Professional Documents

Culture Documents

Pat1 QP Regular 2023 24 Amp

Pat1 QP Regular 2023 24 Amp

Uploaded by

Nature BueatyCopyright:

Available Formats

You might also like

- Assignment 3 Lessons From Derivatives MishapsDocument3 pagesAssignment 3 Lessons From Derivatives MishapsSandip Chovatiya100% (2)

- PAT1-CSS (22519) 2023-24 With Model AnsDocument7 pagesPAT1-CSS (22519) 2023-24 With Model AnsTejaswini NikamNo ratings yet

- Cadcam Model Question PaperDocument2 pagesCadcam Model Question PaperSelvaraj GNo ratings yet

- Btmpe703c 1 112321Document2 pagesBtmpe703c 1 112321AkashNo ratings yet

- CG Paper PUT - SECTION ADocument2 pagesCG Paper PUT - SECTION Akundan kumarNo ratings yet

- BTCS403 End Sem With CODocument4 pagesBTCS403 End Sem With COeverlovingmansiNo ratings yet

- MET385 - Ktu QbankDocument7 pagesMET385 - Ktu Qbankmohammedmaz0786No ratings yet

- Work-Shop-Technology - 3-5th Sem171753-Dec-2019Document2 pagesWork-Shop-Technology - 3-5th Sem171753-Dec-2019Neat & Clean ReviewNo ratings yet

- BMA302 - Computer Aided Design - B Tech ASE 5th SemDocument1 pageBMA302 - Computer Aided Design - B Tech ASE 5th SemArvind KatyayanNo ratings yet

- BDD 40103Document3 pagesBDD 40103zinilNo ratings yet

- CADMDocument3 pagesCADMSaravana Kumar MNo ratings yet

- Advanced Welding Technology EME022Document2 pagesAdvanced Welding Technology EME022Ratan Pal Singh YadavNo ratings yet

- Estimation Quantities and EsmationDocument5 pagesEstimation Quantities and EsmationNURUL MAISARAH MOHD YUSSOFNo ratings yet

- Zeal Polytechnic, Pune.: Third Year (Ty) Diploma in Mechanical Engineering Scheme: I Semester: VDocument20 pagesZeal Polytechnic, Pune.: Third Year (Ty) Diploma in Mechanical Engineering Scheme: I Semester: VOnkar TalekarNo ratings yet

- NSEC 2023 Set 31Document15 pagesNSEC 2023 Set 31Vishnu SinhaNo ratings yet

- Model CS3551 DC Set 2Document2 pagesModel CS3551 DC Set 2NambiRajaNo ratings yet

- ME204Document2 pagesME204raja93satNo ratings yet

- Cadcam Iat - 1 Question PaperDocument2 pagesCadcam Iat - 1 Question PaperSelvaraj GNo ratings yet

- Scheme - I Sample Question Paper: A) B) C) D) E)Document5 pagesScheme - I Sample Question Paper: A) B) C) D) E)Sdoo7No ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- CIE1 - QP-QCRE-Set1Document4 pagesCIE1 - QP-QCRE-Set1GunasekaranNo ratings yet

- Ppce Model QPDocument3 pagesPpce Model QParulsivagiriNo ratings yet

- First Series QPDocument2 pagesFirst Series QPMAHESWARY SREENATH ECNo ratings yet

- PPCE Model QP - 2Document2 pagesPPCE Model QP - 2arulsivagiriNo ratings yet

- Co1 (K) Co1 (K) Co2 (K) Co2 (K) Co2 (K) Co2 (K) Co3 (K) Co3 (K) Co4 (K) Co4 (K)Document2 pagesCo1 (K) Co1 (K) Co2 (K) Co2 (K) Co2 (K) Co2 (K) Co3 (K) Co3 (K) Co4 (K) Co4 (K)Murugesan kNo ratings yet

- Question Bank - Unit Test 1 Advanced Manufacturing Processes (22563)Document2 pagesQuestion Bank - Unit Test 1 Advanced Manufacturing Processes (22563)6403 Rohit Gaikwad0% (1)

- Sin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TDocument6 pagesSin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TBernice JohnsonNo ratings yet

- Wa0006.Document1 pageWa0006.rajashripatil1326No ratings yet

- MP 20Document2 pagesMP 20hkumarchauhan392No ratings yet

- Ucmp Model Set ADocument2 pagesUcmp Model Set ASAMUEL SANJAY RAJA R MECHNo ratings yet

- Winter 2020 AMIIW Question PapersDocument20 pagesWinter 2020 AMIIW Question PapersVigneshwaran VijayakumarNo ratings yet

- UCVL0702-SET-A Dec 2021Document2 pagesUCVL0702-SET-A Dec 2021Siddhi PatilNo ratings yet

- Cadcam Iat - 2 Question PaperDocument1 pageCadcam Iat - 2 Question PaperSelvaraj GNo ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- 16mec324 Cad Cam Cim Question BankDocument8 pages16mec324 Cad Cam Cim Question BankAbdalmalek ShamsanNo ratings yet

- Manufacturing ProcessesDocument4 pagesManufacturing ProcessesAmarjit KeneNo ratings yet

- Adobe Scan 17 Jun 2021Document3 pagesAdobe Scan 17 Jun 2021pNo ratings yet

- EST120 Basiccivil&mechanical PDFDocument12 pagesEST120 Basiccivil&mechanical PDFlecim12450No ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- EST120 Basic - Civil - & - Mechanical PDFDocument12 pagesEST120 Basic - Civil - & - Mechanical PDFlecim12450No ratings yet

- Basics of Civil & Mechanical EngineeringDocument123 pagesBasics of Civil & Mechanical Engineeringfebin philipNo ratings yet

- Chem PT PapersDocument3 pagesChem PT Papersrounitmakheja5No ratings yet

- PCB Design QPDocument3 pagesPCB Design QPvcetnaac c6No ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- CSE PUT Paper MicroprocessorDocument3 pagesCSE PUT Paper Microprocessorrachit koundalNo ratings yet

- 22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Document4 pages22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Roshan Kinholkar100% (1)

- Essay QuestionDocument4 pagesEssay QuestionAnnaIzzatNo ratings yet

- Design Lab Manual GLA NEWDocument36 pagesDesign Lab Manual GLA NEWFirst LastNo ratings yet

- Cel XDocument116 pagesCel Xxae778899No ratings yet

- College ConstructionDocument23 pagesCollege Constructionkailassonawane157No ratings yet

- Universiti Tun Hussein Onn Malaysia: ConfidentialDocument3 pagesUniversiti Tun Hussein Onn Malaysia: ConfidentialStudiePurposeNo ratings yet

- Cadm - Set 2Document4 pagesCadm - Set 2Saravana Kumar MNo ratings yet

- Blob:https:/web Whatsapp ComDocument2 pagesBlob:https:/web Whatsapp ComShanu RawNo ratings yet

- 1718sem1 Me5608Document4 pages1718sem1 Me5608Benedict ChinNo ratings yet

- Mahendra Engineering College) : Continuous Assessment Test - II - Aug - 2019Document2 pagesMahendra Engineering College) : Continuous Assessment Test - II - Aug - 2019Gowri ShankarNo ratings yet

- CSE313Document2 pagesCSE313Damodharan DNo ratings yet

- Summer 2021 AMIIW Question PapersDocument32 pagesSummer 2021 AMIIW Question PapersRiyaz AhmedNo ratings yet

- PTAM University Question PapersDocument6 pagesPTAM University Question PapersAMRISHRAJNo ratings yet

- Transportation EnggDocument3 pagesTransportation EnggUzair KhanNo ratings yet

- Compulsory Sl. No. Questions Marks Co PoDocument1 pageCompulsory Sl. No. Questions Marks Co PoAll_regNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- 20 BCD7263 Sam AltmanDocument32 pages20 BCD7263 Sam Altmananunay.20bcd7263No ratings yet

- Hd-010B Digital Drum: User'S ManualDocument37 pagesHd-010B Digital Drum: User'S Manualjavier_khanNo ratings yet

- Lesson 02 Interview EnglishDocument12 pagesLesson 02 Interview EnglishTang Bui100% (1)

- 2020 8th PEC BahawalpurDocument301 pages2020 8th PEC BahawalpurFast ComputersNo ratings yet

- Jose Rizal's Life, Works and Studies in Europe (Part 1)Document5 pagesJose Rizal's Life, Works and Studies in Europe (Part 1)Russen Belen50% (2)

- Ae112 NotesDocument3 pagesAe112 NotesJillian Shaindy BuyaganNo ratings yet

- Veeam One 10 0 Alarms Guide PDFDocument207 pagesVeeam One 10 0 Alarms Guide PDFBack Office ScannerNo ratings yet

- YAMAHA P121 SmartPianist - Specification - For202101Document2 pagesYAMAHA P121 SmartPianist - Specification - For202101Romélio LustozaNo ratings yet

- Engleski In%C5%BEenjerski%20menad%C5%BEment%20 (OAS) PDFDocument384 pagesEngleski In%C5%BEenjerski%20menad%C5%BEment%20 (OAS) PDFHarini SreedharanNo ratings yet

- Modulo 1 InglesDocument100 pagesModulo 1 Ingleselsa dimas100% (2)

- Learning Activity Sheets Grade 10 - MathematicsDocument4 pagesLearning Activity Sheets Grade 10 - MathematicsMarvin Torre50% (2)

- 03 Worksheet2Document2 pages03 Worksheet2Murielle FajardoNo ratings yet

- Vicarious Liability of StateDocument3 pagesVicarious Liability of StateChitraksh MahajanNo ratings yet

- About Gazi Auto BrickDocument19 pagesAbout Gazi Auto BrickMd. Reza-Ul- HabibNo ratings yet

- Capability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IDocument12 pagesCapability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IAlphard DarmawanNo ratings yet

- Sharjaa CarbonatesDocument190 pagesSharjaa CarbonatesRuben PradaNo ratings yet

- Challan Form No.32-A: State Bank of PakistanDocument1 pageChallan Form No.32-A: State Bank of PakistanZubair KhanNo ratings yet

- Felipe Prueba PresentDocument6 pagesFelipe Prueba PresentdarketaNo ratings yet

- Ten Essential Features of Academic WritingDocument2 pagesTen Essential Features of Academic WritingVita BonumNo ratings yet

- Convertible Note Agreement - SkillDzireDocument16 pagesConvertible Note Agreement - SkillDzireMAツVIcKYツNo ratings yet

- Sociology The Key Concepts PDFDocument5 pagesSociology The Key Concepts PDFneelamNo ratings yet

- KD 3Document9 pagesKD 3abu kahfNo ratings yet

- End Sem Problem Numbers EE-313 Modern Control EngineeringDocument3 pagesEnd Sem Problem Numbers EE-313 Modern Control EngineeringAyush Gupta 4-Year B.Tech. Electrical EngineeringNo ratings yet

- Gondwana Research: Susanne J.H. Buiter, Trond H. TorsvikDocument27 pagesGondwana Research: Susanne J.H. Buiter, Trond H. TorsvikJankoStankovicNo ratings yet

- What Is NSX-T ArchitectureDocument12 pagesWhat Is NSX-T Architecturemohamed100% (1)

- Developing Asp Net Core MVC Web Applications m20486 m20486 PDFDocument6 pagesDeveloping Asp Net Core MVC Web Applications m20486 m20486 PDFJose Augusto Tejada BarrantesNo ratings yet

- PenicillinDocument4 pagesPenicillinEms SekaiNo ratings yet

- Entrepreneurship Management (BBA 5TH SEM)Document3 pagesEntrepreneurship Management (BBA 5TH SEM)SHUVA_Msc IB83% (6)

Pat1 QP Regular 2023 24 Amp

Pat1 QP Regular 2023 24 Amp

Uploaded by

Nature BueatyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pat1 QP Regular 2023 24 Amp

Pat1 QP Regular 2023 24 Amp

Uploaded by

Nature BueatyCopyright:

Available Formats

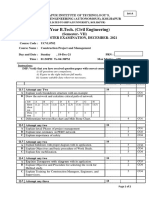

SNJB's Shri Hiralal Hastimal (Jain Brothers, Jalgaon) Polytechnic, Chandwad

(All AICTE Affiliated Programs NBA Accredited)

Academic Year 2023-2024 Odd Semester

PAT1 Offline Mode

Guidelines for setting Question paper

As per MSBTE guidelines, PAT 1 is to be conducted in offline mode during 17 to 19

October 2022

Refer MSBTE curriculum for Specification table for Question paper design

Refer MSBTE sample paper available online on MSBTE website.

Remember level- 30% ,Understand level: 35-40% , Application level- 30 to 40 %

Maximum Marks: 20 with option 26 or 28 or 32 marks

Write list of course outcomes to be considered for designing Question paper

Prepare Question paper specification table as per given format

List of Course Outcomes for PAT 1

CO No. CO Statement Marks out of

26 or 28 or 32 for PAT 1

CO a Maintain the Non-conventional machining process to 12

produce complex & hard to machine components.

CO b Produce components using milling machine. 12

CO c Choose relevant machining process to produce gears. 10

Question paper specification table (Sample)

Question CO No Distribution of Marks

No. R U A

Q.1 Attempt any FOUR (8Marks) 5-6 options

a CO1 02 ---- ----

b CO1 ---- 02 ----

c CO2 02 ---- ----

d CO2 ---- 02 ----

e CO3 02 ---- ----

f CO3 ---- 02 ----

Q.2 Attempt any THREE ( 12 Marks) 4 options

a CO1 ---- 04

b CO1 ---- ---- 04

c CO2 ---- ---- 04

d CO2 ---- 04 ----

e CO3 ---- ---- 04

Total 06 14 12

% 18.75% 43.75% 37.5%

Copy for record

SNJB's Shri Hiralal Hastimal (Jain Brothers, Jalgaon) Polytechnic, Chandwad

(All AICTE Affiliated Programs NBA Accredited)

Academic Year 2023-2024 Odd Semester

PAT 1 Question paper

Program Name: Mechanical Engineering

Program Code: ME

22563

Semester : Fifth

Course : Advanced Manufacturing Processes

Marks : 20

Instructions: All questions are compulsory

1. Illustrate your answers with sketches whenever necessary.

2. Figures to the right indicates full marks

3. Preferably, write the answers in sequential order.

4. Assume suitable data if necessary

Q.1 Attempt any FOUR ( 8 Marks)

CO1(R) a. Name the dielectric fluid used in EDM (any TWO)

CO1(U) b. Draw a working principle diagram of Abrasive Jet Machining.

CO2(R) c. State working principle of milling machine.

CO2(U) d. Classify indexing method

CO3(R) e. State the need of gear finishing process.

CO3(U) f. Classify the hobbing techniques

Q.2 Attempt any THREE ( 12 Marks)

CO1(U) a. Draw a neat sketch of wire cut EDM and label it.

CO1(A) b. Select appropriate non-traditional machining process for following product

applications

1) For cutting hot extrusion to desired length

2) Cutting of industrial diamonds

3) Machining of brittle materials like glass, ceramics, refractories etc.

4) Cutting or engraving patterns on thin films.

CO2(A) c. Select and apply indexing method to produce hexagonal nut.

CO2(U) d. Difference between conventional milling and climb milling.

CO3(A) e. Select and apply the gear shaping method to produce spur gears in which process

needs to be stopped to retract.

Sign of Course Teacher Sign of Moderator Sign of HO

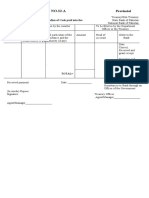

SNJB's Shri Hiralal Hastimal (Jain Brothers, Jalgaon) Polytechnic, Chandwad

(All AICTE Affiliated Programs NBA Accredited)

Academic Year 2023-2024 Odd semester

PAT 1 Question paper

Program Name: Mechanical Engineering

Program Code: ME

22563

Semester : Fifth

Course : Advanced Manufacturing Processes

Marks 20

Instructions: All questions are compulsory

1. Illustrate your answers with sketches whenever necessary.

2. Figures to the right indicates full marks

3. Preferably, write the answers in sequential order.

4. Assume suitable data if necessary

Q.1 Attempt any FOUR ( 8 Marks)

CO1(R) a. Name the dielectric fluid used in EDM (any TWO)

CO1(U) b. Draw a working principle diagram of Abrasive Jet Machining.

CO2(R) c. State working principle of milling machine.

CO2(U) d. Classify indexing method

CO3(R) e. State the need of gear finishing process.

CO3(U) f. Classify the hobbing techniques

Q.2 Attempt any THREE ( 12 Marks)

CO1(U) Draw a neat sketch of wire cut EDM and label it.

CO1(A) b. Select appropriate non-traditional machining process for following product applications

1) For cutting hot extrusion to desired length

2) Cutting of industrial diamonds

3) Machining of brittle materials like glass, ceramics, refractories etc.

4) Cutting or engraving patterns on thin films.

CO2(A) c. Select and apply indexing method to produce hexagonal nut.

CO2(U) d. Difference between conventional milling and climb milling.

CO3(A) e. Select and apply the gear shaping method to produce spur gears in which process

needs to be stopped to retract.

You might also like

- Assignment 3 Lessons From Derivatives MishapsDocument3 pagesAssignment 3 Lessons From Derivatives MishapsSandip Chovatiya100% (2)

- PAT1-CSS (22519) 2023-24 With Model AnsDocument7 pagesPAT1-CSS (22519) 2023-24 With Model AnsTejaswini NikamNo ratings yet

- Cadcam Model Question PaperDocument2 pagesCadcam Model Question PaperSelvaraj GNo ratings yet

- Btmpe703c 1 112321Document2 pagesBtmpe703c 1 112321AkashNo ratings yet

- CG Paper PUT - SECTION ADocument2 pagesCG Paper PUT - SECTION Akundan kumarNo ratings yet

- BTCS403 End Sem With CODocument4 pagesBTCS403 End Sem With COeverlovingmansiNo ratings yet

- MET385 - Ktu QbankDocument7 pagesMET385 - Ktu Qbankmohammedmaz0786No ratings yet

- Work-Shop-Technology - 3-5th Sem171753-Dec-2019Document2 pagesWork-Shop-Technology - 3-5th Sem171753-Dec-2019Neat & Clean ReviewNo ratings yet

- BMA302 - Computer Aided Design - B Tech ASE 5th SemDocument1 pageBMA302 - Computer Aided Design - B Tech ASE 5th SemArvind KatyayanNo ratings yet

- BDD 40103Document3 pagesBDD 40103zinilNo ratings yet

- CADMDocument3 pagesCADMSaravana Kumar MNo ratings yet

- Advanced Welding Technology EME022Document2 pagesAdvanced Welding Technology EME022Ratan Pal Singh YadavNo ratings yet

- Estimation Quantities and EsmationDocument5 pagesEstimation Quantities and EsmationNURUL MAISARAH MOHD YUSSOFNo ratings yet

- Zeal Polytechnic, Pune.: Third Year (Ty) Diploma in Mechanical Engineering Scheme: I Semester: VDocument20 pagesZeal Polytechnic, Pune.: Third Year (Ty) Diploma in Mechanical Engineering Scheme: I Semester: VOnkar TalekarNo ratings yet

- NSEC 2023 Set 31Document15 pagesNSEC 2023 Set 31Vishnu SinhaNo ratings yet

- Model CS3551 DC Set 2Document2 pagesModel CS3551 DC Set 2NambiRajaNo ratings yet

- ME204Document2 pagesME204raja93satNo ratings yet

- Cadcam Iat - 1 Question PaperDocument2 pagesCadcam Iat - 1 Question PaperSelvaraj GNo ratings yet

- Scheme - I Sample Question Paper: A) B) C) D) E)Document5 pagesScheme - I Sample Question Paper: A) B) C) D) E)Sdoo7No ratings yet

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecNo ratings yet

- CIE1 - QP-QCRE-Set1Document4 pagesCIE1 - QP-QCRE-Set1GunasekaranNo ratings yet

- Ppce Model QPDocument3 pagesPpce Model QParulsivagiriNo ratings yet

- First Series QPDocument2 pagesFirst Series QPMAHESWARY SREENATH ECNo ratings yet

- PPCE Model QP - 2Document2 pagesPPCE Model QP - 2arulsivagiriNo ratings yet

- Co1 (K) Co1 (K) Co2 (K) Co2 (K) Co2 (K) Co2 (K) Co3 (K) Co3 (K) Co4 (K) Co4 (K)Document2 pagesCo1 (K) Co1 (K) Co2 (K) Co2 (K) Co2 (K) Co2 (K) Co3 (K) Co3 (K) Co4 (K) Co4 (K)Murugesan kNo ratings yet

- Question Bank - Unit Test 1 Advanced Manufacturing Processes (22563)Document2 pagesQuestion Bank - Unit Test 1 Advanced Manufacturing Processes (22563)6403 Rohit Gaikwad0% (1)

- Sin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TDocument6 pagesSin Cos Cos Sin Cos Sin Cos Sin 2 Cos Sin Cos Sin 2 Sin Cos) (TBernice JohnsonNo ratings yet

- Wa0006.Document1 pageWa0006.rajashripatil1326No ratings yet

- MP 20Document2 pagesMP 20hkumarchauhan392No ratings yet

- Ucmp Model Set ADocument2 pagesUcmp Model Set ASAMUEL SANJAY RAJA R MECHNo ratings yet

- Winter 2020 AMIIW Question PapersDocument20 pagesWinter 2020 AMIIW Question PapersVigneshwaran VijayakumarNo ratings yet

- UCVL0702-SET-A Dec 2021Document2 pagesUCVL0702-SET-A Dec 2021Siddhi PatilNo ratings yet

- Cadcam Iat - 2 Question PaperDocument1 pageCadcam Iat - 2 Question PaperSelvaraj GNo ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- 16mec324 Cad Cam Cim Question BankDocument8 pages16mec324 Cad Cam Cim Question BankAbdalmalek ShamsanNo ratings yet

- Manufacturing ProcessesDocument4 pagesManufacturing ProcessesAmarjit KeneNo ratings yet

- Adobe Scan 17 Jun 2021Document3 pagesAdobe Scan 17 Jun 2021pNo ratings yet

- EST120 Basiccivil&mechanical PDFDocument12 pagesEST120 Basiccivil&mechanical PDFlecim12450No ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- EST120 Basic - Civil - & - Mechanical PDFDocument12 pagesEST120 Basic - Civil - & - Mechanical PDFlecim12450No ratings yet

- Basics of Civil & Mechanical EngineeringDocument123 pagesBasics of Civil & Mechanical Engineeringfebin philipNo ratings yet

- Chem PT PapersDocument3 pagesChem PT Papersrounitmakheja5No ratings yet

- PCB Design QPDocument3 pagesPCB Design QPvcetnaac c6No ratings yet

- Dr. N.G.P. Institute of TechnologyDocument1 pageDr. N.G.P. Institute of TechnologyVasanth KumarNo ratings yet

- CSE PUT Paper MicroprocessorDocument3 pagesCSE PUT Paper Microprocessorrachit koundalNo ratings yet

- 22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Document4 pages22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Roshan Kinholkar100% (1)

- Essay QuestionDocument4 pagesEssay QuestionAnnaIzzatNo ratings yet

- Design Lab Manual GLA NEWDocument36 pagesDesign Lab Manual GLA NEWFirst LastNo ratings yet

- Cel XDocument116 pagesCel Xxae778899No ratings yet

- College ConstructionDocument23 pagesCollege Constructionkailassonawane157No ratings yet

- Universiti Tun Hussein Onn Malaysia: ConfidentialDocument3 pagesUniversiti Tun Hussein Onn Malaysia: ConfidentialStudiePurposeNo ratings yet

- Cadm - Set 2Document4 pagesCadm - Set 2Saravana Kumar MNo ratings yet

- Blob:https:/web Whatsapp ComDocument2 pagesBlob:https:/web Whatsapp ComShanu RawNo ratings yet

- 1718sem1 Me5608Document4 pages1718sem1 Me5608Benedict ChinNo ratings yet

- Mahendra Engineering College) : Continuous Assessment Test - II - Aug - 2019Document2 pagesMahendra Engineering College) : Continuous Assessment Test - II - Aug - 2019Gowri ShankarNo ratings yet

- CSE313Document2 pagesCSE313Damodharan DNo ratings yet

- Summer 2021 AMIIW Question PapersDocument32 pagesSummer 2021 AMIIW Question PapersRiyaz AhmedNo ratings yet

- PTAM University Question PapersDocument6 pagesPTAM University Question PapersAMRISHRAJNo ratings yet

- Transportation EnggDocument3 pagesTransportation EnggUzair KhanNo ratings yet

- Compulsory Sl. No. Questions Marks Co PoDocument1 pageCompulsory Sl. No. Questions Marks Co PoAll_regNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- 20 BCD7263 Sam AltmanDocument32 pages20 BCD7263 Sam Altmananunay.20bcd7263No ratings yet

- Hd-010B Digital Drum: User'S ManualDocument37 pagesHd-010B Digital Drum: User'S Manualjavier_khanNo ratings yet

- Lesson 02 Interview EnglishDocument12 pagesLesson 02 Interview EnglishTang Bui100% (1)

- 2020 8th PEC BahawalpurDocument301 pages2020 8th PEC BahawalpurFast ComputersNo ratings yet

- Jose Rizal's Life, Works and Studies in Europe (Part 1)Document5 pagesJose Rizal's Life, Works and Studies in Europe (Part 1)Russen Belen50% (2)

- Ae112 NotesDocument3 pagesAe112 NotesJillian Shaindy BuyaganNo ratings yet

- Veeam One 10 0 Alarms Guide PDFDocument207 pagesVeeam One 10 0 Alarms Guide PDFBack Office ScannerNo ratings yet

- YAMAHA P121 SmartPianist - Specification - For202101Document2 pagesYAMAHA P121 SmartPianist - Specification - For202101Romélio LustozaNo ratings yet

- Engleski In%C5%BEenjerski%20menad%C5%BEment%20 (OAS) PDFDocument384 pagesEngleski In%C5%BEenjerski%20menad%C5%BEment%20 (OAS) PDFHarini SreedharanNo ratings yet

- Modulo 1 InglesDocument100 pagesModulo 1 Ingleselsa dimas100% (2)

- Learning Activity Sheets Grade 10 - MathematicsDocument4 pagesLearning Activity Sheets Grade 10 - MathematicsMarvin Torre50% (2)

- 03 Worksheet2Document2 pages03 Worksheet2Murielle FajardoNo ratings yet

- Vicarious Liability of StateDocument3 pagesVicarious Liability of StateChitraksh MahajanNo ratings yet

- About Gazi Auto BrickDocument19 pagesAbout Gazi Auto BrickMd. Reza-Ul- HabibNo ratings yet

- Capability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IDocument12 pagesCapability List Document: Document QA-TCL FAA Approved Repair Station TAMY352IAlphard DarmawanNo ratings yet

- Sharjaa CarbonatesDocument190 pagesSharjaa CarbonatesRuben PradaNo ratings yet

- Challan Form No.32-A: State Bank of PakistanDocument1 pageChallan Form No.32-A: State Bank of PakistanZubair KhanNo ratings yet

- Felipe Prueba PresentDocument6 pagesFelipe Prueba PresentdarketaNo ratings yet

- Ten Essential Features of Academic WritingDocument2 pagesTen Essential Features of Academic WritingVita BonumNo ratings yet

- Convertible Note Agreement - SkillDzireDocument16 pagesConvertible Note Agreement - SkillDzireMAツVIcKYツNo ratings yet

- Sociology The Key Concepts PDFDocument5 pagesSociology The Key Concepts PDFneelamNo ratings yet

- KD 3Document9 pagesKD 3abu kahfNo ratings yet

- End Sem Problem Numbers EE-313 Modern Control EngineeringDocument3 pagesEnd Sem Problem Numbers EE-313 Modern Control EngineeringAyush Gupta 4-Year B.Tech. Electrical EngineeringNo ratings yet

- Gondwana Research: Susanne J.H. Buiter, Trond H. TorsvikDocument27 pagesGondwana Research: Susanne J.H. Buiter, Trond H. TorsvikJankoStankovicNo ratings yet

- What Is NSX-T ArchitectureDocument12 pagesWhat Is NSX-T Architecturemohamed100% (1)

- Developing Asp Net Core MVC Web Applications m20486 m20486 PDFDocument6 pagesDeveloping Asp Net Core MVC Web Applications m20486 m20486 PDFJose Augusto Tejada BarrantesNo ratings yet

- PenicillinDocument4 pagesPenicillinEms SekaiNo ratings yet

- Entrepreneurship Management (BBA 5TH SEM)Document3 pagesEntrepreneurship Management (BBA 5TH SEM)SHUVA_Msc IB83% (6)