Professional Documents

Culture Documents

Shaft Design Notes

Shaft Design Notes

Uploaded by

e22mecu0009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shaft Design Notes

Shaft Design Notes

Uploaded by

e22mecu0009Copyright:

Available Formats

Machine Design I III B.

Tech I Sem( Mech) R18

UNIT 5

Shafts: Shafts & Couplings

A shaft is a rotating machine element which is used to transmit power from one place to

another. The power is delivered to the shaft by some tangential force and the resultant torque

(or twisting moment) set up within the shaft permits the power to be transferred to various

machines linked up to the shaft. In order to transfer the power from one shaft to another, the

various members such as pulleys, gears etc., are mounted on it. These members along with

the forces exerted upon them causes the shaft to bending.

In other words, we may say that a shaft is used for the transmission of torque and

bending moment. The various members are mounted on the shaft by means of keys or

splines. The shafts are usually cylindrical, but may be square or cross-shaped in section. They

are solid in cross-section but sometimes hollow shafts are also used. An axle, though similar

in shape to the shaft, is a stationary machine element and is used for the transmission of

bending moment only. It simply acts as a support for some rotating body such as hoisting

drum, a car wheel or a rope sheave. A spindle is a short shaft that imparts motion either to a

cutting tool (e.g. drill press spindles) or to a work piece (e.g. lathe spindles).

Types of Shafts

The following two types of shafts are important from the subject point of view:

1. Transmission shafts. These shafts transmit power between the source and the machines

absorbing power. The counter shafts, line shafts, over head shafts and all factory shafts are

transmission shafts. Since these shafts carry machine parts such as pulleys, gears etc.,

therefore they are subjected to bending in addition to twisting.

2. Machine shafts. These shafts form an integral part of the machine itself. The crank shaft is

an example of machine shaft.

Stresses in Shafts

The following stresses are induced in the shafts:

1. Shear stresses due to the transmission of torque (i.e. due to torsional load).

2. Bending stresses (tensile or compressive) due to the forces acting upon machine elements

like gears, pulleys etc. as well as due to the weight of the shaft itself.

3. Stresses due to combined torsional and bending loads.

Design of Shafts

The shafts may be designed on the basis of

1. Strength, and 2. Rigidity and stiffness.

MRCET Page 178

Machine Design I III B.Tech I Sem( Mech) R18

In designing shafts on the basis of strength, the following cases may be considered:

(a) Shafts subjected to twisting moment or torque only,

(b) Shafts subjected to bending moment only,

(c) Shafts subjected to combined twisting and bending moments, and

(d) Shafts subjected to axial loads in addition to combined torsional and bending loads.

Shafts Subjected to Twisting Moment Only

a) Solid shaft:

When the shaft is subjected to a twisting moment (or torque) only, then the diameter of the

shaft may be obtained by using the torsion equation. We know that

T

J r

Where T = Twisting moment (or torque) acting upon the shaft,

J = Polar moment of inertia of the shaft about the axis of rotation,

τ = Torsional shear stress, and

r = Distance from neutral axis to the outer most fibre

= d / 2; where d is the diameter of the shaft.

We know that for round solid shaft, polar moment of inertia,

J d4

32

d3

Then we get, T

16

From this equation, diameter of the solid shaft (d) may be obtained.

b) Hollow Shaft:

We also know that for hollow shaft, polar moment of inertia,

J (d 0 ) 4 (di ) 4

32

Where do and di = Outside and inside diameter of the shaft, and r = d0 / 2.

Substituting these values in equation (i), we have

Let k = Ratio of inside diameter and outside diameter of the shaft = di / do

Now the equation (iii) may be written as

MRCET Page 179

Machine Design I III B.Tech I Sem( Mech) R18

From the equations, the outside and inside diameter of a hollow shaft may be determined.

It may be noted that

1. The hollow shafts are usually used in marine work. These shafts are stronger per kg of

material and they may be forged on a mandrel, thus making the material more homogeneous

than would be possible for a solid shaft. When a hollow shaft is to be made equal in strength

to a solid shaft, the twisting moment of both the shafts must be same. In other words, for the

same material of both the shafts,

2. The twisting moment (T) may be obtained by using the following relation:

We know that the power transmitted (in watts) by the shaft,

Where T = Twisting moment in N-m, and

N = Speed of the shaft in r.p.m.

3. In case of belt drives, the twisting moment (T) is given by

T = (T1 – T2) R

Where T1 and T2 = Tensions in the tight side and slack side of the belt respectively, and R =

Radius of the pulley.

Shafts Subjected to Bending Moment Only

a) Solid Shaft:

When the shaft is subjected to a bending moment only, then the maximum stress (tensile or

compressive) is given by the bending equation. We know that

Where M = Bending moment,

I = Moment of inertia of cross-sectional area of the shaft about the axis of rotation,

σb = Bending stress, and

y = Distance from neutral axis to the outer-most fibre.

MRCET Page 180

Machine Design I III B.Tech I Sem( Mech) R18

We know that for a round solid shaft, moment of inertia,

Substituting these values in equation

From this equation, diameter of the solid shaft (d) may be obtained.

b) Hollow Shaft:

We also know that for a hollow shaft, moment of inertia,

And y = d0/ 2

Again substituting these values in equation, we have

From this equation, the outside diameter of the shaft (do) may be obtained.

Shafts Subjected to Combined Twisting Moment and Bending Moment

When the shaft is subjected to combined twisting moment and bending moment, then the

shaft must be designed on the basis of the two moments simultaneously. Various theories

have been suggested to account for the elastic failure of the materials when they are subjected

to various types of combined stresses. The following two theories are important from the

subject point of view:

1. Maximum shear stress theory or Guest's theory. It is used for ductile materials such as mild

steel.

2. Maximum normal stress theory or Rankine’s theory. It is used for brittle materials such as

cast iron.

Let τ = Shear stress induced due to twisting moment, and

σb = Bending stress (tensile or compressive) induced due to bending moment.

a) Solid Shaft:

According to maximum shear stress theory, the maximum shear stress in the shaft,

MRCET Page 181

Machine Design I III B.Tech I Sem( Mech) R18

Substituting the values of σb and τ

The expression M 2 T 2 is known as equivalent twisting moment and is denoted by

Te. The equivalent twisting moment may be defined as that twisting moment, which when

acting alone, produces the same shear stress (τ) as the actual twisting moment. By limiting

the maximum shear stress (τmax) equal to the allowable shear stress (τ) for the material, the

equation (i) may be written as

From this expression, diameter of the shaft (d) may be evaluated.

Now according to maximum normal stress theory, the maximum normal stress in the shaft,

1

The expression [M M 2 T 2 ] is known as equivalent bending moment and is denoted

2

by Me. The equivalent bending moment may be defined as that moment which when acting

alone produces the same tensile or compressive stress (σ b) as the actual bending moment. By

limiting the maximum normal stress [σbe(m

quaaxl)]to the allowable bending stress (σ b),

then the equation (iv) may be written as

From this expression, diameter of the shaft (d) may be evaluated.

b) Hollow shaft:

MRCET Page 182

Machine Design I III B.Tech I Sem( Mech) R18

In case of a hollow shaft, the equations (ii) and (v) may be written as

It is suggested that diameter of the shaft may be obtained by using both the theories and the

larger of the two values is adopted.

References:

1. Machine Design - V.Bandari .

2. Machine Design – R.S. Khurmi

3. Design Data hand Book - S MD Jalaludin.

MRCET Page 183

You might also like

- The Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Document6 pagesThe Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Dilshan0% (1)

- Fluid 9ed Solution ManualDocument919 pagesFluid 9ed Solution ManualMohammed Al-Otaibi86% (7)

- 1 Homework 1Document7 pages1 Homework 1Alexis DelgadoNo ratings yet

- Design of ShaftsDocument26 pagesDesign of ShaftsKrishna VamsiNo ratings yet

- Shaft & CouplingDocument56 pagesShaft & CouplingAshenafi KenaNo ratings yet

- Torsional and Bending StressesDocument6 pagesTorsional and Bending StressesSajjadNo ratings yet

- Chapter One Shaft DesignDocument71 pagesChapter One Shaft DesignhaymanotNo ratings yet

- MACHINE DESIGN Part4Document32 pagesMACHINE DESIGN Part4MADHESWARAN SNo ratings yet

- LM2 2Document67 pagesLM2 2MADHESWARAN SNo ratings yet

- Chapter 1 Shaft (Cont'd)Document47 pagesChapter 1 Shaft (Cont'd)Rayuth KEATNo ratings yet

- Introduction To ShaftsDocument10 pagesIntroduction To Shaftsसुमित शर्माNo ratings yet

- Shaft DesignDocument16 pagesShaft DesignOgunsina AdebayoNo ratings yet

- Shafts: Standard Sizes of ShaftsDocument9 pagesShafts: Standard Sizes of ShaftssyampnaiduNo ratings yet

- Analysis of Shaft AssemblyDocument8 pagesAnalysis of Shaft Assemblyvarshasdm1987No ratings yet

- Shaft 1Document15 pagesShaft 1Mahmoud Abdelghafar ElhussienyNo ratings yet

- ShaftsDocument19 pagesShaftsOG HackNo ratings yet

- MUCLecture 2022 52126676Document6 pagesMUCLecture 2022 52126676Princess Mae DesaculaNo ratings yet

- ME374 Module 2Document57 pagesME374 Module 2Christian Breth BurgosNo ratings yet

- Dme Module 2Document37 pagesDme Module 2ashishashi9123No ratings yet

- Deaign of Vibrating ScreenDocument13 pagesDeaign of Vibrating Screenprashant mishraNo ratings yet

- 1 ShaftDocument20 pages1 ShaftAJ BantayNo ratings yet

- ReportDocument25 pagesReport9897856218No ratings yet

- Shaft PulleyDocument12 pagesShaft PulleykeirthNo ratings yet

- Shafts Subjected To Axial Load in Axial Load in Addition To Combined Torsion and Bending Torsion and Bending LoadsDocument7 pagesShafts Subjected To Axial Load in Axial Load in Addition To Combined Torsion and Bending Torsion and Bending LoadsChetan PrajapatiNo ratings yet

- BSC103C Pre-recordedLecture Topic10 v2Document95 pagesBSC103C Pre-recordedLecture Topic10 v2fxl62920No ratings yet

- Shaft Keys Couplings Extra Lecture PDFDocument16 pagesShaft Keys Couplings Extra Lecture PDFHardik ParmarNo ratings yet

- Power Screws Fasteners and Rivted Joints Mech 2011Document12 pagesPower Screws Fasteners and Rivted Joints Mech 2011Eslam Mohamed SayedNo ratings yet

- FMD GTU Study Material E-Notes Unit-8 06042020015812PMDocument20 pagesFMD GTU Study Material E-Notes Unit-8 06042020015812PMRaj PrajapatiNo ratings yet

- Chapter 4: TorsionDocument9 pagesChapter 4: TorsionAshish KumarNo ratings yet

- Machine Design - : Emp 205 CFDocument52 pagesMachine Design - : Emp 205 CFAbdelhay Mohamed HassanNo ratings yet

- Unit 3 Som WatermarkDocument25 pagesUnit 3 Som WatermarkShivam GautreNo ratings yet

- Members Subjected To Torsional LoadsDocument8 pagesMembers Subjected To Torsional LoadsRahulkumarchauhanNo ratings yet

- MD ShaftDocument18 pagesMD Shaftiftikhar ahmedNo ratings yet

- Unit 3 Design of ShaftsDocument14 pagesUnit 3 Design of Shaftsaditya.1540011No ratings yet

- Lecture 8 Shaft DesignDocument65 pagesLecture 8 Shaft DesignYasir A. Al-Shataif100% (1)

- Som 200323142910Document9 pagesSom 200323142910Asante MandioperaNo ratings yet

- MODULE-2 Torsion and Bending StressesDocument14 pagesMODULE-2 Torsion and Bending Stressesrhea lee enriquezNo ratings yet

- CH # 1 Design of ShaftsDocument45 pagesCH # 1 Design of ShaftsWaris Ali BozdarNo ratings yet

- Lecture 6 - Torsion - 2015Document38 pagesLecture 6 - Torsion - 2015imranjamiNo ratings yet

- Chapter OneDocument28 pagesChapter OneAbyot yassabNo ratings yet

- MD VI Shaft DesignDocument11 pagesMD VI Shaft DesignShatendra SahuNo ratings yet

- Lecture 18 TorsionDocument6 pagesLecture 18 TorsionYash PaulNo ratings yet

- Shaft DesignDocument20 pagesShaft DesignHarshal RodgeNo ratings yet

- Types of Shafts: 1. Transmission Shafts. These Shafts Transmit PowerDocument9 pagesTypes of Shafts: 1. Transmission Shafts. These Shafts Transmit PowerTheod S. VilaNo ratings yet

- Strength of MaterialDocument163 pagesStrength of MaterialJackKiaNo ratings yet

- Chapter III - TorsionDocument19 pagesChapter III - TorsionMostafa Essam Ezzat MahmoudNo ratings yet

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocument25 pagesMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MNo ratings yet

- Tutorial 1-sp24Document19 pagesTutorial 1-sp24islameslamoislam807No ratings yet

- Design of Machine ElementsDocument11 pagesDesign of Machine ElementsOmi TareNo ratings yet

- Chapter 7 Torsion Lecture NotesDocument31 pagesChapter 7 Torsion Lecture NotesJeremiah SoonNo ratings yet

- Chapter Three. 3.0 Shaft DesignDocument3 pagesChapter Three. 3.0 Shaft Designpkopus cosmas kotongNo ratings yet

- Internal II Question Bank SOMDocument7 pagesInternal II Question Bank SOMsathyadallyNo ratings yet

- 1-Shaft and Its Design Based On StrengthDocument8 pages1-Shaft and Its Design Based On StrengthJaikishan PandiriNo ratings yet

- Important Questions Unit 1,2Document7 pagesImportant Questions Unit 1,2rajeswariNo ratings yet

- SpringDocument21 pagesSpringa.f .alrawiNo ratings yet

- Lecture 1. Shaft DesignDocument18 pagesLecture 1. Shaft DesignhasanNo ratings yet

- Chapter III: TorsionDocument20 pagesChapter III: TorsionEsra'a SmadiNo ratings yet

- BFC 20903 (Mechanics of Materials) Chapter 6: TorsionDocument26 pagesBFC 20903 (Mechanics of Materials) Chapter 6: TorsionHamierul MohamadNo ratings yet

- EMM213 Strength of Materials: TorsionDocument25 pagesEMM213 Strength of Materials: TorsionNorwahida YusoffNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Cauchy Integral Formula and Related ProblemsDocument16 pagesCauchy Integral Formula and Related Problemse22mecu0009No ratings yet

- Harmonic FunctionDocument9 pagesHarmonic Functione22mecu0009No ratings yet

- Complex Number by Amit TomarDocument8 pagesComplex Number by Amit Tomare22mecu0009No ratings yet

- Metal Forming Lect 7Document22 pagesMetal Forming Lect 7e22mecu0009No ratings yet

- Metal Forming Lect 2Document41 pagesMetal Forming Lect 2e22mecu0009No ratings yet

- Assignment No 5 - EMEC208L - BalancingDocument1 pageAssignment No 5 - EMEC208L - Balancinge22mecu0009No ratings yet

- Assignment 1Document2 pagesAssignment 1e22mecu0009No ratings yet

- MDB Lesson 2 Thin Walled Pressure VesselsDocument12 pagesMDB Lesson 2 Thin Walled Pressure VesselsJoshua John JulioNo ratings yet

- Homework 6 Problem 1Document11 pagesHomework 6 Problem 1Aashish ShahNo ratings yet

- Elasticidad Matrices Ortotropicas PDFDocument118 pagesElasticidad Matrices Ortotropicas PDFAlejandro LauroraNo ratings yet

- Unit-1 Particle Characterization and Their DistributionDocument20 pagesUnit-1 Particle Characterization and Their Distributionyouga SriNo ratings yet

- Chapter 3 SolutionsDocument6 pagesChapter 3 SolutionsAnonymous GjWVoVAnWYNo ratings yet

- Advanced Composite Materials: To Cite This Article: M. Colakoglu (2008) Effect of Temperature On Frequency and DampingDocument15 pagesAdvanced Composite Materials: To Cite This Article: M. Colakoglu (2008) Effect of Temperature On Frequency and DampingAruna AllipilliNo ratings yet

- Astm d6048Document16 pagesAstm d6048gustavomeza4No ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Work and Energy Prac Prob 204qiudDocument5 pagesWork and Energy Prac Prob 204qiudsaparullahNo ratings yet

- m4l26 Lesson 26 The Direct Stiffness Method: Temperature Changes and Fabrication Errors in Truss AnalysisDocument20 pagesm4l26 Lesson 26 The Direct Stiffness Method: Temperature Changes and Fabrication Errors in Truss AnalysisVitor Vale100% (3)

- Handbook For Industrial Noise: ControlDocument148 pagesHandbook For Industrial Noise: ControlpraphasNo ratings yet

- General Physics 1: Quarter 2 - Module 3: Harmonic MotionDocument29 pagesGeneral Physics 1: Quarter 2 - Module 3: Harmonic MotionMarkJosephDichosoRabelasNo ratings yet

- Using Ms Excel For Data Analysis and SimulationDocument15 pagesUsing Ms Excel For Data Analysis and SimulationchanayireNo ratings yet

- 06-01 Chap GereDocument16 pages06-01 Chap Gerehamws100% (2)

- Lab 2 - Modelling CPS With SysMLDocument2 pagesLab 2 - Modelling CPS With SysMLChioma Nkem-EzeNo ratings yet

- Piping Problems With SolutionDocument5 pagesPiping Problems With Solutionganapathi_54No ratings yet

- Spacecraft Inertia Estimation Via Constrained Squares: LeastDocument6 pagesSpacecraft Inertia Estimation Via Constrained Squares: LeastVincenzo PesceNo ratings yet

- Book BankDocument5 pagesBook BankAshish MishraNo ratings yet

- 9702 - s19 - QP - 23 (Dragged)Document2 pages9702 - s19 - QP - 23 (Dragged)Nezza WidarkoNo ratings yet

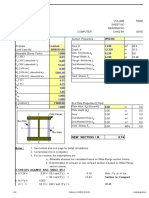

- Beam Design As Per AISC - ASD - 9thED - ModifiedDocument6 pagesBeam Design As Per AISC - ASD - 9thED - ModifiedArif RusyanaNo ratings yet

- Shoe Centreless PaperDocument9 pagesShoe Centreless PaperNimesh SinghNo ratings yet

- Vector Quiz PDFDocument2 pagesVector Quiz PDFSaumya KumarNo ratings yet

- ELMS Task Weeks 12 13 Dancing Oobleck A Non Newtonian Fluid ExperimentationDocument3 pagesELMS Task Weeks 12 13 Dancing Oobleck A Non Newtonian Fluid ExperimentationLead CanadaNo ratings yet

- LecturesDocument34 pagesLecturesYuliarti KusumawardaningsihNo ratings yet

- Samiullah 2007Document3 pagesSamiullah 2007Joshua WrightNo ratings yet

- Rigid Pavement DesignDocument8 pagesRigid Pavement DesignsagarNo ratings yet

- 4 Wave Motion AssignmentDocument34 pages4 Wave Motion Assignmentkamalsharma2014No ratings yet

- Reciprocating: Slider-Crank Mechanism, Arrangement of Mechanical PartsDocument3 pagesReciprocating: Slider-Crank Mechanism, Arrangement of Mechanical PartsHanzlah NaseerNo ratings yet