Professional Documents

Culture Documents

Paint Mate

Paint Mate

Uploaded by

tallest.l.sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paint Mate

Paint Mate

Uploaded by

tallest.l.sCopyright:

Available Formats

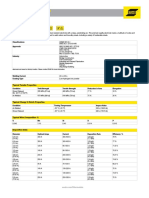

PAINT MATE SERIES 64

Max. load Motion range [˚] Maximum speed [˚/s] J4 Moment J5 Moment J6 Moment

Controlled Repeatability Mechanical

Robot model Controller capacity at Reach [mm] [Nm]/ [Nm]/ [Nm]/ IP Rating

axes [mm] weight [kg]

wrist [kg] J1 J2 J3 J4 J5 J6 J1 J2 J3 J4 J5 J6 Inertia [kgm2] Inertia [kgm2] Inertia [kgm2]

PaintMate 200iA 6 5 ± 0.02 35 704 340/360 200 388 380 240 720 350 350 400 450 450 720 11.9/0.3 11.9/0.3 6.7/0.1 ATEX certification,

Paint Mate R-30iA Mate cat II 2G + 2D

PaintMate 200iA/5L 6 5 ± 0.03 37 892 340/360 230 373 380 240 720 270 270 270 450 450 720 11.9/0.3 11.9/0.3 6.7/0.1

Reach

m

2m

89

70

5L

4m

/

0iA

m

20

20

0iA

5K

g

g

5K

Weight

The following Paint Mate robots models are available:

• Paint Mate 200iA with 5kg payload and 704 mm reach

• Paint Mate 200iA/5L with 5kg payload and 892 mm reach

PRB_Rev_06_2008_01.indd 64 11.01.2010 13:46:57

T H E FA N U C PA I N T M AT E R O B OT S A R E S U I TA B L E FO R A W I D E R A N G E O F PA I N T I N G A N D C OAT I N G

A P P L I CAT I O N S . T H E I R C O M PACT S I Z E , H I G H A X E S S P E E D S A N D H I G H PAY LOA D A L LOW TO A U TO M AT E

S M A L L PA R T S A N D M A N U A L PA I N T I N G A N D A C H I E V E B E S T P R O D U CT I O N R AT E S A N D Q U A L I T Y FO R A L L

S O R T S O F M AT E R I A L S S U C H A S P L A S T I C S , M E TA L , WO O D . ..

FEATURES AND BENEFITS

ALUMINUM LIGHT WEIGHT ARM FOR PAINTING COMMON DESIGN DIRECTION AND COMPONENTS FLOOR, CEILING, WALL AND ANGLE MOUNT

FANUC Paint Mate robots are ideal for many • Aluminum construction • EX proven mechanical unit is achieved by purging the • The Paint Mate robots can easily be mounted above

types of materials and applications: • Requires less power for operation, hence reduced whole cavity of the robot - standard FANUC motors the work piece.

• Automotive components (e.g. mirrors, motor power consumption costs can be used • Robot can be mounted on the floor and on the ceiling

cycle tanks) • Enhanced security: no risk of ignition source in case • As reliable and dynamic as all other FANUC robots without any restrictions.

• Plastics and rubber (e.g. mobile phone, of collision • Standard gears, motors and reducers as used in all • Ceiling mounted robots provide easier access to

helmets) • Easy cleaning FANUC robots with direct motor coupling, hence same machine being serviced and part load/unload area.

• Wood and furniture (e.g. windows) • Waterproof well appreciated reliability • When wall mounted the Paint Mate robots can even

• Steel and fabrication products • Smooth exterior surface to minimise contamination • Proven FANUC robot controller process work pieces as long as 1100mm and 1400mm.

• Consumer good (e.g. TV sets, household • Same program structure as FANUC non-painting

ovens) COMPACT ARM AND SLIM WRIST robots ATEX APPROVED

FOR TIGHEST PAINT BOOTHS • Ease of programming Robot is entirely ATEX certified (explosion proof).

• Anti-corrosion

• With the lowest body mass, smallest footprint in its • Category 2

• ... and many other class the Paint Mate robots are ideal for tightest paint DEDICATED AND POWERFUL APPLICATION • Group IIG (previously zone 1) and Group IID

booths. SOFTWARE = LR PAINTTOOL

• The slim and strong wrist can reach into narrow LR PaintTool offers advanced process functions:

spaces and work pieces, while 5kg payload capacity is • Process orientated operating

sufficient to hold special and double guns. • Saving time for setting of process parameter setting

• Process specific terminology

EXTERNAL CABLE MOUNTING • Atomising and fan air calibrated units

Colour and air hose cables are fixed externally to the J3 • 40 Presets by Color

and J2 arm. • “Hot Edit:” editing of paint parameters and motion

• No restriction in the work envelope points during production

• Greater security thanks to cable fixing • Easy set-up of line tracking programs (See chapter

• Hoses are kept away from the wrist, which keeps the Application Tools)

work piece clean

65

PRB_Rev_06_2008_01.indd 65 11.01.2010 13:47:09

Dimensions 66

Paint Mate 200iA

446 4XM10 X 1.5 THD

260

4XØ11.0 THRU MOUNTING HOLES

20 205 MOUNTING HOLES

160 45°

+ 0.012 190

7.00

15 0.000

Ø 5.000 M5X8.0 DP.

TYP.(4) EQUALLY SPACED

ON 31.5 DIA. B.C.

117 95 130

160

234

265

5.000 DIA. DWL. X 7.0 DP.

TYP.(1) ON 31.5 DIA. B.C.

808

Footprint Wrist

398

6.0

0.000 470

Top R704 -0.025 320

Ø 40.00 Ø 70.0

R181 R-30iA MATE CONTROL CABINET

10°

+ 0.021

0.000

10° Ø 20.00 Top

3.0

80.0

120 104 123

320 C

285 B

137

251

80

300

145

1079

750 75

825

369 128

450 170

307

120

160 108

130

Side A A Front Side Back Side

235

265

333 246

513 704

260

PRB_Rev_06_2008_01.indd 66 11.01.2010 13:47:20

Dimensions 67

Paint Mate 200iA/5L

Footprint

260

4-Ø11 THROUGH 446 4XM10 X 1.5 THD

20 205 MOUNTING HOLES

160 Wrist

15

190

M3X5.0 DP.

TYP.(2)

BOTH SIDES 45°

117 95 130 M5X8.0 DP.

TYP.(4) EQUALLY SPACED

160 ON 31.5 DIA. B.C.

234

265

5.000 DIA. DWL. X 7.0 DP.

TYP.(1) ON 31.5 DIA. B.C.

808

398

Top

R892

6.0

10°

R181 0.000

- 0.025

470

10° Ø 70.0 320

Ø 40.00

R-30iA MATE CONTROL CABINET

+ 0.021

0.000

Ø 20.00

Top

3.0

80.0

104

123

410

C

B

237

120

251

400 145

75 1266

128

450 414 170

371

120

160 273

A A

235 130 Front Side Back Side

246 265

Side

260

742 892

PRB_Rev_06_2008_01.indd 67 11.01.2010 13:47:21

You might also like

- Service Manual: Trinco™ Dry Blast Machinery Model 36 X 30 / PC Direct PressureDocument26 pagesService Manual: Trinco™ Dry Blast Machinery Model 36 X 30 / PC Direct PressureMandy NormanNo ratings yet

- GB Hydraulic BreakersDocument12 pagesGB Hydraulic BreakersMhdNo ratings yet

- Counter Weight DrawingDocument1 pageCounter Weight Drawingrajaguru20003No ratings yet

- Modification in Power Press Machine To Increase Productivity and QualityDocument10 pagesModification in Power Press Machine To Increase Productivity and QualityThomas DonaldNo ratings yet

- Well Head Schematic LVT 2Document1 pageWell Head Schematic LVT 2luico37100% (2)

- Girard Tube Clamps Nuclear CatalogDocument14 pagesGirard Tube Clamps Nuclear Catalogpsbgolf04No ratings yet

- Martillo Komac KB1500 Parts ManualDocument12 pagesMartillo Komac KB1500 Parts ManualJOHN FRADER ARRUBLA LOPEZ100% (1)

- Arc Mate SeriesDocument4 pagesArc Mate SeriesIsrael CastroNo ratings yet

- Datasheet PaintMate 200ia 5LDocument1 pageDatasheet PaintMate 200ia 5LRafa LozanoNo ratings yet

- 489 Fanuc M 10ia Robot AdatlapDocument4 pages489 Fanuc M 10ia Robot AdatlapassNo ratings yet

- Datasheet M-10iD-8LDocument1 pageDatasheet M-10iD-8LjosjcrsNo ratings yet

- M SeriesDocument47 pagesM SeriesMeet PAtelNo ratings yet

- 525 Fanuc M 20ia Robot AdatlapDocument4 pages525 Fanuc M 20ia Robot AdatlapGunjan TrivediNo ratings yet

- Datasheet LRMate-200iD-4S - KUKADocument1 pageDatasheet LRMate-200iD-4S - KUKAJOSE MANUELNo ratings yet

- Top Mounted RobotsDocument4 pagesTop Mounted Robotstallest.l.sNo ratings yet

- Bell Amphibious Excavators April2018 WebDocument12 pagesBell Amphibious Excavators April2018 Webparaia01No ratings yet

- Datasheet LRMate-200iD-7LCDocument1 pageDatasheet LRMate-200iD-7LCPremium WzorceNo ratings yet

- Concrete Trial Mix Summary: Minutes DaysDocument3 pagesConcrete Trial Mix Summary: Minutes DaysDileepa DissanayakeNo ratings yet

- Checklist Quotation CCTV New 2018Document3 pagesChecklist Quotation CCTV New 2018Mark Joseph PunzalanNo ratings yet

- LT 01 Eaii F #Sen #Aip #V2 PDFDocument2 pagesLT 01 Eaii F #Sen #Aip #V2 PDFMohsin RazaNo ratings yet

- M-900 Robot Working Range: 360 KG 2655 MMDocument1 pageM-900 Robot Working Range: 360 KG 2655 MMKAKAKNo ratings yet

- Datasheet M 900ib 360Document1 pageDatasheet M 900ib 360ariyanto prasetioNo ratings yet

- Paint RobotsDocument4 pagesPaint Robotstallest.l.sNo ratings yet

- 505 Fanuc M 1ia 0.5a Robot AdatlapDocument4 pages505 Fanuc M 1ia 0.5a Robot AdatlapMario ManuelNo ratings yet

- 631 Fanuc M 710ic 70 Robot AdatlapDocument4 pages631 Fanuc M 710ic 70 Robot AdatlapTatang Azis MuslimNo ratings yet

- 20&21072018 Magarmc Krrbproject C35aDocument3 pages20&21072018 Magarmc Krrbproject C35aDileepa DissanayakeNo ratings yet

- M-900 Robot Working Range: 330 KG 3203 MMDocument1 pageM-900 Robot Working Range: 330 KG 3203 MMjosjcrsNo ratings yet

- 8FG-8FD (Catalog) (E-Book) 1475745227 PDFDocument8 pages8FG-8FD (Catalog) (E-Book) 1475745227 PDFMamas SoimNo ratings yet

- Datasheet M-1iA-05SDocument1 pageDatasheet M-1iA-05Sketan rsNo ratings yet

- Mars Series Presentation: We Create Advantage. A Member of Haitian InternationalDocument29 pagesMars Series Presentation: We Create Advantage. A Member of Haitian InternationaltmisiakNo ratings yet

- Datasheet LRMate-200iD-7WPDocument1 pageDatasheet LRMate-200iD-7WPperop123No ratings yet

- Catalog - 8FD-8FG Toyota Engine ForkliftDocument8 pagesCatalog - 8FD-8FG Toyota Engine ForkliftKen WalschNo ratings yet

- 320C Perform Report (TEXR0335)Document10 pages320C Perform Report (TEXR0335)suwarjitechnicNo ratings yet

- Folletos FeriaDocument2 pagesFolletos FeriaCarlos Eduardo DuqueNo ratings yet

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNo ratings yet

- °C KG/CM G / / °C / / KG/CM G KG/CM G °C: MM (MM) MM / / PPM PPM KG/CM G CC / / MM 0 /90 /180 /270Document6 pages°C KG/CM G / / °C / / KG/CM G KG/CM G °C: MM (MM) MM / / PPM PPM KG/CM G CC / / MM 0 /90 /180 /270simonchangNo ratings yet

- Chain Type HMCDocument1 pageChain Type HMCAnkit BhadesiaNo ratings yet

- Saw Mild Steel / Low Alloy Steel Dep. Rates: HI 0.06 X A X V / VDocument1 pageSaw Mild Steel / Low Alloy Steel Dep. Rates: HI 0.06 X A X V / VgabrieleNo ratings yet

- Motor Heavy Duty - Rev01 01.02.2021Document6 pagesMotor Heavy Duty - Rev01 01.02.2021fortizuNo ratings yet

- Brosur ToyotaDocument8 pagesBrosur Toyotayuliani fitriaNo ratings yet

- Hard Tough Resin Recommended Settings For PrinterDocument3 pagesHard Tough Resin Recommended Settings For PrinterHafiz GunawanNo ratings yet

- Hard Tough Resin Recommended Settings For PrinterDocument3 pagesHard Tough Resin Recommended Settings For PrinterAdnan4466No ratings yet

- ArcMate0iB Controller30ibDocument1 pageArcMate0iB Controller30ibrguzmanabundisNo ratings yet

- Mashe Malta PDFDocument1 pageMashe Malta PDFluisaNo ratings yet

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFFarooq Al-obaidiNo ratings yet

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFĐorđe NikolajevićNo ratings yet

- Mesh Tech SheetDocument1 pageMesh Tech SheetRiana ZammitNo ratings yet

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFRiana ZammitNo ratings yet

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFKeith Zammit TaboneNo ratings yet

- Mesh Tech Sheet PDFDocument1 pageMesh Tech Sheet PDFluisaNo ratings yet

- PROTH-Precision-Surface-Grinders-General 2Document6 pagesPROTH-Precision-Surface-Grinders-General 2Veselin NedelchevNo ratings yet

- Datasheet LRMate-200iDDocument1 pageDatasheet LRMate-200iDROBERTO CAMARGONo ratings yet

- Bar Sched PDFDocument18 pagesBar Sched PDFseveralchanceNo ratings yet

- NC Specs 3 18 21Document2 pagesNC Specs 3 18 21ai007.rusmanaNo ratings yet

- Form Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11Document117 pagesForm Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11halieyNo ratings yet

- NHA SPECIFICATOIN (1998) For Construction MaterialDocument2 pagesNHA SPECIFICATOIN (1998) For Construction MaterialAbdul SaboorNo ratings yet

- Toyota Forklift 3tDocument13 pagesToyota Forklift 3tGuruh SuprayitnoNo ratings yet

- MVE 500/15E-40A0 (EE40050040A0JA0000) : 3 PH - 4 Poles - 1500 RPM - 220-240/380-415 V - 50 HZDocument1 pageMVE 500/15E-40A0 (EE40050040A0JA0000) : 3 PH - 4 Poles - 1500 RPM - 220-240/380-415 V - 50 HZAmol SarinNo ratings yet

- Magmotor s28Document2 pagesMagmotor s28Chuck SykesNo ratings yet

- WinPet BrochureDocument2 pagesWinPet BrochureTamil KumarNo ratings yet

- H RangeDocument1 pageH RangeAndres HuertasNo ratings yet

- HTL-R-Ultra-Low-Attachment-compressedDocument2 pagesHTL-R-Ultra-Low-Attachment-compressedtchavezNo ratings yet

- 8series - Catalog e 090722 1Document8 pages8series - Catalog e 090722 1suranga yapaNo ratings yet

- Datasheet M 1ia 05ADocument1 pageDatasheet M 1ia 05AHugo SalazarNo ratings yet

- Design of Double Slab at SHC-A1Document24 pagesDesign of Double Slab at SHC-A1dhee2608No ratings yet

- United States Patent: Steigerwalt Et Al. (10) Patent No.: US 7.562.454 B2Document25 pagesUnited States Patent: Steigerwalt Et Al. (10) Patent No.: US 7.562.454 B2Слэйтер Строительная компанияNo ratings yet

- Plough Servo enDocument45 pagesPlough Servo enonion yambolNo ratings yet

- Compression-Stages and ToolingDocument14 pagesCompression-Stages and ToolingMing Yew TingNo ratings yet

- Manual Makita 3710 PDFDocument52 pagesManual Makita 3710 PDFCristian LNo ratings yet

- Linyi Leiao Rigging Co.,ltdDocument23 pagesLinyi Leiao Rigging Co.,ltddereck ngorimaNo ratings yet

- UntitledDocument8 pagesUntitledTomas MalyNo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Filemon - Useful Ranges of Centerpoint Curves For Design of Crank-And-Rocker LinkagesDocument7 pagesFilemon - Useful Ranges of Centerpoint Curves For Design of Crank-And-Rocker LinkagesDavid C HouserNo ratings yet

- Electromechanics & AUTOMATION (1) (1) FiniDocument12 pagesElectromechanics & AUTOMATION (1) (1) FiniSalah ElbakriNo ratings yet

- Fast Moving Parts ListDocument4 pagesFast Moving Parts ListAbhishek ChauhanNo ratings yet

- How The Royal Enfield Bullet 4-Speed Gearbox Works: ShaftsDocument4 pagesHow The Royal Enfield Bullet 4-Speed Gearbox Works: ShaftsgkarthikeyanNo ratings yet

- Chapter 5 Propeller Shaft, Drive Shaft and Universal JointDocument2 pagesChapter 5 Propeller Shaft, Drive Shaft and Universal JointNguyễn Nam AnhNo ratings yet

- Alternator Mounting 50a WithDocument1 pageAlternator Mounting 50a Withardic wiraNo ratings yet

- F.A.L. Conducive Engineering Review CenterDocument3 pagesF.A.L. Conducive Engineering Review CenterAve de GuzmanNo ratings yet

- Eng10003 20S1 W09L08Document41 pagesEng10003 20S1 W09L08Murugaa VengadasanNo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormMd Shariful IslamNo ratings yet

- Specialized Tools CatalogDocument64 pagesSpecialized Tools CatalogHashim YahyaNo ratings yet

- Pentair-GreatWhite User ManualDocument80 pagesPentair-GreatWhite User Manualraul430No ratings yet

- Duplomatic: SeriesDocument36 pagesDuplomatic: SeriesMuhammad ShayanNo ratings yet

- Structural Steel International StandardsDocument4 pagesStructural Steel International StandardsnguyenquanghiepNo ratings yet

- 110 Series Solution Tanks: Low-Cost Chemical Storage Tanks Made For Years of Dependable ServiceDocument2 pages110 Series Solution Tanks: Low-Cost Chemical Storage Tanks Made For Years of Dependable ServiceFer PabNo ratings yet

- Donut Machine XM 3 enDocument10 pagesDonut Machine XM 3 enpaula09No ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- sm-M300-V Electrical1Document36 pagessm-M300-V Electrical1basem elhosany100% (1)