Professional Documents

Culture Documents

Energy-Modeling - Orlando - 2.4.20 - 2 17

Energy-Modeling - Orlando - 2.4.20 - 2 17

Uploaded by

gamedesigning87Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Energy-Modeling - Orlando - 2.4.20 - 2 17

Energy-Modeling - Orlando - 2.4.20 - 2 17

Uploaded by

gamedesigning87Copyright:

Available Formats

MODELING PROCEDURES

S CHEMATIC D ESIGN

1. Review all available documents (owner’s requirements, narratives,

drawings). Extract known data, document assumptions.

2. Compile schedules, lighting power density (LPD), and equipment power

density (EPD) design data for team to review, get info for ASHRAE fan

power calculation (filters, sound attenuation, etc.)

3. Evaluate those things that can’t be modeled with alternative methods

(e.g., thermodynamic equivalent, spreadsheet, 8760 schedule, etc.)

4. Evaluate impact of change from “reference” to “technical potential”

5. Define several HVAC alternatives

6. Expand EEMs to include synergistic elements

7. Make series of runs that include one EEM at a time to facilitate quality

control

8. Define packages to cover range of targets

9. Check results against metrics (site, plant, end-use) and targets

33

33

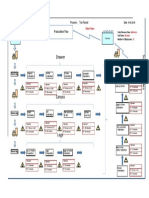

MODELING PROCEDURES

S CHEMATIC D ESIGN

Building

Items Considered

Original EEM

Schedule: 2am - 7pm (class C) Schedule: 3am - 5pm (class B) DIN EN 15232

DIN EN 15232 Warehouse: 13°C (24hrs)

Thermostat (efficiency class B) Warehouse: 20°C (24hrs) Office: 26°C / 30°C (cooling)

Office: 20°C /15.6°C (heating)

24°C / 26.7°C (Cooling)

Schedule: 4am - 5pm 30% Schedule: follow occupancy, 5% at night

Lighting Control night office ASHRAE

Warehouse lights run 24hr (warehouse remain the same)

Storage: 3 ach Storage: 0.4 ach

Tightening and sealing the Office: 0.001133 m³/s . m² Office: 0.4 ach

EEM Details

building envelop exterior surface Leakage test protocol for buidling envelops v3

2012

Wall: Double brick air gap Wall: Insulation in the gap or interior

Additional insulation w here

we can (roof/walls)

gypsum insulation (addition of 4in)

Roof: Metal Decking Roof: addition of 12in

Window Replacement / Single glazed 3.5 W/m².K addition of double glazed low E unit on the

improvement inside 2 W/m².K

Office 7.5W/m²

Lower Lighitng Levels Warehouse 3.34 W/m² Office Corridors 5.4W/m²

(Design Guide) 11.8 W/m² Server Rooms 7.5W/m²

Warehouse: 5.4W/m²

Lighting Controls (Da ylight /

Occupa ncy)

none Daylight sensors added where possible

Improved fan efficiencies Constant Volume Variable volume

and control eff 0.55 0.65

System Comparisons

COMPARIS ON OF T HE S YSTEMS

Improved Pump Efficiencies none for cooling

Rese t controls on the Chiller None

Variable high efficiency

As ASHRAE 90.1 2007

140

AHU checks temperature every 30 minutes

Night Cycle Control None

and cycles on if necessary at night

Variable fan for Warehouse,

120 3%

90 kBtu/ft2 HVAC Replaceme nt DX cooling DOAS system with Heat exchanger - individual

zone conditioning w/cental chiller

Solar Thermal Could use Solar thermal to feed into radiant

Energy Use Intensity kBtu/ft²

n/a

100 (for SHW needs) systems

Annual Energy Use

58.4 kBtu/ft² 61.8 kBtu/ft² 34%

80 2

51% 50%

60 Interior Equipment 4

20.4 kBtu/ft²

33.1 kBtu/ft²

Interior Lighting 57 kBtu/ft2

19.8 kBtu/ft²

18.8 kBtu/ft² 18.9 kBtu/ft²

40 Fans

8.4 kBtu/ft² 8.4 kBtu/ft² 8.3 kBtu/ft²

12.4 kBtu/ft² 12.6 kBtu/ft² Pumps

7.2 kBtu/ft² 7.3 kBtu/ft² 6.2 kBtu/ft²

20 6.6 kBtu/ft² 6.4 kBtu/ft² 5.1 kBtu/ft² 5. kBtu/ft² 5.6 kBtu/ft²

Cooling

8.6 kBtu/ft² 8.6 kBtu/ft² 8.6 kBtu/ft² 8.6 kBtu/ft² 8.6 kBtu/ft²

8. kBtu/ft² 8. kBtu/ft² 8. kBtu/ft² 8. kBtu/ft² 8. kBtu/ft²

Heating 1 3 5

- Current Technical Potential Implementable

1a - VAV

1b - VAV

DualDuct /

DualDuct /

Radiant /

3 - DOAS

2b - DOAS

Energy Use

2 - DOAS

30 kBtu/ft2 Minimum

DTU

FCU

FCU

Technical Potential Constraints 34

34

17

You might also like

- Ansi Ashrae Standard 94.2-2010Document20 pagesAnsi Ashrae Standard 94.2-2010Michael ZannisNo ratings yet

- Sample Raci Matrix For Xyz ProjectDocument5 pagesSample Raci Matrix For Xyz ProjectUmair Baig100% (7)

- Report On Temperature ExtremesDocument9 pagesReport On Temperature ExtremesAnant RathodNo ratings yet

- Renr1368 05 01 All PDFDocument2 pagesRenr1368 05 01 All PDFJonathan Luiz Poleza50% (2)

- Technovate Refrigeración y Aire AcondicionadoDocument34 pagesTechnovate Refrigeración y Aire Acondicionadojpg60No ratings yet

- ME TimetableDocument8 pagesME TimetableTOP 5 GHOSTNo ratings yet

- Static Equipment - A Look Inside The How and Why' of SpecificationDocument16 pagesStatic Equipment - A Look Inside The How and Why' of SpecificationmatodelanusNo ratings yet

- Propeller Repair: Cost-Efficient Straightening and WeldingDocument2 pagesPropeller Repair: Cost-Efficient Straightening and WeldingSaNdeep ChedeNo ratings yet

- 03 Quick Kaizen PDCA EngDocument8 pages03 Quick Kaizen PDCA EngFrancisco de PaulaNo ratings yet

- Basic Concepts of Thermal Engineering - Gate Mechanical NotesDocument3 pagesBasic Concepts of Thermal Engineering - Gate Mechanical NotesAjit PanjaNo ratings yet

- Integrated Concurrent Engineering: Big IdeaDocument60 pagesIntegrated Concurrent Engineering: Big IdeaEduardo MenaNo ratings yet

- Hvac Design For HospitalDocument13 pagesHvac Design For Hospitalmohamedmetwally784No ratings yet

- Career EpisodesDocument18 pagesCareer EpisodesSandeep K AugustineNo ratings yet

- Training Need AnalysisDocument18 pagesTraining Need AnalysisSanjeet SinghNo ratings yet

- DFM Model Question Paper VTUDocument2 pagesDFM Model Question Paper VTUHari Kiran M P100% (1)

- Daily Heavy Equipment Working Form: General Information Equipment Fuel ConsumptionDocument1 pageDaily Heavy Equipment Working Form: General Information Equipment Fuel ConsumptionT Abdi Maulana HusnyNo ratings yet

- Análisis Térmico de Una Cámara de CombustiónDocument8 pagesAnálisis Térmico de Una Cámara de CombustiónFrank Rubio CNo ratings yet

- Contoh Research GapDocument1 pageContoh Research GapDhika AdhityaNo ratings yet

- Iii Semester Teaching Hours /week ExaminationDocument8 pagesIii Semester Teaching Hours /week ExaminationPramod PujariNo ratings yet

- Mecchsyll PDFDocument172 pagesMecchsyll PDFPavana KumaraNo ratings yet

- Dominique Dutscher Sas: Technical Data SheetDocument3 pagesDominique Dutscher Sas: Technical Data Sheetalex bbapNo ratings yet

- k3p 07AS SheetDocument2 pagesk3p 07AS SheetsoniNo ratings yet

- User'S Guide: FX - 4Ad-Pt Special Function BlockDocument8 pagesUser'S Guide: FX - 4Ad-Pt Special Function BlockYuwarath SuktrakoonNo ratings yet

- Advanced Thermal ProjectDocument57 pagesAdvanced Thermal ProjectGiulio MarinoNo ratings yet

- Air Source Heat PumpDocument12 pagesAir Source Heat PumpZsoltNo ratings yet

- VRV System PDFDocument100 pagesVRV System PDFpNo ratings yet

- 34 TergraeeDocument2 pages34 TergraeeSwaroop SomannaNo ratings yet

- IKR270Document2 pagesIKR270e.montgomeryNo ratings yet

- Model Question Paper (CBCS)Document2 pagesModel Question Paper (CBCS)Swaroop SomannaNo ratings yet

- Manual de Instalación SideSmart VRF Descarga HorizontalDocument110 pagesManual de Instalación SideSmart VRF Descarga HorizontalCarlos ConsuegraNo ratings yet

- HC-702WE - Service Manual (20-Mar-2013) PDFDocument16 pagesHC-702WE - Service Manual (20-Mar-2013) PDFPaulAbiNasrNo ratings yet

- Temperature Based Fan Speed Controller: Problem SolutionDocument2 pagesTemperature Based Fan Speed Controller: Problem SolutionShubham GuptaNo ratings yet

- EHVPD & HVPD - COA Weekly Safety Report (Overall) : Week No: DateDocument6 pagesEHVPD & HVPD - COA Weekly Safety Report (Overall) : Week No: DateShafie ZubierNo ratings yet

- Thesis DefenseDocument37 pagesThesis DefenseJhon Rey DecatoriaNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument16 pagesCambridge International Advanced Subsidiary and Advanced LevelSmol PoTayToeNo ratings yet

- Ficha OrdesaDocument1 pageFicha Ordesaluigi schiavoneNo ratings yet

- Mathematical Modelling of Processor HeatingDocument19 pagesMathematical Modelling of Processor HeatingRaees (F-Name Khuda Baksh)No ratings yet

- Ideal Gas CyclesDocument8 pagesIdeal Gas CyclesMLNDG boysNo ratings yet

- Engr. Romano E. TorranoDocument14 pagesEngr. Romano E. TorranoMerry Ann Manalo CabralNo ratings yet

- Stirling Motor: Technical Teaching EquipmentDocument3 pagesStirling Motor: Technical Teaching EquipmentpfalencarNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Design of HVAC With VRF System For A Space House in AhmedabadDocument7 pagesDesign of HVAC With VRF System For A Space House in AhmedabadrkibNo ratings yet

- Timetable CS&IT SemesterWise Winter2024 V 1.4Document7 pagesTimetable CS&IT SemesterWise Winter2024 V 1.4fpbnzzghd9No ratings yet

- CM61 Installation Guide PDFDocument2 pagesCM61 Installation Guide PDFjosep sampolNo ratings yet

- Operational Manual of SKZ1053 TGADocument19 pagesOperational Manual of SKZ1053 TGAsolomon g/meskelNo ratings yet

- DFMEA - Carrier Seal-Hood ODS - PT00138273Document4 pagesDFMEA - Carrier Seal-Hood ODS - PT00138273Laboratorio MapremecNo ratings yet

- O General Duct Unit Inverter 2022Document2 pagesO General Duct Unit Inverter 2022Mohd TabishNo ratings yet

- Scope of Supply: Bar and Wire Rod MillDocument2 pagesScope of Supply: Bar and Wire Rod MillsaikatNo ratings yet

- IAQ Air Diffusion Sum 04Document3 pagesIAQ Air Diffusion Sum 04Santiago J. ramos jrNo ratings yet

- A01461101 Ice & Water - Automatic Defrost Side by Side - R134ADocument2 pagesA01461101 Ice & Water - Automatic Defrost Side by Side - R134AJOSE JIMENEZNo ratings yet

- Ese201LabReport Exp2Document5 pagesEse201LabReport Exp2Özge AlkanNo ratings yet

- Standard Kaizen / Pdca (Chronical Problems) : Plan DO PlanDocument14 pagesStandard Kaizen / Pdca (Chronical Problems) : Plan DO Plansuraj rawatNo ratings yet

- Experimental Mapping of The Thermodynamic Losses in Vapor Compression Refrigeration SystemsDocument7 pagesExperimental Mapping of The Thermodynamic Losses in Vapor Compression Refrigeration SystemssatyabrataNo ratings yet

- Value Stream Mapping: DrawerDocument1 pageValue Stream Mapping: DrawerzaferNo ratings yet

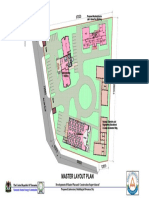

- Master Layout Plan: Proposed Nuclearphysics Lab & Gama Ray BuildingDocument1 pageMaster Layout Plan: Proposed Nuclearphysics Lab & Gama Ray BuildingElton MaroNo ratings yet

- Uvce Be 2nd3rd 4th Year Mech Engg Syl PDFDocument66 pagesUvce Be 2nd3rd 4th Year Mech Engg Syl PDFNAGENDRA0% (1)

- Technical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control SystemDocument126 pagesTechnical Manual: Combination Inverter Driven Multi-Indoor Unit Climate Control Systemh logoNo ratings yet

- Laura ProductDocument10 pagesLaura ProductCatrinaNo ratings yet

- Screenshot 2023-01-28 at 5.55.21 PMDocument5 pagesScreenshot 2023-01-28 at 5.55.21 PMmohamad zulkhairyNo ratings yet

- Because There Are Only Two Possibilities For Conve...Document1 pageBecause There Are Only Two Possibilities For Conve...Wan Nur AtikahNo ratings yet

- The-E-Myth 51Document1 pageThe-E-Myth 51gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 87Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 87gamedesigning87No ratings yet

- The-E-Myth 39Document1 pageThe-E-Myth 39gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 14Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 14gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 88Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 88gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 22Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 22gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 3Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 3gamedesigning87No ratings yet

- New - Gauge - Measurement - Systems 10Document1 pageNew - Gauge - Measurement - Systems 10gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 84Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 84gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 6Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 6gamedesigning87No ratings yet

- Handbook of Green Building Des6d7b8f7089cb - Anna's Archive 1Document1 pageHandbook of Green Building Des6d7b8f7089cb - Anna's Archive 1gamedesigning87No ratings yet

- New - Gauge - Measurement - Systems 8Document1 pageNew - Gauge - Measurement - Systems 8gamedesigning87No ratings yet

- New - Gauge - Measurement - Systems 11Document1 pageNew - Gauge - Measurement - Systems 11gamedesigning87No ratings yet

- New - Gauge - Measurement - Systems 9Document1 pageNew - Gauge - Measurement - Systems 9gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 12Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 12gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 9Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 9gamedesigning87No ratings yet

- New - Gauge - Measurement - Systems 12Document1 pageNew - Gauge - Measurement - Systems 12gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 15Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 15gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 11Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 11gamedesigning87No ratings yet

- PG23 6Document1 pagePG23 6gamedesigning87No ratings yet

- Leed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 2Document1 pageLeed-Green-Assoc-Leed-V4-Edition-Us-2-Pdf-Free 2gamedesigning87No ratings yet

- Heat Transfer Problems Solutions Rev 1Document22 pagesHeat Transfer Problems Solutions Rev 1Charlyn Flores100% (1)

- Che f241 HT HandoutDocument2 pagesChe f241 HT Handoutudit singhNo ratings yet

- Heat & Mass Transfer Jan 2014Document2 pagesHeat & Mass Transfer Jan 2014Prasad C M100% (1)

- Sam French WalkthroughDocument87 pagesSam French Walkthroughdan themanNo ratings yet

- Cooling of Photovoltaic Cells Under Concentrated Illumination - A Criti PDFDocument33 pagesCooling of Photovoltaic Cells Under Concentrated Illumination - A Criti PDFAnonymous PzbYdcEzNo ratings yet

- Environmental Chemodynamics - Ünzile GüvenDocument37 pagesEnvironmental Chemodynamics - Ünzile GüvenÜnzile Güven GülhanNo ratings yet

- Heat ExchangerDocument27 pagesHeat ExchangerPRATIK P. BHOIR100% (1)

- CFE - Assesment SheetDocument13 pagesCFE - Assesment SheetRonnick De La TongaNo ratings yet

- ME-131 Thermodynamics - I: BS Mechanical EngineeringDocument44 pagesME-131 Thermodynamics - I: BS Mechanical EngineeringHahshskakagaNo ratings yet

- Airvent - Load Calculations ProblemsDocument34 pagesAirvent - Load Calculations ProblemsSol S.No ratings yet

- Printed Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Document2 pagesPrinted Pages-4 (10×2 20) : (Sem. V) Odd Semester Theory EXAMINATION 2013-14Syam RajuNo ratings yet

- Final - Syllabus - Chemical Engg PDFDocument94 pagesFinal - Syllabus - Chemical Engg PDFALOK SHARMANo ratings yet

- Antara A, B, C Dan D Yang Manakah Mewakili Zarah Gas?: Perubahan Keadaan Jirim Bahagian ADocument5 pagesAntara A, B, C Dan D Yang Manakah Mewakili Zarah Gas?: Perubahan Keadaan Jirim Bahagian ARadamael MaembongNo ratings yet

- Unit I PDFDocument112 pagesUnit I PDFEr S Karthick Annamalai50% (2)

- Thermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)Document8 pagesThermal Conductivity Apparatus: (Two Slab Guarded Hot Plate Method)AdityaNo ratings yet

- Student Steam Tables V5.1 PDFDocument32 pagesStudent Steam Tables V5.1 PDFlouis_parker_5553No ratings yet

- Applications of Air ConditioningDocument6 pagesApplications of Air Conditioningloriel maliglig100% (1)

- Dasar Teori PendinginDocument64 pagesDasar Teori PendinginsuhandywNo ratings yet

- Presentation 1 - Introduction To Air ConditioningDocument19 pagesPresentation 1 - Introduction To Air ConditioningRenee CruzNo ratings yet

- Katalog6 En+erg Nzung-1Document50 pagesKatalog6 En+erg Nzung-1mealysrNo ratings yet

- Write A Program To Convert Temperature From Celsius To Fahrenheit and Vice-VersaDocument7 pagesWrite A Program To Convert Temperature From Celsius To Fahrenheit and Vice-VersaabhinavthedhimanNo ratings yet

- r050212306 Transport Phenomena in BioprocessDocument5 pagesr050212306 Transport Phenomena in BioprocessSrinivasa Rao GNo ratings yet

- Activity 4 (Physics)Document2 pagesActivity 4 (Physics)Dudekula Shareef AhmedNo ratings yet

- Preventative Maintenance Checklist: When To Schedule MaintenanceDocument3 pagesPreventative Maintenance Checklist: When To Schedule MaintenanceMdShafquat AzadNo ratings yet

- CIBSE Knowledge Series KS19 Dwyer Tim Humidification The Chartered Institution of Building Services Engineers 2012Document43 pagesCIBSE Knowledge Series KS19 Dwyer Tim Humidification The Chartered Institution of Building Services Engineers 2012Celrose FernandezNo ratings yet

- TABLE 13-1 Constant-Pressure Liquid-Vapor Equilibrium Data For Selected Binary SystemsDocument4 pagesTABLE 13-1 Constant-Pressure Liquid-Vapor Equilibrium Data For Selected Binary SystemsThaly MejiaNo ratings yet

- Fabrication of Hybrid Solar Dryer: Jyoti Singh, Pankaj VermaDocument8 pagesFabrication of Hybrid Solar Dryer: Jyoti Singh, Pankaj VermaimranakhtarNo ratings yet

- Refrigeration: Refrigeration Is The Process of Removing Heat From A Substance Under ControlledDocument15 pagesRefrigeration: Refrigeration Is The Process of Removing Heat From A Substance Under ControlledWala LangNo ratings yet