Professional Documents

Culture Documents

Fuel Injection Pump

Fuel Injection Pump

Uploaded by

Antonio AvilesCopyright:

Available Formats

You might also like

- RTA-48 Instruction For Replacement of NOx Relevant ComponentsDocument5 pagesRTA-48 Instruction For Replacement of NOx Relevant ComponentsCatalin CataNo ratings yet

- Maintenance Manual For Sulzer Diesel Engines Rta76Document412 pagesMaintenance Manual For Sulzer Diesel Engines Rta76miloslakovic96% (23)

- Electrical WiringDocument86 pagesElectrical Wiringche-ahmad-majdi-7191100% (1)

- XR250R Owners Manual 1983Document88 pagesXR250R Owners Manual 1983Matt ReganNo ratings yet

- Exhaust Pipe at Support For By-Pass ArrangementDocument4 pagesExhaust Pipe at Support For By-Pass ArrangementAntonio AvilesNo ratings yet

- RTA-22.1 Waisted Bolts For Piston Crown Spraying PlateDocument3 pagesRTA-22.1 Waisted Bolts For Piston Crown Spraying PlateCatalin CataNo ratings yet

- ABB Type VTR 4 Turbochargers Cleaning of Turbine and Blower SideDocument14 pagesABB Type VTR 4 Turbochargers Cleaning of Turbine and Blower SideAntonio AvilesNo ratings yet

- Service Bulletin A-17: 28.11.97 Technical Information To All The Owners of Sulzer AL25 and AV25 Type Diesel EnginesDocument3 pagesService Bulletin A-17: 28.11.97 Technical Information To All The Owners of Sulzer AL25 and AV25 Type Diesel EnginesgeamuccioNo ratings yet

- RTA-29 Improved Oil Supply To The Integrated Axial DetunerDocument3 pagesRTA-29 Improved Oil Supply To The Integrated Axial DetunerCatalin CataNo ratings yet

- Piston Assembly, Skirt and Ring RTA-72Document6 pagesPiston Assembly, Skirt and Ring RTA-72rafaelNo ratings yet

- Idoc - Pub - Maintenance Manual For Sulzer Diesel Engines Rta76 PDFDocument412 pagesIdoc - Pub - Maintenance Manual For Sulzer Diesel Engines Rta76 PDFЮрий Климкин100% (1)

- Service Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Document4 pagesService Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Diego ReggianiniNo ratings yet

- RTA-64 Modification of Fuel Pump Block and Pressure BushesDocument7 pagesRTA-64 Modification of Fuel Pump Block and Pressure BushesCatalin CataNo ratings yet

- Service Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel EnginesDocument20 pagesService Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel Engineszbkt07100% (1)

- Sulzer-Rta76.part 1Document205 pagesSulzer-Rta76.part 1Long NguyễnNo ratings yet

- RTA-10 Piston Skirt in Two PartsDocument6 pagesRTA-10 Piston Skirt in Two PartsCatalin CataNo ratings yet

- RTA 03.4 Fuel Injection NozzlesDocument5 pagesRTA 03.4 Fuel Injection NozzlesAlexis Barnabás Collins100% (1)

- Service Bulletin S - 3: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 01.09.94Document4 pagesService Bulletin S - 3: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 01.09.94Diego ReggianiniNo ratings yet

- RTA-56 Indicator ValvesDocument4 pagesRTA-56 Indicator ValvesCatalin CataNo ratings yet

- Service Bulletin S - 6: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 15.09.95Document3 pagesService Bulletin S - 6: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 15.09.95Diego ReggianiniNo ratings yet

- Conversion To Loop Cooler RLB-90Document16 pagesConversion To Loop Cooler RLB-90rafaelNo ratings yet

- Rta 70Document6 pagesRta 70George Domusciu100% (1)

- Relief Valve 274HD RTA-69Document7 pagesRelief Valve 274HD RTA-69rafaelNo ratings yet

- ABB Type VTR 4 Turbochargers Cooling Water ArrangementDocument5 pagesABB Type VTR 4 Turbochargers Cooling Water ArrangementAntonio AvilesNo ratings yet

- Sulzer ZAV 40Document59 pagesSulzer ZAV 40Curtler Paquibot100% (1)

- zv40 480Document6 pageszv40 480World Service100% (1)

- ZXXCDocument7 pagesZXXCarness22100% (1)

- Service Bulletin ZAS-34: 26.06.98 Technical Information To All Owners / Operators of Sulzer ZA 40S EnginesDocument3 pagesService Bulletin ZAS-34: 26.06.98 Technical Information To All Owners / Operators of Sulzer ZA 40S Enginesarness22No ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Piston Rod Gland Box VentiongDocument5 pagesPiston Rod Gland Box VentiongrafaelNo ratings yet

- RTA-33.1 Crank Pin Bearing ShellsDocument13 pagesRTA-33.1 Crank Pin Bearing ShellsCatalin CataNo ratings yet

- RTA-08 Cylinder Liners and Reinforced Water Guide JacketsDocument13 pagesRTA-08 Cylinder Liners and Reinforced Water Guide JacketsCatalin CataNo ratings yet

- Service Bulletin S - 8: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 22.03.96Document4 pagesService Bulletin S - 8: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 22.03.96Diego ReggianiniNo ratings yet

- Intervalo 2000 Horas - 938KDocument3 pagesIntervalo 2000 Horas - 938KMatheus MongesNo ratings yet

- RTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitDocument7 pagesRTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitCatalin CataNo ratings yet

- SB3 1 101Document3 pagesSB3 1 101jussmeeeNo ratings yet

- SL08 495KNBSL2008 495 PDFDocument6 pagesSL08 495KNBSL2008 495 PDFDenim102No ratings yet

- Assessment of Main and Connecting Rod BearingsDocument9 pagesAssessment of Main and Connecting Rod BearingsAntonio AvilesNo ratings yet

- RT-97 - Injection Valve Modification - Size3Document5 pagesRT-97 - Injection Valve Modification - Size3YIU KWOK KeungNo ratings yet

- RTA-20 - Rotational Safety Studs For Roller Guide of Fuel Pumps and Exhaust Valve ActuatorDocument3 pagesRTA-20 - Rotational Safety Studs For Roller Guide of Fuel Pumps and Exhaust Valve Actuatordhilip87No ratings yet

- Rta 15Document7 pagesRta 15George DomusciuNo ratings yet

- ZAV 40S Maintenance ManualDocument273 pagesZAV 40S Maintenance ManualAntonio AvilesNo ratings yet

- RT-flex-03 CLU Cylinder LubricationDocument11 pagesRT-flex-03 CLU Cylinder LubricationCatalin CataNo ratings yet

- Service Bulletin A - 11: Technical Information To All The Owners of Sulzer A 20 Type Diesel Engines 15.09.95Document3 pagesService Bulletin A - 11: Technical Information To All The Owners of Sulzer A 20 Type Diesel Engines 15.09.95Gaetano MuccioNo ratings yet

- Over GreasingDocument6 pagesOver GreasingantonyaleNo ratings yet

- RTA-27 Plastic Water SeparatorDocument5 pagesRTA-27 Plastic Water SeparatorCatalin CataNo ratings yet

- 1d Dvs Sulzer Rta48t Codebook 812Document812 pages1d Dvs Sulzer Rta48t Codebook 812BorysNo ratings yet

- Data & Specifications: Wärtsilä Low-Speed EnginesDocument13 pagesData & Specifications: Wärtsilä Low-Speed Enginesherysyam1980No ratings yet

- RTA-25 Flange For 2-Way Valve of Hydraulic Actuator PumpDocument4 pagesRTA-25 Flange For 2-Way Valve of Hydraulic Actuator PumpCatalin CataNo ratings yet

- RT-96 - Exhaust Valve Spindle LubricationDocument6 pagesRT-96 - Exhaust Valve Spindle LubricationGeorgios MariolisNo ratings yet

- Xeulfdwlqj2Loviru$% 57xuerfkdujhuv: 7iipixxivDocument3 pagesXeulfdwlqj2Loviru$% 57xuerfkdujhuv: 7iipixxivAlexanderNo ratings yet

- Practical Tips For RT-flex-1Document8 pagesPractical Tips For RT-flex-1George DomusciuNo ratings yet

- Ks Si 0010 en WebDocument0 pagesKs Si 0010 en WebMoaed KanbarNo ratings yet

- ML AuxiliaryEngineCompleteManualMAN BW8L20 27Document466 pagesML AuxiliaryEngineCompleteManualMAN BW8L20 27Leonid KolesnikovNo ratings yet

- RTA-47 Draining of Fuel Oil PipesDocument7 pagesRTA-47 Draining of Fuel Oil PipesCatalin CataNo ratings yet

- RTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersDocument5 pagesRTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersCatalin CataNo ratings yet

- A002E1S1Document1 pageA002E1S1381tutNo ratings yet

- Service Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94Document9 pagesService Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94Flo MarineNo ratings yet

- Turbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingDocument3 pagesTurbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingmariodalNo ratings yet

- RT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4Document4 pagesRT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4lijinNo ratings yet

- RTA-37.1 Reconditioning of Piston RodsDocument11 pagesRTA-37.1 Reconditioning of Piston RodsCatalin Cata100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- 04-Monitor Compliance With Legislative Requirements Jefe MaqDocument6 pages04-Monitor Compliance With Legislative Requirements Jefe MaqAntonio AvilesNo ratings yet

- 21-Personal Safety On Vessels Jefe MaqDocument7 pages21-Personal Safety On Vessels Jefe MaqAntonio AvilesNo ratings yet

- 07-Start Up & Shut Down Machinery & Systems Jefe MaqsDocument10 pages07-Start Up & Shut Down Machinery & Systems Jefe MaqsAntonio AvilesNo ratings yet

- Grundfos Pump LP65-125 Preheater MEDocument53 pagesGrundfos Pump LP65-125 Preheater MEAntonio AvilesNo ratings yet

- Marine Engineering - Boilers & CombustionDocument51 pagesMarine Engineering - Boilers & CombustionAntonio AvilesNo ratings yet

- MAN B&W CYLINDER HEAD Chapter 605Document37 pagesMAN B&W CYLINDER HEAD Chapter 605Antonio AvilesNo ratings yet

- MAN B&W Engine Data Chapter 600Document28 pagesMAN B&W Engine Data Chapter 600Antonio AvilesNo ratings yet

- LM SeriesDocument16 pagesLM SeriesAntonio AvilesNo ratings yet

- Inert Gas SystemsDocument95 pagesInert Gas SystemsAntonio AvilesNo ratings yet

- Thermal Oil Pump - CouplingDocument2 pagesThermal Oil Pump - CouplingAntonio AvilesNo ratings yet

- Parts Code Book Plate 310-354Z Pages 114-144Document34 pagesParts Code Book Plate 310-354Z Pages 114-144Antonio AvilesNo ratings yet

- Crude Oil Washing SystemsDocument99 pagesCrude Oil Washing SystemsAntonio AvilesNo ratings yet

- Octamar Complete PDSDocument2 pagesOctamar Complete PDSAntonio AvilesNo ratings yet

- 6735-1 A1 WASTE-GATE - Dismantling and AssemblingDocument4 pages6735-1 A1 WASTE-GATE - Dismantling and AssemblingAntonio AvilesNo ratings yet

- 4301-1 A1 STARTING AIR DISTRIBUTOR - Dismantling and AssemblingDocument3 pages4301-1 A1 STARTING AIR DISTRIBUTOR - Dismantling and AssemblingAntonio AvilesNo ratings yet

- Waterproof - Getting StartedDocument11 pagesWaterproof - Getting StartedAntonio AvilesNo ratings yet

- FO Pump O RingsDocument1 pageFO Pump O RingsAntonio AvilesNo ratings yet

- 2722-2 A1 FUEL INJECTION VALVE - Checking The Condition of The Spraying PressureDocument2 pages2722-2 A1 FUEL INJECTION VALVE - Checking The Condition of The Spraying PressureAntonio AvilesNo ratings yet

- B&W HITZ S42MC Parts - CompleteDocument116 pagesB&W HITZ S42MC Parts - CompleteAntonio AvilesNo ratings yet

- Taiko ProductsDocument7 pagesTaiko ProductsAntonio AvilesNo ratings yet

- 2718-1 A1 STARTING VALVE IN THE CYLINDER HEAD - Removing From The Cylinder Head, Dismantling, Lapping-In, Assembling and FittingDocument2 pages2718-1 A1 STARTING VALVE IN THE CYLINDER HEAD - Removing From The Cylinder Head, Dismantling, Lapping-In, Assembling and FittingAntonio AvilesNo ratings yet

- 2720-1 A1 INLET AND EXHAUST VALVES - Replacing Valve Springs As Well As Removing and Fitting of ValvesDocument3 pages2720-1 A1 INLET AND EXHAUST VALVES - Replacing Valve Springs As Well As Removing and Fitting of ValvesAntonio AvilesNo ratings yet

- 2720-2 A1 INLET AND EXHAUST VALVES - Regrinding The SeatsDocument2 pages2720-2 A1 INLET AND EXHAUST VALVES - Regrinding The SeatsAntonio AvilesNo ratings yet

- 2105-2 A1 CYLINDER LINER - Removing and Fitting A Cylinder LinerDocument4 pages2105-2 A1 CYLINDER LINER - Removing and Fitting A Cylinder LinerAntonio AvilesNo ratings yet

- 2722-1 A1 FUEL INJECTION VALVE - Removing, Dismantling and AssemblingDocument3 pages2722-1 A1 FUEL INJECTION VALVE - Removing, Dismantling and AssemblingAntonio AvilesNo ratings yet

- 2701-6 A1 CYLINDER HEAD - Pressure Test of Water SpacesDocument1 page2701-6 A1 CYLINDER HEAD - Pressure Test of Water SpacesAntonio AvilesNo ratings yet

- 6601-1 A1 CHARGE AIR COOLER - Removal, Cleaning and MountingDocument5 pages6601-1 A1 CHARGE AIR COOLER - Removal, Cleaning and MountingAntonio AvilesNo ratings yet

- 2701-5 A1 CYLINDER HEAD - Replacing The Valve Guides For The Inlet and Exhaust ValvesDocument1 page2701-5 A1 CYLINDER HEAD - Replacing The Valve Guides For The Inlet and Exhaust ValvesAntonio AvilesNo ratings yet

- 1202-1 A1 - CRANKSHAFT THRUST BEARING - Replacement of Bearing Shells and Thrust Ring HalvesDocument5 pages1202-1 A1 - CRANKSHAFT THRUST BEARING - Replacement of Bearing Shells and Thrust Ring HalvesAntonio AvilesNo ratings yet

- Safety Drill 16Document1 pageSafety Drill 16Antonio AvilesNo ratings yet

- PATS Diagnostic Flowchart TSBDocument31 pagesPATS Diagnostic Flowchart TSBMiguel CarrilloNo ratings yet

- Szr660 Service ManualDocument207 pagesSzr660 Service ManualvancapNo ratings yet

- 00055009920-TDI Diesel Injection and Glow Plug System (4-Cyl) 08 99 ÄDocument100 pages00055009920-TDI Diesel Injection and Glow Plug System (4-Cyl) 08 99 Ämenardcharlelie6No ratings yet

- Normet - NORMET RBODocument2 pagesNormet - NORMET RBORahul Kumar Gupta0% (1)

- Roll Cage, Safety and Ergonomics Report: AbstractDocument32 pagesRoll Cage, Safety and Ergonomics Report: AbstractJuicYm mNo ratings yet

- FD Fan Sop - OpgDocument7 pagesFD Fan Sop - OpgNarayanan KharthiNo ratings yet

- S6000-Operation-Manual SkyliftDocument50 pagesS6000-Operation-Manual SkyliftSetiawan Tuhu basukiNo ratings yet

- Write A Story About A Person With A Hidden TalentDocument2 pagesWrite A Story About A Person With A Hidden TalentMustafa Shahbaz50% (2)

- Audi 6.0L W12 Engine in The Audi A8LDocument84 pagesAudi 6.0L W12 Engine in The Audi A8LAkash Ghosh100% (1)

- Item # at 200 - 0.8S, at Turbo Blower: 108 Independence Way Coatesville, PA 19320 - WebsiteDocument2 pagesItem # at 200 - 0.8S, at Turbo Blower: 108 Independence Way Coatesville, PA 19320 - WebsiteAlexis ElíasNo ratings yet

- Kata LogDocument351 pagesKata LogБојан ДумитровићNo ratings yet

- Forklift Safety Manual PolicyDocument6 pagesForklift Safety Manual PolicyHIGH REACH EQUIPMENTNo ratings yet

- Questions To Probe The Candidate's Underpinning Knowledge Satisfactory Response Extension/Reflection Questions Yes NoDocument4 pagesQuestions To Probe The Candidate's Underpinning Knowledge Satisfactory Response Extension/Reflection Questions Yes NoDaniel ReyesNo ratings yet

- Section Electrical Manual Number KM815070 Date 05/01/18Document111 pagesSection Electrical Manual Number KM815070 Date 05/01/18Carlos Mauricio Amorocho Castellanos100% (9)

- 00 Manual de Partes REIMERDocument79 pages00 Manual de Partes REIMERFenix MechanicsNo ratings yet

- Basics of Mechanisms: Unit IDocument76 pagesBasics of Mechanisms: Unit IMudit MaheshwariNo ratings yet

- Anti Lock Braking SystemDocument29 pagesAnti Lock Braking SystemPravin DeshmaneNo ratings yet

- Yanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts ManualDocument4 pagesYanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts Manualdenise100% (32)

- Sun Industries, Inc.: For Foldover, Card Feeder, & Product Transfer Diagrams Refer To Dwg. #P/8-96-1001Document1 pageSun Industries, Inc.: For Foldover, Card Feeder, & Product Transfer Diagrams Refer To Dwg. #P/8-96-1001Carl PotschNo ratings yet

- Checklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Document1 pageChecklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Subistia IrwanNo ratings yet

- DTC Headlamp Range Adj - ALLDocument3 pagesDTC Headlamp Range Adj - ALLletgoeverythingyoufeartoloseNo ratings yet

- 61xx Service Manual Rev C ml60 70xv 70xvDocument178 pages61xx Service Manual Rev C ml60 70xv 70xvIago NunesNo ratings yet

- CAT320Document20 pagesCAT320Bilal VURALNo ratings yet

- 4140D Motor Grader: Tough World. Tough EquipmentDocument2 pages4140D Motor Grader: Tough World. Tough EquipmentAmirul Wiyatno100% (1)

- TTT - D9R - General Literature ListDocument6 pagesTTT - D9R - General Literature ListStasNo ratings yet

- Codigos de Fallas de Motor DT 466eDocument5 pagesCodigos de Fallas de Motor DT 466eBruno Adrover100% (1)

- Brochure Hyundai Forklift Diesel 100D-9Document8 pagesBrochure Hyundai Forklift Diesel 100D-9Raka RakaNo ratings yet

- Doosan P222 PartsDocument104 pagesDoosan P222 PartsTom LeonardNo ratings yet

Fuel Injection Pump

Fuel Injection Pump

Uploaded by

Antonio AvilesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Injection Pump

Fuel Injection Pump

Uploaded by

Antonio AvilesCopyright:

Available Formats

Service Bulletin ZAS–32.

1

13.12.99

Technical Information to all Owners / Operators (Supersedes Bulletin

of Sulzer ZA 40S Engines ZAS–32 of 31.03.98)

Fuel Injection Pump

Contents: Page

1. Introduction 1

2. Modification to the

Fuel Pump Cover 1

3. Soft Iron Joints in the

Fuel Oil System 1

4. Service Bulletins Published for 3

ZA 40S Engines

28.51.71.40 – Printed in Switzerland

Wärtsilä NSD Switzerland Ltd PO Box 414 Tel. +41 52 262 49 22

Wärtsilä NSD Schweiz AG CH-8401 Winterthur Fax +41 52 212 49 17

Wärtsilä NSD Suisse SA Switzerland Tlx 896 659 NSDL CH

1. INTRODUCTION

This Service Bulletin describes a modification to the fuel pump cover which improves the sealing

effect of the O–ring between fuel pump cover and pump housing.

A second paragraph informs you about a new material specification for joints used in the fuel oil

system.

The original edition contained a misprint of the code number in the figure on page 1.

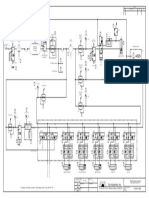

2. MODIFICATION TO THE FUEL PUMP COVER

The following modification is only valid for fuel pump covers with a conical seal between pump

cover and high pressure fuel pipe:

conical seal

Fuel pump cover (KS 55008) with conical seal

An O–ring is fitted between the fuel pump cover and pump housing in order to avoid fuel leakage.

This O–ring is exposed to heavy pressure pulsations in the fuel oil system. With the introduction of

a back–up ring above the O–ring, its sealing effect is improved and its stresses are reduced.

Therefore the O–ring groove has to be larger. For new engines this modification is standard.

Existing engines with repeated leakages on fuel pump covers can be retrofitted accordingly.

If a back–up ring is to be fitted on an existing fuel pump cover, the height of the O–ring groove has

to be enlarged from 7 to 8.8 mm (see drawing on next page).

Both O–ring (code no. KS 55036) and back–up ring (code no. KS 55038) can be ordered through

Wärtsilä NSD France, Mantes or our Network Companies.

Important: The O–ring should be renewed during each dismantling of the fuel pump cover or of

the fuel pump.

3. SOFT IRON JOINTS IN THE FUEL OIL SYSTEM

Fuel oil with high sulphur content leads to corrosion attack on copper joint rings and thus may cause

fuel leakages. Therefore we have, some time ago, changed the material specification for gaskets

used in the fuel oil system from copper to soft iron.

We strongly recommend to exchange copper joint rings in the fuel oil system with soft iron rings at

the next opportunity (code no. KS 87191, KS 87192, KS 87194, KS 87196, KS 87215, KS 87216

and KS 87217, please refer to the Code Book). Any parts needed are available through Wärtsilä

NSD France, Mantes or our Network Companies.

1/3 Service Bulletin ZAS–32.1

Modification to an existing fuel pump cover

when fitting a back–up ring

Modification

Detail A

Back–upRing

O–Ring

This Service Bulletin should be kept in a separate file in the control room. The respective pages

or tables of the Service Bulletin with modifications to the Operating Manual, Maintenance

Manual or Code Book should be copied and filed in the respective Manual or Book.

Wärtsilä Switzerland Ltd has issued this Service Bulletin with their best knowledge and ability.

However, Wärtsilä Switzerland Ltd can not take any liability for any or all information contained

in this or any other Service Bulletin.

Changes of any nature to the form and or to the content of this or any other Service Bulletin as

published by Wärtsilä Switzerland Ltd, are not permitted.

2/3 Service Bulletin ZAS–32.1

4. SERVICE BULLETINS PUBLISHED FOR ZA 40S ENGINES

We have so far published the following Service Bulletins which are valid for ZA 40S type engines:

ZAS–1.2 dated 02.02.96 Cylinder Liner Overhaul

ZAS–2.1 dated 29.08.97 Overhaul of Cylinder Head

ZAS–3 dated 10.06.93 Oil Scraper Rings

ZAS–4.4 dated 26.02.99 Piston Rings

ZAS–5 dated 03.12.93 Instruction for Testing of Fuel Injection Nozzles

ZAS–6.1 dated 23.02.96 Piston Rotating Mechanism

ZAS–7 dated 05.04.94 Adjustments and Maintenance Requirements on Oil Mist Detector

ZAS–8.1 dated 16.05.97 Turnomat for Exhaust Valves and Rotocap for Inlet Valves

ZAS–9 dated 01.06.94 Exhaust Pipe Expansion Bellows

ZAS–10 dated 01.08.94 High Temperature Cooling Water System

ZAS–11.1 dated 31.03.98 Cylinder Liner with a Thread

ZAS–12 dated 01.03.95 New Spindle Design for Pressure Control Valve KS 87085

ZAS–13.1 dated 18.12.98 Inlet Valves

ZAS–14.1 dated 27.02.98 High Pressure Fuel Pipe

ZAS–15.1 dated 30.01.98 Fuel Injection Nozzle Specification

ZAS–16 dated 10.08.95 Flow Control Valve KS 72126 for Cylinder Lubrication

ZAS–17.3 dated 18.05.99 VTR ..4 Turbochargers After Sales Service Information issued by ABB

ZAS–18.1 dated 27.02.98 Tightening Instructions

ZAS–19 dated 17.11.95 New Piston Ring Fitting Tool

ZAS–20 dated 17.11.95 New Spring Cage KS 28042 for Rocker Gear

ZAS–21 dated 22.03.96 Differences in the Drive for the Cylinder Lubrication between

Engines with 660 kW/Cyl. and 720 kW/Cyl.

ZAS–22 dated 08.11.96 Adjustments of Fuel Oil Systems

ZAS–23 dated 19.11.96 Modification to the Oil Mist Detector

ZAS–24 dated 28.01.97 Alphabetical Index of Topics of Service Bulletins

ZAS–25 dated 16.95,97 Tightening Instructions for the Connecting Rod Big End Bearing

ZAS–26 dated 30.05.97 ABB Type VTR..4 Turbochargers

Cleaning of Turbine and Blower Side

ZAS–27 dated 29.08.97 Lubricating Oil Treatment and Requirements

ZAS–28 dated 29.08.97 Assessment of Main and Connecting Rod Bearings

ZAS–29 dated 29.08.97 Undersized Bearings and Reconditioning of Crankshafts

ZAS–30 dated 31.10.87 ABB Type VTR..4 Turbochargers Cooling Water Arrangement

ZAS–31 dated 31.10.97 Flushing Instructions

ZAS–32.1 dated 13.12.99 Fuel Injection Pump

ZAS–33 dated 31.03.98 Shim between Connecting Rod and Big End Bearing

ZAS–34 dated 26.08.98 Hand Rails for Engine-mounted Platforms

ZAS–35 dated 09.06.99 Variable Damping Plunger

ZAS–36 dated 11.10.99 Exhaust Pipe at Support for By-Pass Arrangement

Should you not be in possession of the above mentioned documentation suitable for your plant, kindly contact your

local Wärtsilä NSD representative for your copy.

3/3 Service Bulletin ZAS–32.1

You might also like

- RTA-48 Instruction For Replacement of NOx Relevant ComponentsDocument5 pagesRTA-48 Instruction For Replacement of NOx Relevant ComponentsCatalin CataNo ratings yet

- Maintenance Manual For Sulzer Diesel Engines Rta76Document412 pagesMaintenance Manual For Sulzer Diesel Engines Rta76miloslakovic96% (23)

- Electrical WiringDocument86 pagesElectrical Wiringche-ahmad-majdi-7191100% (1)

- XR250R Owners Manual 1983Document88 pagesXR250R Owners Manual 1983Matt ReganNo ratings yet

- Exhaust Pipe at Support For By-Pass ArrangementDocument4 pagesExhaust Pipe at Support For By-Pass ArrangementAntonio AvilesNo ratings yet

- RTA-22.1 Waisted Bolts For Piston Crown Spraying PlateDocument3 pagesRTA-22.1 Waisted Bolts For Piston Crown Spraying PlateCatalin CataNo ratings yet

- ABB Type VTR 4 Turbochargers Cleaning of Turbine and Blower SideDocument14 pagesABB Type VTR 4 Turbochargers Cleaning of Turbine and Blower SideAntonio AvilesNo ratings yet

- Service Bulletin A-17: 28.11.97 Technical Information To All The Owners of Sulzer AL25 and AV25 Type Diesel EnginesDocument3 pagesService Bulletin A-17: 28.11.97 Technical Information To All The Owners of Sulzer AL25 and AV25 Type Diesel EnginesgeamuccioNo ratings yet

- RTA-29 Improved Oil Supply To The Integrated Axial DetunerDocument3 pagesRTA-29 Improved Oil Supply To The Integrated Axial DetunerCatalin CataNo ratings yet

- Piston Assembly, Skirt and Ring RTA-72Document6 pagesPiston Assembly, Skirt and Ring RTA-72rafaelNo ratings yet

- Idoc - Pub - Maintenance Manual For Sulzer Diesel Engines Rta76 PDFDocument412 pagesIdoc - Pub - Maintenance Manual For Sulzer Diesel Engines Rta76 PDFЮрий Климкин100% (1)

- Service Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Document4 pagesService Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Diego ReggianiniNo ratings yet

- RTA-64 Modification of Fuel Pump Block and Pressure BushesDocument7 pagesRTA-64 Modification of Fuel Pump Block and Pressure BushesCatalin CataNo ratings yet

- Service Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel EnginesDocument20 pagesService Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel Engineszbkt07100% (1)

- Sulzer-Rta76.part 1Document205 pagesSulzer-Rta76.part 1Long NguyễnNo ratings yet

- RTA-10 Piston Skirt in Two PartsDocument6 pagesRTA-10 Piston Skirt in Two PartsCatalin CataNo ratings yet

- RTA 03.4 Fuel Injection NozzlesDocument5 pagesRTA 03.4 Fuel Injection NozzlesAlexis Barnabás Collins100% (1)

- Service Bulletin S - 3: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 01.09.94Document4 pagesService Bulletin S - 3: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 01.09.94Diego ReggianiniNo ratings yet

- RTA-56 Indicator ValvesDocument4 pagesRTA-56 Indicator ValvesCatalin CataNo ratings yet

- Service Bulletin S - 6: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 15.09.95Document3 pagesService Bulletin S - 6: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 15.09.95Diego ReggianiniNo ratings yet

- Conversion To Loop Cooler RLB-90Document16 pagesConversion To Loop Cooler RLB-90rafaelNo ratings yet

- Rta 70Document6 pagesRta 70George Domusciu100% (1)

- Relief Valve 274HD RTA-69Document7 pagesRelief Valve 274HD RTA-69rafaelNo ratings yet

- ABB Type VTR 4 Turbochargers Cooling Water ArrangementDocument5 pagesABB Type VTR 4 Turbochargers Cooling Water ArrangementAntonio AvilesNo ratings yet

- Sulzer ZAV 40Document59 pagesSulzer ZAV 40Curtler Paquibot100% (1)

- zv40 480Document6 pageszv40 480World Service100% (1)

- ZXXCDocument7 pagesZXXCarness22100% (1)

- Service Bulletin ZAS-34: 26.06.98 Technical Information To All Owners / Operators of Sulzer ZA 40S EnginesDocument3 pagesService Bulletin ZAS-34: 26.06.98 Technical Information To All Owners / Operators of Sulzer ZA 40S Enginesarness22No ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Piston Rod Gland Box VentiongDocument5 pagesPiston Rod Gland Box VentiongrafaelNo ratings yet

- RTA-33.1 Crank Pin Bearing ShellsDocument13 pagesRTA-33.1 Crank Pin Bearing ShellsCatalin CataNo ratings yet

- RTA-08 Cylinder Liners and Reinforced Water Guide JacketsDocument13 pagesRTA-08 Cylinder Liners and Reinforced Water Guide JacketsCatalin CataNo ratings yet

- Service Bulletin S - 8: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 22.03.96Document4 pagesService Bulletin S - 8: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 22.03.96Diego ReggianiniNo ratings yet

- Intervalo 2000 Horas - 938KDocument3 pagesIntervalo 2000 Horas - 938KMatheus MongesNo ratings yet

- RTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitDocument7 pagesRTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitCatalin CataNo ratings yet

- SB3 1 101Document3 pagesSB3 1 101jussmeeeNo ratings yet

- SL08 495KNBSL2008 495 PDFDocument6 pagesSL08 495KNBSL2008 495 PDFDenim102No ratings yet

- Assessment of Main and Connecting Rod BearingsDocument9 pagesAssessment of Main and Connecting Rod BearingsAntonio AvilesNo ratings yet

- RT-97 - Injection Valve Modification - Size3Document5 pagesRT-97 - Injection Valve Modification - Size3YIU KWOK KeungNo ratings yet

- RTA-20 - Rotational Safety Studs For Roller Guide of Fuel Pumps and Exhaust Valve ActuatorDocument3 pagesRTA-20 - Rotational Safety Studs For Roller Guide of Fuel Pumps and Exhaust Valve Actuatordhilip87No ratings yet

- Rta 15Document7 pagesRta 15George DomusciuNo ratings yet

- ZAV 40S Maintenance ManualDocument273 pagesZAV 40S Maintenance ManualAntonio AvilesNo ratings yet

- RT-flex-03 CLU Cylinder LubricationDocument11 pagesRT-flex-03 CLU Cylinder LubricationCatalin CataNo ratings yet

- Service Bulletin A - 11: Technical Information To All The Owners of Sulzer A 20 Type Diesel Engines 15.09.95Document3 pagesService Bulletin A - 11: Technical Information To All The Owners of Sulzer A 20 Type Diesel Engines 15.09.95Gaetano MuccioNo ratings yet

- Over GreasingDocument6 pagesOver GreasingantonyaleNo ratings yet

- RTA-27 Plastic Water SeparatorDocument5 pagesRTA-27 Plastic Water SeparatorCatalin CataNo ratings yet

- 1d Dvs Sulzer Rta48t Codebook 812Document812 pages1d Dvs Sulzer Rta48t Codebook 812BorysNo ratings yet

- Data & Specifications: Wärtsilä Low-Speed EnginesDocument13 pagesData & Specifications: Wärtsilä Low-Speed Enginesherysyam1980No ratings yet

- RTA-25 Flange For 2-Way Valve of Hydraulic Actuator PumpDocument4 pagesRTA-25 Flange For 2-Way Valve of Hydraulic Actuator PumpCatalin CataNo ratings yet

- RT-96 - Exhaust Valve Spindle LubricationDocument6 pagesRT-96 - Exhaust Valve Spindle LubricationGeorgios MariolisNo ratings yet

- Xeulfdwlqj2Loviru$% 57xuerfkdujhuv: 7iipixxivDocument3 pagesXeulfdwlqj2Loviru$% 57xuerfkdujhuv: 7iipixxivAlexanderNo ratings yet

- Practical Tips For RT-flex-1Document8 pagesPractical Tips For RT-flex-1George DomusciuNo ratings yet

- Ks Si 0010 en WebDocument0 pagesKs Si 0010 en WebMoaed KanbarNo ratings yet

- ML AuxiliaryEngineCompleteManualMAN BW8L20 27Document466 pagesML AuxiliaryEngineCompleteManualMAN BW8L20 27Leonid KolesnikovNo ratings yet

- RTA-47 Draining of Fuel Oil PipesDocument7 pagesRTA-47 Draining of Fuel Oil PipesCatalin CataNo ratings yet

- RTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersDocument5 pagesRTA-09 Cylinder Covers With Erosion and Corrosion Resistant CladdersCatalin CataNo ratings yet

- A002E1S1Document1 pageA002E1S1381tutNo ratings yet

- Service Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94Document9 pagesService Bulletin A - 2.2: Technical Information To All The Owners of Sulzer A - Type Diesel Engines 30.11.94Flo MarineNo ratings yet

- Turbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingDocument3 pagesTurbocharger NR 12 / S - Introduction of Splash Oil Cooling Modification of Locating BearingmariodalNo ratings yet

- RT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4Document4 pagesRT-flex-07 - 07 - New Setting of Fuel Pressure Control Valve - Size4lijinNo ratings yet

- RTA-37.1 Reconditioning of Piston RodsDocument11 pagesRTA-37.1 Reconditioning of Piston RodsCatalin Cata100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- 04-Monitor Compliance With Legislative Requirements Jefe MaqDocument6 pages04-Monitor Compliance With Legislative Requirements Jefe MaqAntonio AvilesNo ratings yet

- 21-Personal Safety On Vessels Jefe MaqDocument7 pages21-Personal Safety On Vessels Jefe MaqAntonio AvilesNo ratings yet

- 07-Start Up & Shut Down Machinery & Systems Jefe MaqsDocument10 pages07-Start Up & Shut Down Machinery & Systems Jefe MaqsAntonio AvilesNo ratings yet

- Grundfos Pump LP65-125 Preheater MEDocument53 pagesGrundfos Pump LP65-125 Preheater MEAntonio AvilesNo ratings yet

- Marine Engineering - Boilers & CombustionDocument51 pagesMarine Engineering - Boilers & CombustionAntonio AvilesNo ratings yet

- MAN B&W CYLINDER HEAD Chapter 605Document37 pagesMAN B&W CYLINDER HEAD Chapter 605Antonio AvilesNo ratings yet

- MAN B&W Engine Data Chapter 600Document28 pagesMAN B&W Engine Data Chapter 600Antonio AvilesNo ratings yet

- LM SeriesDocument16 pagesLM SeriesAntonio AvilesNo ratings yet

- Inert Gas SystemsDocument95 pagesInert Gas SystemsAntonio AvilesNo ratings yet

- Thermal Oil Pump - CouplingDocument2 pagesThermal Oil Pump - CouplingAntonio AvilesNo ratings yet

- Parts Code Book Plate 310-354Z Pages 114-144Document34 pagesParts Code Book Plate 310-354Z Pages 114-144Antonio AvilesNo ratings yet

- Crude Oil Washing SystemsDocument99 pagesCrude Oil Washing SystemsAntonio AvilesNo ratings yet

- Octamar Complete PDSDocument2 pagesOctamar Complete PDSAntonio AvilesNo ratings yet

- 6735-1 A1 WASTE-GATE - Dismantling and AssemblingDocument4 pages6735-1 A1 WASTE-GATE - Dismantling and AssemblingAntonio AvilesNo ratings yet

- 4301-1 A1 STARTING AIR DISTRIBUTOR - Dismantling and AssemblingDocument3 pages4301-1 A1 STARTING AIR DISTRIBUTOR - Dismantling and AssemblingAntonio AvilesNo ratings yet

- Waterproof - Getting StartedDocument11 pagesWaterproof - Getting StartedAntonio AvilesNo ratings yet

- FO Pump O RingsDocument1 pageFO Pump O RingsAntonio AvilesNo ratings yet

- 2722-2 A1 FUEL INJECTION VALVE - Checking The Condition of The Spraying PressureDocument2 pages2722-2 A1 FUEL INJECTION VALVE - Checking The Condition of The Spraying PressureAntonio AvilesNo ratings yet

- B&W HITZ S42MC Parts - CompleteDocument116 pagesB&W HITZ S42MC Parts - CompleteAntonio AvilesNo ratings yet

- Taiko ProductsDocument7 pagesTaiko ProductsAntonio AvilesNo ratings yet

- 2718-1 A1 STARTING VALVE IN THE CYLINDER HEAD - Removing From The Cylinder Head, Dismantling, Lapping-In, Assembling and FittingDocument2 pages2718-1 A1 STARTING VALVE IN THE CYLINDER HEAD - Removing From The Cylinder Head, Dismantling, Lapping-In, Assembling and FittingAntonio AvilesNo ratings yet

- 2720-1 A1 INLET AND EXHAUST VALVES - Replacing Valve Springs As Well As Removing and Fitting of ValvesDocument3 pages2720-1 A1 INLET AND EXHAUST VALVES - Replacing Valve Springs As Well As Removing and Fitting of ValvesAntonio AvilesNo ratings yet

- 2720-2 A1 INLET AND EXHAUST VALVES - Regrinding The SeatsDocument2 pages2720-2 A1 INLET AND EXHAUST VALVES - Regrinding The SeatsAntonio AvilesNo ratings yet

- 2105-2 A1 CYLINDER LINER - Removing and Fitting A Cylinder LinerDocument4 pages2105-2 A1 CYLINDER LINER - Removing and Fitting A Cylinder LinerAntonio AvilesNo ratings yet

- 2722-1 A1 FUEL INJECTION VALVE - Removing, Dismantling and AssemblingDocument3 pages2722-1 A1 FUEL INJECTION VALVE - Removing, Dismantling and AssemblingAntonio AvilesNo ratings yet

- 2701-6 A1 CYLINDER HEAD - Pressure Test of Water SpacesDocument1 page2701-6 A1 CYLINDER HEAD - Pressure Test of Water SpacesAntonio AvilesNo ratings yet

- 6601-1 A1 CHARGE AIR COOLER - Removal, Cleaning and MountingDocument5 pages6601-1 A1 CHARGE AIR COOLER - Removal, Cleaning and MountingAntonio AvilesNo ratings yet

- 2701-5 A1 CYLINDER HEAD - Replacing The Valve Guides For The Inlet and Exhaust ValvesDocument1 page2701-5 A1 CYLINDER HEAD - Replacing The Valve Guides For The Inlet and Exhaust ValvesAntonio AvilesNo ratings yet

- 1202-1 A1 - CRANKSHAFT THRUST BEARING - Replacement of Bearing Shells and Thrust Ring HalvesDocument5 pages1202-1 A1 - CRANKSHAFT THRUST BEARING - Replacement of Bearing Shells and Thrust Ring HalvesAntonio AvilesNo ratings yet

- Safety Drill 16Document1 pageSafety Drill 16Antonio AvilesNo ratings yet

- PATS Diagnostic Flowchart TSBDocument31 pagesPATS Diagnostic Flowchart TSBMiguel CarrilloNo ratings yet

- Szr660 Service ManualDocument207 pagesSzr660 Service ManualvancapNo ratings yet

- 00055009920-TDI Diesel Injection and Glow Plug System (4-Cyl) 08 99 ÄDocument100 pages00055009920-TDI Diesel Injection and Glow Plug System (4-Cyl) 08 99 Ämenardcharlelie6No ratings yet

- Normet - NORMET RBODocument2 pagesNormet - NORMET RBORahul Kumar Gupta0% (1)

- Roll Cage, Safety and Ergonomics Report: AbstractDocument32 pagesRoll Cage, Safety and Ergonomics Report: AbstractJuicYm mNo ratings yet

- FD Fan Sop - OpgDocument7 pagesFD Fan Sop - OpgNarayanan KharthiNo ratings yet

- S6000-Operation-Manual SkyliftDocument50 pagesS6000-Operation-Manual SkyliftSetiawan Tuhu basukiNo ratings yet

- Write A Story About A Person With A Hidden TalentDocument2 pagesWrite A Story About A Person With A Hidden TalentMustafa Shahbaz50% (2)

- Audi 6.0L W12 Engine in The Audi A8LDocument84 pagesAudi 6.0L W12 Engine in The Audi A8LAkash Ghosh100% (1)

- Item # at 200 - 0.8S, at Turbo Blower: 108 Independence Way Coatesville, PA 19320 - WebsiteDocument2 pagesItem # at 200 - 0.8S, at Turbo Blower: 108 Independence Way Coatesville, PA 19320 - WebsiteAlexis ElíasNo ratings yet

- Kata LogDocument351 pagesKata LogБојан ДумитровићNo ratings yet

- Forklift Safety Manual PolicyDocument6 pagesForklift Safety Manual PolicyHIGH REACH EQUIPMENTNo ratings yet

- Questions To Probe The Candidate's Underpinning Knowledge Satisfactory Response Extension/Reflection Questions Yes NoDocument4 pagesQuestions To Probe The Candidate's Underpinning Knowledge Satisfactory Response Extension/Reflection Questions Yes NoDaniel ReyesNo ratings yet

- Section Electrical Manual Number KM815070 Date 05/01/18Document111 pagesSection Electrical Manual Number KM815070 Date 05/01/18Carlos Mauricio Amorocho Castellanos100% (9)

- 00 Manual de Partes REIMERDocument79 pages00 Manual de Partes REIMERFenix MechanicsNo ratings yet

- Basics of Mechanisms: Unit IDocument76 pagesBasics of Mechanisms: Unit IMudit MaheshwariNo ratings yet

- Anti Lock Braking SystemDocument29 pagesAnti Lock Braking SystemPravin DeshmaneNo ratings yet

- Yanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts ManualDocument4 pagesYanmar 4tnv98 Znms2 Engine 3tnv82a Bpms Engine Parts Manualdenise100% (32)

- Sun Industries, Inc.: For Foldover, Card Feeder, & Product Transfer Diagrams Refer To Dwg. #P/8-96-1001Document1 pageSun Industries, Inc.: For Foldover, Card Feeder, & Product Transfer Diagrams Refer To Dwg. #P/8-96-1001Carl PotschNo ratings yet

- Checklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Document1 pageChecklist Maintenance Per 6 Bulan (Januari Dan Juni) : Conveyor (ALL)Subistia IrwanNo ratings yet

- DTC Headlamp Range Adj - ALLDocument3 pagesDTC Headlamp Range Adj - ALLletgoeverythingyoufeartoloseNo ratings yet

- 61xx Service Manual Rev C ml60 70xv 70xvDocument178 pages61xx Service Manual Rev C ml60 70xv 70xvIago NunesNo ratings yet

- CAT320Document20 pagesCAT320Bilal VURALNo ratings yet

- 4140D Motor Grader: Tough World. Tough EquipmentDocument2 pages4140D Motor Grader: Tough World. Tough EquipmentAmirul Wiyatno100% (1)

- TTT - D9R - General Literature ListDocument6 pagesTTT - D9R - General Literature ListStasNo ratings yet

- Codigos de Fallas de Motor DT 466eDocument5 pagesCodigos de Fallas de Motor DT 466eBruno Adrover100% (1)

- Brochure Hyundai Forklift Diesel 100D-9Document8 pagesBrochure Hyundai Forklift Diesel 100D-9Raka RakaNo ratings yet

- Doosan P222 PartsDocument104 pagesDoosan P222 PartsTom LeonardNo ratings yet