Professional Documents

Culture Documents

Ammonia Refilling Procedure

Ammonia Refilling Procedure

Uploaded by

osama0 ratings0% found this document useful (0 votes)

2 views2 pagesAmmonia refilling procedure

Original Title

Ammonia refilling procedure

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAmmonia refilling procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesAmmonia Refilling Procedure

Ammonia Refilling Procedure

Uploaded by

osamaAmmonia refilling procedure

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

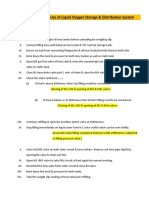

Ammonia refilling procedure

*Before starting the job of the ammonia filling should decrease the level of 118E005 to 30%.

*Hoses should be tested for ammonia P&T.

*High /low ammonia leakage should be covered with risk assessment.

A. Remove insulation boxes on drains valve 2, 4.

B. Connect nitrogen hose at valve 4 and keep it closed.

C. Connect hose for depressurization at valve 2 to the drain of depressurization line of

118P002 to 365D002 to flare.

D. Connect Ammonia truck hose at flange 6.

E. Open nitrogen hose at valve 4 to pressurize the connection, watch closely the pressure

gauge connected between valve 4&4A and soap test is made for all flanges to assure

tightness, once the test is O.K insure closing the nitrogen valve 4A then start to depressurize

to flare through valve 2 then close it tightly.

F. Open valve 5 slightly to pressurize with ammonia.

G. Open valve 3 gradually until fully open.

H. Open valve 1 slightly to control ammonia vapor flow to 118E005, with close observation for

opening of PV118121 will increase, TT118126, TT119098, PV119181A,PV119001; increasing

opening of valve 1 according to pressure difference between truck and the system with

time.

I. Valve 5 to be controlled in opening according to filling rate and pressure difference between

truck and the system and truck vaporizer efficiency.

After completion of ammonia refilling:

A. Gradually close valve 5 till fully close.

B. Gradually close valve 1 till fully close.

C. Gradually open to flare via valve 2 till fully to depressurize (note check valve will

close when delta P across it achieved).

D. Open nitrogen hose at valve 4A to pressurize connection with nitrogen and close

valve 2 respectively to make piston purge for the connection.

E. Repeat previous step until we assure there is no remaining ammonia vapor in the

connection by closing all related valves then watch the pressure at the PI to insure

there is no valves leaking and if take the right action.

F. Finally close valve 3 then we can use fabricated spool for flushing connection with

water by dismantling nitrogen hose at valve 4A and connect spool then filling

connection with water then drain to sewer system.

G. Repeat flushing with water till release any residual ammonia smell.

H. Dismantle truck hose at flange 6 and install blind.

I. Dismantle hoses at valve 2, 4 and reinstall insulation boxes.

Prepared by.

Mohamed Elashry

You might also like

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoNo ratings yet

- Ampoule Filling & Sealing MachineDocument1 pageAmpoule Filling & Sealing MachineAbesh DasNo ratings yet

- Boiler Survey ProcedureDocument5 pagesBoiler Survey ProcedureMeghali Borle100% (1)

- 980a2542 PDFDocument58 pages980a2542 PDFMichael DavenportNo ratings yet

- Molasse Tank Safety DesignDocument10 pagesMolasse Tank Safety DesignChristian BarNo ratings yet

- Ashrae 90.1-2010Document317 pagesAshrae 90.1-2010DomenicoSalimbeni100% (2)

- How To Charge R410A in A Split Type AirconDocument2 pagesHow To Charge R410A in A Split Type AirconLala GuanyesNo ratings yet

- Fuel Fill Purge ProcedureDocument3 pagesFuel Fill Purge Procedureteguh.setionoNo ratings yet

- Chapter 2 Operation Rev.1Document9 pagesChapter 2 Operation Rev.1Sajeev NerurkarNo ratings yet

- Charging of RefrigerantDocument14 pagesCharging of RefrigerantMARIO BULANADINo ratings yet

- Pipeline PiggingDocument1 pagePipeline PiggingRajan Singh PalNo ratings yet

- Ammonia Leak TestDocument9 pagesAmmonia Leak TestAdnan SheikhNo ratings yet

- Vacuum Test Procedure PDFDocument2 pagesVacuum Test Procedure PDFDanilo de JurasNo ratings yet

- Ammonia Plant SopsDocument31 pagesAmmonia Plant SopsKarthik Manjunath100% (1)

- Wa0001Document1 pageWa0001Hanif HushairiNo ratings yet

- BR5100 Installation and TroubleshootingDocument2 pagesBR5100 Installation and TroubleshootingRégis OngolloNo ratings yet

- Wato 2Document103 pagesWato 2Soluciones Biomedicas de ColombiaNo ratings yet

- AGRINOZE Quality Control Plan (Final)Document8 pagesAGRINOZE Quality Control Plan (Final)Juleha PermatasariNo ratings yet

- Experiment 4: Level Measurement & CalibrationDocument12 pagesExperiment 4: Level Measurement & Calibrationmirza farhanNo ratings yet

- Solvent Conversion Procedures: B. Preparation For Initial Start-UpDocument5 pagesSolvent Conversion Procedures: B. Preparation For Initial Start-UpEliasNo ratings yet

- Fafa Hydrostatic PumpDocument1 pageFafa Hydrostatic PumprmaffireschoolNo ratings yet

- Experiment 4: Level Measurement & CalibrationDocument12 pagesExperiment 4: Level Measurement & Calibrationfatin norainiNo ratings yet

- Liquid EndsDocument4 pagesLiquid EndsShesharam ChouhanNo ratings yet

- Pump Le400 Roy LmiDocument4 pagesPump Le400 Roy LmiShesharam ChouhanNo ratings yet

- Boiler Q&A FurtherDocument7 pagesBoiler Q&A FurtherRachitNo ratings yet

- Check Anaesthetic MachineDocument3 pagesCheck Anaesthetic MachinePaulaTracanaNo ratings yet

- Experiment 4 - Level Measurement & CalibrationDocument12 pagesExperiment 4 - Level Measurement & CalibrationRobert GilmoreNo ratings yet

- Section-3 Hydraulic Test: ISGEC John ThompsonDocument4 pagesSection-3 Hydraulic Test: ISGEC John ThompsonMithilesh YadavNo ratings yet

- Solutions: TankersDocument7 pagesSolutions: TankersKirtishbose ChowdhuryNo ratings yet

- All About Carbon DioxideDocument3 pagesAll About Carbon DioxideShiva RajNo ratings yet

- Pig Launching and Receiving Procedure For Liquid and Gas ServicesDocument5 pagesPig Launching and Receiving Procedure For Liquid and Gas ServicesKyaw Kyaw AungNo ratings yet

- SamplingDocument1 pageSamplingPopa Costin AugustinNo ratings yet

- SOP Gas AbsorptionDocument19 pagesSOP Gas AbsorptionKevin EsmunaldoNo ratings yet

- Pig Launching & Receiving Procedures: TypicalpiglaunchingproceduresDocument3 pagesPig Launching & Receiving Procedures: TypicalpiglaunchingproceduresHuythuong NguyenNo ratings yet

- Changing CylindersDocument1 pageChanging CylindersZeina FarhatNo ratings yet

- Charging and Discharging RefrigeratorDocument1 pageCharging and Discharging RefrigeratorMateo, Dale Vincent A.No ratings yet

- Soldier Step by Step Card 3Document6 pagesSoldier Step by Step Card 3roberto gonzalezNo ratings yet

- SOP AKR PCS Fuel Filling ProcedureDocument3 pagesSOP AKR PCS Fuel Filling Proceduremr_darwitoNo ratings yet

- Boiler Emergencies - 2017Document10 pagesBoiler Emergencies - 2017RAJKUMAR100% (1)

- KaplanDocument2 pagesKaplanJan Marvin TamseNo ratings yet

- Boiler Pot On Service After MaintenanceDocument12 pagesBoiler Pot On Service After MaintenanceNatane AlvesNo ratings yet

- Inspections and Survey Procedures in Auxiliary BoilerDocument16 pagesInspections and Survey Procedures in Auxiliary BoilerkrishnaNo ratings yet

- National Pump JET-PUMPDocument6 pagesNational Pump JET-PUMPOsamaNo ratings yet

- What Is The Boiler Cool Down ProcedureDocument2 pagesWhat Is The Boiler Cool Down ProcedureRitche Lim BragaisNo ratings yet

- Pipeline Hydro Testing ProceduresDocument3 pagesPipeline Hydro Testing ProceduresRussell DayNo ratings yet

- 5-3 Annexure-6 Sampling Procedure For Various TypesDocument7 pages5-3 Annexure-6 Sampling Procedure For Various Typesdhiaa mohammedNo ratings yet

- Flowing Freely, Under No Pressure. To Adjust Pressure, First Loosen The LocknutDocument2 pagesFlowing Freely, Under No Pressure. To Adjust Pressure, First Loosen The LocknutbabjihanumanthuNo ratings yet

- Jetpump Iom 7-2016 FinalDocument8 pagesJetpump Iom 7-2016 FinalErma BagacinaNo ratings yet

- Cek Mesin AnestesiDocument3 pagesCek Mesin AnestesiAchmad MustikaNo ratings yet

- Hydrotest Procedure For TankDocument3 pagesHydrotest Procedure For TankmuhammedazamNo ratings yet

- SOP For LOX Tank UseDocument5 pagesSOP For LOX Tank UseAchintaNo ratings yet

- Study of Vacuuming of Refrigeration SystemDocument2 pagesStudy of Vacuuming of Refrigeration Systemsantosh IndulkarNo ratings yet

- FH3 EL FHT ManualDocument2 pagesFH3 EL FHT ManualRubi WantoNo ratings yet

- 5000psi Gas Gun Operation and MaintenanceDocument6 pages5000psi Gas Gun Operation and MaintenanceVahidNo ratings yet

- Manufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)Document2 pagesManufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)babjihanumanthuNo ratings yet

- BoilerDocument7 pagesBoilerAlexander LakraNo ratings yet

- Series TK-9A Installation InstructionsDocument4 pagesSeries TK-9A Installation InstructionsWattsNo ratings yet

- Checklist For Wet SprayingDocument4 pagesChecklist For Wet SprayingWiwa Hernandez DonosoNo ratings yet

- Birla MEEP Op ManualDocument43 pagesBirla MEEP Op ManualAshok ChettiyarNo ratings yet

- Nitrogen Layup Procedure Dry LayupDocument2 pagesNitrogen Layup Procedure Dry LayupTrần Văn Trọng 7350No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- HSE-024 Confined Space Entry (Rev.3A) PDFDocument31 pagesHSE-024 Confined Space Entry (Rev.3A) PDFfrancis100% (1)

- Summed Area TablesDocument29 pagesSummed Area TablesDhillonvNo ratings yet

- Protect Fuse Switch Disconnector, XLBM 160-630ADocument32 pagesProtect Fuse Switch Disconnector, XLBM 160-630Azg828No ratings yet

- Ebook Opengl DistilledDocument250 pagesEbook Opengl Distilledpl363tch100% (3)

- Wild Country Cam Book 2MbDocument32 pagesWild Country Cam Book 2MbMark BrowndayNo ratings yet

- Sinking and Sourcing For The PLC ExplainedDocument5 pagesSinking and Sourcing For The PLC ExplainedTarek KhafagaNo ratings yet

- 51 43 252 Removing and Installing/replacing Panel For Rear Roof Pillar (D-Pillar), Left or Right Special Tools RequiredDocument2 pages51 43 252 Removing and Installing/replacing Panel For Rear Roof Pillar (D-Pillar), Left or Right Special Tools Requiredapi-3744308No ratings yet

- Meaning of Dispersion With ObjectivesDocument11 pagesMeaning of Dispersion With ObjectivesDeepakgupta0001No ratings yet

- E-Ticket: Departure FlightDocument3 pagesE-Ticket: Departure FlightJafet BongNo ratings yet

- Eu Requirements For Transformers PDFDocument4 pagesEu Requirements For Transformers PDFpitigoiNo ratings yet

- Fanuc Training Guide 2009 IBDocument56 pagesFanuc Training Guide 2009 IBEdgardo Aguillon100% (1)

- Mining Equipment Maintenance PDFDocument93 pagesMining Equipment Maintenance PDFGanapati Hegde100% (1)

- Brake Noise, Judder and Dragging Diagnosis and ServicingDocument4 pagesBrake Noise, Judder and Dragging Diagnosis and ServicingbeyondteckNo ratings yet

- Wellputt1 - 회사 소개Document20 pagesWellputt1 - 회사 소개Younghak HongNo ratings yet

- Energy Crisis in PakistanDocument14 pagesEnergy Crisis in PakistanshahmeerbilalNo ratings yet

- Introduction To Drilling EngineeringDocument29 pagesIntroduction To Drilling EngineeringshanecarlNo ratings yet

- Strategic AllianceDocument12 pagesStrategic AllianceRishika Nayyar100% (1)

- Oracle®Solaris ZFSAdministration GuideDocument332 pagesOracle®Solaris ZFSAdministration GuideParashar SinghNo ratings yet

- PDFDocument38 pagesPDFM.RezvaniNo ratings yet

- 02 Courier System ManagementDocument49 pages02 Courier System Managementranahamid007100% (3)

- The Effects of E Books Among The Computer Engineering Students of Adamson University With Their Laboratory ReportsDocument33 pagesThe Effects of E Books Among The Computer Engineering Students of Adamson University With Their Laboratory Reportsjuncos0729No ratings yet

- EC-2nd Year: TIME TABLE (Session 2013-14) (ODD SEMESTER)Document2 pagesEC-2nd Year: TIME TABLE (Session 2013-14) (ODD SEMESTER)Saurabh SinghNo ratings yet

- Engine HistoryDocument10 pagesEngine HistoryFelipe SierraNo ratings yet

- Form 1-A (To Claim 1st Instalment Under PMMVYDocument6 pagesForm 1-A (To Claim 1st Instalment Under PMMVYDanish MushtaqNo ratings yet

- Cat Bpe PDFDocument57 pagesCat Bpe PDFJohnNo ratings yet

- JPerf and IPerfDocument5 pagesJPerf and IPerfjuharieNo ratings yet

- 01.2 Small-Cell Report - Full ReportDocument31 pages01.2 Small-Cell Report - Full Reportwalia_anujNo ratings yet

- Lidar Data SlidesDocument39 pagesLidar Data SlidesJasorsi GhoshNo ratings yet