Professional Documents

Culture Documents

IDAX-Monitoring UG en

IDAX-Monitoring UG en

Uploaded by

Nisal AmarasingheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IDAX-Monitoring UG en

IDAX-Monitoring UG en

Uploaded by

Nisal AmarasingheCopyright:

Available Formats

IDAX Monitoring

SW to monitor processes using

Dielectric Frequency Response

User’s Manual

WWW.MEGGER.COM

Art No. ZP-AG02E Doc. AG033573AE V01a 2017

IDAX Monitoring

SW to monitor processes using

Dielectric Frequency Response

User’s Manual

NOTICE OF COPYRIGHT & PROPRIETARY RIGHTS

© 2016, Megger Sweden AB. All rights reserved.

The contents of this manual are the property of Megger Sweden AB. No part of this work may be reproduced or transmitted in any form or

by any means, except as permitted in written license agreement with Megger Sweden AB. Megger Sweden AB has made every reasonable

attempt to ensure the completeness and accuracy of this document. However, the information contained in this manual is subject to change

without notice, and does not represent a commitment on the part of Megger Sweden AB. Any attached hardware schematics and technical

descriptions, or software listings that disclose source code, are for informational purposes only. Reproduction in whole or in part to create

working hardware or software for other than Megger Sweden AB products is strictly prohibited, except as permitted by written license

agreement with Megger Sweden AB.

TRADEMARK NOTICES

Megger® and Programma® are trademarks registered in the U.S. and other countries. All other brand and product names mentioned in this

document are trademarks or registered trademarks of their respective companies.

Megger Sweden AB is certified according to ISO 9001 and 14001.

Postal address: Visiting address:

Megger Sweden AB Megger Sweden AB

Box 724 Rinkebyvägen 19

SE-182 17 DANDERYD SE-182 36 DANDERYD

SWEDEN SWEDEN

T +46 8 510 195 00 seinfo@megger.com

F +46 8 510 195 95 www.megger.com

AG033573AE ZP-AG02E IDAX Monitoring 3

Contents

1 Introduction

................................................................ 6

Software Installation...........................................6

2 Getting Started

................................................................ 8

3 Sample connection

.............................................................. 10

Oven bushings and high temperature coaxial cables... 10

4 Sweep and temperature settings....... 12

4.1 Overview....................................................12

4.2 Sweep........................................................13

4.3 Temperature...............................................13

Automatic entry......................................................... 13

Manual entry............................................................. 13

Loading a temperature profile.................................... 14

5 Export and Report

.............................................................. 16

5.1 Export and report........................................16

Design a personalized report...................................... 16

5.2 Settings......................................................17

5 Appendix A

.............................................................. 18

Individual Temperature Correction (ITC).............18

4 IDAX Monitoring ZP-AG02E AG033573AE

AG033573AE ZP-AG02E IDAX Monitoring 5

1 Introduction

1 Introduction

IDAX Monitoring is an additional feature to IDAX 5.0

SW to make it possible use a IDAX 300 to monitor

Software Installation

processes using DFR (Dielectric Frequency Response). Monitoring functionality is installed during installation

Examples of processes to be monitored are: of IDAX 5.0 software, but it is disabled by default. In

order to enable this functionality a licence code must

▪▪Dry-outs, reduction of moisture content, of un- be obtained.

impregnated as well as impregnated cellulose in

e.g. power transformers. For such processes ITC Monitoring functionality can be activated by entering

(Individual Temperature Corrected) dissipation factor user name and corresponding activation code.

are most commonly used

▪▪Impregnation, e.g. impregnation of dry cellulose

with insulation liquids or resins. For such processes

ITC (individual Temperature Corrected) capacitance

may be used; however, be aware of that

temperature change the geometry and the effect of

geometry is not corrected in the ITC.

▪▪Curing of resins. Curing status strongly affect the

dielectric properties of the insulation material and

therefore monitor of such process is possible. See

e.g. “Analysis of Dielectric Response Measurement

Methods and Dielectric Properties of Resin-Rich

Insulation During Processing” by Anders Helgeson

IDAX Monitoring can be used in factory environment

as well as in the field.

The connection to a PC or other intelligent system

is the same as for IDAX via the USB port and/or the

Ethernet port on the IDAX front panel.

The IDAX may be connected to the PC or other

intelligent system operation, however, you may

disconnect and reconnect at a later occasion during

the monitoring process. Then IDAX Monitoring SW

automatically collect all data points collected.

6 IDAX Monitoring ZP-AG02E AG033573AE

1 Introduction

AG033573AE ZP-AG02E IDAX Monitoring 7

2 Getting Started

2 Getting Started

This section provides a step-by-step instruction. Important

“Monitor” has inherited most of func-

1] Start the IDAX 5.0 SW.

tionality from “Moisture” and therefore

SW will appear similar to picture below.

“Test Objects” available is limited to those

2] All data will always be saved in a file, there- currently available in “Moisture”, and

fore, you should press the “New File” button only one “Test Mode” per test is allowed.

(right-hand side). For monitoring, UST configuration is

strongly recommended and therefore

the “Two Winding Transformer” with

“Test Mode” CHL (UST-R) can be used for

almost all samples (if a GST measurement

is required, select e.g. “Auto Transformer

Without Tertiary”).

4] Select “Test Object” (normally Two Winding

Transformer even if you intend monitoring a

current transformer, bushing etc.).

5] Enter temperatures into compulsory fields

“Ambient Temperature” and “Object Tem-

perature”, e.g. 22C. These two fields are

3] Then the “Create a New File” window will

there as inherited from “Moisture”, these

appear, defaulted to “Moisture”. Press the

values will not be used in the Monitoring

“Monitor” tab. For more information by

function.

“Moisture”/”DFR”/”%DF/%PF/”DC” and

the tabs “Single Test”/”Multiple Tests/”Use 6] Enter other fields if you need information (or

Measurement as Template”, see IDAX User’s add information to nameplate later).

manual. 7] Press “Create”.

8] Save the “File” at location of your choice

8 IDAX Monitoring ZP-AG02E AG033573AE

2 Getting Started

Act. Energy Activation Energy used for ITC tem-

perature correction. Incorrect values

scale data slightly incorrect but has

limited impact as long as Reference

temperature is not too far from actual

measurement temperature. Typical

values (Cellulose means pressboard,

Kraft paper or Crepe paper):

9] Now, you have a “Test” (labeled CHL, upper, ▪▪Oil-impregnated cellulose,

left-hand side of window) that can be run -20-80°C: 0.9 eV

(after connected to IDAX and start by press ▪▪Non-impregnated cellulose,

“Start” button in lower right-hand side cor- >80°C: 1.0 eV

ner Temperature Reference temperature for ITC

Moisture Select a database (Default or other,

to be modified in Settings tab), and

Moisture is plotted. Note that in

case Moisture is selected, Activation

energy and (reference) Temperature

is fixed to value determined by the

selected database

In lower part of right-hand side, it is a section labeled

“Settings” that display part of settings for the test:

Stop Lowest frequency to be used in DFR

frequency sweep of the full sweep defined on

settings tab (see section Settings tab).

You may change “Stop frequency” in

drop down list.

Test mode By clicking this button you see the

basic connection diagram.

Voltage Applied voltage level. You may use

(RMS) any voltage level, however, if you

use voltage level below 7 Vrms (10 V

peak), you preferable change from

200 V peak amplifier to 10 V peak

amplifier on Settings page (may be

advisable measuring under Vapor

Phase conditions).

AG033573AE ZP-AG02E IDAX Monitoring 9

3 Sample connection

3 Sample connection

This section provides a step-by-step instruction on

how to connect the test specimen.

1] Start the IDAX 5.0 SW.

2] All data will always be saved in a file, there-

fore, you start by press “New File” button.

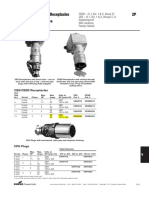

Oven bushings and high

temperature coaxial cables

A common application of IDAX Monitoring is monitor

sample during processing in a climate chamber, e.g.

oven drying or Vapor Phase drying. In this case, bush-

ings for bringing cables into the chamber are neces-

sary and often also special high-temperature cables,

which does not get damaged by high temperatures

and kerosene. There are different types of connectors

and cables on the market that will work for this

application, description below will act as example.

BNC-connectors:

▪▪BNC Adapter, female/female: Rosenberger 51K501-

K00N4

▪▪High temperature cable: PRO POWER, RG142

Coaxial Cable, RG142, 50 ohm, order code

2064894

▪▪BNC connector (fit to cable above): Rosenberger

51S107-108N5

10 IDAX Monitoring ZP-AG02E AG033573AE

3 Sample connection

AG033573AE ZP-AG02E IDAX Monitoring 11

4 Sweep and temperature

settings

4.1 Overview Moisture By select a database, you activate

Moisture assessment based on table

In the Overview tab, the measurement results as

database selected (see Settings page).

function of time are presented.

Inactivate the function by selecting

Note One or more parameters (e.g. %DF) to be “None”. If a database is selected,

plotted need to be activated; otherwise the Frequency (Hz), Act Energy (eV) and

graph will be empty. Temperature (°C) are set to fixed val-

ues determined by database selected.

The parameters buttons (below the graph) are:

%M The moisture content in % based on Moisture

assessment table: Left-hand side axis

°C The temperature in degree Celsius; Left-hand

side axis

C Capacitance in Farad; Right-hand side Y-axis

C’’ Complex part of complex capacitance

(Impedance Z = 1/(j*2*pi*frequency*(C-jC’’))

%DF Dissipation factor*100 = Loss current*100 /

Capacitive current = C’’*100/C

%PF Power factor*100 = Loss current*100/Total

current = C’’*100/(sqrt(C’’^2+C^2))

Based on settings of “Settings” (lower part of right-

hand section of window) the frequency sweep data

are plotted differently:

Frequency Frequency for data to be plotted

(Hz)

Act. Energy Activation energy if ITC temperature

(eV) correction is enabled

Temperature By select a temperature you activate

(°C) ITC temperature correction to selected

temperature (otherwise, select None)

12 IDAX Monitoring ZP-AG02E AG033573AE

4 Sweep and temperature settings

4.2 Sweep 4.3 Temperature

In the Sweep tab, the measurement sweeps are In the temperature tab, the measurement tempera-

presented. At left-hand side the frequency sweeps are tures are presented. At left-hand side the temperature

listed labeled with Date+Time. labeled with Date+Time is listed (format according to

computer settings) at the right hand the temperature

Note One or more parameters (e.g. C and %DF) to at the specific time.

be plotted need to be activated; otherwise the

graph will be empty.

Automatic entry

The parameters buttons (below the graph) are: Measurement temperatures may be read using

C Capacitance in Farad; Right-hand side Y-axis either automatic logging device (default) or logfile.

C’’ Complex part of complex capacitance Automatic logger use Modbus data interface and is

(Impedance Z = 1/(j*2*pi*frequency*(C-jC’’)) connected via LAN (Ethernet). In order to use it the

%DF Dissipation factor*100 = Loss current*100 / IP address or hostname must be entered in the field

Capacitive current = C’’*100/C “IP / Hostname”

%PF Power factor*100 = Loss current*100/Total

current = C’’*100/(sqrt(C’’^2+C^2))

You may change interval at which data are read and

saved. It must be verified with specifications of log-

ging device if other parameters need to be changed in

case different logger than Querx-PT100 is used.

Use any compatible temperature logger with Modbus

TCP interface.

Manual entry

▪▪Press “Add” button to enter temperature manually.

▪▪To delete a temperature data point, press “Del”.

▪▪Delete all data points by pressing “Clear”.

▪▪Load temperature data points by pressing the

“Load” button (more information about “Load” see

section “Loading a temperature profile” below).

▪▪The “Edit” function is activated by double-clicking

on a temperature in the list.

The data points are automatically sorted by date/time

and extrapolated before after covered times (using

AG033573AE ZP-AG02E IDAX Monitoring 13

4 Sweep and temperature settings

two last data points if more than one data point).

If you need two constant temperatures, e.g. 100°C

and 120°C use 4 data points (two at 100°C and 2 at

120°C).

Note If no temperature is entered “Ambient Tem-

perature” from Nameplate is used.

Loading a temperature profile

It is also possible to load a complete temperature

profile. The file should be semicolon separated *.csv

with the following format:

YYYY-MM-DD HH:MM;Temperature

Example

YYYY-MM-DD HH:MM;Temperature

can be:

2013-09-19 09:42;21,5

The first row means 19th (19) September (09) 2013,

at 09:42 (24h syntax). Temperature in degree Celsius

is shown after the semicolon.

1] By pressing “Load” button, an Open dialog

window will appear showing all files with

extension “.csv”.

The “Load” function accepts both point and

comma as decimal separator.

Note By changing view to show all files “*.*” it is

possible to show files created e.g. as *.txt

14 IDAX Monitoring ZP-AG02E AG033573AE

4 Sweep and temperature settings

AG033573AE ZP-AG02E IDAX Monitoring 15

5 Export and Report

5 Export and Report

5.1 Export and report

1] Press the “Export” button to export all meas-

urement data into a *.txt-file

2] Pressing the “Report” button connects data

to Microsoft Word and opens a report dialog

where pre-defined report templates are

available.

3] Select “Monitor_Example_A4” and press

3] Below you see the data “Overview (picture)”

“Generate”.

that earlier was placed under the Overview

name. By delete the square (the overview

picture from template) and then drag-and-

drop e.g. Sweep (Picture) to same location,

you have changed the template.

Note All graphs/pictures will be in report as in SW,

if you have enabled only %DF in Overview

graph, only %DF will be present in Overview

graph in report.

4] Save it under a new name that will appear

under Template next time you press “Report”

Design a personalized report button.

The most simple way of designing a personalized

report template is to select an existing template and

then modify it.

Example

1] Select “Monitor_Example_A4”.

2] Press “Modify”.

The “Monitor_Example_A4” report can now

be modified under “File”.

You may design the report using normal

Word functionality and “drag-and-drop”

data from the legend on left-hand side of

report generator.

16 IDAX Monitoring ZP-AG02E AG033573AE

5 Export and Report

5.2 Settings ▪▪At left hand-side, bottom section, you may add

a new table “New”, delete an exciting table

“Remove” or “Import” a table into the SW (e.g.

created by another SW installation).

Export is available from bottom part of table (right-

hand side).

▪▪“Moisture Table” is the actual table selected

• Name is simply the name.

• Frequency affects the relation between dissipation

factor and moisture, therefore the frequency for the

table need to be stated.

• Temperature affects the relation between dissipation

factor and moisture, therefore the frequency for the

table need to be stated.

The Settings Tab looks similar to standard IDAX SW,

described in IDAX User’s manual. • Activation energy for the material assessed affects

In bottom, middle, part of the window a section labe- the ITC correction and therefore it need to be stated

led Monitoring is added with the following functions: (estimated).

• The table is the relation between %DF (dissipation

Sleep Time: (Default 15 minutes) factor/100) and moisture content. Values between

After a measurement is completed, the system waits points are interpolated using Log(%DF) and

(sleep) for the selected time before next measurement Log(Moisture%) and extrapolated from two last points

is started. If a frequency sweep takes about 5 minutes outside covered range.

to perform (1 kHz to 10 mHz, single frequency meas- Delete data pair by pressing the red “X”

urements) and sleep time is 15 minutes you will get a Add new data pair by pressing the green “Add” button.

new sweep every 20 minutes. Selectable alternatives Press “Save” to save the data table.

are none, 5, 10, 15, 20, 30, 60 or 120 minutes. Press“Export” of table, to be stored or imported by

other used.

Time Format: (Default “Process Time”) Edit assessment limits

Each DFR sweep has a Date+Time stamp (when it starts) Assessment limits for %DF, %PF and Moisture can be

and each temperature also has a date+Time stamp. adjusted to suit particular requirements. These limits

You can select if data should be plotted with X-axis are applicable only to measurements during monitor-

set as Date+Time (Computer time) or if time = 0 is set ing process.

at start of first measurement sweep (Process time).

Edit Ranges (screen shot below)

A moisture table may be selected which maps an ITC

corrected dissipation factor at a certain frequency to a

moisture content.

▪▪At left hand side you have available tables.

The “Default” table comes with installation.

AG033573AE ZP-AG02E IDAX Monitoring 17

5 Appendix A

5 Appendix A

Individual Temperature

Correction (ITC)

An important property on most insulation materials is

the possibility makes a master curve from a set of DFR

data obtained at different insulation temperatures [1].

10

DF at 20C

DF at 40C

DF at 60C

DF at 80C

1

Dissipation factor

Figure 2. Master curve at 20°C, dry Kraft paper

0,1

Since the master curve now describe the relation

between frequency and temperature, dielectric

0,01 parameters such as the dissipation factor (DF) at 50

Hz can now be plotted as function of temperature [2].

See Figure 3.

0,001

0,001 0,01 0,1 1 10 100 1000

Frequency, [Hz] This technique is used to establish individual

Figure 1. DFR of dry mass-impregnated Kraft paper at differ- temperature correction factors (ITC) [3] to correct

ent temperatures. measurements performed at a higher, or lower, than a

reference temperature of e.g. 20°C.

To create a master curve, you prepare the insulation

sample and measure the sample at different temper- For example if measure the DF at 50 Hz of the

atures while making sure that other entities such as insulation material in Figure 1-3 at 40°C, the DF is

moisture content is kept constant. See Figure 1. The about 0,004 or 0,4%, see figure 1 (or Figure 3). By

temperatures in Figure 1 are 20°C (blue, lowest dis- measure a frequency sweep and plot it as function of

sipation factor at 1 Hz), 40°C (green), 60°C (orange) temperature, the estimated dissipation factor at 20°C

and 80°C (red, highest dissipation factor at 1 Hz). is about 0,005 (0,5%).

The curves are then shifted in frequency by using

Arrhenius equation with activation energy as a single

parameter and temperature as variable. Figure 2 show

the master curve created from measurement data in

Figure 1. The activation energy is 0.9 eV.

Figure 3. DF at 50 Hz as function of temperature (°C)

A similar application is to estimate the DF at a high

operating temperature based on a measurement at

ambient temperature. In Figure 4, the DF as function

of frequency is measured on an about 100 m oil-filled

400 kV cable at about 20°C; the cable connects a

Generator Step-Up transformer to the substation.

18 IDAX Monitoring ZP-AG02E AG033573AE

5 Appendix A

REFERENCES

[1] U Gafvert, “Condition Assessment of Insulation

Systems, Analysis of Dielectric Response Methods, NORD-IS

1996

[2] ITC patent. US2010/0106435 A1

[3] M Ohlen et al, Dielectric frequency response and

temperature dependence of dissipation factor, TechCon

Asia Pacific, Australia, 2009

Figure 4. DF as function of frequency for an oil-filled 400 kV

cable

The DF is high, about 0,01 (1%) at 50 Hz but is it

critical or not? By looking at the 50 Hz DF as function

of temperature, see Figure 5, heat dissipation cal-

culations showed that the if DF at 60-80°C is above

about 10%, there is a large risk of a thermal runaway

breakdown. The cable was replaced prior any failure.

Figure 5. DF at 50 Hz as function of temperature. Data from

figure 4.

Other examples are when evaluating new of modified

insulation materials. A manufacturer of Kraft papers

for bushings was evaluating different modifications

in order to lower the DF. The new material had

significantly lower DF at 20 °C, however, DFR meas-

urement showed increase loss at lower frequencies

and consequently, the 50 Hz DF was higher at 90°C

compared to the original bushing paper.

AG033573AE ZP-AG02E IDAX Monitoring 19

Your “One Stop” Source for all your electrical test equipment needs

▪▪Battery Test Equipment Megger is a leading global manufacturer and supplier

▪▪Cable Fault Locating Equipment of test and measurement instruments used within the

electric power, building wiring and telecommunication

▪▪Circuit Breaker Test Equipment

industries.

▪▪Data Communications Test Equipment

With research, engineering and manufacturing facilities

▪▪Fiber Optic Test Equipment in the USA, UK, Germany and Sweden, combined with

▪▪Ground Resistance Test Equipment sales and technical support in most countries, Megger

is uniquely placed to meet the needs of its customers

▪▪Insulation Power Factor (C&DF) Test Equipment worldwide.

▪▪Insulation Resistance Test Equipment

Megger is certified according to ISO 9001 and 14001.

▪▪Line Testing Equipment Megger is a registered trademark.

▪▪Low Resistance Ohmmeters

▪▪Motor & Phase Rotation Test Equipment

▪▪Multimeters

Megger Group Limited

▪▪Oil Test Equipment UNITED KINGDOM

Dover, Kent CT17 9EN

▪▪Portable Appliance & Tool Testers ENGLAND

▪▪Power Quality Instruments ▪▪AUSTRALIA ▪▪POLAND

▪▪BULGARIA ▪▪ROMANIA

▪▪Recloser Test Equipment ▪▪CANADA ▪▪RUSSIA

▪▪Relay Test Equipment ▪▪CZECH REPUBLIC ▪▪SINGAPORE

▪▪CHINA ▪▪SLOVAK REPUBLIC

▪▪T1 Network Test Equipment

▪▪FRANCE ▪▪SOUTH AFRICA

▪▪Tachometers & Speed Measuring Instruments ▪▪GERMANY ▪▪SPAIN

▪▪TDR Test Equipment ▪▪HUNGARY ▪▪SWEDEN

▪▪INDIA ▪▪SWITZERLAND

▪▪Transformer Test Equipment ▪▪INDONESIA ▪▪TAIWAN

▪▪Transmission Impairment Test Equipment ▪▪KINGDOM OF BAHRAIN ▪▪THAILAND

▪▪KOREA ▪▪UNITED ARAB EMIRATES

▪▪Watthour Meter Test Equipment

▪▪MALAYSIA ▪▪USA

▪▪STATES® Terminal Blocks & Test Switches ▪▪PAKISTAN ▪▪VIETNAM

▪▪Professional Hands-On Technical and ▪▪PHILIPPINES

Safety Training Programs

WWW.MEGGER.COM

Postal address: Visiting address:

Megger Sweden AB Megger Sweden AB

Box 724 Rinkebyvägen 19

SE-182 17 DANDERYD SE-182 36 DANDERYD

SWEDEN SWEDEN

T +46 8 510 195 00 seinfo@megger.com

F +46 8 510 195 95 www.megger.com

Subject to change without notice. Printed matter No. ZP-AG02E Doc. AG033573AE V01a 2017

You might also like

- TN500 - Using Old and New Alarm Data From WWALMDBDocument7 pagesTN500 - Using Old and New Alarm Data From WWALMDBtuandanhbk10No ratings yet

- Qubino ZW+ Safety ReportDocument21 pagesQubino ZW+ Safety ReportpaulNo ratings yet

- TempSen Tempod User ManualDocument23 pagesTempSen Tempod User Manualalbarokatur rizkyNo ratings yet

- Product User Guide: Cryo-TempDocument2 pagesProduct User Guide: Cryo-TempMauren Lorena Aullon SuarezNo ratings yet

- Manual Idax Support MIX 090608Document8 pagesManual Idax Support MIX 090608Felipe FlorezNo ratings yet

- CryoTemp-MadgeTech Product User GuideDocument2 pagesCryoTemp-MadgeTech Product User GuideBrayan Camilo SdvsfNo ratings yet

- Testo 557 ManualDocument26 pagesTesto 557 ManualInstalatiiGeneraleNo ratings yet

- Product User Guide: Vaccine Temperature Monitoring SystemDocument9 pagesProduct User Guide: Vaccine Temperature Monitoring SystemSlavaNo ratings yet

- Temperature Control and Data Acquisition Method For Factory Using LabviewDocument14 pagesTemperature Control and Data Acquisition Method For Factory Using LabviewIAEME PublicationNo ratings yet

- 0252.090 Rev. A English 0252 Configuration ToolDocument12 pages0252.090 Rev. A English 0252 Configuration ToolOwais JafriNo ratings yet

- Ijtag Embedded Instrument ADC Xilinx SYSMONDocument11 pagesIjtag Embedded Instrument ADC Xilinx SYSMONMoni QueNo ratings yet

- An Intelligent Architecture For Industrial Automation Using RTOS TechnologyDocument6 pagesAn Intelligent Architecture For Industrial Automation Using RTOS TechnologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- PC-Lab2000: Software For Velleman PC Peripherals: PCS500 / PCS100 / K8031 / PCG10 / K8016Document12 pagesPC-Lab2000: Software For Velleman PC Peripherals: PCS500 / PCS100 / K8031 / PCG10 / K8016nihilistu12No ratings yet

- Vm1118 Vertiv Geist Watchdog 100 ManualDocument42 pagesVm1118 Vertiv Geist Watchdog 100 ManualAnderson Joel Navarro YarlequeNo ratings yet

- Pr1000is PugDocument4 pagesPr1000is Pugfranco bejaranoNo ratings yet

- Application Guide Over-Current Protection TutorialDocument37 pagesApplication Guide Over-Current Protection Tutorialluhusapa-1No ratings yet

- 20 - HW + SW InstallationDocument15 pages20 - HW + SW Installationdavid_gdsbsNo ratings yet

- Agfa Drystar 5500 Image Printer - Software UpgradeDocument20 pagesAgfa Drystar 5500 Image Printer - Software Upgradeelom djadoo-ananiNo ratings yet

- 20 - Instalacion HW y SoftwareDocument15 pages20 - Instalacion HW y Softwarevictor.ciudad.carpelNo ratings yet

- TCP/IP PLC Simulator User Guide IGSS Version 10.0Document16 pagesTCP/IP PLC Simulator User Guide IGSS Version 10.0IosifCornelNo ratings yet

- STULZ WIB8000 G67C 1118 enDocument52 pagesSTULZ WIB8000 G67C 1118 enOctavio Farid Rossi YumhaNo ratings yet

- MT 512riplusDocument2 pagesMT 512riplusAlex PullaNo ratings yet

- Distance TutorialDocument30 pagesDistance TutorialBaiceanu Florin100% (1)

- Project ReportDocument24 pagesProject ReporthoodychanNo ratings yet

- ObjectiveDocument6 pagesObjectiveFlorin ZahariaNo ratings yet

- STG 1608Document18 pagesSTG 1608Scott CaoNo ratings yet

- Marl Sop For XRDDocument7 pagesMarl Sop For XRDAbdul ArifNo ratings yet

- Magnetrol Eclipse 700 Instrukcja HART enDocument92 pagesMagnetrol Eclipse 700 Instrukcja HART enjai5hanka6No ratings yet

- Eclipse®: Installation & Maintenance InstructionsDocument69 pagesEclipse®: Installation & Maintenance InstructionsKarim AhmedNo ratings yet

- Overheat Detector 53-59-60Document23 pagesOverheat Detector 53-59-60anushka aroraNo ratings yet

- User Manual-SRD-1694,1685-ENGLISH - Web-0519Document148 pagesUser Manual-SRD-1694,1685-ENGLISH - Web-0519Thanh Kieu TienNo ratings yet

- 7272 - All Active Solutions: September 2007Document84 pages7272 - All Active Solutions: September 2007Taseer IqbalNo ratings yet

- DNP3 8600Document19 pagesDNP3 8600Felipe Acevedo ValdesNo ratings yet

- Comparison of Internal and External Watchdog TimersDocument4 pagesComparison of Internal and External Watchdog TimersN SUJENDRANo ratings yet

- GY-271 Compass Magnetic Module ENGDocument32 pagesGY-271 Compass Magnetic Module ENGeasy labNo ratings yet

- LOGO Set9 Master Slave enDocument14 pagesLOGO Set9 Master Slave enTagno Miguel MacedoNo ratings yet

- Digitilt DatamateDocument19 pagesDigitilt DatamateLawrence Martin LausNo ratings yet

- G190ean01 0Document28 pagesG190ean01 0kalanghoNo ratings yet

- DALOG BusyBee MKM Viewer ManualDocument16 pagesDALOG BusyBee MKM Viewer ManualGilberto PérezNo ratings yet

- NI PXIe-6544 - Getting Starter GuideDocument20 pagesNI PXIe-6544 - Getting Starter Guide차지형No ratings yet

- Outdoor High-Security Digital Motion Detector: Installation GuideDocument36 pagesOutdoor High-Security Digital Motion Detector: Installation GuideMetalurgica VISILUNo ratings yet

- Ajay D - (MC & MP ASSIGN)Document7 pagesAjay D - (MC & MP ASSIGN)Viswanath K ReddyNo ratings yet

- Gtwk3 Help Got2000 eDocument2,916 pagesGtwk3 Help Got2000 eFlávio Henrique VicenteNo ratings yet

- SOP SDT Discovery 650 (July 17 2019)Document11 pagesSOP SDT Discovery 650 (July 17 2019)Silvina RamosNo ratings yet

- Photo Stability Chamber With Temperature and Humidity Control ManufacturersDocument3 pagesPhoto Stability Chamber With Temperature and Humidity Control Manufacturersjames smithNo ratings yet

- Procedure For Realdisp5Document10 pagesProcedure For Realdisp5ridhwan wahyudiNo ratings yet

- Nirs DS2500 Analyzer: ManualDocument54 pagesNirs DS2500 Analyzer: Manualedward tagarinoNo ratings yet

- Cryotemp: Product User GuideDocument4 pagesCryotemp: Product User GuideSlavaNo ratings yet

- Tessent Integrated Flow Lab2 IJTAG Introduction Ex2-3Document23 pagesTessent Integrated Flow Lab2 IJTAG Introduction Ex2-3Bryan FallasNo ratings yet

- Communication and Data Saving From Zelio REG Controller With A Hmi ?Document9 pagesCommunication and Data Saving From Zelio REG Controller With A Hmi ?Juan LivingstonNo ratings yet

- GOT1000 Quick Start GuideDocument56 pagesGOT1000 Quick Start GuideTetsusaigaNo ratings yet

- DTU User ManualDocument24 pagesDTU User ManualSunil SinghNo ratings yet

- User Manual: Product: Tempmate.®-M1 Data Logger Scope: Operations InstructionsDocument6 pagesUser Manual: Product: Tempmate.®-M1 Data Logger Scope: Operations InstructionsAbdalhakeem AlturkyNo ratings yet

- Home Monitoring/Automation System Using WSN by IotDocument21 pagesHome Monitoring/Automation System Using WSN by IotHarish KhanNo ratings yet

- List of Steps To Measure Thermocouple With MATLABDocument1 pageList of Steps To Measure Thermocouple With MATLABDaniel Pedroza BaltazarNo ratings yet

- Communication Interface Manual: Insulation ResistancetesterDocument36 pagesCommunication Interface Manual: Insulation ResistancetesterNui DirekNo ratings yet

- Software For PID Design: Benefits and PitfallsDocument6 pagesSoftware For PID Design: Benefits and PitfallsAleksandar MicicNo ratings yet

- Bowie IDS ESU - Test ProcedureDocument28 pagesBowie IDS ESU - Test ProcedureCruz S FrankNo ratings yet

- Gokaraju Rangaraju Institute of Engineering and Technology: Project Report OnDocument14 pagesGokaraju Rangaraju Institute of Engineering and Technology: Project Report OnSri Vishnu ThatiNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Earthing Conductor CalculatorDocument5 pagesEarthing Conductor CalculatorNisal AmarasingheNo ratings yet

- 2018.10.08 Transfer Of Assets Comments AM&CMDocument2 pages2018.10.08 Transfer Of Assets Comments AM&CMNisal AmarasingheNo ratings yet

- Parliament of The Democratic Socialist Republic of Sri LankaDocument41 pagesParliament of The Democratic Socialist Republic of Sri LankaNisal AmarasingheNo ratings yet

- Transmission Planning Code 25 April 2011 PublishDocument7 pagesTransmission Planning Code 25 April 2011 PublishNisal AmarasingheNo ratings yet

- Booklet 1 Land Acquisition EnglishDocument17 pagesBooklet 1 Land Acquisition EnglishNisal AmarasingheNo ratings yet

- Volume 1 of 8 - PSRSP - P3 - CompleteDocument45 pagesVolume 1 of 8 - PSRSP - P3 - CompleteNisal AmarasingheNo ratings yet

- XP30-90 Hardware ManualDocument88 pagesXP30-90 Hardware ManualNisal AmarasingheNo ratings yet

- Pro Pam360Document2 pagesPro Pam360Nisal AmarasingheNo ratings yet

- Procedure 1Document9 pagesProcedure 1Siphesihle NkosiNo ratings yet

- Wafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds ApprovedDocument1 pageWafer Butterfly Valve With Tamper Switch (Xd371X), Ul/Fm/Vds Approved Lugged Wafer Butterfly Valve With Tamper Switch (Xd371Xl), Ul/Fm/Vds Approvedtaaj77No ratings yet

- Cim Iscas 2021Document9 pagesCim Iscas 2021Lean Karlo TolentinoNo ratings yet

- Electrical Machines (Induction Motor)Document5 pagesElectrical Machines (Induction Motor)Faizan MateenNo ratings yet

- Troubleshooting Manual AK06 UMKA03Document271 pagesTroubleshooting Manual AK06 UMKA03Jorge JimenezNo ratings yet

- Tpca8a10 HDocument9 pagesTpca8a10 HThirdyOjelaNo ratings yet

- R&S®HL300 Handheld Log-Periodic AntennaDocument2 pagesR&S®HL300 Handheld Log-Periodic AntennaCucar MackNo ratings yet

- Ascr Acss Accc Comparison BiccDocument4 pagesAscr Acss Accc Comparison Biccsupernaenergy100% (1)

- EWD-Alarm InnovaDocument1 pageEWD-Alarm InnovasundayautoserviceNo ratings yet

- 6GK51021GS002AC2 Datasheet enDocument2 pages6GK51021GS002AC2 Datasheet enyanti yanzNo ratings yet

- Single P-Channel Trench MOSFET, - 30V, - 11A, 17m: General Description FeaturesDocument6 pagesSingle P-Channel Trench MOSFET, - 30V, - 11A, 17m: General Description FeaturesdungNo ratings yet

- ELMEK - ABB Plugin BushingDocument1 pageELMEK - ABB Plugin BushingsivajiNo ratings yet

- FB2255 Series Instrument PC2255: Service ManualDocument125 pagesFB2255 Series Instrument PC2255: Service ManualAldo Angel ValdiviaNo ratings yet

- 1309A TechdataDocument2 pages1309A TechdataDarwin DiazNo ratings yet

- Division 16 Electrical IBSDocument386 pagesDivision 16 Electrical IBSmasahinNo ratings yet

- Phase Shift Provided by One Phase Shift Network in RC Phase Shift Oscillator in 3 Stage IsDocument5 pagesPhase Shift Provided by One Phase Shift Network in RC Phase Shift Oscillator in 3 Stage IsJoyce GeorgeNo ratings yet

- Motor Control Centers-Low Voltage Section 12Document22 pagesMotor Control Centers-Low Voltage Section 12victor_omoniyiNo ratings yet

- Battery ChargerDocument16 pagesBattery Chargerdimasrimantikto100% (2)

- 3000/01-002 2-Channel Servo Card: Technical ManualDocument32 pages3000/01-002 2-Channel Servo Card: Technical ManualJoaquín LunaNo ratings yet

- MMP MINDRAY PM-9000 MS v8.0 PDFDocument110 pagesMMP MINDRAY PM-9000 MS v8.0 PDFDaniel Felipe Bello TorresNo ratings yet

- U87 PDFDocument4 pagesU87 PDFjorgeNo ratings yet

- MPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Document2 pagesMPR Quick Start Guide For Powering and Installation 3db20024caaatnzza Ics01Omar sameerNo ratings yet

- Crouse Hinds CesDocument3 pagesCrouse Hinds CesJohn ThomasNo ratings yet

- Design of Induction Motors With Flat Wires and Copper Rotor For E-Vehicles Traction SystemDocument10 pagesDesign of Induction Motors With Flat Wires and Copper Rotor For E-Vehicles Traction SystemMehmet AKBABANo ratings yet

- LeroySumer LSA-47.2 PDFDocument12 pagesLeroySumer LSA-47.2 PDFSureshkumar Kulanthai VeluNo ratings yet

- Catálogo Generadores Ultra Silenciosos KIPORDocument16 pagesCatálogo Generadores Ultra Silenciosos KIPORPacho SantacruzNo ratings yet

- CSE 350: Data Communications: Mostofa Rafid UddinDocument20 pagesCSE 350: Data Communications: Mostofa Rafid UddinMuhammad Abu Bakar SiddikNo ratings yet