Professional Documents

Culture Documents

Electrotechnology n3 Study Guide 2

Electrotechnology n3 Study Guide 2

Uploaded by

kwazi6001Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrotechnology n3 Study Guide 2

Electrotechnology n3 Study Guide 2

Uploaded by

kwazi6001Copyright:

Available Formats

lOMoARcPSD|40521374

Electrotechnology N3 Study Guide 2

Electro Techniques (Damelin)

Scan to open on Studocu

Studocu is not sponsored or endorsed by any college or university

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

NATIONAL N CERTIFICATION IN ENGINEERING STUDIES

ELECTROTECHNOLOGY N3

STUDY GUIDE

2021

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Copyright © Educor 2020

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any

form or by any means, including photocopying, recording, or other electronic or mechanical

methods, without the prior written permission of Educor Holdings. Individual’s found guilty of

copywriting will be prosecuted and will be held liable for damages.

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

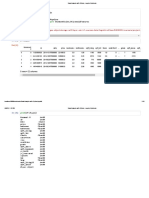

1 Table of Contents

1 About DAMELIN ......................................................................................................................... 6

2 Our Teaching and Learning Methodology................................................................................... 7

2.1 Icons ................................................................................................................................ 10

3 Introduction to the Module ..................................................................................................... 13

3.1 Module Information ......................................................................................................... 13

3.2 Module Purpose............................................................................................................... 13

3.3 Outcomes ........................................................................................................................ 13

3.4 Assessment ...................................................................................................................... 15

3.5 Planning Your Studies / Resources Required for this Module: ........................................... 16

4 Prescribed Reading .................................................................................................................. 17

4.1 Prescribed Book ............................................................................................................... 17

4.2 Recommended Articles .................................................................................................... 17

4.3 Recommended Multimedia .............................................................................................. 17

5 Module Pacing ......................................................................................................................... 18

5.1 Week 1: DC MACHINES, GENERATOR AND MOTOR PRINCIPLES ........................................ 19

5.1.1 Introduction to Direct Current Machines .................................................................. 20

5.1.2 Construction of a DC Machine .................................................................................. 21

5.1.3 Armature reaction .................................................................................................... 22

5.1.4 Commutation ........................................................................................................... 23

5.1.5 Introduction to the operation of motors and generators .......................................... 24

5.1.6 Generator principle of operation .............................................................................. 25

5.1.7 Motor principle of operation .................................................................................... 26

5.1.8 Self-Assessment ....................................................................................................... 29

5.2 Week 2: DIRECT CURRENT GENERATORS .......................................................................... 29

5.2.1 Types of generators .................................................................................................. 30

5.2.2 Load characteristics of separately-excited generator ................................................ 31

5.2.3 Load characteristics of series-wound generator ........................................................ 31

5.2.4 Load characteristics of shunt-wound generator ........................................................ 32

5.2.5 The basic operation of a shunt generator ................................................................. 33

5.2.6 Cumulative compound generator ............................................................................. 33

5.2.7 Self-Assessment ....................................................................................................... 34

5.3 Week 3: DIRECT CURRENT MOTORS ................................................................................. 35

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.3.1 Introduction to Direct Current Motors ...................................................................... 36

5.3.2 Torque and speed of a DC Motor .............................................................................. 36

5.3.3 Types of dc motor and their characteristics .............................................................. 37

5.3.4 Methods used to control speed ................................................................................ 38

5.3.5 DC Motor Starters .................................................................................................... 39

5.3.6 Reversing the direction of rotation of DC Motors ...................................................... 39

5.3.7 Self-Assessment ....................................................................................................... 40

5.4 Week 4: AC THEORY, DC MACHINES EFFICIENCY & TRANSFORMERS ................................. 40

5.4.1 Introduction alternating current theory .................................................................... 41

5.4.2 Definitions of alternating current terms .................................................................... 41

5.4.3 The generation of an alternating current .................................................................. 42

5.4.4 The value of the induced emf ................................................................................... 42

5.4.5 Maximum, rms and average values........................................................................... 42

5.4.6 The mid-ordinate rule............................................................................................... 43

5.4.7 Alternating current circuits ....................................................................................... 44

5.4.8 Series circuits ........................................................................................................... 46

5.4.9 Series connected impedances ................................................................................... 47

5.4.10 Power and power factor ........................................................................................... 47

5.4.11 Series resonance ...................................................................................................... 47

5.4.12 Losses in dc machines ............................................................................................... 48

5.4.13 Efficiency of dc machines .......................................................................................... 49

5.4.14 Determination of efficiency ...................................................................................... 50

Transformers......................................................................................................................... 51

5.4.15 Construction and principle of operation ................................................................... 52

5.4.16 Double-wound transformer ...................................................................................... 52

5.4.17 The transformer ratio ............................................................................................... 53

5.4.18 Three-phase transformers ........................................................................................ 53

5.4.19 The auto transformers .............................................................................................. 53

5.4.20 losses in transformers............................................................................................... 54

5.4.21 Cooling of transformers ............................................................................................ 54

5.4.22 Self-Assessment ....................................................................................................... 55

5.4.23 Losses in dc machines .................................................... Error! Bookmark not defined.

5.4.24 Self-Assessment ............................................................ Error! Bookmark not defined.

5.5 Week 5: MEASURING INSTRUMENTS & ELECTRONICS ...................................................... 55

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.5.1 Introduction ............................................................................................................. 56

5.5.2 Measuring instruments have basically three mechanisms: ........................................ 57

5.5.3 Eddy-current damping .............................................................................................. 57

5.5.4 Air damping .............................................................................................................. 57

5.5.5 Moving –iron instruments ........................................................................................ 58

5.5.6 Moving-coil instrument ............................................................................................ 58

5.5.7 The dynamometer instrument .................................................................................. 59

5.5.8 Instrument transformers .......................................................................................... 59

5.5.9 Semiconductors devices ........................................................................................... 60

5.5.10 The p-n junction diode.............................................................................................. 61

5.5.11 Forward bias conditions of a diode ........................................................................... 61

5.5.12 Reverse bias conditions of a diode ............................................................................ 61

5.5.13 Ac to dc conversion (rectification) ............................................................................ 61

5.5.14 Transistors................................................................................................................ 62

5.5.15 Transistor configurations .......................................................................................... 62

5.5.16 The silicon-controlled rectifier (SCR) ......................................................................... 63

5.5.17 Self-Assessment ....................................................................................................... 65

6 References............................................................................................................................... 65

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

1. About DAMELIN

VISION

To lead and inspire quality private education and training throughout Southern Africa and the African

continent

MISSION

We pride ourselves on being the provider of quality learner focused education. It is our mission to

deliver innovative, yet relevant programmes on multiple NQF levels while contributing with integrity

and commitment to the community ideals of skills development and employability. Our mission is to

meet regulatory requirements as they apply to private institutions and exceed the expectations of

quality

Our core values are:

Academic commitment

Reputable and quality brand

Innovative relevant programmes

Skills development and employability

Integrity

Entrepreneurial spirit

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

STUDENT SUPPORT

The support systems which we at Damelin have put in place to support to our students, aims to have

a significant influence on how well our students will achieve. Students Support will assist students to

achieve academically, to make the correct programme choices, and be oriented into Further Education

and Training opportunities at Damelin.

Damelin envisages to provide holistic services to students that embraces the full range of any single

student’s interaction with the College.

1. Selection and Placement into

Pre-entry appropriate programmes

Admission

2. Contract of enrolment

3. Orientation and Code of Conduct

4. Academic Support

Performance monitoring and

STUDENT On course feedback, Workshops, Study

SUPPORT Academic Guides, Academic Advising Centre

programme 5. Personal Support

Life skills, counselling, Health and

Wellness

Exit 6. Higher Education

7. Self-employment

Work

8. Employment

readiness 9. In-service Training

Students are encouraged to make use of the Student Support Services available on each of our

campuses. Each campus has Lecturer consultation times where you will be able to have a consultation

with your subject lecturer should you require additional support.

2. Our Teaching and Learning Methodology

DAMELIN strives to promote a learning-centered and knowledge-based teaching and learning

environment. Teaching and learning activities primarily take place within academic programmes and

guide students to attain specific outcomes.

• A learning-centered approach is one in which not only lecturers and students, but all

sections and activities of the institution work together in establishing a learning

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

community that promotes a deepening of insight and a broadening of perspective with

regard to learning and the application thereof.

• An outcomes-oriented approach implies that the following categories of outcomes are

embodied in the academic programmes:

• Culminating outcomes that are generic with specific reference to the critical cross-field

outcomes including problem identification and problem-solving, co-operation, self-

organisation and self-management, research skills, communication skills,

entrepreneurship and the application of science and technology.

• Empowering outcomes that are specific, i.e. the context specific competencies students

must master within specific learning areas and at specific levels before they exit or move

to a next level.

• Discrete outcomes of community service learning to cultivate discipline-appropriate

competencies.

DAMELIN actively strives to promote a research culture within which a critical-analytical approach and

competencies can be developed in students at undergraduate level. DAMELIN accepts that students’

learning is influenced by a number of factors, including their previous educational experience, their

cultural background, their perceptions of particular learning tasks and assessments, as well as

discipline contexts.

Students learn better when they are actively engaged in their learning rather than when they are

passive recipients of transmitted information and/or knowledge. A learning-oriented culture that

acknowledges individual student learning styles and diversity and focuses on active learning and

student engagement, with the objective of achieving deep learning outcomes and preparing students

for lifelong learning, is seen as the ideal. These principles are supported through the use of an engaged

learning approach that involves interactive, reflective, cooperative, experiential, creative or

constructive learning, as well as conceptual learning via online-based tools.

Effective teaching-learning approaches are supported by:

• Well-designed and active learning tasks or opportunities to encourage a deep rather than

a surface approach to learning.

• Content integration that entails the construction, contextualization and application of

knowledge, principles and theories rather than the memorization and reproduction of

information.

• Learning that involves students building knowledge by constructing meaning for

themselves.

• The ability to apply what has been learnt in one context to another context or problem.

• Knowledge acquisition at a higher level that requires self-insight, self-regulation and self-

evaluation during the learning process.

• Collaborative learning in which students work together to reach a shared goal and

contribute to one another’s learning at a distance.

• Community service learning that leads to collaborative and mutual acquisition of

competencies in order to ensure cross cultural interaction and societal development.

• Provision of resources such as information technology and digital library facilities of a high

quality to support an engaged teaching-learning approach.

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

• A commitment to give effect teaching-learning in innovative ways and the fostering of

digital literacy.

• Establishing a culture of learning as an overarching and cohesive factor within institutional

diversity.

• Teaching and learning that reflect the reality of diversity.

• Taking multi culturality into account in a responsible manner that seeks to foster an

appreciation of diversity, build mutual respect and promote cross-cultural learning

experiences that encourage students to display insight into and appreciation of

differences.

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

2.1 Icons

The icons below act as markers, that will help you make your way through the study guide.

Additional Information

All supplementary and recommended learning resources

Announcements

Important announcements made via myClass

Assessments

Continuous and Summative Assessments

Audio Material

Audio recordings and podcasts

Calculator

Activities that require calculation and equation base solutions

Case Study

Working examples of concepts and practices

Chat

A live chat with your Online Academic Tutor

Discussion Forum

Topic to be explored in the weekly discussion forum

Glossary

Learning activity centered on building a module glossary

10

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Group Assignment

Assignments to be completed with peers

Help

Instructions on how to receive academic support and guidance

Individual Assignment

Assignments to be completed individually

Lesson Material

Learning content in myClass as per the units below

Module Information

Important information regarding your module like outcomes, credits,

assessment, and textbooks

Module Welcome

A welcome to the module in myClass to introduce you to the module and

important module information

Outcomes

Learning outcomes you will meet at the end of a section or module

Survey

A poll, feedback form or survey to complete

Practice

Indicates an activity for you to practice what you’ve learnt

Lesson/Virtual Class

Virtual Class links available via myClass

11

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Quote

A thought, quote or important statement from a thought leader in the

specialist field

Reading

Prescribed reading material and module textbooks

Revision

Questions and activities that will support your module revision

Self-Assessment Quiz

Weekly quizzes to complete to self-measure if you have a complete

understanding of the lesson material

Shout Out | Example

Examples and highlights to contextualize the learning material, critical

concepts and processes

Lesson Material

Indicates sections of learning material in myClass

Thinking Point

A question, problem or example posed to you for deeper thinking,

interrogation, and reflection

Time

The allocated time required per week, unit and module related to the module

credit structure as per your factsheet

Video

Additional videos, video tutorials, desktop capture/screen recording and

other audiovisual supplementary material

Vocabulary

Important words and their definitions that aid the development of your

specialist vocabulary

12

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

3 Introduction to the Module

Welcome to Electrotechnology N3.

Electrotechnology N3 covers eight chapters which have been divided into 7 weeks of which the weeks

are listed as follows 1. Dc Machines, Generators and Motor principles; 2. Direct current Generators;

3. Direct current Motors; 4. Ac Theory; 5. Dc Machines Efficiency and Transformers; 6. Measuring

Instruments; 7. Electronics. The study guide was developed with the aim of assisting you and giving

you a better understanding all the content of your course. This study guide is not to be used in isolation

of a recommended textbook, recommended reading and research.

3.1 Module Information

Qualification title National N Certificate In Engineering Studies

Module Title Electrotechnology N3

NQF Level Level 3

3.2 Module Purpose

This subject covers the fundamentals of electro-technical control technology

and practical experience and is designed to be an asset to the electrical drive

technology field. It will equip you with machine installation and

control related skills for the manufacturing industry. Workshop and field work

procedures that conform to safety regulations and safe working practices

will be learned.

The industry is changing and growing at a rapid rate as technology advances

and develops in fields such as: data communication, home automation,

intelligent systems for industrial and facilities management and

renewable/sustainable energy.

3.3 Outcomes

At the end of this module you should be able to:

Identify and solve problems in which responses display that responsible decisions using

critical and creative thinking have been made.

Work effectively with others as a member of a team, group organization, community.

Organise and manage oneself and ones activities responsibly and effectively. Collect,

analyse, organise and critically evaluate information.

Communicate effectively using visual, mathematical and/or language skills in the modes of

oral and/or written presentation.

Use science and technology effectively and critically, showing responsibility towards the

environment and the health of others.

Demonstrate an understanding of the world as a set of related systems by recognizing that

problem solving contexts do not exist in isolation.

13

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Describe the construction of a dc machine.

List and discuss the components of a dc machine.

Distinguish between wave and lap windings.

Explain the function of brushes in a dc machine.

Discuss the types of brushes in a dc machine.

Understand what is meant by armature reaction.

Discuss armature reaction fully with the aids of sketches.

Explain the different methods used to improve commutation.

Define the principles of a generator and motor

Define Faraday’s law

Explain Fleming’s right-hand rule.

Define Lenz’s law.

Name four factors that determine the magnitude of the induced emf in a conductor.

Explain what is meant by back emf.

Explain in detail what is meant by separate excitation and self-excitation.

Draw load characteristic of a separately excited and series generator.

Explain load characteristic of a separately excited, series and shunt generator.

Explain residual magnetism.

Explain basic operation of a shunt generator.

Differentiate between cumulative and differential compound generator.

Explain what is meant by level-compounded.

Draw neat schematic diagrams of long shun and short shunt compound generators.

Draw and describe the characteristics of an over and under compounded generator.

State the purpose of a starting resistance in a dc motor starter.

Explain with the use of a neat diagram the action of a face-plate starter for a shunt motor.

Explain the action of a no-volt release fully

Explain the action of a dashpot type and a bi-metal type overload device.

Differentiate between the differential and cumulative compound motor.

Explain why the differential and cumulative compound motor cannot be used for the same

purpose.

Explain the load and torque characteristics of a shunt motor.

Define instantaneous value, period and frequency.

Explain the meaning of rms and average value.

Define the form factor and crest factor of an ac waveform.

Perform all the calculations in this unit.

Define the term power factor of an ac circuit.

Draw the phasor diagrams to show the relationship between voltage and current.

Define efficiency.

Discuss eddy currents and hysteresis losses.

Discuss the basic losses in a dc machine.

Explain the constant losses of a dc machine.

Explain the rope brake test with the aid of a neat sketch.

Deduce efficiency formula by means of a rope brake test.

Differentiate between rope brake test and an indirect test.

Define mutual induction.

Define self-induction.

Explain the operation of a transformer with the aid of a neat sketch.

Name methods used to cool transformers.

Purpose of instrument transformers.

14

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Function of a deflecting, damping, and control mechanism.

Explain with sketches aid air damping and eddy-current damping.

Explain the purpose of hairsprings in an instrument.

Explain what are current and voltage transformers.

Explain operation of a moving-coil instrument.

Differentiate between a dynamometer and a moving coil instrument

Discuss the shunt.

Explain why must the secondary winding of a current transformer be earthed.

Recognize the importance of testing and measurements in electric circuits.

Appreciate instrument ‘loading’ effect.

Calculate periodic time, frequency, peak-to-peak values from waveforms on an oscilloscope.

Appreciate forward and reverse bias of p – n junction.

Importance of valence shell and valence electrons.

Understand p – n junction.

Recognize the symbols used to represent diodes in circuit diagrams.

Understand the importance of diode characteristics and maximum ratings.

Classify materials as conductors, semiconductors or insulators.

3.4 Assessment

You will be required to complete both formative and summative assessment activities.

Formative assessment:

The assessment of the theoretical component in ELECTROTECHNOLOGY Level 3

takes the form of observation, class questions, group work, informal group

competitions with rewards, individual discussions with students, class, topic

and semester tests and internal examinations. Lecturers can observe students

when marking exercises from the previous day and asking class questions.

Assignments, case studies and tests can be completed at the end of a topic. Tests and internal

examinations

must form part of the internal assessment.

These are compulsory internal assessments which are compulsory and contribute towards your

Term Mark.

1. NATIONAL TEST

WEIGHTING TOWARDS TERM MARK: 30%

2. NATIONAL DP EXAMINATION

WEIGHTING TOWARDS TERM MARK: 70%

Summative assessment:

The assessment of the theoretical component in ELECTROTECHNOLOGY Level 3

takes the form of observation, class questions, group work, informal group

15

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

competitions with rewards, individual discussions with students, class, topic

and semester tests and internal examinations. Lecturers can observe students

when marking exercises from the previous day and asking class questions.

Assignments, case studies and tests can be completed at the end of a topic. Tests and internal

examinations

must form part of the internal assessment.

These are external assessments from the DHET. Students must be registered with the DHET in order

to write these assessments.

ENTRANCE TO SUMMATIVE EXAMINATION REQUIREMENTS:

MINIMUM TERM MARK OF 40%

Mark allocation

The assessment of the theoretical component in ELECTROTECHNOLOGY Level 3

takes the form of observation, class questions, group work, informal group

competitions with rewards, individual discussions with students, class, topic

and semester tests and internal examinations. Lecturers can observe students

when marking exercises from the previous day and asking class questions.

Assignments, case studies and tests can be completed at the end of a topic. Tests and internal

examinations

must form part of the internal assessment.

The marks are derived as follows for this module:

Test 1 30%

Test 2( Mock Exam) 70%

TOTAL 100%

3.5 Planning Your Studies / Resources Required for this Module:

What equipment will I need? Access to a personal computer and internet.

Access to academic journals

Calculator

Recommended textbook

16

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

4 Prescribed Reading

4.1 Prescribed Book

Bakker P.JA. (1998). Electrotechnology N3, 1st edition. Northcliff: Troupant. ISBN: 9781919780269

4.2 Recommended Articles

Please refer to the additional resources that are mentioned throughout the various weeks.

4.3 Recommended Multimedia

Please refer to the video resources that are mentioned throughout the various weeks.

MODULE OVERVIEW – ELECTROTECHNOLOGY N3

17

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5 Module Pacing

NAME OF TOPIC FOR THE WEEK AS PER THIS GUIDE AND REFLECTIVE OF LMS

Weeks WEEKLY TOPICS FOR THE TRIMESTER

2021

1

Direct Current Machines, Generator and Motor Principles

Direct Current Generators

2

Direct Current Motors

3

4 AC Theory, DC Machines Efficiency & Transformers

5 Measuring Instruments & Electronics

Exam

Week

18

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.1 Week 1: DC MACHINES, GENERATOR AND MOTOR PRINCIPLES

The first week of this module will introduce the construction of DC Machines,

Purpose Armature winding, Armature reaction, Commutation and applications of dc

motors. We also look at Faraday’s, Lenz’s laws and Fleming’s right-hand rule.

At the end of this week, you should be able to:

Describe the construction of a dc machine.

List and discuss the components of a dc machine.

Distinguish between wave and lap windings.

Explain the function of brushes in a dc machine.

Discuss the types of brushes in a dc machine.

Understand what is meant by armature reaction.

Discuss armature reaction fully with the aids of sketches.

Learning

Explain the different methods used to improve commutation.

Outcomes Define the principles of a generator and motor

Define Faraday’s law

Explain Fleming’s right-hand rule.

Define Lenz’s law.

Name four factors that determine the magnitude of the induced emf

in a conductor.

Explain what is meant by back emf.

Time It will take you 2 hours to make your way through this study week.

Prescribed Bakker P.J.A. (1998). Electrotechnology N3, 1st edition. Northcliff: Troupant.

Reading ISBN: 9781919780269

19

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.1.1 Introduction to Direct Current Machines

When the input to an electrical machine is electrical energy, (seen as applying a voltage to the

electrical terminals of the machine), and the output is mechanical energy, (seen as a rotating shaft),

the machine is called an electric motor. Thus an electric motor converts electrical energy into

mechanical energy.

When the input to an electrical machine is mechanical energy, (seen as, say, a diesel motor, coupled

to the machine by a shaft), and the output is electrical energy, (seen as a voltage appearing at the

electrical terminals of the machine), the machine is called a generator. Thus, a generator converts

mechanical energy to electrical energy. The operation of DC motors and generators is not only the

same in principle, but the practical design does not differ much either. The construction of a dc

motor is the same as a dc generator. The only difference is that in a generator the generated e.m.f is

greater than terminal voltage, whereas in a motor the generated e.m.f is less than the terminal

voltage. Dc motors are often used in power stations to drive emergency stand-by pump systems

A DC motor can be used as a generator and vice versa. When we look at purpose and application of

each machine, there are a few differences in construction. Generators are normally installed in

buildings where they operate under ideal atmospheric conditions and may be of an open-type

design. While a motor maybe installed where it is subjected to abnormal weather conditions,

temperature changes, gases, etc.

Refer to page 1 in your prescribed textbook for a comprehensive dc machines introduction.

Let’s Watch!

YouTube. 2020. Construction of DC Machine and its components. [online]. Available

at: <https://m.youtube.com/watch?v=xsWNG-jds> [Accessed 16 December 2020].

20

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.1.2 Construction of a DC Machine

The basic parts of any dc machine are shown as above, Comprise:

(a) A stationery part called the stator having,

A steel ring called the yoke, to which are attached

The magnetic poles, around which are the

Field windings, i.e. many turns of a conductor wound round the pole core; current

passing through this conductor creates an electromagnet

(b) A rotating part called the armature mounted in bearings housed in the stator and having,

A laminated cylinder of icon or steel called the core, on which teeth are cut to

house the

Armature winding i.e. single or multi-loop conductor system and

The commutator

Brushes and brush gear

brushes for use in dc machines mainly consist of a carbon and graphite mixture. The brushes are

obtainable in different grades of hardness which are determined by the percentage of graphite in

the mixture. Care must be taken that brushes of the correct shape, size, and grade are used for a

specific machine. The correct pressure on the brush is of great importance, because excessive

pressure damages the brush and shorten its lifetime.

The types of brushes normally used are the following:

The electrographite brush

Graphite brushes

Copper-graphite brushes

Carbon brushes

Armature windings

The choice of the type of winding is determined by factors such as the size and function of the

machine. Two very important factors concerning the design of an armature, and thus also the choice

of the windings, are:

The pole pitch, i.e. the distance between the centre of the poles

The coil pitch, i.e. the distance between the coil sides.

Armature windings can be divided into two groups, depending on how the wires are joined to the

commutator. These are called wave windings and lap windings (also known as an overlap or parallel

winding).

21

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

(a) In wave windings there are two paths in parallel irrespective of the number of poles, each

path supplying half the total current output. Wave wound generators produce high voltage,

low current outputs.

(b) In lap windings there are as many paths in parallel as the machine has poles. The total

current output divides equally between them. Lap wound generators produce high current,

low voltage output.

The e.m.f generated by the armature is equal to the e.m.f generated by one of the parallel

paths.

Refer to pages 1 to 3 in your prescribed textbook for a comprehensive explanation of

construction of a direct current machine and components thereof PLEASE NOTE: The extra

information above has been added for your convenience.

5.1.3 Armature reaction

When the armature of any direct current generator or motor rotates, then the two fields of the

machine are acting upon each other, i.e. the one field has an influence on the movement and

distribution of the other. This effect is called armature reaction and it can be defined as follows:

Armature reaction is the distortion of the main magnetic field as a result of the current flowing in

the armature conductors, or it is the effect of the armature ampere-turns upon the value and the

distribution of the magnetic flux entering and leaving the armature core.

Armature reaction is the effect that the magnetic field produced by the armature current has on the

magnetic field produced by the field system. In a generator, armature reaction results in a reduced

output voltage, and in a motor, armature reaction results in increased speed.

22

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

2. A way of overcoming the effect of armature reaction is to fit compensating windings, located

in slots in the pole face.

Armature reaction in a dc generator

By armature reaction is meant the effect of magnetic field set up by armature current on the

distribution of flux under main poles of a generator. The armature magnetic field has two effects:

(a) It demagnetises or weakens the main flux and

(b) It cross-magnetises or distorts it.

Armature reaction in a dc motor

Since current flows through the armature conductors of a motor, a magnetic field will be set up

around the conductors. This magnetic field will also distort the main field, just as in the case of a

generator. It is therefore obvious that the dc motor is also subject to the effect of armature reaction.

Refer to pages 3 to 4 in your prescribed textbook for a comprehensive explanation of

armature reaction.

5.1.4 Commutation

The emf generated in the conductors of a dc armature is an alternating emf. The current flows in one

direction when the conductor is moving under the N pole and in the reverse direction when it is

moving under the S pole. This reversal of current in a coil has to take place while the two

commutator segments, to which the coil is connected, are being short-circuited by a brush. This

process is termed commutation. (see page 4 for further explanation)

Methods of improving commutation

It is obvious that the commutation process is subject to various factors which may have a negative

influence on it. Four (4) methods are normally used to limit these factors

(a) Increasing the brush contact resistance

(b) Shifting the brushes

(c) Interpoles

(d) Compensating windings

Refer to pages 5 to 6 in your prescribed textbook for a comprehensive explanation of

commutation and the four (4) methods.

23

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.1.5 Introduction to the operation of motors and generators

The principle of electromagnetic induction was discovered by Michael Faraday. After several

experiments he defined the concept “electromagnetic induction” as follows

When a conductor cuts a magnetic flux or is cut by a magnetic flux, an emf is generated in the

conductor. The magnitude of this generated emf is directly proportional to the rate at which the

conductor cuts the magnetic flux or is cut by the magnetic flux.

The principle of generation is explained in an elementary way in the book on page 7.

The magnitude of the induced emf in a conductor therefore depends on:

The strength of the magnetic field;

The rate at which the magnetic flux is cut by the moving conductor;

The number of active conductors connected in series;

The number of pairs of poles used.

The direction of the induced emf depends on various factors. There are two ways to deduce the

direction of the induced or generated emf:

Fleming’s right-hand rule

Lenz’s law.

The former is empirical, but the latter is fundamental in that it is based upon electrical principles.

Fleming’s right-hand rule: If the index finger of the right hand points in the direction of the magnetic

flux and the thumb is pointed in the direction of the motion of the conductor relative to the

magnetic field, then the middle finger, held at right angles to both the thumb and the index finger,

indicates the direction of the induced emf (figure below)

Lenz’s law: The direction of an induced emf is the always such that it tends to set up current

opposing the motion or the change of flux responsible for inducing that emf.

This law is used in all electric machines where the concept of induction applies, e.g. motors and

transformers.

Fleming’s left-hand rule: as shown in the figure below. In this figure the index finger indicates the

main field, the middle finger the direction of current through the armature conductors, and the

thumb the direction of rotation.

24

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

The prescribed textbook covers this learning material on pages 7 – 15.

5.1.6 Generator principle of operation

An electrical generator is a machine which converts mechanical energy (or power) into electrical

energy (or power). The energy conversion is based on the principle of the production of dynamically

(or motional) induced emf. Whenever a conductor cuts magnetic flux, dynamically induced emf is

produced in it according to Faraday’s Laws of Electromagnetic Induction. This emf causes a current

to flow if the conductor circuit is closed.

Hence, two basic essential parts of an electrical generator are(i) a magnetic field and (ii) a conductor

or conductors which can so move as to cut the flux.

Refer to page 7 in your prescribed textbook for a comprehensive explanation of operation

of dc generator.

Elementary dc generator

Fig. below shows an armature coil which is connected to a commutator with two segment. When the

armature rotates the flux is cut by the conductors and an emf is induced. This is an alternating emf

and the commutator changes the ac to a dc. The wave of induced emf is sinusoidal (Fig. 2.4 in the

book) and the output waveform of the dc generator is as shown in the book on page 8 Fig. 2.5.

25

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Refer to page 8 in your prescribed textbook for a comprehensive explanation of

elementary dc generator.

5.1.7 Motor principle of operation

A rectangular coil which is free to rotate about a fixed axis is shown placed inside a magnetic field

produced by permanent magnets in figure below. A direct current is fed into the coil via carbon

brushes bearing on a commutator, which consists of a metal ring split into two halves separated by

insulation.

When current flows in the coil a magnetic field is set up around the coil which interacts with the

magnetic field produced by the magnets. This causes a force F to be exerted on the current-carrying

conductor which, by Fleming’s left-hand rule, is downwards between points A and B and upward

26

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

between C and D for the current direction shown. This causes a torque and the coil rotates

anticlockwise. When the coil has turned through 90 degrees from the position shown in Figure

above the brushes connected to the positive and negative terminals of the supply make contact with

different halves of the commutator ring, thus reversing the direction of the current flow in the

conductor. If the current is not reversed and the coil rotates past this position the forces acting on it

change direction and it rotates in the opposite direction thus never making more than half a

revolution. The current direction is reversed every time the coil swings through the vertical position

and thus the coil rotates anticlockwise for as long as the current flows. This is the principle of

operation of a dc motor which is thus a device that takes in electrical energy and converts it into

mechanical energy.

Please note: You can also find a similar principle of operation in the book on page 14 with relevant

figures.

Back emf

When the armature of a dc machine rotates, the armature coils cut the magnetic field and a voltage

or emf is induced in these coils. The direction of this induced emf is, according to Lenz’s law,

opposite to that of the applied emf. For this reason, it is termed back emf.

This back emf is dependent upon the same factors as the generated emf in a generator, namely the

speed, direction of rotation and the magnetic field strength of the machine. A stronger field and

higher speed will thus generate a larger back emf.

Please note: For back emf in a dc motor and generator refer to the book on page 15-16.

Now that we have covered some of the important foundational concepts, complete this

self-check activity to gauge your understanding:

1. State functions of the following as applicable to dc machines:

(a) Brushes

(b) Field winding

(c) Laminated iron sheets

(d) Main frame

(e) Pole core

2. Define the following terms as applicable in dc machines

(a) Commutation

(b) Pole pitch

3. What is meant by armature reaction?

27

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Refer to pages 1 - 8 & 14 - 15 in your textbook for a complete overview of the learning

content discussed up to this point.

We have covered important foundational concepts and terminology, so do make sure that you

isolate and highlight critical areas in your textbook for later study. The above summary of the main

areas should give you an understanding of the most important aspects to focus on.

Once you have read through the prescribed textbook, attempt the revision questions below.

REVISION QUESTIONS

1. Draw a neat, fully labelled sketch of a four-pole dc machine/ draw a sketch of a dc machine

and indicate pole pitch, interpoles and directions of rotation for a motor and a generator.

2. Briefly discuss the following components of a dc machine

a) Stator

b) field poles

c) armature core

3. Distinguish between wave and lap windings.

4. Name and discuss the four (4) methods of improving commutation.

5. Describe the action of a commutator.

6. Define Lenz’s law.

7. Define Faraday’s law.

8. Explain Flaming’s right hand rule.

9. Name four factors that determine the magnitude of the induced emf in a conductor.

10. Explain fully the basic operation of a motor and generator.

Refer to pages 6, 13 & 28 in your textbook for more questions regarding this chapter.

28

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.1.8 Self-Assessment

Let’s see what you have learned so far by taking this short self-assessment.

The Self-Assessment for this unit is embedded within your

ELECTROTECHNOLOGY N3 in myClass. Head on to the quiz to see how you have

fared with this section of content!

Be sure to complete the self-assessment quiz before you move on to the next

section!

5.2 Week 2: DIRECT CURRENT GENERATORS

This week focuses on the types of generators ,their characteristics, and

Purpose

methods of excitation.

By the end of this week, you will be able to:

Explain in detail what is meant by separate excitation and self-

excitation.

Draw load characteristic of a separately excited and series generator.

Explain load characteristic of a separately excited, series and shunt

generator.

Explain residual magnetism.

Explain basic operation of a shunt generator.

Learning

Differentiate between cumulative and differential compound

Outcomes generator.

Explain what is meant by level-compounded.

Draw neat schematic diagrams of long shun and short shunt

compound generators.

Draw and describe the characteristics of an over and under

compounded generator.

Time It will take you 2 hours to make your way through this study week.

Prescribed Bakker P.J.A. (1998). Electrotechnology N3, 1st edition. Northcliff: Troupant.

Reading ISBN: 9781919780269

29

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.2.1 Types of generators

Generators are usually classified according to the way in which their fields are excited. Generators

may be divided into (a) separately-excited generators and (b) self-excited generators.

(a) Separately-excited generators are those whose field magnets are energized from an

independent external source of dc current. It is shown diagrammatically below

(b) Self-excited generators are those whose field magnets are energized by the current

produced by the generators themselves. Due to residual magnetism, there is always

present some flux in the poles. When the armature is rotated, some emf and hence

some induced current is produced which is partly or fully passed through the field

coils thereby strengthening the residual pole flux.

There are three types of self-excited generators named according to the manner in which their field

coils (or windings) are connected to the armature.

(i) Shunt wound The field windings are connected across or in parallel with the armature

conductors and have the full voltage of the generator applied across them (see Figure

below)

(ii) Series wound The field winding are joined in series with the armature conductors. As

they carry full load current, they consist of relatively few turns of thick wire or strips.

Such generators are rarely used except for special purposes i.e. as boosters etc.

(iii) Compound wound It is a combination of a few series and a few shunt windings and can

be either short-shunt or long-shunt as shown below. In compound generator, the shunt

field is stronger than the series field. When series field aids the shunt field, generator is

said to be commutatively-compounded. On the other hand, if series field opposes the

shunt field, the generator is said to be differentially compounded

30

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Refer to pages 9 – 10 in your prescribed textbook for a comprehensive explanation on the

methods of excitation.

5.2.2 Load characteristics of separately-excited generator

The terminal voltage gradually decreases with an increase in load current. This decrease in terminal

voltage is due to armature reaction and the voltage drop in the armature circuit.

Application: This generator is often used in automatic motor control systems. In these systems the

field current is controlled by an amplifier and the output is used to drive a motor.

Disadvantage lies in requiring a separate source of direct current

5.2.3 Load characteristics of series-wound generator

Under no-load conditions there is no current flow and therefore only a very small emf will be

induced in the armature. This emf is due to the residual magnetism and is indicated on the curve.

If load is connected there will be a flow of current and the field strength and terminal voltage will

increase. A further increase in current will increase the field strength and a high voltage will be

generated in the armature winding.

31

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Application: The series generator is seldom used but its normal application is as a booster on dc

transmission lines. The fact that its supply voltage is proportional o the armature current makes it

suitable for this type of application.

5.2.4 Load characteristics of shunt-wound generator

When a shunt generator is loaded the maximum terminal voltage is obtained in a very short period

of time.

This is shown in Fig. when the load is increased there is a decrease in terminal voltage which is

partly due to the increased IaRa voltage drop in the armature winding and partly to armature

reaction. The shunt current is also decreased and therefore the flux and the generated emf are

reduced, thereby causing a further reduction in terminal voltage.

If the load current is increased beyond there will be a sharp drop in terminal voltage and therefore is

the ultimate point for generation.

Application: The shunt machine is the type of dc generator most frequently used. However, the load

current must be limited to a value well below the maximum value, thereby avoiding excessive

variation of the terminal voltage. It is therefore used where a constant voltage is required e.g.

battery charging and excitation for ac generators.

Let’s watch this video on the types of generators, to see these aspects clearer:

YouTube. 2021. Types of DC Generators in detail #1. [online] Available

at: <https://www.youtube.com/watch?v=wPyyTKJy780> [Accessed 05 January 2021].

32

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.2.5 The basic operation of a shunt generator

The armature of the generator is driven up to the required speed.

The lines of force due to the residual magnetism in the main poles are cut by the armature

conductors.

The initial cutting of flux induces an emf in the armature conductors.

This induced emf is applied across the field since the field is connected in parallel with the

armature.

A current flows in the field coils causing a field which strengthens the residual field.

The armature conductors are now cutting a stronger field and the induced emf increases

until maximum voltage is obtained.

At this stage the magnitude of the terminal voltage can be controlled by the rheostat.

5.2.6 Cumulative compound generator

In this case the series and shunt field coils are connected in such a way that the fields support each

other. The two coils carry currents in the same direction so that the total magneto-motive force is

the sum of the mmf’s in the two coils (Fig. 2.16 in the book).

The machine reacts to a light load in exactly the same way as a shunt generator under no-load

conditions. When the load increases, the effect of the series coil automatically increases the

excitation. By suitable regulating it can be arranged that the series windings provide only the

additional excitation necessary to maintain a constant voltage. The machine is then called “level-

compounded”.

Please note: For series-parallel, cumulative compound and Differential compound generators refer

to the book on page 11 - 13.

Let’s watch! The interconnected operation of DC Shunt generators.

YouTube. 2021. Interconnected operation – DC shunt generators. [online] Available

at: <https://www.youtube.com/watch?v=YaQ_BIBXEpA> [Accessed 05 January 2021].

Once you have made your way through that content, you should be able to answer the

following self-check questions:

33

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

1. Explain the basic operation of shunt generator?

2. What is meant by residual magnetism?

3. Mention the applications of series, shunt, and compound generators.

Refer to pages 9 - 13 in your textbook for a complete overview of the learning content

discussed up to this point.

We have covered important foundational concepts, so do make sure that you isolate and highlight

critical areas in your textbook for later study. The above summary of the main areas should give you

an understanding of the most important aspects to focus on.

Once you have read through the prescribed textbook, attempt the revision questions below.

REVISION QUESTIONS

1. Explain what is meant by separate excitation and self-excitation.

2. Draw and describe the load characteristics of a separately excited generator.

3. Draw and explain the load characteristics of a series generator.

4. Explain fully the load characteristics of a shunt generator.

5. Differentiate between cumulative and differential compound generators.

6. Draw neat schematic diagrams of long-shunt, and short-shunt compound generators.

7. Draw and describe the characteristics of an over and under compounded generator.

8. What is meant by “level-compounded”.

5.2.7 Self-Assessment

Let’s see what you have learned so far by taking this short self-assessment.

34

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

The Self-Assessment for this unit is embedded within your

ELECTROTECHNOLOGY N3 in myClass. Head on to the quiz to see how you have

fared with this section of content!

Be sure to complete the self-assessment quiz before you move on to the next

section!

5.3 Week 3: DIRECT CURRENT MOTORS

This week focuses on the dc motors in detail, the types of dc motors, speed

Purpose

control and overload protective devices.

By the end of this week, you will be able to:

State the purpose of a starting resistance in a dc motor starter.

Explain with the use of a neat diagram the action of a face-plate

starter for a shunt motor.

Explain the action of a no-volt release fully

Explain the action of a dashpot type and a bi-metal type overload

Learning

device.

Outcomes Differentiate between the differential and cumulative compound

motor.

Explain why the differential and cumulative compound motor cannot

be used for the same purpose.

Explain the load and torque characteristics of a shunt motor.

Time It will take you 2 hours to make your way through this study week.

Prescribed Bakker P.J.A. (1998). Electrotechnology N3, 1st edition. Northcliff: Troupant.

Reading ISBN: 9781919780269

35

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.3.1 Introduction to Direct Current Motors

Typically, these motors are deployed in equipment that requires some form of rotary or motion-

producing control. Direct current motors are essential components in many electrical engineering

projects. Having a good understanding of DC motor operation and motor speed regulation enables

engineers to design applications that achieve more efficient motion control.

Unlike AC motors, DC motors operate on DC power-non-sinusoidal, unidirectional power.

Let’s watch this video on DC motors and the types of DC motors, to see these aspects clearer:

YouTube. 2021.Types of DC motors #1. [online] Available

at: <https://www.youtube.com/watch?v=ASnDSEeWADk> [Accessed 06 January 2021].

5.3.2 Torque and speed of a DC Motor

It will be proven that though torque of a motor is admittedly a function of flux and armature current,

yet it is independent of speed. In fact, it is the speed which depends on torque and not vice versa. It

has been proven earlier that

V – IaRa KEb

N = K =

ɸ ɸ

Also, Ta α Ia

It is seen from above that increase in flux would decrease the speed but increase the armature

torque. It cannot be so because torque always tends to produce rotation. If torque increases, motor

speed must increase rather than decrease. The apparent inconsistency between the above two

equations can be reconciled in the following way:

1. Back emf Eb (= Nɸ /K) drops instantly (the speed remains constant because of inertia of the

heavy armature).

2. Due to decrease in Eb, Ia is increased because Ia = (V – Eb)/Ra. Moreover, a small reduction in

flux produces a proportionately large increase in armature current.

3. Hence, the equation Ta α Ia, a small decrease in ɸ is more than counterbalanced by a large

increase in Ia with the results that there is a net increase in Ta.

4. This increase in Ta produces an increase in motor speed.

It is seen from above that with applied voltage V held constant, motor speed varies inversely as the

flux. However, it is possible to increase flux and, at the same time, increase the speed provided I a is

held constant as is actually done in a dc servomotor.

36

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.3.3 Types of dc motors and their characteristics

.1. Shunt-wound motor

In the shunt-wound motor the field winding is in parallel with the armature across

the supply as shown below

Characteristics

The two principal characteristics arte the torque/armature current and speed/armature current

relationship. From these, the torque/speed relationship can be derived.

(i) The theoretical torque/armature current characteristic can be derived from the

expression Ta α Ia. For a shunt-wound motor, the field winding is connected in parallel

with the armature circuit and thus the applied voltage gives a constant field current, i.e.

a shunt-wound motor is a constant flux machine.

(ii) The armature circuit of a dc motor has resistance due to the armature winding and

brushes, Ra ohms, and when armature current Ia is flowing through it, there is a voltage

drop of IaRa volts

.2. Series-wound motor

In the series-wound motor the field winding is in series with the armature across the

supply as shown below.

Characteristics

In a series motor, the armature current flows in the field winding and is equal to the supply current,

I.

37

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

The torque/current characteristic

Torque is Ta α ɸIa, since the armature and field currents are the same current, I, in a series machine,

then T α ɸI over a limited range, before magnetic saturation of the magnetic circuit of the motor is

reached, (i.e. the linear portion of the B-H curve for the yoke, poles, air gap, brushes and armature in

series)

.3. Compound-wound motor

There are two types of compound-wound motor

.3.1. Cumulative compound, in which the series winding is so connected that the field due

to it assists that due to the shunt winding.

.3.2. Differential compound, in which the series winding is so connected that the field due

to it opposes that due to the shunt winding.

Characteristics

A compound-wound motor has both a series and a shunt field winding, (i.e. one winding in series

and one in parallel with armature), and is usually wound to have a characteristic similar in shape to a

series-wound motor. A limited amount of shunt winding is present to restrict the no-load speed to a

safe value. However, by varying the number of turns on the series and shunt windings and the

directions of the magnetic fields produced by these windings (assisting or opposing), families of

characteristics may be obtained to suit almost all applications.

Let’s watch!

YouTube. 2021. Characteristics of DC Motors. [online] Available at:

<https://www.youtube.com/watch?v=cNI-G8gKsyU> [Accessed 06 January 2021].

5.3.4 Methods used to control speed

Although the speed of all dc motors is controlled by a starter during the starting process, it is not the

purpose of a starter to control the speed during operation. The design of any starter is such that it

cannot allow a high current for a long period of time, and therefore the following methods are used

to control the speed of dc motors:

Varying the voltage supplied to the armature;

Varying the strength of the magnetic field; and

Varying the effective number of armature conductors.

The third method is seldom used, because it involves changing the brush positions. The first two

methods are mainly used to keep the speed normal, above normal or below normal.

38

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.3.5 DC Motor Starters

If a dc motor whose armature is stationary is switched directly to its supply voltage, it is likely that

the fuses protecting the motor will burn out. This is because the armature resistance is small,

frequently being less than one ohm. Thus, additional resistance must be added to the armature

circuit at the instant of closing the switch to start the motor.

As the speed of the motor increases, the armature conductors are cutting flux and a generated

voltage, acting opposition to the applied voltage, is produced, which limits the flow of armature

current. Thus the value of the additional armature resistance can then be reduced.

When at normal running speed, the generated emf is such that no additional resistance is required

in the armature circuit. To achieve this varying resistance in the armature circuit on starting, a dc

motor starter is used

5.3.6 Reversing the direction of rotation of DC Motors

The direction of rotation of a direct current motor depends on the direction of the main magnetic

field and the direction of the armature current in the conductors cutting the field. If either of these

can be changed, the motor will run in a reverse direction. To reverse the direction of rotation of a dc

motor, the rule is therefore to reverse the connections of either the field or the armature, but not

both. If both connections are reversed, the motor will run in the same direction as before.

All dc moors can be reversed by changing over only the armature connections at the motor terminal

box, treating interpole coils as part of the armature winding.

It may be necessary to move the brushes when the motor is reversed in order to achieve sparkles

commutation. Many manufacturers mark the brush position for both directions of rotation.

Refer to pages 17 - 28 in your textbook for a complete overview of the learning content

discussed up to this point.

We have covered important foundational concepts, so do make sure that you isolate and highlight

critical areas in your textbook for later study. The above summary of the main areas should give you

an understanding of the most important aspects to focus on.

Once you have read through the prescribed textbook, attempt the revision questions below.

39

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

REVISION QUESTIONS

1. Explain back-emf.

2. Discuss Fleming’s left-hand rule.

3. Deduce the speed equation of a dc motor.

4. Deduce the emf equation for a dc machine.

5. Deduce the formula used to calculate the torque of a dc motor.

6. Discuss the properties of a series motor.

7. Name two applications of a shunt motor.

8. Explain the load and torque characteristics of a shunt motor.

Refer to pages 28 - 29 in your textbook for more questions regarding this chapter.

5.3.7 Self-Assessment

Let’s see what you have learned so far by taking this short self-assessment.

The Self-Assessment for this unit is embedded within your

ELECTROTECHNOLOGY N3 in myClass. Head on to the quiz to see how you have

fared with this section of content!

Be sure to complete the self-assessment quiz before you move on to the next

section!

5.4 Week 4: AC THEORY, DC MACHINES EFFICIENCY & TRANSFORMERS

This week focuses on the efficiency of dc machines, transformers, cooling

Purpose methods of transformers and the generation of an alternating current, the ac

components, resonance and power factor correction.

By the end of this week, you will be able to:

Define instantaneous value, period and frequency.

Explain the meaning of rms and average value.

Define the form factor and crest factor of an ac waveform.

Learning Perform all the calculations in this unit.

Outcomes Define the term power factor of an ac circuit.

Draw the phasor diagrams to show the relationship between voltage

and current.

Define efficiency.

Discuss eddy currents and hysteresis losses.

Discuss the basic losses in a dc machine.

40

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Explain the constant losses of a dc machine.

Explain the rope brake test with the aid of a neat sketch.

Deduce efficiency formula by means of a rope brake test.

Differentiate between rope brake test and an indirect test.

Define mutual induction.

Define self-induction.

Explain the operation of a transformer with the aid of a neat sketch.

Name methods used to cool transformers.

Purpose of instrument transformers.

Time It will take you 2 hours to make your way through this study week.

Prescribed Bakker P.J.A. (1998). Electrotechnology N3, 1st edition. Northcliff: Troupant.

Reading ISBN: 9781919780269

5.4.1 Introduction alternating current theory

Electricity is produced by generators at power stations and then distributed by a vast network of

transmission lines (called the National Grid system) to industry and for domestic use. It is easier and

cheaper to generate alternating current(a.c.) than direct current (d.c.) and a.c. is more conveniently

distributed than d.c. since its voltage can be readily altered using transformers. Whenever d.c. is

needed in preference to a.c., devices called rectifiers are used for conversion.

Direct current (DC) is the flow of electric charge in only one direction.

Alternating current (DC) is the flow of electric charge that periodically reverses direction.

5.4.2 Definitions of alternating current terms

Instantaneous value: The instantaneous value of an alternating current or voltage is that

specific value which can be determined at a certain moment in terms of current or voltage.

They are represented by small letters i, e.

Maximum value, peak value or amplitude: It is the maximum or peak value of an

alternating current wave and is shown by E or I (also E max or Imax).

Period (t): the time taken to complete one full cycle (in seconds).

Cycle: One complete set of changes which an alternating quantity undergoes.

Frequency: The total number of complete changes in a given time (usually one second).

The unit of frequency is the hertz (Hz).

41

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

5.4.3 The generation of an alternating current

To explain the generation of an alternating current we can use an elementary generator consisting

of two poles and a single-loop coil rotating in an anticlockwise direction between the poles (Fig.

below). Suppose the coil is in position A, i.e. horizontal and thus perpendicular to the magnetic field.

No emf is now induced in the coil. The value of the induced emf will gradually increase between 0°

and 90° as a result of the movement of the coil through the field. At B the coil will be at right angle

to the field and a maximum, emf will be induced. While the coil is moving to C the value of the emf

will decrease so that it will be zero at C (after 180°). Up to now the coil has moved through the field

in the same (or positive) direction only; therefore, the induced emf was also in one direction. A

movement of the coil from C to D is in the opposite direction, i.e. the induced emf is negative. At D a

negative value is reached and the cycle is completed at A. the sine wave (Fig. 5.4.3) is a graphic

representation of the movement of the coil.

To summarize:

At A (0°) – No induced emf

At B (90°) – maximum emf (positive)

At C (180°) – zero again

At D (270°) – minimum induced emf (negative direction)

At A (360°) – zero.

5.4.4 The value of the induced emf

When a conductor cuts a magnetic field or is cut by a magnetic field, an emf is induced in the

conductor. The value of this emf is directly proportional to the rate at which the conductor cuts the

magnetic field.

Where e = instantaneous value in volts (V)

B = flux density in teslas (Wb/m2)

l = length of the conductor in meters (m)

v = velocity of the conductor at a right angle to the magnetic field in meters per second

(m/s).

5.4.5 Maximum, rms and average values

42

Downloaded by Kwazi Mehlo (kwazimehlo@gmail.com)

lOMoARcPSD|40521374

ELECTROTECHNOLOGY N3 Damelin©

Rms, Virtual or effective value: The rms value of an alternating current or voltage is that value which

has the same heating effect as a direct current of the same value. For a uniform sine wave

Erms = 0,707 X Emax volts, and Irms = 0,707 X Imax amperes

Average value: The average value of an alternating current or voltage is the average of the

instantaneous values over a half-cycle. For a uniform sine wave

Eave = 0.637 X Emax volts, and Iave = 0.637 X I max amperes

Form factor: Form factor is the ratio of the rms value to the average value of the wave:

Form factor = Erms/Eave or Irms/Iave

For a uniform sine wave the form factor will always be 1,11. Form factor has no units because it is only

a ratio between two quantities.

Crest factor: It is the ratio of the maximum value to the rms value of the wave:

Crest factor = Emax/Erms or Imax/Irms

For a uniform sine wave the crest factor will always be 1,414.