Professional Documents

Culture Documents

Case For Change Jan2015

Case For Change Jan2015

Uploaded by

dspinelliCopyright:

Available Formats

You might also like

- MBA 204-18-Human Resource Management (A) - NAMRATA BHALLADocument31 pagesMBA 204-18-Human Resource Management (A) - NAMRATA BHALLAMehak Arora0% (1)

- PepsiCo S Op Using Sap Apo at PepsicoDocument17 pagesPepsiCo S Op Using Sap Apo at PepsicoShivran RoyNo ratings yet

- Corperate Presentation July 2020Document18 pagesCorperate Presentation July 2020iganu76No ratings yet

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- Absorption Variable and Throughput Costing Macaculop RayosDocument24 pagesAbsorption Variable and Throughput Costing Macaculop RayosJohn BernabeNo ratings yet

- Questionnaire-Benchmarking of Best HR PracticesDocument13 pagesQuestionnaire-Benchmarking of Best HR PracticesUtkalKhatiwadaNo ratings yet

- Communication Skills Jan2008Document28 pagesCommunication Skills Jan2008Bosse BoseNo ratings yet

- Communication Skills Jan2008Document28 pagesCommunication Skills Jan2008dspinelliNo ratings yet

- S4HANA FundamentalsDocument77 pagesS4HANA FundamentalsLaksana Dewa100% (1)

- Resume - BALARAGHAVAN UDocument2 pagesResume - BALARAGHAVAN UubraghuNo ratings yet

- ANPQP - 3.0 - in ActionDocument14 pagesANPQP - 3.0 - in Actionjefry sitorus100% (1)

- 6 SAP PP Level I TrainingDocument45 pages6 SAP PP Level I TrainingsowjanyaNo ratings yet

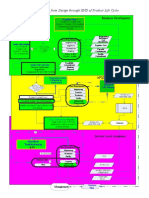

- APQP FLOW From Design Through END of Product Life Cycle: N N N NDocument1 pageAPQP FLOW From Design Through END of Product Life Cycle: N N N NgaviotaperezNo ratings yet

- FMEA Link To APQPDocument1 pageFMEA Link To APQPiltem.islamNo ratings yet

- Bharath Original Resume FormatDocument2 pagesBharath Original Resume Formatarulanandhan10No ratings yet

- Automotive Core Tools - (APQP - PPAP - FMEA - MSA - SPC) - AIAGDocument5 pagesAutomotive Core Tools - (APQP - PPAP - FMEA - MSA - SPC) - AIAGMiguel RiusNo ratings yet

- Bharat HakeDocument2 pagesBharat HakebharatNo ratings yet

- Core Competencies - Quality and Reliability Methodology - Quality-OneDocument3 pagesCore Competencies - Quality and Reliability Methodology - Quality-OneTOSIF MUJAWARNo ratings yet

- SAP For Automotive: Industry Briefing BookDocument52 pagesSAP For Automotive: Industry Briefing BookAjay KumbharNo ratings yet

- Dear Sir. Am Interested in Production ND QualityDocument2 pagesDear Sir. Am Interested in Production ND QualitySinkar ManojNo ratings yet

- Apqp PQP Flow ChartDocument1 pageApqp PQP Flow ChartmjapmgNo ratings yet

- Management Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceDocument2 pagesManagement Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceHeart Touching VideosNo ratings yet

- Resume SambhajiDocument3 pagesResume SambhajiSambhaji GaikwadNo ratings yet

- PepsiCo S Op Using Sap Apo at Pepsico PDFDocument17 pagesPepsiCo S Op Using Sap Apo at Pepsico PDFsaranpcNo ratings yet

- DeepakKumarDeb 13463624 - 09 00 - 1Document3 pagesDeepakKumarDeb 13463624 - 09 00 - 1Mayur ShindeNo ratings yet

- SD - Output Determination ConfigurationDocument3 pagesSD - Output Determination ConfigurationsreekanthNo ratings yet

- ASAPDocument17 pagesASAPdspinelliNo ratings yet

- Sektion: Introduction: (C) Sap Ag TAMM40 1-1Document16 pagesSektion: Introduction: (C) Sap Ag TAMM40 1-1Jeferson SilvaNo ratings yet

- Poornachandran - Procurement Profile (3+years)Document2 pagesPoornachandran - Procurement Profile (3+years)chandranNo ratings yet

- S4 HANA Manufacturing 1610 InnovationsDocument26 pagesS4 HANA Manufacturing 1610 Innovationsabhi100% (5)

- SAP TRAINING SESSION - EditionDocument19 pagesSAP TRAINING SESSION - EditionJ Zhou (AU Accounting Office)No ratings yet

- APO Overview v1Document58 pagesAPO Overview v1topankajNo ratings yet

- SAP aATP New in 2020Document39 pagesSAP aATP New in 2020Rajesh Bhattu100% (2)

- Refining OverviewDocument53 pagesRefining OverviewSeptiaNo ratings yet

- Systems As The Way We Work - Innovation in QMS ImplementationDocument58 pagesSystems As The Way We Work - Innovation in QMS ImplementationSelvaraj SNo ratings yet

- PPW-Auto Parts-B2B-Objective-2024Document15 pagesPPW-Auto Parts-B2B-Objective-2024Jegan SubramaniamNo ratings yet

- SAP OverviewDocument13 pagesSAP OverviewRahulNo ratings yet

- Appendix: SAP Data & Analytics - Solution Architect & Lead ConsultantDocument4 pagesAppendix: SAP Data & Analytics - Solution Architect & Lead ConsultantAjay KumarNo ratings yet

- Welcome - Day 1 2012: Failure Mode and Effects AnalysisDocument63 pagesWelcome - Day 1 2012: Failure Mode and Effects AnalysisKaya Eralp AsanNo ratings yet

- TRL 123564Document26 pagesTRL 123564Mostfa RiahiNo ratings yet

- Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialDocument29 pagesAdvanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialxiwaxeNo ratings yet

- TEF - Awareness - Mining ForumDocument18 pagesTEF - Awareness - Mining ForumTC BengalonNo ratings yet

- KMM Suplier Quality Manual 2018Document23 pagesKMM Suplier Quality Manual 2018Jesus Cardona RezaNo ratings yet

- Iso Qualified Company Standard Procedure BUSINESS Process MapDocument13 pagesIso Qualified Company Standard Procedure BUSINESS Process MapJohn P. BandoquilloNo ratings yet

- GP Training Apqp-Ppap RevafDocument29 pagesGP Training Apqp-Ppap RevafNitipal SinghNo ratings yet

- SAP Plant Maintenance ConsultantDocument3 pagesSAP Plant Maintenance ConsultantSiva Kumar R MNo ratings yet

- APQPDocument2 pagesAPQPVbaluyoNo ratings yet

- Validation of SAP R/3 in Compliance With Part 11 RequirementsDocument46 pagesValidation of SAP R/3 in Compliance With Part 11 RequirementsSuraj Pratap PhalkeNo ratings yet

- Honda-Goa, 06th May 2009 1Document57 pagesHonda-Goa, 06th May 2009 1Avinash DondapatyNo ratings yet

- SAP Overview & SAP Navigation Template v1.1Document51 pagesSAP Overview & SAP Navigation Template v1.1Nurul Hasanatul LailaNo ratings yet

- Strategy MappingDocument6 pagesStrategy MappingLuis Carlos RodriguezNo ratings yet

- OpenSAP Plm1-1 Week 3 All SlidesDocument108 pagesOpenSAP Plm1-1 Week 3 All SlidesnataliasouzabrametalNo ratings yet

- Lean ManufacturingDocument5 pagesLean ManufacturingruturrajNo ratings yet

- Resume Er.Document2 pagesResume Er.rajpootanant1No ratings yet

- Optimizing Bea Weblogic ApplicationsDocument31 pagesOptimizing Bea Weblogic ApplicationsgauravpmNo ratings yet

- RENAULT Quality PlanningDocument20 pagesRENAULT Quality PlanningEhsan ArbabtaftiNo ratings yet

- RajanKhurana (21 0)Document3 pagesRajanKhurana (21 0)SAMSON GLOBALNo ratings yet

- BPCL PPT LatestDocument20 pagesBPCL PPT LatestBasu0% (1)

- Functional StructureDocument8 pagesFunctional StructureVishal RathiNo ratings yet

- Inspection ControlDocument10 pagesInspection ControlIvan D. RiveraNo ratings yet

- LCUSA SAP Implemention Strategy V3.1Document17 pagesLCUSA SAP Implemention Strategy V3.1Madhu MNo ratings yet

- SAP Purchasing/SalesDocument157 pagesSAP Purchasing/SalesSuave679100% (1)

- Sample Visual Plan Supporting PiecesDocument10 pagesSample Visual Plan Supporting PiecesdspinelliNo ratings yet

- JIT Visible Planning VGDocument40 pagesJIT Visible Planning VGdspinelliNo ratings yet

- East and WestDocument150 pagesEast and WestdspinelliNo ratings yet

- GM 1927-07 APQP Supplier AssessmentDocument5 pagesGM 1927-07 APQP Supplier AssessmentdspinelliNo ratings yet

- Change Request TemplateDocument8 pagesChange Request TemplatedspinelliNo ratings yet

- GM 1927-17 (GP-5) SQ Processes and Measurements Procedure (GP-5) - July2016 (To Be Posted)Document103 pagesGM 1927-17 (GP-5) SQ Processes and Measurements Procedure (GP-5) - July2016 (To Be Posted)dspinelliNo ratings yet

- GB SPC Formulary V02Document16 pagesGB SPC Formulary V02dspinelliNo ratings yet

- John Bicheno's Top 100 Lean Books - V 22: Author Title Publisher Date Serv / Man Comment Stars Amazon SalesDocument6 pagesJohn Bicheno's Top 100 Lean Books - V 22: Author Title Publisher Date Serv / Man Comment Stars Amazon SalesdspinelliNo ratings yet

- BTS - MIC Drop (Steve Aoki Remix) LyricsDocument5 pagesBTS - MIC Drop (Steve Aoki Remix) LyricsrhavenbhanNo ratings yet

- It Was A Peaceful Campaign For Reforms Towards Changing The Political and SocialDocument19 pagesIt Was A Peaceful Campaign For Reforms Towards Changing The Political and SocialNicole JunioNo ratings yet

- Elvis Presley - Original Soundtrack CD CompilationDocument36 pagesElvis Presley - Original Soundtrack CD CompilationElvis Presley Animal InstintNo ratings yet

- Macroeconomics in Action MASTER CLASS RANDELL BasicDocument66 pagesMacroeconomics in Action MASTER CLASS RANDELL BasicZorin RealceNo ratings yet

- Coding JRDocument15 pagesCoding JRajay1989sNo ratings yet

- 01 TallyPrime Material FinalDocument25 pages01 TallyPrime Material FinalRishi SrivastavaNo ratings yet

- Suttmeier Weekly Market BriefingDocument3 pagesSuttmeier Weekly Market BriefingRichard SuttmeierNo ratings yet

- Technology and Livelihood Education: 1St Generation Modules - Version 2.0Document21 pagesTechnology and Livelihood Education: 1St Generation Modules - Version 2.0Jerwine RoldanNo ratings yet

- A.Raghavamma V A.ChenchammaDocument2 pagesA.Raghavamma V A.ChenchammaajkNo ratings yet

- Hazlet Cinemark LawsuitDocument45 pagesHazlet Cinemark LawsuitDennis CarmodyNo ratings yet

- Introduction To Islamic Law PDFDocument20 pagesIntroduction To Islamic Law PDFAngelSebial7No ratings yet

- Topic 4 Investment AnalysisDocument22 pagesTopic 4 Investment Analysistinie@surieqNo ratings yet

- DTP MswdoDocument18 pagesDTP MswdoGermaine EraulaNo ratings yet

- CONVENTION No. 169Document160 pagesCONVENTION No. 169Wanderer leeNo ratings yet

- Etherscope Core Rulebook (Etherscope Roleplaying Game) (Nigel Mcclellan, Ben Redmond) (Z-Library)Document288 pagesEtherscope Core Rulebook (Etherscope Roleplaying Game) (Nigel Mcclellan, Ben Redmond) (Z-Library)Helena Castro GodinhoNo ratings yet

- 11 ABM Sean Jairus Lauta FABM PT #1 (AutoRecovered)Document20 pages11 ABM Sean Jairus Lauta FABM PT #1 (AutoRecovered)Sean LautaNo ratings yet

- ISC EconomicsDocument49 pagesISC Economicskrittika190% (1)

- Cotton Registration Suspension NotificationDocument3 pagesCotton Registration Suspension NotificationcottontradeNo ratings yet

- AC13 Accenture & The Hartford - Elicitation PDFDocument14 pagesAC13 Accenture & The Hartford - Elicitation PDFsonnyNo ratings yet

- 1997Document2 pages1997api-502941124No ratings yet

- Division of WorkDocument19 pagesDivision of WorkBharadwaj KwcNo ratings yet

- Definition of EquityDocument5 pagesDefinition of EquityTumwine BarnabasNo ratings yet

- Business English VocabularyDocument28 pagesBusiness English VocabularyputriNo ratings yet

- Cathay Pacific Airways, Ltd. v. Court of AppealsDocument8 pagesCathay Pacific Airways, Ltd. v. Court of AppealsriaheartsNo ratings yet

- 6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDocument5 pages6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDaniela DurducNo ratings yet

- Lesson Plan JK RowlingDocument5 pagesLesson Plan JK Rowlingapi-280552667No ratings yet

- Chapter 9Document25 pagesChapter 9Putri RiskiNo ratings yet

Case For Change Jan2015

Case For Change Jan2015

Uploaded by

dspinelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case For Change Jan2015

Case For Change Jan2015

Uploaded by

dspinelliCopyright:

Available Formats

Corporate Quality Development Center

A Case For Change

Copyright © 2016 Ford Motor Company. All rights reserved.

1

A Case for Change

Program

Management

Corporate Quality Global Product

Development

Development Center Sourcing

for Quality System (GPDS)

SREA

Gage R&R

Failure Mode Effects

Analysis (FMEA)

Statistical Process

Trademarking Control Plans Control (SPC)

APQP

Production Parts Global

Quality Supply Approval Process Phased

A Case (PPAP) / Capacity PPAP

Base

for Change Q1 Segmentation Verification / VPP / MPP

Partnering

Q1 Skills Print Reading, Geometric

Manufacturing Dimensioning & Tolerancing

ISO/TS 16949 Site Assessment (GD&T), Technical Specifications

Lean - Value Stream

STA Mapping/Error Proofing QOS

Functional

Application The STA

Job Campaign Prevention,

Lean - Measurables

Warranty Field Actions, Stop Ship

Plant (Resident) /

Lean - Basics Current Model

8D Analysis Product/QR2

Global 8D BSAQ

Copyright © 2016 Ford Motor Company. All rights reserved. 2

A Case for Change

Why CQDC?

As STA Engineers, we need a global

standard skill set to be effective.

CQDC is a rigorous, technically focused,

global curriculum that provides the tools

needed to successfully improve our

supplier quality, which will help improve our

customer satisfaction.

Copyright © 2016 Ford Motor Company. All rights reserved. 4

A Case for Change

Objectives

– Explain Ford’s responsibility to focus on quality and how

to address potential issues

– Describe the working relationship necessary within

Purchasing and Ford to meet Purchasing objectives

– Describe the Supplier relationship values and rules of

conduct

Copyright © 2016 Ford Motor Company. All rights reserved. 5

A Case for Change

Supplier Relationship Values

• Act like a partner to be a partner

• Trust and be trustworthy

• Communicate with consistency

• Be fact based

• Think value, not just price

Become the Original Equipment Manufacturer (OEM) of choice!

Copyright © 2016 Ford Motor Company. All rights reserved. 6

A Case for Change

Who do we interact with?

• Suppliers

• Purchasing

• Manufacturing

• Engineering

Copyright © 2016 Ford Motor Company. All rights reserved. 7

A Case for Change

Purchasing Responsibilities

• Identify suppliers who deliver the required product development capability

• Ensure technical resources are available to close deficiency gaps

• Verify supplier quality capabilities and utilize a metrics-driven assessment

• Facilitating a cross-functional sourcing consensus

• Issue target agreements

• Develop forward-model-sourcing strategies

• Ensure supplier responsiveness

• Drive adherence to the Purchasing Supplier Relationship Values

• Involve STA early in the sourcing process

Copyright © 2016 Ford Motor Company. All rights reserved. 8

A Case for Change

Supplier Responsibilities

• Deliver the right product, at the right time, in the right quantity

• Meet the technical, financial, and process capability objectives

• Staff the program with sufficient resources

• Complete product assurance and timing plans

• Challenge seemingly redundant Ford requirements

Copyright © 2016 Ford Motor Company. All rights reserved. 9

A Case for Change

Engineering Responsibilities

• Provide customer requirements, program scope, and quality and

reliability objectives

• Provide clarification on proposed direction

• Establish a product assurance management process

• Monitor and manage supplier execution

• Participate actively in supplier technical and process capability reviews

• Lead regular and periodic risk assessments

• Lead problem resolution and continuous improvement efforts

Copyright © 2016 Ford Motor Company. All rights reserved. 10

A Case for Change

Manufacturing Responsibilities

• Participate in sourcing decisions, based on quality history and total cost

• Provide shipping requirements, shipment windows, and packaging

requirements

• Monitor supplier quality deficiencies and communicate them to the suppliers

and STA/Purchasing

• Maintain historical data on supplier’s quality and shipping performance

• Participate in quality reviews at the supplier sites

• Conduct quality reviews of selected suppliers at Ford Manufacturing Plants

• Provide technical/manufacturing knowledge and assistance to suppliers that

have major quality/productivity issues

Copyright © 2016 Ford Motor Company. All rights reserved. 11

A Case for Change

STA Engineer and Purchasing Shared Responsibilities

• Achieve common understanding of supply base

• Recognize areas of concern

• Understand which suppliers are doing it right

• Work together to source new business

• Deal with ongoing performance issues

Copyright © 2016 Ford Motor Company. All rights reserved. 12

A Case for Change

Resources

Global Purchasing homepage

http://my.purchasing.ford.com/

STA homepage

http://www.purchasing.ford.com/prch_sta/

Copyright © 2016 Ford Motor Company. All rights reserved. 13

You might also like

- MBA 204-18-Human Resource Management (A) - NAMRATA BHALLADocument31 pagesMBA 204-18-Human Resource Management (A) - NAMRATA BHALLAMehak Arora0% (1)

- PepsiCo S Op Using Sap Apo at PepsicoDocument17 pagesPepsiCo S Op Using Sap Apo at PepsicoShivran RoyNo ratings yet

- Corperate Presentation July 2020Document18 pagesCorperate Presentation July 2020iganu76No ratings yet

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- Absorption Variable and Throughput Costing Macaculop RayosDocument24 pagesAbsorption Variable and Throughput Costing Macaculop RayosJohn BernabeNo ratings yet

- Questionnaire-Benchmarking of Best HR PracticesDocument13 pagesQuestionnaire-Benchmarking of Best HR PracticesUtkalKhatiwadaNo ratings yet

- Communication Skills Jan2008Document28 pagesCommunication Skills Jan2008Bosse BoseNo ratings yet

- Communication Skills Jan2008Document28 pagesCommunication Skills Jan2008dspinelliNo ratings yet

- S4HANA FundamentalsDocument77 pagesS4HANA FundamentalsLaksana Dewa100% (1)

- Resume - BALARAGHAVAN UDocument2 pagesResume - BALARAGHAVAN UubraghuNo ratings yet

- ANPQP - 3.0 - in ActionDocument14 pagesANPQP - 3.0 - in Actionjefry sitorus100% (1)

- 6 SAP PP Level I TrainingDocument45 pages6 SAP PP Level I TrainingsowjanyaNo ratings yet

- APQP FLOW From Design Through END of Product Life Cycle: N N N NDocument1 pageAPQP FLOW From Design Through END of Product Life Cycle: N N N NgaviotaperezNo ratings yet

- FMEA Link To APQPDocument1 pageFMEA Link To APQPiltem.islamNo ratings yet

- Bharath Original Resume FormatDocument2 pagesBharath Original Resume Formatarulanandhan10No ratings yet

- Automotive Core Tools - (APQP - PPAP - FMEA - MSA - SPC) - AIAGDocument5 pagesAutomotive Core Tools - (APQP - PPAP - FMEA - MSA - SPC) - AIAGMiguel RiusNo ratings yet

- Bharat HakeDocument2 pagesBharat HakebharatNo ratings yet

- Core Competencies - Quality and Reliability Methodology - Quality-OneDocument3 pagesCore Competencies - Quality and Reliability Methodology - Quality-OneTOSIF MUJAWARNo ratings yet

- SAP For Automotive: Industry Briefing BookDocument52 pagesSAP For Automotive: Industry Briefing BookAjay KumbharNo ratings yet

- Dear Sir. Am Interested in Production ND QualityDocument2 pagesDear Sir. Am Interested in Production ND QualitySinkar ManojNo ratings yet

- Apqp PQP Flow ChartDocument1 pageApqp PQP Flow ChartmjapmgNo ratings yet

- Management Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceDocument2 pagesManagement Representative (MR) - QMS Process Improvement TQM Customer Representative - Supplier Quality AssuranceHeart Touching VideosNo ratings yet

- Resume SambhajiDocument3 pagesResume SambhajiSambhaji GaikwadNo ratings yet

- PepsiCo S Op Using Sap Apo at Pepsico PDFDocument17 pagesPepsiCo S Op Using Sap Apo at Pepsico PDFsaranpcNo ratings yet

- DeepakKumarDeb 13463624 - 09 00 - 1Document3 pagesDeepakKumarDeb 13463624 - 09 00 - 1Mayur ShindeNo ratings yet

- SD - Output Determination ConfigurationDocument3 pagesSD - Output Determination ConfigurationsreekanthNo ratings yet

- ASAPDocument17 pagesASAPdspinelliNo ratings yet

- Sektion: Introduction: (C) Sap Ag TAMM40 1-1Document16 pagesSektion: Introduction: (C) Sap Ag TAMM40 1-1Jeferson SilvaNo ratings yet

- Poornachandran - Procurement Profile (3+years)Document2 pagesPoornachandran - Procurement Profile (3+years)chandranNo ratings yet

- S4 HANA Manufacturing 1610 InnovationsDocument26 pagesS4 HANA Manufacturing 1610 Innovationsabhi100% (5)

- SAP TRAINING SESSION - EditionDocument19 pagesSAP TRAINING SESSION - EditionJ Zhou (AU Accounting Office)No ratings yet

- APO Overview v1Document58 pagesAPO Overview v1topankajNo ratings yet

- SAP aATP New in 2020Document39 pagesSAP aATP New in 2020Rajesh Bhattu100% (2)

- Refining OverviewDocument53 pagesRefining OverviewSeptiaNo ratings yet

- Systems As The Way We Work - Innovation in QMS ImplementationDocument58 pagesSystems As The Way We Work - Innovation in QMS ImplementationSelvaraj SNo ratings yet

- PPW-Auto Parts-B2B-Objective-2024Document15 pagesPPW-Auto Parts-B2B-Objective-2024Jegan SubramaniamNo ratings yet

- SAP OverviewDocument13 pagesSAP OverviewRahulNo ratings yet

- Appendix: SAP Data & Analytics - Solution Architect & Lead ConsultantDocument4 pagesAppendix: SAP Data & Analytics - Solution Architect & Lead ConsultantAjay KumarNo ratings yet

- Welcome - Day 1 2012: Failure Mode and Effects AnalysisDocument63 pagesWelcome - Day 1 2012: Failure Mode and Effects AnalysisKaya Eralp AsanNo ratings yet

- TRL 123564Document26 pagesTRL 123564Mostfa RiahiNo ratings yet

- Advanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialDocument29 pagesAdvanced Product Quality Planning (APQP) and Production Part Approval Process (PPAP) Training MaterialxiwaxeNo ratings yet

- TEF - Awareness - Mining ForumDocument18 pagesTEF - Awareness - Mining ForumTC BengalonNo ratings yet

- KMM Suplier Quality Manual 2018Document23 pagesKMM Suplier Quality Manual 2018Jesus Cardona RezaNo ratings yet

- Iso Qualified Company Standard Procedure BUSINESS Process MapDocument13 pagesIso Qualified Company Standard Procedure BUSINESS Process MapJohn P. BandoquilloNo ratings yet

- GP Training Apqp-Ppap RevafDocument29 pagesGP Training Apqp-Ppap RevafNitipal SinghNo ratings yet

- SAP Plant Maintenance ConsultantDocument3 pagesSAP Plant Maintenance ConsultantSiva Kumar R MNo ratings yet

- APQPDocument2 pagesAPQPVbaluyoNo ratings yet

- Validation of SAP R/3 in Compliance With Part 11 RequirementsDocument46 pagesValidation of SAP R/3 in Compliance With Part 11 RequirementsSuraj Pratap PhalkeNo ratings yet

- Honda-Goa, 06th May 2009 1Document57 pagesHonda-Goa, 06th May 2009 1Avinash DondapatyNo ratings yet

- SAP Overview & SAP Navigation Template v1.1Document51 pagesSAP Overview & SAP Navigation Template v1.1Nurul Hasanatul LailaNo ratings yet

- Strategy MappingDocument6 pagesStrategy MappingLuis Carlos RodriguezNo ratings yet

- OpenSAP Plm1-1 Week 3 All SlidesDocument108 pagesOpenSAP Plm1-1 Week 3 All SlidesnataliasouzabrametalNo ratings yet

- Lean ManufacturingDocument5 pagesLean ManufacturingruturrajNo ratings yet

- Resume Er.Document2 pagesResume Er.rajpootanant1No ratings yet

- Optimizing Bea Weblogic ApplicationsDocument31 pagesOptimizing Bea Weblogic ApplicationsgauravpmNo ratings yet

- RENAULT Quality PlanningDocument20 pagesRENAULT Quality PlanningEhsan ArbabtaftiNo ratings yet

- RajanKhurana (21 0)Document3 pagesRajanKhurana (21 0)SAMSON GLOBALNo ratings yet

- BPCL PPT LatestDocument20 pagesBPCL PPT LatestBasu0% (1)

- Functional StructureDocument8 pagesFunctional StructureVishal RathiNo ratings yet

- Inspection ControlDocument10 pagesInspection ControlIvan D. RiveraNo ratings yet

- LCUSA SAP Implemention Strategy V3.1Document17 pagesLCUSA SAP Implemention Strategy V3.1Madhu MNo ratings yet

- SAP Purchasing/SalesDocument157 pagesSAP Purchasing/SalesSuave679100% (1)

- Sample Visual Plan Supporting PiecesDocument10 pagesSample Visual Plan Supporting PiecesdspinelliNo ratings yet

- JIT Visible Planning VGDocument40 pagesJIT Visible Planning VGdspinelliNo ratings yet

- East and WestDocument150 pagesEast and WestdspinelliNo ratings yet

- GM 1927-07 APQP Supplier AssessmentDocument5 pagesGM 1927-07 APQP Supplier AssessmentdspinelliNo ratings yet

- Change Request TemplateDocument8 pagesChange Request TemplatedspinelliNo ratings yet

- GM 1927-17 (GP-5) SQ Processes and Measurements Procedure (GP-5) - July2016 (To Be Posted)Document103 pagesGM 1927-17 (GP-5) SQ Processes and Measurements Procedure (GP-5) - July2016 (To Be Posted)dspinelliNo ratings yet

- GB SPC Formulary V02Document16 pagesGB SPC Formulary V02dspinelliNo ratings yet

- John Bicheno's Top 100 Lean Books - V 22: Author Title Publisher Date Serv / Man Comment Stars Amazon SalesDocument6 pagesJohn Bicheno's Top 100 Lean Books - V 22: Author Title Publisher Date Serv / Man Comment Stars Amazon SalesdspinelliNo ratings yet

- BTS - MIC Drop (Steve Aoki Remix) LyricsDocument5 pagesBTS - MIC Drop (Steve Aoki Remix) LyricsrhavenbhanNo ratings yet

- It Was A Peaceful Campaign For Reforms Towards Changing The Political and SocialDocument19 pagesIt Was A Peaceful Campaign For Reforms Towards Changing The Political and SocialNicole JunioNo ratings yet

- Elvis Presley - Original Soundtrack CD CompilationDocument36 pagesElvis Presley - Original Soundtrack CD CompilationElvis Presley Animal InstintNo ratings yet

- Macroeconomics in Action MASTER CLASS RANDELL BasicDocument66 pagesMacroeconomics in Action MASTER CLASS RANDELL BasicZorin RealceNo ratings yet

- Coding JRDocument15 pagesCoding JRajay1989sNo ratings yet

- 01 TallyPrime Material FinalDocument25 pages01 TallyPrime Material FinalRishi SrivastavaNo ratings yet

- Suttmeier Weekly Market BriefingDocument3 pagesSuttmeier Weekly Market BriefingRichard SuttmeierNo ratings yet

- Technology and Livelihood Education: 1St Generation Modules - Version 2.0Document21 pagesTechnology and Livelihood Education: 1St Generation Modules - Version 2.0Jerwine RoldanNo ratings yet

- A.Raghavamma V A.ChenchammaDocument2 pagesA.Raghavamma V A.ChenchammaajkNo ratings yet

- Hazlet Cinemark LawsuitDocument45 pagesHazlet Cinemark LawsuitDennis CarmodyNo ratings yet

- Introduction To Islamic Law PDFDocument20 pagesIntroduction To Islamic Law PDFAngelSebial7No ratings yet

- Topic 4 Investment AnalysisDocument22 pagesTopic 4 Investment Analysistinie@surieqNo ratings yet

- DTP MswdoDocument18 pagesDTP MswdoGermaine EraulaNo ratings yet

- CONVENTION No. 169Document160 pagesCONVENTION No. 169Wanderer leeNo ratings yet

- Etherscope Core Rulebook (Etherscope Roleplaying Game) (Nigel Mcclellan, Ben Redmond) (Z-Library)Document288 pagesEtherscope Core Rulebook (Etherscope Roleplaying Game) (Nigel Mcclellan, Ben Redmond) (Z-Library)Helena Castro GodinhoNo ratings yet

- 11 ABM Sean Jairus Lauta FABM PT #1 (AutoRecovered)Document20 pages11 ABM Sean Jairus Lauta FABM PT #1 (AutoRecovered)Sean LautaNo ratings yet

- ISC EconomicsDocument49 pagesISC Economicskrittika190% (1)

- Cotton Registration Suspension NotificationDocument3 pagesCotton Registration Suspension NotificationcottontradeNo ratings yet

- AC13 Accenture & The Hartford - Elicitation PDFDocument14 pagesAC13 Accenture & The Hartford - Elicitation PDFsonnyNo ratings yet

- 1997Document2 pages1997api-502941124No ratings yet

- Division of WorkDocument19 pagesDivision of WorkBharadwaj KwcNo ratings yet

- Definition of EquityDocument5 pagesDefinition of EquityTumwine BarnabasNo ratings yet

- Business English VocabularyDocument28 pagesBusiness English VocabularyputriNo ratings yet

- Cathay Pacific Airways, Ltd. v. Court of AppealsDocument8 pagesCathay Pacific Airways, Ltd. v. Court of AppealsriaheartsNo ratings yet

- 6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDocument5 pages6 - European Cluster Partnership For Excellence - European Cluster Collaboration PlatformDaniela DurducNo ratings yet

- Lesson Plan JK RowlingDocument5 pagesLesson Plan JK Rowlingapi-280552667No ratings yet

- Chapter 9Document25 pagesChapter 9Putri RiskiNo ratings yet