee ad 2

Test Value *

‘yatta Bending Test] mance | aencunae | Beet | TRH | TR Ninsnivcre | aeHI

Fa | Filet wows | Hardness | Fete | Mote [OMe lvcoser] “owe |

oe | me | we |e] ee wo] treo | 0

Deel |p sepaulbatee tame tes = [recaoatzor

mn oe Rk ‘Welding Condition mi iE Certified

wae, | EH, | BBSE | BEIT [eermersno ie

: z a

eee

‘mem | MeaWa

ee eee

anne

cin

& i |onenmam: 0.0%

REMARKS | GeN10204 3.1

‘GHP ATSOS Revd DIOIOD

we A eR OG

Material Verification Report

LTD/QRZL-01-01

RR bh rs

inspector WALR> SE

REVIEWEOR]

NOTED FOR INFORMATION ONLY.

fy9GS CSTC STANDARDS TECHNICAL

SERVICESCO.LTID_IND464

avery

2}. 7.03

FMA Date: 2023.02.14

AEH me hes es EOS RES

Material Name Specification Material Grade LotNo. Pipe( Plate)No Report No.

ca o12 GTN-cMs FSNOOsT ’ L1DFI.230214.001,

46% iB / Chemical Composition % CAARHE Test Standard: ASTM E3047-2016)

_ c si Mn s P cr Ni Mo | cu | noma | Fe Ti co | al

ea aao7 | 006 | 00s | oor | ooo | 205 | 90 | 90 | oo | am | oos | ox ! 0.04

Measured Value : :

wie

neat v v v Vv v it v v Vv ! v

A (Note

ORE a a

| Surface Quality Qualified Qualified

ER aie

Basis OF Evaluation se Qualified

YM M ih FB kk AOR A Al

Cangzhou Longtaidi Pipe Technology Co., Ltd

lb ARS ARR LTD/QRZL-44

Inner surface visual inspection by endoscope report

BH Pa wR xe Ras

Name Specification Material Qy ReportNo.

Clad Pipe 323.84(9.5343) mm. ‘A106 GR.B (NACE) +N08825 1 LTD/NKJ-PJ-021

SLPS See the attached table/

HAE Attached map:

2023.08.27

Customer,

HH inspection Rest

rams ase ‘eect ‘seat eee ARMRNES

Product No Specification | Defect Location | Defect Type Defect Size | Rustremoval grade onthe in Jusion

GIGC-20160I3 | 325.8%0.53+3) mm L 1 i 2s3

i i l 7 / 1 ey

7 7 7 7 7 7 1

7 i 7 1 7 7 1

i 7 7 7 7 7 7

7 7 7 i 7 7 7

7 1 1 i 7 7 7

/ 7 7 7 7 7 7

7 7 7 i / ni 7

7 7 7 1 7 7 7

7 i 7 7 1 7 7

7 i i 7 i / 7

i t 0 7 7 0 7

7 : : i t 7 7

7 / i 7 i 7 7

/ 7 / L 7

L 1 L —" 7

/ 7 / Nuts 1

1 7 / Sep. 7

7 7 7 / 7

t 7 / : 7

ON ONLY CY a a f t L

1S TECHNICAL t 7 / / 7

TROL a D 7 ri 7

Dw Curren}

Ww) J.03~

feet ULTRASONIC TESTING REPORT UTI #

(Cange Langa Pipe Technology Ce Led (THICKNESS GAUGING-CRA CLAD#EUEH S182)

Projet Nonter 8 A aoe Report NORGE + LTDCSCHDINND-021

Prat Name ERCC OF CP-OML TREATMENT SYSTEM AND AUXILIARY SYSTEM PROJECT.

PROCEDURE SECIRICATION ACCEPTANCE CRITERIA

‘SPECIMEN DATAR ER

SURFACE CONDITIONER. + Gant BaF

CAL BLOCK aE ‘Sma Block APSE

SUINGRT + tm

PQUIPMENT/RORE DETAILS & 88.

MODEL Sl.No. + crs

PROBE MODEL SL NOWRA Daal Comal Probe SCI

FREQUENCY /ANGLEBLE AL shite

(CRYSTAL Sze 853 Ma

ABBREVIATIONS. 9S

RL Reyne 14880

Ro: Repeat Of + Over Mice DNC + Dos Not Comp

Nw Rew Weld EFS toe rest CN Comair

ie aT aa

ne) ten 8 te a setnnt | wat | smmann | uaa | “St

reas Pe Ba emotion | sr

[AFTER GRINDING BEFORE CADDINGHT A

Pe om vw [vt [or | | wr [| ow [om | oe | 9 | wm | row | oss

[Arren CLADDINGH =m

[ERA TRCN

7 ¥ us [3m [oe [os fo [ow [ox [se [on | oo | oe [om

we za [oe [ae [ox [16 | om | 2 [om | | 10 | oo | oo

REMARK YP cod alg ICEnG ay Te IGT doe band weld ony anasto ARERR AE, WIL RRA RH

REVEWED 7 WINGED BY HTH

vane, 40

DATES Sins

NOTEO FOR INFORMATION ONLY

SGS CSTC STANDARDS TECHNICAL

SERVICESCO LTD __IND464

Ip PAE ea nT,

a Ltt SAK Bnole~voed+

| them no [Be Start | ime Finish

i

3G WITNESSEOm

REMEWESS:

NOYE2ER : NOTED FOR INFORMATION ONLYO

SGS CSTC STANDARDS TECHNICAL

2/Add legend X if out of range of WPS / WPS fUIMSET x

1.Add legend vif within range of WPS / WPS iiTHIa v

SERVICESCO LTD __IND464

3.Check every 30 minutes. 1% 304) oR — we.

phe Craven}

WI.

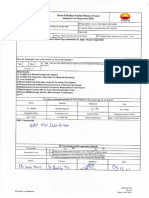

WELDING CONTROL SHEET

Ne ee Pe hill 2

Project No TEMAS : 2 lh

Weld Station

wes No :[{fWis-rob +)

Date HM WLS

‘Weld wire HIN #463? %5 : Finfoed |

Gis Batch No~ "UES XRB- fp Gore

LnD/QRSO- 68

T ~y

Time Finish ete

Item No

ne Ge MEW)

Wire Feed

ced

see

mm/min)

ee

Woe

|e

Wao

yo

swe

sae

NOTED FOR INFORMATIQNSO

Welder fy

aT Vevey SGS CSTC. STANDARDS TOR BAB

SERVICES CO LTD IND464

NOTE tka: Dh fy

oy

1.Add legend if within range of WPS WP:

2:Add legend X if out of range of WPS / WPS

3.Check every 30 minutes. / 4% 305) PP Wl —2 .

MTOR

FOU IR

Visual Examination Report LTDIQRZL-73

BEL POC OF CPF-OIL-TREATIMENTSYsTEM | Ati viper

Project Name AND AUXILIARY SYSTEM PROTECT Report No

Pie a 8

Product Name cao rae ‘Specification

EES Poe

aes ASTM AID6 GR B (NACE) + NOES en

load ASME IX & DNVGL-ST-F101 fatal

“es Stand Acceptance Std

Pan

eee cuoc 20163

HM oe fF

xaminaion Coons

DREN Ar age Preperation AP Aswedeo

bean (0 _S#E2 JG After Welding RRS 418 Ground

Seaton mR AFT suteeCndtin [SRA si

A IRIRN2 A Ater Horo. Tew ARBRE Pot Suri Tromment

RARER | 0 IR aera

Tecniqse | Diet Visual Examination Rome Vil Examintion

SE ~ ‘aac e

Light Intensity sean _Equipment&e Tools: u

wei wea a

Joint No ste Findings

ae

Cracks: U t FNone:

mi

_ 1 ’ HNowe

ame Ce

‘Lack of Fusion ; Cel : cone

AH

Lack of Penetration ! / Fitton

RAE

Other Linear Indications / / ane

“tl ef

Porosity ' ! m=

fe

Weld Reinforcement u : "

wit ny

Results eee

rae + ROM

Gl ein 4, Rego Dt ee

NOTED FOR INEREWATION GNLY #P as

SGS CS[C_STANBARDS TECHNICAL hemi baie!

SERVICESCO LTD __IND464

Y/N SEAS A PRA]

Cangzhou Longtaidi Pipe Technology Co.,Ltd

Mom Me eR

Finished Product Inspection Record

LTD/QRZL-03-01

ane FE 7a a aes

contact No brodt Name spenteatin Maral Reon No

22.2016 CLAD PIPE 323810533) mm ASTRIATOG GRB (NACE) + NOWIDS TORII

wens | wean | *S20S1°| FARES] wir icion Go] Am) aT

Petes aE ‘Whale body | Whole body ‘Out-of-Roundness: erga | $i Cm) Meine

Fitantn| uccitem| Sees | Seis | am] om| am | om) 22 | #88 Lewores sae | "ERD [ye | an bil

i SRL | iS] Btn] ao] sean] sen] Benge | SEA | Monin] rae | 20 | T##08 | auto | cancae i508

7 <05%D

t , 1 joe ’ ’ i ' , ! L ! 1

i il ; aatereod’ ||? 1 aslo dar

RA: IPAS RM ARBRE TRA ReReNESe | (0%

Description: This batch of pipe fittings has be y |defects found by visual inspection.

ERE + Bl! if 1a Bie

Basis of Evaluation s |-13 [0-CPE-999-K /- Hd Conclusion fie Acc.

WIEN Inspectors + — Dh. (urvetiees reviewers RG, #895 BM Repor Date: 2023.08.27

¢ aw

WI.

AB

i

wy. 33 y

6 1 ee WW Hk

LTD/QRZL-27

PMI Test Report

ews HEAP [EPCC OF CPF-OIL TREATMENT SYSTEM AND

Report No Hineeney Project Name ‘AUXILIARY SYSTEM PROJECT

He Ae

=

ree

Rae Pee at am at aie

Product No. ‘Name Specification ‘Material Qty Ma a 2 ad ze Conclusion

05 po0230] >! e 100

crocanieres | ciappire | s23aresv3)mm | Astmatoecrsevaceynossas | 1 | ars | 2153 | aN RoF BA 337 | ote,

|

ala forbes 5

WiNessi

ie: LRP RINSE,

‘REA Inspector: We

Conclusion: Ate the PMI analysis, fu.

si

#855 WF Report Date:

2023 £8 27

HBA OLA RA

‘angzhou Longtaid Pipe Technology Co. Ltd

RE EWR

Surface Hardness Test Report LTDIQRZL-45-03

pital L1DPL-YD-021 ATMENT SYSTEM.

SRE

Reference Standard

#URA® Inspection ge

etd sas Hot

Product Name | — Specification Material

(NACE)+Noss2s

7 7 1 i ai 1 7

7 7 1 1 i 1 1

1 7 i 1 i 1 7

1 7 i 7 i 7 i

1 7 1 1 i i i

7 i 1 1 i i i

1 i i 1 i i 7

1 7 i 1 1 7 i

7 7 1 1 i 7 i

i 7 1 1 i 7

i i i 1 1 1 femwy

1 1 i 1 1 1

1 i 1 1 1 7 in

i 1 i i

1 1 1 1

jos] 7 1 1 1

1 1 7 1

1 1 / 7

i i 1 1

1 1 7 7

1 1 i 7

=a we

TP Chie

ON MEAS BEN BEA IRA

Cangzhou Longtaidi Pipe Technology Co., Ltd

BPRS

Ultrasonic Test Report

LIDIQRZL-13

Raho Lrom.T2016¢01 Inet ode Fxurasoc few Bast a BS | ingest vice | oreetComace

ead Pom wan TR aie ia LI rae

Probe Speciation 23P99K1 Couper pesiapaste Coupling Compensation UT percent

ae aera RE “ASTM A2688 ASTM RRS Law

‘Test Bleck Type ese AIBC Surface condition Aftemachining Suraceteaiment

; Hi aeTransverse Wave: 80% Wave Height of NS Not “RHE

ect Sev Me SEAS gaia tine Weegee cee BK91-1S10-CPF-999-MAW-SPC-0001_1

rams miei i wat ct eae ai

ods prc Nene speiion teat ey [ee | macam | maaamen | xmom | nite | costtion

ype_| oceton fom | Lacon om baton | Length | win

- ASTNCATOG GRE

ioc 2016813 CAD PIPE masosamam | ATMATCGRE 1 i ; i ; oles

SGS es a ; : ‘ 7 7 5 7 5

NOTED FOR INFORMATION ONLY. : 7 ‘ : J ‘ ‘

'SGS CSIC. STANDAHDS TECHNICAL 5 zi 5 qi 7 7 7 7

PTY 7 7 zi 7 i ) 7 ,

BER Cw [0 3 a UTM i. fs

oe 3 Aaa Beas ie Sy) [mene

ae =H

Supervisor Ph Cli

ON MEAS ih BIBRA PRA

Cangzhou Longtaidi Pipe Technology Co., Ltd

CARRE

PT Inspection Report

LTD/QRZL-14

eS RAE emetle) Bard

is Lipps Pr-021 Lae War mas 10-20min ely a1076Lx

1h Sar “aan eee RRR

Penetrant_ a Developer ad Developing Time ieee Test location CRA & Bevel Ends

ware a ERE ane ‘a A me emt 100%

Anping Peerant seeay maging agent Somny Inspection Tempesture Inspection Ratio

RES Ba A, Fa-aR RH MERCH oR BKOISIOCPFDIS-

TestBlck Size Type8 Mtiodofobserion | Visul¥Endoscope Tes Standard Acceptance Cited _| _MAW-SPC.0001_1

De

rams | Aer spelitcn vtia | ity [RR] RPGR ERA | EE em | Rm | call

Type | tocaeatemor | .aeaiontom Datum | “Leng” | "wat

cocaners | ciappPe | aaeesmm | AAEGRE [1 ' 1, : : z oaks

7 : qi 7 7 7 7 7 7 7 7

7 ; 7 7 7 7 5 7 7 7 7

7 7 7 7 7 7 7 7

7 7 7 7 7 7 7 7

7 7 7 7 7 7

7 7 7 7 7 7

aaa Crh HV 3 a (PTB)

npr It) BRD Review @T i) 222 20230827

8 BEB

Supervisor TPL

YIN RE Feith SPER A BR ZS

Cangzhou Longtaidi Pipe Technology Co.,Ltd

¥ es

ii ORDA oo

Hydrostatic Test Report

BiH 2% — | EPCC OF CPP-OIL'TREATMENT SYSTEM eS

Project Name__| AND AUXILIARY SYSTEM PROJECT ReportNo. Empey sy-02t

PREM HAS, 106 GRB (NACE) +

wee CLAD PIPE ete son

oy Pa

Speifiation 323:80,5343) mm as GAporcess

RRRERIR ae zy

Test Instrument and Fixture

URE Ara en = Hark

‘Test Pressure! Holding Time ieee Pressure Gage Ri SMP

BREA * 2

“Test medium Water Gaon Sa

mee RE COD

Accuracy Class 25 | BavironmentTeeperaure | Mit Room Temperature

ik HA

Roane SC-YLB-023/SC-YLB-024 ae 2022.12.13-2023 6.12

Rha

‘Test Sundar cereal

MPa

| 7.8MPa

AAR a ?

Hyénstaic Test | | ' |

cure / | |

i |

i 7

| RAM

/ Holding Time

GME OMAR RNB VET SMPa, (REDS, RMRLLARY See ON AONE ICIS RIAL IL

wiowig | 2% PSAPISLDA RAE, MaCRRaRERiE eH

reavonh Rise the test pressure up to 7.8MPa and hold 208 when perform the hydrostatic test of pipe, there is no leakage

SEEOTENSSS | and visible deformable onthe pipe outer wall and weld seam, which conform tothe regulation of API SLD, it

is qualified

a #d f em mW eA

2 WT B= we

+ sone WEDS | (0's Tl Client

NOTED FOR INFORMATION ONTY|

‘SGS CSTC STANDARDS TECHNICAL

SERVICESCO LTD _IND464

YO) REAR A BEAR]

Cangzhou Longtaidi Pipe Technology Co., Ltd

MPLA RE RIES

Chemical Mechanical Performance Test Report

LTDIQRZL-32

Faas HEE ae FAS FT T oo

Product No Material Name Specification Material Grade Hest Number Report No

6100-20161 CLAD PIPE 323.8"(95343)mm__ | ASTMA106GRB (NACE)+Noss2s | 23300075+FsNoo8T LID PI-XN-2016-021

4% & 4 / Chemical Composition % (i MAHRME Test Standard: ASTM £3047-2016)

_ c si Mn s P cr Ni Mo | Novta Fe PREN

ea <0.10 <050

BS

Me. | ots osx 0167 0.0002 0.0008 216 ei ss9 | 382s 3.60 50.08

2, / i nr j j

Be - v Y v V y XO vy [oq y v

‘$1 AE / Mechanical Properties (iX9A4K%E Test Standard: ASTM A370)

voesiot mea | ARE MPa | HK AM laters aT —~ vies lupe Teves EV)

ad TS. km YS. RpO2 Elongation YITRatio 2 =

_ ‘Test piece Size _| Temperature ! 2 3. || TSA

of

oe Bais 2240 22 / 230 23 | 240

Meade | 500 m 4 / rasiosss a | a | ns

Hie v

Result * ® v t v v Vv

areas | ah

Basis of Evasion | Qualitie

SRI toepestns WEBS 85 FAME Report Dates 2023.08.27

- SGS CSTC STANDARDS TECHNICAL

SERVICESCO.LTO _INO454

Je}. 7.03

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CAMCE QA QC Team Updates On Approval Dated 01.08.2023Document1 pageCAMCE QA QC Team Updates On Approval Dated 01.08.2023Panneer SelvamNo ratings yet

- Welding Summary Sheet: Package:1310-U112-SO-HT-008Document5 pagesWelding Summary Sheet: Package:1310-U112-SO-HT-008Panneer SelvamNo ratings yet

- BK91-1310-CPF-169-PIP-IDX-0001 - 1 - Piping Isometric Drawing Index For Fuel Gas System - C4Document71 pagesBK91-1310-CPF-169-PIP-IDX-0001 - 1 - Piping Isometric Drawing Index For Fuel Gas System - C4Panneer SelvamNo ratings yet

- Bk91-1310-Cpf-182-Pip-Lay-0001 - 0 - Piping Layout For Chemical Injection Skid (01) - C1Document1 pageBk91-1310-Cpf-182-Pip-Lay-0001 - 0 - Piping Layout For Chemical Injection Skid (01) - C1Panneer SelvamNo ratings yet

- 457直管 批检 ReviewDocument27 pages457直管 批检 ReviewPanneer SelvamNo ratings yet

- General Assembly of LPG Storage Tank (CPF-129-T-01ABC)Document10 pagesGeneral Assembly of LPG Storage Tank (CPF-129-T-01ABC)Panneer SelvamNo ratings yet

- 111 Remaining Construction Work Schedule-20231206-ADocument1 page111 Remaining Construction Work Schedule-20231206-APanneer SelvamNo ratings yet

- 273 直管 批检 ReviewDocument27 pages273 直管 批检 ReviewPanneer SelvamNo ratings yet

- BK91 1310 CPF Pip RT 0015 1Document5 pagesBK91 1310 CPF Pip RT 0015 1Panneer SelvamNo ratings yet

- BK91 1310 CPF Pip RT 0020Document3 pagesBK91 1310 CPF Pip RT 0020Panneer SelvamNo ratings yet

- BK91 1310 CPF Pip MT 0041 5Document1 pageBK91 1310 CPF Pip MT 0041 5Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Document26 pagesBK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Panneer SelvamNo ratings yet

- BK91 1310 CPF Pip MT 0055 2Document1 pageBK91 1310 CPF Pip MT 0055 2Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1Document12 pagesBK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1Panneer SelvamNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Document178 pagesBK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Panneer SelvamNo ratings yet

- BK91-1318-01-FSF-000-PIP-RFI-0034 Request For Pipe Fittings of Size, Type, Visual and Dimension Inspection - SignedDocument148 pagesBK91-1318-01-FSF-000-PIP-RFI-0034 Request For Pipe Fittings of Size, Type, Visual and Dimension Inspection - SignedPanneer SelvamNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- BK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedDocument293 pagesBK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedPanneer SelvamNo ratings yet

- BK91 1332 01 FSF 000 PIP RFI 0092 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 11 - SignedDocument2 pagesBK91 1332 01 FSF 000 PIP RFI 0092 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 11 - SignedPanneer SelvamNo ratings yet

- BK91 1332 01 FSF 000 PIP RFI 0101 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 12 - SignedDocument2 pagesBK91 1332 01 FSF 000 PIP RFI 0101 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 12 - SignedPanneer SelvamNo ratings yet

- Bk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersDocument8 pagesBk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersPanneer SelvamNo ratings yet

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet