Professional Documents

Culture Documents

Sec Ii D Ma App 1

Sec Ii D Ma App 1

Uploaded by

silvanopipeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec Ii D Ma App 1

Sec Ii D Ma App 1

Uploaded by

silvanopipeCopyright:

Available Formats

Mandatory Appendices

MANDATORY APPENDIX 1

BASIS FOR ESTABLISHING

--```,,`,`,````,`,``,`,,``,```,-`-`,,`,,`,`,,`---

STRESS VALUES IN TABLES 1A AND 1B

1-100 DERIVATION OF ALLOWABLE ST p specified minimum tensile strength at room

STRESS VALUES temperature, ksi

SY p specified minimum yield strength at room

The values in Tables 1A and 1B are established by the temperature, ksi

Committee only. In the determination of allowable stress n p a negative number equal to ⌬ log time-to-

values for materials, the Committee is guided by success-

rupture divided by ⌬ log stress at 100,000 hr

ful experience in service, insofar as evidence of satisfac-

NA p not applicable

tory performance is available. Such evidence is

considered equivalent to test data where operating condi- The maximum allowable stress shall be the lowest

tions are known with reasonable certainty. In the evalua- value obtained from the criteria in Table 1-100. The

tion of new materials, the Committee is guided to a certain mechanical properties considered, and the factors applied

extent by the comparison of test information with avail- to establish the maximum allowable stresses, are as given

able data on successful applications of similar materials. below.

(a) At temperatures below the range where creep and

Nomenclature: stress rupture strength govern the selection of stresses,

Favg p multiplier applied to average stress for rup- the maximum allowable stress value is the lowest of the

ture in 100,000 hr. At 1500°F and below, following:

Favg p 0.67. Above 1500°F, it is determined (1) the specified minimum tensile strength at room

from the slope of the log time-to-rupture ver- temperature divided by 3.5;

sus log stress plot at 100,000 hr such that log (2) the tensile strength at temperature divided by

Favg p 1/n, but it may not exceed 0.67. 3.5;

RT p ratio of the average temperature dependent (3) two-thirds of the specified minimum yield

trend curve value of tensile strength to the strength at room temperature;

room temperature tensile strength (4) two-thirds of the yield strength at temperature.

RY p ratio of the average temperature dependent In the application of these criteria, the Committee con-

trend curve value of yield strength to the room siders the yield strength at temperature to be SYRY, and

temperature yield strength the tensile strength at temperature to be 1.1STRT.

SC p average stress to produce a creep rate of Two sets of allowable stress values are provided in

0.01%/1,000 hr Tables 1A and 1B for austenitic materials and specific

SRavg p average stress to cause rupture at the end of nonferrous alloys. The higher alternative allowable

100,000 hr stresses are identified by a footnote to the tables. These

SRmin p minimum stress to cause rupture at the end stresses exceed two-thirds but do not exceed 90% of the

of 100,000 hr minimum yield strength at temperature. The higher stress

791

Copyright ASME International

Provided by IHS under license with ASME Licensee=Sofregaz/5959055001

No reproduction or networking permitted without license from IHS Not for Resale, 04/18/2005 08:21:12 MDT

1-100 2004 SECTION II 1-100

values should be used only where slightly higher deforma- (2) 100Favg% of the average stress to cause rupture

tion is not in itself objectionable. These higher stresses at the end of 100,000 hr;

are not recommended for the design of flanges or other (3) 80% of the minimum stress to cause rupture at

strain sensitive applications. the end of 100,000 hr.

(b) At temperatures in the range where creep and stress Stress values for high temperatures are based, when-

rupture strength govern the selection of stresses, the maxi- ever possible, on representative uniaxial properties of the

mum allowable stress value for all materials is established materials obtained under standard ASTM testing condi-

by the Committee not to exceed the lowest of the fol- tions or equivalent. The stress values are based on basic

lowing: properties of the materials and no consideration is given

(1) 100% of the average stress to produce a creep for corrosive environment, for abnormal temperature and

--```,,`,`,````,`,``,`,,``,```,-`-`,,`,,`,`,,`---

rate of 0.01%/1,000 hr; stress conditions, or for other design considerations.

792

Copyright ASME International

Provided by IHS under license with ASME Licensee=Sofregaz/5959055001

No reproduction or networking permitted without license from IHS Not for Resale, 04/18/2005 08:21:12 MDT

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS

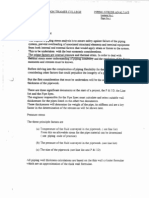

TABLE 1-100

CRITERIA FOR ESTABLISHING ALLOWABLE STRESS VALUES FOR TABLES 1A AND 1B

Below Room

Temperature Room Temperature and Above

Tensile Yield Tensile Yield Stress Creep

Product/Material Strength Strength Strength Strength Rupture Rate

2 2 2

Wrought or cast ST ⁄3 SY ST 1.1 ⁄3 SY ⁄3 SYRY FavgSR avg 0.8SR min 1.0Sc

S R

ferrous and 3.5 3.5 3.5 T T or 0.9SYRY

nonferrous [Note (1)]

793

2 2 2

Welded pipe or 0.85 ⁄3 ⴛ 0.85SY 0.85 (1.1 ⴛ 0.85) ⁄3 ⴛ 0.85SY ⁄3 ⴛ 0.85SYRY (Favg ⴛ 0.85)SR avg (0.8 ⴛ 0.85)SR min 0.85Sc

S S ST RT

tube, ferrous and 3.5 T 3.5 T 3.5 or 0.9 ⴛ 0.85SYRY

nonferrous [Note (1)]

NOTE:

Licensee=Sofregaz/5959055001

(1) Two sets of allowable stress values may be provided in Table 1A for austenitic materials and in Table 1B for specific nonferrous alloys. The

lower values are not specifically identified by a footnote. These lower values do not exceed two-thirds of the minimum yield strength at

PART D — PROPERTIES (CUSTOMARY)

Not for Resale, 04/18/2005 08:21:12 MDT

temperature. The higher alternative allowable stresses are identified by a footnote. These higher stresses may exceed two-thirds but do not

exceed 90% of the minimum yield strength at temperature. The higher values should be used only where slightly higher deformation is not

in itself objectionable. These higher stresses are not recommended for the design of flanges or for other strain sensitive applications.

Table 1-100

--```,,`,`,````,`,``,`,,``,```,-`-`,,`,,`,`,,`---

You might also like

- UG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99Document3 pagesUG-99 Standard Hydrostatic Test: ASME BPVC - VIII.1-2019 UG-99sergiotero100% (1)

- Chemistry 8 Grade Past PapersDocument14 pagesChemistry 8 Grade Past PapersVirti Desai100% (2)

- Proving Ring ExperimentDocument7 pagesProving Ring ExperimentPrateek AggarwalNo ratings yet

- Engineering Espresso AssignmentDocument8 pagesEngineering Espresso AssignmentVamsi SrinivasanNo ratings yet

- Volumetric Analysis Involving Acids and AlkalisDocument56 pagesVolumetric Analysis Involving Acids and AlkalisRyanNo ratings yet

- App 1 PDFDocument2 pagesApp 1 PDFSantos RandazzoNo ratings yet

- Allowable Stress BasisDocument9 pagesAllowable Stress BasisNAMONo ratings yet

- Sec Ii D Ma App 2Document3 pagesSec Ii D Ma App 2silvanopipeNo ratings yet

- Casting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFDocument3 pagesCasting Quality Factor Ec 302.3.3 ASME B31.3 2020 PDFedisjdavNo ratings yet

- Asme Sec II D Ma App 2Document3 pagesAsme Sec II D Ma App 2GicuNo ratings yet

- Asme Sec Viii d1 Nma App PDocument2 pagesAsme Sec Viii d1 Nma App PJessica Tatiana Muñoz OrtizNo ratings yet

- Asme B31.8 - Allow Stress SaDocument1 pageAsme B31.8 - Allow Stress Sajoaquin torrano veraNo ratings yet

- Relief Valve Settings PDFDocument5 pagesRelief Valve Settings PDFAnandababuNo ratings yet

- Line Traps CalculationDocument22 pagesLine Traps Calculationashwani21010% (1)

- 2004 Article - Ripple Current ConfusionDocument2 pages2004 Article - Ripple Current ConfusiondaveNo ratings yet

- Calculation of Thermowell Strength To ASME PTC 19.3 TW-2010Document2 pagesCalculation of Thermowell Strength To ASME PTC 19.3 TW-2010Irfan SyukranNo ratings yet

- Astm D 3497 - 79 (Reapproved 2003)Document3 pagesAstm D 3497 - 79 (Reapproved 2003)Esmeralda Cerda SánchezNo ratings yet

- Richmond Stress NotesDocument110 pagesRichmond Stress Notessateesh chand100% (1)

- IS 16227 (Part 2) : 2016 IEC 61869-2: 2012Document1 pageIS 16227 (Part 2) : 2016 IEC 61869-2: 2012NIKUNJ KUMARNo ratings yet

- Analisis de Stress en TuberíasDocument4 pagesAnalisis de Stress en TuberíasJanneth Herrera Flores100% (1)

- What Is Piping PDFDocument7 pagesWhat Is Piping PDFZaytj CondorNo ratings yet

- HowLowCanMegohmsGo 0711Document3 pagesHowLowCanMegohmsGo 0711andres monederoNo ratings yet

- SD PDFDocument7 pagesSD PDFTech To BarNo ratings yet

- Fatigue: © 2008 ASM International. All Rights Reserved. Elements of Metallurgy and Engineering Alloys (#05224G)Document23 pagesFatigue: © 2008 ASM International. All Rights Reserved. Elements of Metallurgy and Engineering Alloys (#05224G)Juanra MartínezNo ratings yet

- Compression Dead End & Compression Midspan JointDocument23 pagesCompression Dead End & Compression Midspan JointibnuilyasNo ratings yet

- Voltage Definitions For Phase Control and Bi-Directionally Controlled Thyristors by Hitachi EnergyDocument4 pagesVoltage Definitions For Phase Control and Bi-Directionally Controlled Thyristors by Hitachi EnergyㄉㄨㄤNo ratings yet

- 49 CFR Ch. I (10-1-10 Edition) 178.46: Rejected Cylinders. Reheat TreatDocument5 pages49 CFR Ch. I (10-1-10 Edition) 178.46: Rejected Cylinders. Reheat TreatyatheendravarmaNo ratings yet

- A Comparison of The ANSI/IEEE and The CENELEC/IEC Approaches To Overload Protection of Insulated Power CablesDocument5 pagesA Comparison of The ANSI/IEEE and The CENELEC/IEC Approaches To Overload Protection of Insulated Power CablesDao DaoNo ratings yet

- Sec Ii Appendix 8Document1 pageSec Ii Appendix 8silvanopipeNo ratings yet

- Sizing Steam TrapsDocument4 pagesSizing Steam Trapsjesus_manrique2753No ratings yet

- 5689989cd50c6620659291f6898623e7Document13 pages5689989cd50c6620659291f6898623e7rahulmecNo ratings yet

- Technical Update Ripple Current CapabilitiesDocument5 pagesTechnical Update Ripple Current CapabilitiesLuciano AlvesNo ratings yet

- Richmond Stress NotesDocument110 pagesRichmond Stress Notesmsaad2100% (2)

- Equation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesDocument6 pagesEquation 1: The Following Products/services Are Available: 1 A Range of Standard Heatsinks and AccessoriesgoaltechNo ratings yet

- Appendix P Basis For Establishing Allowable Stress ValuesDocument2 pagesAppendix P Basis For Establishing Allowable Stress ValuesAhmedNo ratings yet

- Non-Mandatory Appendix PDocument2 pagesNon-Mandatory Appendix PMuhammed Abo-FandoodNo ratings yet

- MUR480EG, MUR4100EG Switchmode Power Rectifiers: Ultrafast "E'' Series With High Reverse Energy CapabilityDocument6 pagesMUR480EG, MUR4100EG Switchmode Power Rectifiers: Ultrafast "E'' Series With High Reverse Energy Capabilitycorrales_86No ratings yet

- Analysis of The Fatigue Strength of A Stainless Steel Based On The Energy DissipationDocument14 pagesAnalysis of The Fatigue Strength of A Stainless Steel Based On The Energy DissipationEngels OchoaNo ratings yet

- DS IN0015 en Co 1353Document7 pagesDS IN0015 en Co 1353Vignesh DheenakumarNo ratings yet

- Earthing Tool CalculatorDocument36 pagesEarthing Tool CalculatorJejomar ErebarenNo ratings yet

- Il Temperature: Temperature Specifications For Inline TerminalsDocument1 pageIl Temperature: Temperature Specifications For Inline TerminalsJohn EvansNo ratings yet

- Neutral Grounding Resistor - BrochureDocument10 pagesNeutral Grounding Resistor - Brochuregabo diazNo ratings yet

- Yeild CriteriaDocument9 pagesYeild CriteriaDhruv PatelNo ratings yet

- TES-P-119.06 R0 - Surge ProtectionDocument15 pagesTES-P-119.06 R0 - Surge ProtectionMohamed Eldin100% (2)

- 1JNL000294 - Reactor TU-GUIDocument11 pages1JNL000294 - Reactor TU-GUIspationeNo ratings yet

- Squirrel Cage Crane Duty Induction Motors: Motors For The Long Run!Document12 pagesSquirrel Cage Crane Duty Induction Motors: Motors For The Long Run!Sudipta DasNo ratings yet

- KD Crane Duty MotorsDocument12 pagesKD Crane Duty MotorsVasudev AgrawalNo ratings yet

- Microsemi Power Diode Datasheet Notation AN1829Document12 pagesMicrosemi Power Diode Datasheet Notation AN1829scribddderNo ratings yet

- FatigueDocument14 pagesFatiguejimmyboy1234No ratings yet

- Ozone-Resistant Thermoplastic Elastomer Insulation For Wire and Cable, 90°C OperationDocument2 pagesOzone-Resistant Thermoplastic Elastomer Insulation For Wire and Cable, 90°C Operationmkaseem74No ratings yet

- HTD Dim HT As1252Document36 pagesHTD Dim HT As1252ppaabbllooalvarezNo ratings yet

- A Basic Description of Transformer TestsDocument8 pagesA Basic Description of Transformer Testsyeoj_aromNo ratings yet

- A697a697m 13Document11 pagesA697a697m 13diego rodriguezNo ratings yet

- Explanation of RoutineTests For FATs On Current Transformers According To IEC 60044Document6 pagesExplanation of RoutineTests For FATs On Current Transformers According To IEC 60044Hung VuNo ratings yet

- Rotex: Torsionally Flexible CouplingsDocument1 pageRotex: Torsionally Flexible CouplingsL.kolekarNo ratings yet

- Testing of Power TransformersDocument30 pagesTesting of Power TransformersAlind Dubey100% (2)

- CT Details Rishabh MakeDocument31 pagesCT Details Rishabh MakeSanjeev DhariwalNo ratings yet

- Part KD - Design RequirementsDocument2 pagesPart KD - Design RequirementsEmilse GonzalezNo ratings yet

- High Impedance Technical ReportDocument4 pagesHigh Impedance Technical Reportgovindaraj171No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Vibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingFrom EverandVibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingNo ratings yet

- Sec Ii D Int Vol 52Document5 pagesSec Ii D Int Vol 52silvanopipeNo ratings yet

- Sec Ii D Nma App BDocument4 pagesSec Ii D Nma App BsilvanopipeNo ratings yet

- Sec Ii D Ma App 4Document1 pageSec Ii D Ma App 4silvanopipeNo ratings yet

- Sec Ii D Si UnitsDocument5 pagesSec Ii D Si UnitssilvanopipeNo ratings yet

- Trouvay Cauvin 2001 Copy RasterDocument381 pagesTrouvay Cauvin 2001 Copy RastersilvanopipeNo ratings yet

- A85780-16 Attachment 14 To IR No. 5.1 - L3R-WPDS-3 Rev. 2 - A5T7R8Document1 pageA85780-16 Attachment 14 To IR No. 5.1 - L3R-WPDS-3 Rev. 2 - A5T7R8silvanopipeNo ratings yet

- Pig Launching & Receiving SystemsDocument4 pagesPig Launching & Receiving SystemssilvanopipeNo ratings yet

- Kanoria Chemicals and Industries LimitedDocument6 pagesKanoria Chemicals and Industries LimitedAPIIC EENo ratings yet

- Operating Instructions 1LE0 Export Low-Voltage MotorsDocument26 pagesOperating Instructions 1LE0 Export Low-Voltage MotorsRafik HergéNo ratings yet

- Bolt Design and Embedment Length CheckDocument6 pagesBolt Design and Embedment Length CheckHarish M PNo ratings yet

- Propuesta Tecnica Economica N°02749-04-14mcDocument5 pagesPropuesta Tecnica Economica N°02749-04-14mclaboratoriocgssa cgssaNo ratings yet

- HILTI HDA ANCHOR DESIGN Technical-InformationDocument12 pagesHILTI HDA ANCHOR DESIGN Technical-InformationNeil WayneNo ratings yet

- Soal ScienceDocument2 pagesSoal ScienceIshaTa Anaknya ChaeGyeong100% (1)

- 107865-Aalba Dent CatDocument44 pages107865-Aalba Dent CatbuzatugeorgescuNo ratings yet

- Heat Exchanger and Chiller Cleaning in PlaceDocument2 pagesHeat Exchanger and Chiller Cleaning in PlaceChris HaslegoNo ratings yet

- Patente EGDocument19 pagesPatente EGRodrigo Thomaz TaralloNo ratings yet

- FRS MethodologyDocument2 pagesFRS MethodologyHenry FlorendoNo ratings yet

- KSWM - 3rd Year (New)Document21 pagesKSWM - 3rd Year (New)Sandy TrumpNo ratings yet

- Persuasive EssayDocument8 pagesPersuasive EssayEvan EldridgeNo ratings yet

- ESAB Filler Book - 2015Document505 pagesESAB Filler Book - 2015Charlie MillerNo ratings yet

- Okb MateDocument18 pagesOkb MateunicornmfkNo ratings yet

- Central Luzon State University: Science City of Muñoz 3120 Nueva Ecija, PhilippinesDocument11 pagesCentral Luzon State University: Science City of Muñoz 3120 Nueva Ecija, PhilippinesAngelyn CayabanNo ratings yet

- Instant Download Think Public Relations 2nd Edition Wilcox Solutions Manual PDF Full ChapterDocument33 pagesInstant Download Think Public Relations 2nd Edition Wilcox Solutions Manual PDF Full Chapterkietcuongxm5100% (13)

- Design of PavementDocument82 pagesDesign of PavementRameshNayaka100% (1)

- Whmis Self Directed Lesson PowerpointDocument20 pagesWhmis Self Directed Lesson Powerpointapi-246988528100% (2)

- Pemanfaatan Limbah Plastik Menjadi Biji Plastik Yang Bernilai Tambah Ekonomi Di Kelurahan Dadap TangerangDocument11 pagesPemanfaatan Limbah Plastik Menjadi Biji Plastik Yang Bernilai Tambah Ekonomi Di Kelurahan Dadap TangerangKamiludinNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- IR0451 Defect DescriptionsDocument20 pagesIR0451 Defect DescriptionsMani Rathinam RajamaniNo ratings yet

- Chemistry AssignmentDocument14 pagesChemistry AssignmentWasle YarNo ratings yet

- Lab 3: Degradable and Non-Degradable Polymers Ryan BetzDocument11 pagesLab 3: Degradable and Non-Degradable Polymers Ryan Betzapi-417373570No ratings yet

- 2016 Annual Non Metallic Price MonitorDocument2 pages2016 Annual Non Metallic Price MonitorTitoNo ratings yet

- Table of K ValuesDocument7 pagesTable of K ValuesdasoodaseeNo ratings yet

- Pub - Solid State Physics PDFDocument299 pagesPub - Solid State Physics PDFMohit PandeyNo ratings yet