Professional Documents

Culture Documents

34 23 71-OCS TESTING AND COMMISSIONING-Rev 5c

34 23 71-OCS TESTING AND COMMISSIONING-Rev 5c

Uploaded by

Soheil MoradiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

34 23 71-OCS TESTING AND COMMISSIONING-Rev 5c

34 23 71-OCS TESTING AND COMMISSIONING-Rev 5c

Uploaded by

Soheil MoradiCopyright:

Available Formats

Regional Connector Transit Corridor Project

SECTION 34 23 71

OCS TESTING AND COMMISSIONING

PART 1 - GENERAL

1.1 DESCRIPTION

A. The Work specified in this Section includes final testing and commissioning of the

Overhead Contact System (OCS), and the furnishing of acceptance measurement

and test equipment required for the tests.

B. The Contractor shall furnish the special tools as specified in Section 34 23 70 for

acceptance measurement and test equipment:

C. During construction and acceptance measurements, the acceptance measurement

and test equipment shall remain the property of the Contractor, and be used by the

Contractor and Metro.

D. At completion of the work, all acceptance measurement and test equipment shall be

turned over to Metro in serviceable condition.

1.2 QUALITY CONTROL

A. Comply with Section 01 43 10, Project Quality Program Requirements –

Design/Build.

B. The Contractor shall perform the Work included in this Section in strict

accordance with the requirements of the Approved Contractor's Quality Control

Program.

1.3 REFERENCE

A. Pertinent provisions of the following listed standards shall apply to the work of this

Section, except as they may be modified herein, and are hereby made part of this

Specification to the extent required:

1. State of California, Public Utilities Commission (CPUC):

General Order No. 95 - Rules for Overhead Electric Line Construction.

B. Federal, State and Local Authorities: All applicable codes and regulations.

1.4 SUBMITTALS

A. The Contractor shall submit the following:

1. Resumes of field service engineer and instructors.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 1 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

2. Training course outline and lesson plans.

3. Training schedule.

4. Field service engineer's logs.

B. Test Program Plan: The Contractor shall submit a Test Program Plan for

acceptance. The purpose of this plan is to ensure that the Contractor has

considered all of the testing requirements contained in this and other sections of the

specifications, and has made adequate provisions for testing in his overall program

plans and schedules, and to achieve an early mutual understanding between the

Contractor and Metro on the range, depth and other aspects of tests to be

conducted. The Test Program Plan shall contain as a minimum the following data:

1. A flow diagram indicating the logical sequence of tests, starting with factory

tests and continuing on to conclude with field demonstration tests.

2. A list of test procedures (by test procedure number) to be submitted,

preliminary submittal schedule, a preliminary schedule of tests, and a brief

description of each factory and field test. The schedule portion of the Test

Program Plan shall be a dynamic document to be updated as the program

progresses.

3. An outline and format of the procedure and test data sheets for each type of

test.

4. Requirements and recommendations for witnessing by Metro or its

designated representative.

5. The acceptance measurement form and a description of the Contractor's in-

plant and field test organization.

6. A detailed Safety Program defining all precautions to be taken, notices,

signs and barriers to be posted concerning the safety of the public, work

personnel and equipment. The program shall define precautionary

measures to be taken prior to, during and following the test until such time

as normal work is resumed.

C. Test Procedures: Test procedures shall be submitted for acceptance. The test

procedure shall include, as a minimum: Objective and scope; test set-up; test

equipment to be used; personnel required for the test; estimated duration of the

test; pass/fail criteria; and samples of data sheets to be used. All tests must be

performed in accordance with the test procedures. No deviations will be allowed

unless accepted by Metro.

D. Test Reports: Six (6) certified copies of Test Reports shall be submitted for

acceptance. Test reports must contain all the data obtained during tests, an

analysis of the data and conclusions relating to the test pass/fail criteria outlined in

the test procedure. A test that fails must be repeated and any corrective action

taken to pass the re-test must be outlined in a new test report.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 2 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

E. Types of Tests: The types of tests to be covered in the Test Program Plan shall

include those required for testing and commissioning the Overhead Contact System

following completion of construction, as specified hereinafter in Part 3 of this

Section. The following commissioning tests are required:

1. Acceptance Measurements.

2. Visual Inspection of Completed Overhead Catenary/Conductor Rail.

3. Clearance Envelope Tests for Pantograph and Vehicle.

4. Overhead Contact System Electrical Tests.

5. Live Line Run Testing.

F. General: Refer to Section 01 33 00, Submittal Procedures.

1.5 PERSONNEL QUALIFICATIONS

A. The field service engineer and operation and maintenance instructors shall be

qualified to perform the functions as indicated. The Contractor shall submit a

resume for each individual nominated, a minimum of 120 days prior to the approved

scheduled date for the commencement of training.

PART 2 - PRODUCTS

2.1 MATERIALS

A. General

1. The Contractor shall provide tools, instruments, calibration devices, meters,

and other equipment necessary to connect, monitor, and adjust during start-

up and testing.

2. The Contractor shall provide spare parts as required to conduct the start-up

and testing.

3. The Contractor shall furnish the special tools, and all other equipment and

personnel services necessary to make Acceptance Measurements. The

Contractor shall also provide all the electrical equipment and personnel

services required to perform the OCS Electrical Tests.

PART 3 - EXECUTION

3.1 FIELD SERVICE ENGINEER

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 3 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

A. The Contractor shall provide the services of a qualified field support engineer at the

project site, to assist as required during startup and system integration testing.

B. Upon approval, the field service engineer shall advise Metro on traction power

system energization and start-up.

C. The field service engineer shall have a thorough knowledge of the Overhead

Contact System as well as installation, start-up, and testing requirements for all

components furnished under this Contract.

D. The field service engineer shall be available on site 5 working days after notification.

Weekly logs shall be maintained and submitted. Logs shall show tasks performed

with dates and duration.

3.2 START-UP

A. Upon successful completion of the testing, adjustment, and calibration as specified

herein and as indicated in the sections pertaining to the components of the

Overhead Contact System, Metro shall be notified when each line section is ready

for energization. Ten working days subsequent to the notification, Metro will

complete arrangements for the provision of power by the utility company

concerned.

B. When approved by Metro, each line/conductor rail section shall be energized.

3.3 INTEGRATED SYSTEM TEST SUPPORT

A. The Contractor shall provide labor and tools to support integrated system testing.

Testing support includes:

1. Provision and connection of testing equipment in accordance with the

system test plan.

2. Calibration and adjustment of protective devices in accordance with

equipment manufacturers' instructions.

3. Witnessing the testing.

4. Disconnecting testing equipment when testing is completed.

B. The Contractor shall advise Metro regarding test procedures, analysis of results,

and recommended correction actions.

3.4 TEST PROCEDURES AND EQUIPMENT

A. The acceptance measurement and test equipment will be used by the Contractor

and Metro for checking the location of the contact wire, and verifying that the

registration assemblies conform to the clearance requirements of the pantograph

clearance envelope. Each item of equipment will be used as follows:

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 4 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

1. Insulated telescoping height measurement sticks will be used to measure

the heights of conductors and guys, track clearances to undersides of

catenary/conductor rail structures, and other installed details.

2. Optical stagger gauges will be used to verify the measurements given by

the Contractor in the Acceptance Measurement Form.

3. The mobile height and stagger gauge will be used only on electrically de-

energized overhead catenary/conductor rail, and for two purposes:

a. For visually checking the location (height and stagger) of the contact

wire throughout the completed new electrified lines/conductor rails.

b. To confirm that the contact wire registration assemblies are installed

in conformance with the requirements of the pantograph clearance

gauge.

B. One insulated telescoping height measuring stick, and one optical stagger gauge,

shall be readily available for use at any time during the construction and acceptance

measurement periods.

C. All measuring tapes, poles, sticks, etc., used to collate data when the OCS is

energized must be non-conducting. In no circumstances will use of metallic or

conductive measuring tapes, chains and other devices be permitted.

3.5 ACCEPTANCE MEASUREMENTS

A. Upon completion of all construction, the Contractor shall measure the contact wire

height, stagger, and other required dimensions and record the readings on an

Acceptance Measurement Form, in the presence of Metro.

B. The Acceptance Measurements shall be used to determine compliance with the

design and will inform the Contractor of necessary corrections.

C. The Contractor shall execute corrections at no further cost to Metro, except for

adjustments required by Metro which are changes beyond the requirements

specified in the Contract Documents.

D. After execution of corrections, the Contractor shall remeasure and record affected

data and submit the results to Metro.

E. The work of this Section will not be complete until corrections are completed and

accepted by Metro.

F. Completed Acceptance Measurement Forms shall be submitted in accordance with

the requirements.

3.6 VISUAL INSPECTION OF COMPLETED OVERHEAD CONTACT SYSTEM

A. At Contact Wire Level, the Contractor shall make the following checks, and remedy

unsatisfactory conditions uncovered therein:

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 5 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

1. Check fit and tightness of all components.

2. Check split pins and locknuts are secure.

3. Check contact wire for kinks, rolls, and damage.

4. Check messenger wire for damage to strands. Check conductor rail fittings.

5. Check correct steady arm fittings.

6. Check heel settings.

7. Check that jumpers are of correct type, have adequate travel capability, are

properly fitted, and are well formed to reduce fatigue failure.

8. Check posture of pulley plates.

9. Check that hinge fittings have freedom to move under load.

10. Check that a wire passing through a cantilever and not attached to it will

clear any part of this cantilever by at least 3 inches throughout the

temperature range 25-130 degrees F.

11. Check clearance between adjacent or crossing catenaries/conductor rail.

12. Check installation at locations of possible interference with passage of

pantographs to ensure that proper mechanical clearance is maintained at

registration arms or tunnel supports, and that the pantograph will ride

smoothly across crossing wires and insulated units without entanglement.

B. From the Ground, the Contractor shall make the following checks:

1. Check that counterweights have freedom to travel and that counterweight

band does not bear on guide pipe.

2. Check that cantilevers have correct along-track offset.

3. Check that hangers are plumb and within design position. Check the

conductor rail is installed plumb with adequate insulation and supports.

4. Check out safety requirements in accordance with General Order No. 95,

and other applicable safety codes.

5. Check the system integrity like section gaps and insulated overlaps, and

ensure all the installation in compliance with the design of Engineer Record.

3.7 CLEARANCE ENVELOPE TESTS FOR PANTOGRAPH AND VEHICLE

A. General: The purpose of these tests is to verify the mechanical and electrical

clearances of the light rail vehicle (LRV) units on each section of the system. The

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 6 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

tests shall be conducted after all installations are complete. Any section found to

have insufficient clearance shall be adjusted to provide the required clearance.

B. Pantograph Clearance Envelope: Tests shall be performed initially with a rail

mounted height and stagger gauge having the same profile as the vehicle

pantograph. This gauge shall be used to verify the mechanical clearances between

the pantograph and OCS components such as conductor rail supports, the heels of

steady arms and contact wire clamps, and the electrical clearances between the

OCS/pantograph combination and civil structures such as tunnel. Following these

tests, final tests shall be performed with an actual LRV to verify the initial simulated

results.

C. LRV Clearance Envelope: Tests shall be performed with an LRV towed or pushed

through each track section. The following tests shall be performed:

1. Dead Slow Tests at Walking Speed: The driver of the towing unit must be

prepared to stop at short notice during these tests.

a. Trackside Structural Clearances to LRV Body and Pantograph: This

includes poles, tunnels, awnings, wayside signaling and electrical

equipment housings.

b. LRV body clearances shall be checked at:

1) The ends of each unit.

2) The midspan between trucks.

2. Slow Speed Tests listed above under Sub-paragraph 1 shall be repeated at

higher LRV speeds. Test speeds shall be raised in successive increments

recommended not to exceed 5 mph each. The maximum LRV dead wire

run speeds shall be as recommended by the LRV manufacturer.

3.8 OVERHEAD CONTACT SYSTEM ELECTRICAL TESTS

A. Circuit Continuity and Loop Resistance:

1. General: The purpose of this test is to obtain the DC loop resistance of

each OCS section. This test checks both the OCS and the rail return

system for electrical continuity and the absence of high resistance

connections or inadvertent ground connections.

2. Procedures: The test entails short circuiting a discrete section of the OCS

by connecting the OCS to its rails at one end, and applying a DC voltage at

the other end. The length of section under test should be about 1 to 2

miles. The test shall be carried out in the following steps:

a. Along-track feeders which are electrically common to the OCS shall

be connected to the OCS.

b. A DC source is required which will provide a current of nominally

100 amperes with an applied voltage of 24 volts (e.g. 2 car batteries

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 7 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

in series).

c. Measurements shall be made of the DC voltage and DC current, the

circuit resistance calculated from the measured values of voltage,

and current shall be compared with the design value.

d. Any section having a discrepancy of more than 20 percent between

the design value and the measured value shall be rechecked to

ensure that all electrical connections are correctly made, or that

there are no inadvertent ground connections to the OCS which are

reducing the total length of the loop.

e. DC voltage shall be applied as shown in attached Figure C-1.

f. The following items shall be recorded for each section, using

attached Table C-1:

Length of section (miles)

DC volts

DC amps

Ohms

Ohms/mile

3. Precautions: The tests required for the loop resistance require passing

relatively high DC currents through the OCS and rails. Proper regard must

be paid to safety. Test zones shall be clearly identified. All safety

requirements established in the Safety program concerning the public, work

personnel and equipment shall be strictly enforced. Personnel not directly

associated with the tests should be clear of the tracks. The section of OCS

and associated feeders under test must be isolated from the adjacent

sections of the system.

B. Hi-Pot Insulation Testing:

1. General: DC Hi-pot tests shall be performed on the Overhead Contact

System (OCS). The Hi-pot tests serve the following purposes:

a. Components such as insulators and feeders are checked for

leakage.

b. The electrical withstand of minimum clearance areas, such as

tunnel, are verified under static conditions.

c. The electrical withstand of section insulators and disconnect

switches are verified.

d. The test provides a means of periodically checking for any reduction

in the insulation level of the OCS sections, by comparing voltage

and leakage current with previously measured values.

A nominal DC Hi-pot voltage of 2 x OCS rated voltage plus 1 kV

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 8 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

shall be used for the test. Hi-pot tests shall be carried out on the

OCS sections as soon as possible after the continuity tests have

been completed, in order to ensure that all of the section being

tested is electrically continuous and is subjected to the test voltage.

Leakage currents between 0 and 5 mA can be expected for section

lengths of 1-2 miles.

2. Procedure for Main Line Tracks: Along-track feeders which are electrically

common to the OCS but disconnected from the substations. Adjacent OCS

sections which are electrically isolated from the section under test shall be

grounded by connecting the OCS to the rails. All surge diverters shall be

disconnected from the section under test. A DC test voltage shall be

applied to each OCS section in 1 kV increments up to the nominal test

voltage. The test voltage shall be held for 30 seconds at each increment.

Circuit connections shall be as shown in Attached Figure D-1. The leakage

current at each value shall be measured and recorded as shown in attached

Table D-1, together with the weather conditions and temperature.

3. Precautions: The Hi-pot measurements require application of high voltage

to the OCS. Proper regard must be paid to safety. Test zones shall be

clearly identified. All safety requirements established in the Safety program

concerning the public, work personnel and equipment shall be strictly

enforced. Personnel not directly associated with the test should be clear of

the tracks. Sections of OCS and associated feeders under test shall be

isolated from the adjacent sections of the system, and all OCS sections

adjacent to the section under test shall be grounded.

C. Section Proving:

1. Section Proving is a process of verification of the correct connection and

isolation of each electrical segment of the OCS.

2. Contractor shall verify that:

a. TPS feeder breakers are connected to the correct OCS section

and not to any other OCS section.

b. Disconnects and load break switches connect the correct sections

of OCS together and are connected to any other OCS section.

c. OCS sectionalization, provided through section insulators and/or

insulated overlaps, ensures isolation of one OCS section from all

other adjacent OCS sections.

3. The means of testing shall be through the energization of the OCS from

Traction substations and the applicable opening and closing of circuit

breakers, load breaks and disconnect switches. Contractor shall prove

that appropriate sections of OCS are energized and de-energized by

means of OCS voltage detection equipment. Any section of OCS that

should be de-energized, but is found to have a voltage of 50 volts or

greater will be deemed to have failed.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 9 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

D. Ground Resistance Measurement at Surge Arresters:

1. General: The purpose of this test is to measure the ground resistance at

each surge arrester location where the arrester is connected to a ground

rod(s).

2. Procedure:

a. The ground resistance megger shall be connected as shown in the

attached Figure B-1. The lead from P1/C1 shall be as short as

possible, and the electrodes and the ground rod should be in a

straight line. It is not essential that the electrodes be parallel to the

track, but this configuration will probably be the most convenient.

b. The electrodes shall be positioned at distances as shown in

attached Table B-1 test position 1, i.e., with x = 66 ft. and y + 105 ft.

Current and potential electrodes shall be inserted into the earth to

about six to ten inches. For very dry soil, water shall be poured

around the current electrodes. To ensure acceptable values of

resistance, the ratio of distances (x/y) must be approximately 62

percent. The resistance, shall be measured and recorded.

c. Keeping the x dimension the same as in step b, the current

electrode shall be re-positioned to y + 6 feet (test position 2), and the

resistance measured and recorded.

d. The resistance values obtained in steps b and c shall be compared.

If the readings obtained are within 5 percent of each other, no further

measurements are required, and the average value shall be used as

the actual resistance. If the readings differ by more than 5 percent,

x shall be increased by ten feet and y made equal to (x + 10)/0.62

approximately (test position 3), and steps b, c, and d shall be

repeated as necessary.

e. This procedure shall be repeated for each surge arrester location for

which a ground resistance measurement is required.

f. A measured ground resistance value of 5 ohms or less is desirable.

Values ranging between 5 and 20 ohms, or as recommended by the

manufacturer, may be acceptable with Metro's acceptance, with

values greater than 20 ohms will require remedial action.

3.9 LIVE LINE RUN TESTING

A. General: The purpose of these tests are to evaluate:

1. The current collection performance between the LRV and the OCS.

2. The adequacy of the power supplied by the OCS for required vehicle

performance.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 10 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

3. The operating parameter between overhead contact wire and pantograph.

The documentation can be used as bas for the reduce maintenance work

and efficiency for the OCS.

B. Procedures:

1. Current collection performance tests shall be performed at LRV speeds in

increasing increments of 5 mph each up to the in service speeds permitted

by track speed limits. LRV test speeds shall not exceed the specified track

speed limits or as directed by the Public Utilities Commission regulations for

test vehicles.

2. During the current performance tests, particular attention shall be paid to:

a. Behavior of the paragraph on various contact wire profiles for signs

of loss of contact.

b. Overlaps, cross-contacts, turn-outs, tunnel approach spans, and

section insulators for smooth running and takeover.

c. Take-over points at overlaps, cross contacts, turn-outs and section

insulators for smooth transitions.

d. Dynamic clearances at tunnel fittings, fascias, crossing and parallel

contacts, clearances to uplifted steady arms and supports.

e. Midspan offsets, stagger effects and contact wire sweep.

3. Locations where problems are observed shall be recorded for its

recommendations on corrective action.

4. The Contractor shall provide equipment for video recording of the current

collection performance tests. The video taping of one or more round trips

on the LRT extension is necessary to obtain significant data regarding

pantograph behavior and wire test. Provide a file with test data, which can

be printed, and record the force between the wire and the pantograph, wire

height, wire stagger, arcing (if any), distance travel and speed and location

of the specific event. The contractor shall deliver five videotapes with

recorded data in Excel format, which shall be used to facilitate detailed

analysis of the OCS after the tests have been made.

5. If adjustments are made to the OCS or to track alignment after the initial

tests, the tests shall be repeated on the affected sections, and their results

documented in the same manner as detailed in the preceding paragraphs.

3.10 ANALYSIS OF RESULTS

A. Analysis of test results shall be performed jointly by Metro, the Overhead Contact

System designer, and the LRV manufacturer.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 11 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

B. Recommendations of system changes shall be jointly evaluated for feasibility by the

above listed parties.

3.11 ACCEPTANCE RECORDS

A. Records shall be made of all tests listed under Paragraph 3.06, 3.07, 3.08, 3.09 and

3.10 in accordance with the requirements of the:

1. State of California Public Utilities Commission Regulations Engineer.

2. Overhead Contact System Designer.

3. Light Rail Vehicle Manufacturer.

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 12 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

Exhibit A

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 13 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 14 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

Exhibit B

DATE: _______________________________________

WEATHER CONDITIONS: ________________________________________

TEMPERATURE: ________________________________________

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 15 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

Exhibit C

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 16 Regional Connector

Original Conformed

Document

Regional Connector Transit Corridor Project

Exhibit D

DATE: _______________________________________

WEATHER CONDITIONS: ________________________________________

TEMPERATURE: ________________________________________

END OF SECTION

OCS TESTING AND COMMISSIONING ISSUED: 01/07/13

34 23 71 - 17 Regional Connector

Original Conformed

Document

You might also like

- DTC CodesDocument83 pagesDTC CodesAnd Dron100% (15)

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsabdullasamNo ratings yet

- Project Name Cleveland Clinic Job # For: ISSUED: Nov 2013Document10 pagesProject Name Cleveland Clinic Job # For: ISSUED: Nov 2013Jidu M DivakaranNo ratings yet

- bd16080 FIELDTESTDocument23 pagesbd16080 FIELDTESTBrando Neil SarciaNo ratings yet

- HVAC TescomDocument14 pagesHVAC Tescomamsal kotoNo ratings yet

- Commissioning of Earthing and Lightning SystemsDocument14 pagesCommissioning of Earthing and Lightning SystemsManikandan BalasubramanianNo ratings yet

- A 11 Commissioning ProcessDocument19 pagesA 11 Commissioning ProcessMohammed Ahmed Khan100% (1)

- Method Statement For Public Address System T&CDocument8 pagesMethod Statement For Public Address System T&Canver.yusifNo ratings yet

- QUALITY ASSURANCE - QUALITY CONTROL Rev.1Document9 pagesQUALITY ASSURANCE - QUALITY CONTROL Rev.1mohdNo ratings yet

- 230800Document5 pages230800Sergio Henrique F. CArniettoNo ratings yet

- Testing Electrical Equipment 26 08 00Document99 pagesTesting Electrical Equipment 26 08 00Joe GrosirNo ratings yet

- 26 08 00 Electrical Equipment Site Acceptance TestingDocument99 pages26 08 00 Electrical Equipment Site Acceptance TestingArianna IsabelleNo ratings yet

- Attachment C Data Center Commissioning SpecsDocument24 pagesAttachment C Data Center Commissioning SpecsDilip PaliwalNo ratings yet

- 23 08 00 Commissioning of HVACDocument10 pages23 08 00 Commissioning of HVACSoumojit SamantaNo ratings yet

- Commisioning Guidelines EPADocument29 pagesCommisioning Guidelines EPAAndy MoviemakersNo ratings yet

- 210800Document5 pages210800Saber ElkassasNo ratings yet

- 01 75 16 Startup ProceduresDocument2 pages01 75 16 Startup ProceduresShahid AkramNo ratings yet

- Section 26 08 00 - Electrical Systems Commissioning GeneralDocument6 pagesSection 26 08 00 - Electrical Systems Commissioning GeneralRenan Verolli Dal'AvaNo ratings yet

- Commissioning CoordinationDocument65 pagesCommissioning CoordinationMaria Gonzalez100% (1)

- General Commissioning Requirements TA1056 MBI Sampang Agung Brewery Extension 019113 - 1Document3 pagesGeneral Commissioning Requirements TA1056 MBI Sampang Agung Brewery Extension 019113 - 1ery achjariNo ratings yet

- Cleanroom SpecDocument6 pagesCleanroom SpecxukaiauNo ratings yet

- Commissioning Process: Comm. Organization Chart PDFDocument15 pagesCommissioning Process: Comm. Organization Chart PDFAzeta RobertNo ratings yet

- Quality Control & Tests Plan: BAZ-KSA-QAC-034Document12 pagesQuality Control & Tests Plan: BAZ-KSA-QAC-034Raghad GNo ratings yet

- Plumbing CommissioningDocument5 pagesPlumbing CommissioningZineddine ALICHENo ratings yet

- Testing and CommissioningDocument10 pagesTesting and Commissioningsallammohamed100% (1)

- Pre-Commissioning TestsProcedure For SEC Transmission Electrical InstallationDocument222 pagesPre-Commissioning TestsProcedure For SEC Transmission Electrical Installationsmi198986% (7)

- Hvac Testing & AdjustingDocument7 pagesHvac Testing & AdjustingSanthosh KumarNo ratings yet

- University of Houston Master Construction Specifications Insert Project NameDocument6 pagesUniversity of Houston Master Construction Specifications Insert Project NamesbunNo ratings yet

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Document13 pages03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNo ratings yet

- SECTION 01900 General Commissioning Requirements Part 1 - GeneralDocument24 pagesSECTION 01900 General Commissioning Requirements Part 1 - GeneralArch HebaNo ratings yet

- Testing & Commissioning Manual SECDocument125 pagesTesting & Commissioning Manual SECmissle2007100% (6)

- FCG Sample Fire Alarm CX SpecDocument12 pagesFCG Sample Fire Alarm CX SpecreedazNo ratings yet

- Contract Close-OutDocument3 pagesContract Close-OutParents' Coalition of Montgomery County, MarylandNo ratings yet

- Commissioning Process 3.13.2 Electives 1Document14 pagesCommissioning Process 3.13.2 Electives 1uben755No ratings yet

- Contractor Quality ControlDocument8 pagesContractor Quality Controllmn_grssNo ratings yet

- 01 91 13 General Commissioning RequirementsDocument25 pages01 91 13 General Commissioning Requirementsvin ssNo ratings yet

- Method Statement For Testing, Adjusting & Balancing of CHW SystemsDocument10 pagesMethod Statement For Testing, Adjusting & Balancing of CHW SystemsAbdülhamit KAYYALİNo ratings yet

- BSC Specs 7-99 0612 2012Document60 pagesBSC Specs 7-99 0612 2012Waqar AshrafNo ratings yet

- Broadcast Reception InstallationDocument44 pagesBroadcast Reception InstallationTrần ChâuNo ratings yet

- Testing and Commissioning Procedure For Broadcast Reception InstallationDocument45 pagesTesting and Commissioning Procedure For Broadcast Reception Installationriyan hidayatullahNo ratings yet

- CommissioningDocument9 pagesCommissioningIsmael Ochoa JimenezNo ratings yet

- 230593-TESTING, ADJUSTING, AND BALANCING FOR HVACDocument32 pages230593-TESTING, ADJUSTING, AND BALANCING FOR HVACMohamed SokarNo ratings yet

- SECTION 01 91 00 General Commissioning Requirements Part 1 - General 1.1 Commissioning DescriptionDocument74 pagesSECTION 01 91 00 General Commissioning Requirements Part 1 - General 1.1 Commissioning DescriptionJuanPaoloYbañezNo ratings yet

- 23 05 93 HVAC - TAB Guide Specification 8-28-2014Document9 pages23 05 93 HVAC - TAB Guide Specification 8-28-2014Naeem KhanNo ratings yet

- Commissioning Template PDFDocument5 pagesCommissioning Template PDFHadjon PhillNo ratings yet

- CATV Testing ChecklistDocument47 pagesCATV Testing ChecklistHussainShabbirNo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- Comm ProcDocument15 pagesComm Procpaul AzanorNo ratings yet

- Dartmouth College Design June 15, 2006 & Construction GuidelinesDocument4 pagesDartmouth College Design June 15, 2006 & Construction GuidelinesCUTto1122100% (1)

- Section 019100 Commissioning - Rev0Document9 pagesSection 019100 Commissioning - Rev0Al LopezNo ratings yet

- Guide 16995Document7 pagesGuide 16995djukalNo ratings yet

- COMMISSIONINGDocument17 pagesCOMMISSIONINGVenkataramanan SNo ratings yet

- Testing, Adjusting, and Balancing - TabDocument19 pagesTesting, Adjusting, and Balancing - TabAmal Ka100% (1)

- c109 PDFDocument23 pagesc109 PDFjulia2k1No ratings yet

- Commissioning Plan Jun 2019Document22 pagesCommissioning Plan Jun 2019Manikandan BalasubramanianNo ratings yet

- Project Close Out DocumentDocument15 pagesProject Close Out DocumentCharles SamuelNo ratings yet

- Testing CommissioningDocument23 pagesTesting CommissioningSaber Abdel Moreid83% (6)

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Livre AoIP PDFDocument135 pagesLivre AoIP PDFfdbttTKLCNo ratings yet

- Rac03 PRJ1Document54 pagesRac03 PRJ1Max TeleNo ratings yet

- Search Results: Issuu Download As PDF Issuu Download As PDF Hack Issuu Download Android Issuu Download ApkDocument3 pagesSearch Results: Issuu Download As PDF Issuu Download As PDF Hack Issuu Download Android Issuu Download ApkNwachukwu HenryNo ratings yet

- Debug 1214Document3 pagesDebug 1214dikaNo ratings yet

- Details PDF: Image Part Number Description Manufacturer QtyDocument1 pageDetails PDF: Image Part Number Description Manufacturer QtyTom TomNo ratings yet

- GEH-6421 Vol IIDocument608 pagesGEH-6421 Vol IIadrianorexNo ratings yet

- Usermanual Ocs PDFDocument8 pagesUsermanual Ocs PDFSariRantawiNo ratings yet

- Microprocessor Controller - Directions For Use: KN KN S MMDocument26 pagesMicroprocessor Controller - Directions For Use: KN KN S MM- CrabMan-100% (1)

- Y280 WML 604Document25 pagesY280 WML 604Injeletro DieselNo ratings yet

- RV365D-M - RV365D-4X2 AntennaDocument3 pagesRV365D-M - RV365D-4X2 AntennaChee LeongNo ratings yet

- Ada2200 Evalz - Ug 702Document10 pagesAda2200 Evalz - Ug 702sunilsheelavantNo ratings yet

- Water Cooled Screw ChillerDocument20 pagesWater Cooled Screw ChillerDoan ThanhBinhNo ratings yet

- Blue3 User GuideDocument47 pagesBlue3 User GuideDanny DawsonNo ratings yet

- Siemens-Getting CPU LED Status On HMIDocument13 pagesSiemens-Getting CPU LED Status On HMIchezhiyan143100% (1)

- TRN-WW-CTR85X83LX2-01 - CTR8540 - 8300 Installation - Operation and Maintenance (CE - Layer2) Course - 1Document5 pagesTRN-WW-CTR85X83LX2-01 - CTR8540 - 8300 Installation - Operation and Maintenance (CE - Layer2) Course - 1Ahmed DoeNo ratings yet

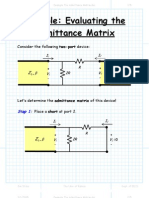

- Example The Admittance MatrixDocument5 pagesExample The Admittance Matrixamando1janNo ratings yet

- Midas C06 Pressure TXDocument8 pagesMidas C06 Pressure TXKamitkumar PatelNo ratings yet

- Metrawattfma 1Document4 pagesMetrawattfma 1Alexandra GrigoreNo ratings yet

- Common Mode Filters: For General Signal Line/power LineDocument3 pagesCommon Mode Filters: For General Signal Line/power LineLuiz EduardoNo ratings yet

- Chart of The NuclidesDocument9 pagesChart of The NuclidesEmmy1706No ratings yet

- En - GB - ODIS Service Quick Guide Fьr UMB - v1 - 1Document26 pagesEn - GB - ODIS Service Quick Guide Fьr UMB - v1 - 1marusv100% (1)

- Classroom Language Phraselist For Praising Consoling and EncouragingDocument2 pagesClassroom Language Phraselist For Praising Consoling and Encouragingcorina_lulariu1861No ratings yet

- Pinout Nissan Ecr33 Rb25detDocument1 pagePinout Nissan Ecr33 Rb25detElmer AlanesNo ratings yet

- User Guide: Moisture Encounter PlusDocument25 pagesUser Guide: Moisture Encounter PlustonyNo ratings yet

- Visionic 5.2 Release NotesDocument2 pagesVisionic 5.2 Release NotesintorelNo ratings yet

- Pigments TiO2Document43 pagesPigments TiO2dougNo ratings yet

- Multimedia Database Content and PDFDocument12 pagesMultimedia Database Content and PDFlesocrateNo ratings yet

- G Group 6 Troubleshooting: 1. When Starting Switch Is Turned On, Cluster Lamp Does Not Light UpDocument9 pagesG Group 6 Troubleshooting: 1. When Starting Switch Is Turned On, Cluster Lamp Does Not Light UpKevine KhaledNo ratings yet

- The Control UnitDocument38 pagesThe Control UnitIvan EinsteinNo ratings yet