Professional Documents

Culture Documents

Repairs and Maintenance: Service Manual

Repairs and Maintenance: Service Manual

Uploaded by

kumpulantiga3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Repairs and Maintenance: Service Manual

Repairs and Maintenance: Service Manual

Uploaded by

kumpulantiga3Copyright:

Available Formats

ServiceManual SectionI (87)

Repairs Air conditioning

andmaintenance

Downloaded from www.Manualslib.com manuals search engine

Volvos ar8 sold in vercions adapted for differsnt matksF.

These adaptions d€psnd on many factoB including legal,

taxationand mark€tr€ouir€m€nts.

Thb manual may thersforB show illustrctions and text

which do not applyto cars in your country.

Order No TP 30161/1

ThismanualsuD€rcedes:

IP 11633/1 24o Air conditioning

fP 1124A/1 260 Air conditioninq

fP 115A4/1 240 Air conditionina

{USA,/Canaoa,

TP 11412/2 260 Ait @Nitionins{USA,/Canada}

We ressrv€the right to make alter8rions

Downloaded from www.Manualslib.com manuals search engine

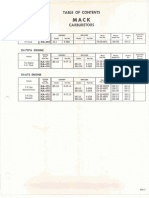

Contents

Operation Page

Specifications 2

Special tools 4

Generalrepairinstructions

D a m a q ecda u s ebdyd i r t m . o i s t u er et c . . . . . . . . . . . . . . . .

Receiver/Dryer.......... 6

Lubricating oil

l']srallirgnew system

1 e a k a s.e. . . . . . . . . . . . . . . 7

Safetyprecautions .... 7

Faulttracing

Modificatio ns th roug hout the years . . . .

't2

Draining refrigerant

Filling relrigerant B 1-21

Leadtest ............ a 22-27 21

York compressor (24O petrol/gasoline)

B 20 enqrnes c 1-3 23

B21engines......... c 4,12

Oillevelcheck 26

C l u t crhe p l a c e m (ernncr a r ) . . . . . . . . . . c 16-20 27

Disassemby assembly c2144 2A

Sankyo compressor {240 Diesel)

Removing fifling belladjusrmenr Dt 5 33

Replacement (compressor removed):

C'urch p .u l l e yc .a b o ns e a l. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D 6-24 34

Bearing. ragnet D624 34

V a L v e p l a.t.e. . . . . . . . . . . D 26-29 39

Delco compressor {6-cyl. petrol/gasoline}

Femoving -fittrng - bek adjustmenl.. 40

Replacrng: clutch.pulley.bea ng. magnet E 4-5 41

Disassembly- asserbly .. E645 42

Evaporator, replacemem F 1-a 50

Evaporatorthermostat,replacement, modification ......... F9 - 1 5 52

I n s p e f l r o. .n. . . . . . . . . . . . . . . . . . . . F 16-20 54

Expansionvalve (nearevaporator),replacemem....... G 1-5 55

Expansionvalve - suction dischaagevalve on dryer, re-

pracemem........... Ht 5 56

Condenser,replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J14 57

Receiver/dryer,dryingage (desiccant)

replacement K]6 58

Eetrigerant hoses L'I 60

H e a t e rc o n t r ovl a l v e ,c h e c k i n g . . . . . . . . . . . . . . . . . . . . . 60

AC compensation {idle speed compensation)

C a r b u r e t et endg i n e s .............. N 1-5

I n j e c t e dn g i n e s .................. N6-16 63

\Mring diagrams:

240,1975-1977 68

260, t915 1517 69

70

240,260, t97I 11

2 4 0 , 2 6 0 ,1 9 8 0 72

2 4 0 ,2 6 0 ,1 9 8 1 - 13

Indexpage74

Downloaded from www.Manualslib.com manuals search engine

Group87 Air conditioning

Specifications

Specifications

test, seepage2l

Perfomance

Air conditioning24O

R e f r i g e r a tnytp, e . . . . . . . . R 12 (diclorodif luoromethanel

quantity 197F1978 1 . 1k g 2 . 4 l b s

1 9 7 9 -. . . . . . . . . . . . . . . 1 . 3k s 2 . 9 l b s

1980-.......... 1.3 ks 2.9 lbs

CompressorYork (Petrol/Gasolineengines)

Type(1975-1979) York A 209

No. cylinderc 2

Swepivolume.....,,,,,, 147cm3(9.0in3)

M a x .r e v . . . , l OOr,/s (6 OOOr,/min)

Lubricatngoil capacity 3oo cm3(0.64us pint)

Type {1979-} YorkA 21o

No. cylinderc 2

Sweplvolume........... 164 cm3(10 in3)

t M a xr.e v . . . . . . . . . . . . . . 100 r/s {6 ooo r,hin)

Lubncatingoil capacity 300 cm3{0.64 us pint)

Lubricalingoil. wpe compressor oil P,/N | 160048-3 or Suniso5,

BPEnergol LPT1OO,ShellClavus33, Tex6coCapella

E 500

Sankyocompressor(Diesel)

1980-1941 1942-

Type . . . . . . . . . . . . . . . . . . SankyoSD-508 SankyoSD5lO

N o .c y l i n d e. r. . . . . . . . . . . . 5 5

S w e p vi o | u m e . . . . . . . . . . . 138 cm3{8,4in3) 164cm3(10in3)

l ! 4 3 xr .e v . . . . . . . . . . . . . . . . l oo r,/s (6 000 r/min) 1oo r,/s (6 ooo r/min)

Lubricatingoil capaciry 135cm3{o.3uS pintt 135 cm3{0.3us pintl

Lub cating oil, typ€ Compressor oil P,/N1 160048 3 or Suniso5,

BP EneEolLPT100, Shellclavus33, Texaco

CapellaE 5OO

Downloaded from www.Manualslib.com manuals search engine

Group87 Air conditioning

Specificationt 240, 260

Tighteningtorques

Nm ft. lbs.

Pulleyse, n g i n ec r a n k s h a f{to u t e F i n n e 8

r )1 7 - B 2 3 . . . . . . . . . . . 6-10 4.4-7.4

Unions, expansionvalve pressurcequalizingpipe 't7

12.5

expans|onvalve 30 22

expansionvalve hose 30 22

evaporatorhose 30 22

c o n d e n s e '. . 11 12.5

r c c e i v e r / d r y e. .t . . . . 25 18

c o n p r e s s oYro A 2 0 9 , / 2 1 O. . . . . . . . . . 30 22

S a n k yS o D 5 O 8S . DsIO ........... 30 22

Compressor,{Yoft 2O9l21 0)

c y l i n d ebr l o c k . . . . . 20-30 15-22

bottom cover 20-30 15-22

rear beanngcover 20 15

conrcdbolts.... 20

o i lp r u g . . . . . . . . . . . . . . . . . 5 3.7

C o m p r c s s colru t c hc, e n r ebr o | t . . . . . . . . . . . . . . . 25-30 1822

Compressor, Sankyo

cyhnderblock 32 24

searerreta,ner..... 12

o i lp 1 u 9 . . . . . . . . . . . . . . . . . . . . 10 7.4

varve pdte ....... ....... 1l

C o m p r e s scol ru r c hu. e n r r b eo l l . . . . . . . . . . . 38 2A

Air conditioning260

Refrigerant, iype B 12 (diclorodifl

uoromethane)

1975-1978 1.1 kg 3.4 lbs.

1979- 1.5 kg 3.3 lbs.

CompressorDelco

Delco

6

Sweptvolume(1975-1977) 150.7cm3{9.2in3}

(1978-) 208cm3(12.7in3)

91.6r/s {5 500 r/min)

Lubricatingoil, volume 310cm3(0.65US pint)

Lubdcatingoil, type Compressoroil P/N 'l 160048-3or Suniso5,

BPEnergolLPT100,Shell Clavus,33,Texaco

Capella E 500

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Specifications260, Special tools

Tighteningtorques

ft. lbs.

Unions, co'1denser 1l

ev.porarorhose 30 22

'DWH hos. ftom conder 't7 12.5

hose (rhick)'DWH to evdporator 30 22

h o s el r h i n )e v d p o r a l orro D W F . . 24 t8

hose'DWH rc comprcsso 30 22

nose ec€ver'drye1 r 1979-) ... .. 24 18

e x p a n s o nv a r v ee q u d l DT p i p " . . . . . . . . 17 12.5

erPdnsronvalva 30 22

e x p a n s p rv d N en o s e . . . . . 30 22

c o f p r c s s o .r . . . . . 35 26

'DWH - Receiver./dryer incorporatingequalizing

vaMenousng

C o m p r e s s ocro, n r e c l i op1l a l e . . . .......... 1A-34 10-25

r c a ." y t , n d e5re a d . . . . . 26-34 19-25

c o m p r c s s co ur l c h .s h a f tn u t ............ 19 35 14 26

14-19 10-14

Specialtools

999

1801-3 Siandard handle

2261-9 PulleriSankyocompfessor

pulleY

5085-9 Presstool: nstalLing

5133'7 Counterhold:compressor

cluich

5134-5 pulley

Puller:DeLcocompressor

5!35-2 S p a c e rP

: ulley

5137-a orifr Puley

1801

5138-6 Drift: Installingpulleybeanng

5139-4 Putler;Ceramicsleeve

5140-2 Puller:Frontsea

5141-0 Adaptor:Compressor

5142-a Suppon:compressor

5143-6

5'lil4,4

5152-7

Fillingstation

Leakdetecror

Pre$ tool: c utch

encont€lner

5153-5 Nipple:ireo

o

seal

9175-4 Puller:compressor

2261

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Special tools

5140

f tri

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

General r epai insttuctions

Generalrepairinstructions

..-';.

I

240 1974- 2 260 1975-1978

3

Caution Fitting new air conditioningsystem

A I leaksmust be rectifiedas soon as possibleto prevent The compressorshould contaln oil. Other components

moistureor foreignparticleslrom enteringintothe system.

To r€ducethe risk of moistureingressduring reparNork,

keep surfacesdry and cLean.

9 i rs h o u l ob e s l o ' F dI n a 1 a i r

I n e c o - p r e s s o r. u b 1 c a r . r o lmportant

tight containerotherwiseit will absorbmoisturefrom the The air conditionlngsystem mlst be filledwith refiigerant

air. immedlatelyafterinstallationro m inimiz€the riskoi coro-

Do not rernovethe protedive plugson new pa.ts untiliust sion. For instruclionson how to fil the system see page

beforerhe part is to be fitled. Leaveone ofthe hose con_ 16.

nections unconnectedwhen fltting the component and f the air conditioningsystem has been left empty (in a

fllshthe completesystemwith refrige.antfor15-20 sec closed state) for more than 24 houls h mLrstbe fllshed

ondsbeforeconnectingit. This removesany impuit€s and tw ce with about2OOgmms (O.5lb) refrigerantbeforethe

mo sture. Do not howeverflushtoo stronglyotherwlseihe finalfill ng. The system must also be evacuatedfor about

lubncatingoil will be flushedout as well.

I n t h e e v e n t o f a c o l l i s i o n ,c h e c kv e r y c a r e f ul y e v e r y

c o m p o n e n tw , h i c h m a y h a v eb e e nd a m a g e d c. h e c kt h e

s o d e r e dj o i n t s e x t r ac a r e f u l l y D

. e f o r m e do r s p l i l p i p e s

10 minutesbetweenthe firstand secondflush. Following

the instructionson page 16.

o

nr!st not be repaired. Topping up with lubricatingoil

Note I Too mLrchoil causespoorcool ng. Too ittle will da

mage the compressor.

*Receiver/dryer

Top up the compressorafter repanng a leak or replacLng

The receiver/dryer,orthedryingagent,shouLdbe rcplaced one or more of the componentsin the system.

d f t e r- d . o r e p . t r . , n v o l v i r g l e d t a o "o r w l ' e r ' i n i r q 1 e w

components, or if moisture is suspected in ihe air

condltioningsystem.

* U S A : t o c o n f o r mw i t h W a r r a n t yp o l i c y ,t h e r e c e i v e r /

t i m e t h e s y s t e mi s o p e n e d .

d r y e r m u s tb e r e p l a c e d e a c h

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Leakage safety precautions

Slow leakages(more than 24 hours) Ouickleakages(e.9.bursthose)

Normallythis does not involveany loss of lubicating oil. This usuallyinvolvesa loss of lubricatingoil.

When replacingcomponentsobserue:

The following volumesapply when fitting a new compo

Compressor

Drainandmeasure theoil fromthe old compressor. dl US pint

Alsodraintheoiifromthenewcompressor. Thenadd o.3

thesameamountof oil (new),aswasdrainedfromthe o.7 o.t5

old compressorto the new compressor.{At least 1 Drier o.5 o.1

dl=0.2US pint) 0.5 o.1

o.5 o.1

Other components

Drainand measurethe amountof oil. Add the rcquired

amountof oiito the new component

beforcflttingit.

Thisdoes not applyto air condirioningsystemswith

Yo'l compressors.In such casesallortrs addeddF

rectryto th€ compressor.

Safety precautions

Always wear tight tining safety Use tap water to remove refrigerant WARNING!

glasseswhen there is dangerof re-

frigerantloss. Gases lormed by heating refrigerant

are a serious health risk and can

cause serious lung damage.

-,;"

Safetyglassesshouldalwaysbewom when wo*ing with G e t i n t o u c hw i t h a d o c t o ri f t h e i n j u r yd o e sn o t h e a l ,o r

or nearrefrigerants.Rubber gloves should be worn and s i g h t i s a f f e c t e d .A v o i d w o r k i n g n e a r n a k e d f l a m e s ,

allform of skin contactshould beavoidedsince refriger cigarettesetc. High tem peratures causeth e refrigerante

ants causetrostbite. lf refrige.antshouldcontactthe eyes t o l o r m p o i s o n o u sf u m e s w h i c h a r e t o x i c i n h i g h c o n -

or skin, splashthe eves or affectedarea with cold water

{preferablyfor15 min)andtreatthe injuryin thesame way

NotelThe gasesca.| causeseriouslung darage eve.1in

low concenrrarronsThe symptoms may rol becomeevl

dentfor severalhourc or perhapseven a day later.

WARNING- EXPLOSION

RISK!

Do not sublect refrigerant coniainers to high

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ai conditioning

Fault tacing, symptoms

Faulttracing

How to usethe FaultTracingtables

Findoutthe mostpossiblecauseofthe fault by checkingthe crosseson the left.Check

o

eachitem {startwithitemswhichareeasytocheck).Notethatthefaultsarenot listedin

order of orobabiliw.

lf it is not possibleto locatethe fault, pressuretest the systemto checkfor internal

faults,seepages10 & 11,

BrMnlus€

I checkflses

| lseewiin! didsram)

P@r(onnsctiororshor I ch€cf alccoles

l@mpr€ssordo€s nol opsBts)

coFpressor(oupl'ns bumt I R€ol6ca.oJphns rs"P secr'o1on Lorpr€ssoa

Fanmoror{blowarr.

do.s not op.rdr. I Checrcaolesanondor

Fan molor {blowor),poo. opoEtion Chock/Gpac€

Brck n or Doorconnectionin como4$or R.pl.c. cluich (see seci on oi conpressor)

clutchwindinq(clutchmwes in a^dour)

F6n motor scBgch€s orcontacG fan shroud I Ch€ck

D.ve belr roo l@5e or cra,red

rla5ra' contol valva od's n

II Ta.s'on o' '€pl.ce b€r

I CFscLvalv€. see pasp 60

Sse<scnon on.ompGsror o

an ducb blocl€d ch.ck 6ndclean

An inl6i in lrcnt of windscEenlshleld bock.d I Cheokand cl6an

Clutch baa ng wom or ofi-cente R6pac€ b€a ng. S€€ s6ctionon comprcssor.

corp,es{, wo- o, r@s. I F*-"h.- --pF*-, see secnonon conp,essor

tnw o'llav.l n (onprcssor{2501 | orair sysron. Medsu.edmoun

(warmlnd.healh) | Mustbe d Lea$1 5 dl 10.3US pift) rarhcompEssor,

repLacedryinsasenrin €c€iv€/dry.r andretksystem.

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Fault tacing, symptoms

Symptom

--777)possib,ecause

Remedy

,/^.'/p94Y,/

/*"lc/,&/"*7

EvaForarorrhemosiardoesnotdisensasecompressor check/rcplac. thdrmostat See pag6 54

Expansion!a!e sruck in opan position

Top-op sysrem. Find eakaseand repan.

BLockedho.6 or component CheckJlow ihroush each componeni.

Add GfriseEni S.a pase 16

A r flow rh@ush condens6rbocked

Evaporatorblockadon an coo ing sid€

E6pofalo. lhomosrar ncorectly adjosidd Check lhemostat. See pag6 54.

nsufiicientretigerant iwhistli^g noisefrom evaporaror Drain and rafil system. See pag4 15 16

near erpanson valve, bubblesin sichi slass)

tupansionvalv€ capilary lube

Moisrurein syslem. C@lng c.pacnysdod atstan llew Drain.ysrem, replacoreceiverldryerordyins agent, fil

mnures)rhen poor. O. pooroparction ar hish ambienr wih retrlgeranr.See paq€ 15.

orarn system, rep ace raceiverldryeror dyins asem, litl

w th rerr se6nt. See pag6 15.

Su.lion discharQevalveseiz6d.Low pressuB n fronr ot Replace!a ves on r..everldryer SeepageS6

compressor,low suction {MoisruG in syslemJ

ce on evaporaioratrc@lnq sde {ihomosiar adjusted Check evapo€tor rhormosrar.See pago 54. Tesr wnh

tm ow or ran nor op6rarns)

Looseevaporatorrhermosrar Ch6ck/r6plrce See pa96 54

P@rcontactbetweonorpansionvalvecapI aryiob66nd

evaporaroroullel or poor insularon

T@ l6r€ea d fierencebelween ofiand on lor evaporator

Syfem d.rtull causes cr.shins noiso or vib€tions Dmii Sysiem Reft a.cod nO id pages j S j 6.

rrom h sh prcssurclines, ctckins nose trom compres

sori exdessivecompressorpr€ssuG and sucion pGs

suro, hissns nois€fbh expansionva ve, bubbtasorva

pour in sisht gla3s. ll conpr€ssor vatves damased by

derfillins, compr.ssor pressur. witbe loo low

Moislure in sysiem, c.n cause noso from expanson DEin r*em, rep4s4ecdwt

S e ep a a e 1 5 , t 6 5 a .

Downloaded from www.Manualslib.com manuals search engine

Group87 Coolingsystern

Farlt tacing. Ue66ureEsting

Fault tracing Pressuretesting

A s€paratepressuregaugekit or the pressuregaugeson lhe lillingstation(5143)shouldbe

ussd for ths following tests.

S€e n€xt pag€ for pr€ssur€s.

HiSh

1- Exp€mion valv. bl@k€d or 11. R€move blocl€96. R€pla@

6.iz€d in clos.d pcsition

2. ExpEBion €lv6 oplllary 12, R.pl6c6 sFNion v.lv., 55

tub€ damaqe - liqoid lc.

3. Moistu6 In 6vsi6m, ca!$t 3, DEinst€t.m. A.pllc€ 15,16

ico in dp8cio valv.. r€coiv.r/dry.r. Evaclaro B 1-26

1. Not mugh r€frig.Enl rl,DEin3yd€m,Ev€cu.t .nd 16.16 B1-26

ntl

2. O y 260 19t6-1977 2,Feplaceexpansion

valve,Fill 56 H 1-5

No bubbl6 in sisht sl.sr,

p@surs galgo rordhlF v€ry

lM. Posslblvno rdtdeamnrin

This can cao.o larg. l6.k€g3.

Erpansionutu€ crn b. bl@ksd or

seiz€din op.n pcilion-

Hish 1- Bl@k6€€in iocetver/dryer 1 Roplace R€md6 block6g€. 58

Hlgh 1, EtpaNion valv. s€iz.d in G14

2. Apamion v€ts 6il 6!6insr

4.poBrd dtrEr, r@s€4

3- Not .f,ouqh Efrig66nt, 3. Odin svsl€m, Ev.cu.t .nd filt. 15,15

Pcsilly bubbl* in 3isht sl.Bt. B 1-?6

1. R.pailGplac.. B.pla@ S€€3€ctionon compressor

High L DEinst$6m. Ewaaro andfll

Hlgh B 1-26

2. No @ld .ir r.rch.. @nd€B.r

ch6ck cFling lan and b.lG-

3. Bl@k8g. in high pBsuro sid€

4. Engin. €diator dsft.ar.d

5. An in sysr€n, P@r €vaclatio 6. DEin s'€tom. R.pl6c.

End filling ol .sfigorant, @co'vdldry€r. Ev&uat and fill B 1-26

accodino to imtrucrionr.

1. Moisturein sist€m, @c..iorl 1, Dr.insy.t.m. R.pl!c. 15,16

lom.rion ot i@. Low presuE @.iv.r/dry.r. Ev.cuar6and fll B 1-26

sido9@6!F v.ri6. c@ling .c6ding ro isrrudions

abilityOK in c6l @nditioB

blt pod or mn disronr h hot

musl bo r.pltc.d 6achliho the syslemk op€ned.

To contom with W.rsnly policv,lh. E@ivor/dryer

10

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Fauktracing,prcssuretesting

Testconditions{24O,260l

1975-1978 1979-

Open Closed

Open Closed

Enginespeed 33 t/s (2 0OOr,/rnin) 33 r,/s {2 OOOr,hin)

CONTBOL

SETTINGS

3 (max) 3

Cool Cool

FLOOR Closed

DEF Closed Closed

aEc

Open Open

An conditioningswrrch On

240 Petrol/casoline1975-1978

Ambienttemp P.essureai pressurear

in lront of car compressorinlet compresso, Notel Pressuresrefer to sea level,and can vary ae

oC {oF) bar (psil outlet bar (psi} pendingon altitude,equipment,test conditionserc.

20 168) 1 . 72 . a \ 2 4 2 A 1 1 0 1 3 ( 1 3 91 8 1 )

30 (86) 2 . 2 - 2 . 7l 3 1 4 a t 1 3 _ 1 6( 1 S 1 _ 2 2 3 )

40 (104) 3 V3 414247) 1A 22 Q\O 3a7)

260 Petrol/Gasoline1 975-1 97?

24O Petrol/casoline1979-

Ambienttemp Evaporator Pressureat

Ambiemtemp Pressurear Pressureat in ftont oI car pressureat c.mpressor

in front of car compressorinler comDressor feliefvalve

'c fF) bar tpsil ourtetbar (psil (low pressurel

'c {'F) bar (psi} outlet bar {psi)

20 (68) 1 . 2 2 6 1 1 73 6 ) 6 . 5 9 . 0( 9 1 1 2 5 )

30 {86) 20 (68) 19-2.0\26-28) 913(125 181)

1.4-2.6 9-36) 8.O_12.0

30 (86) 2 . 2 - 2 . 1B 1 3 A l 1 5 - 1 8 ( 2 0 9 2 5 1 )

(111_167)

40 (to4) (18) 40 (104) 2 8-3.5(39-49) 19 231265_3211

1.3 14.8 (206)

2/tODiesel198G- 260 1978-Petrol/Gasoline

Ambienttemp Pressureat Pressureat Ambienttemp Pressureat Pressurear

in front of car compressorinlet compressor in front of car compressorinlet compressor

'C {.F) bar (psi} ourletbar (psi} 'ceF) bar (psil outlet bar {psi)

1 . 4 - 2 . 7\ 1 4 - 3 7 t 6 . 7 1 O . 9( 9 3 - r 5 2 ) 20 ( 6 8 ) 1 . 02 . 4( 1 4 - 3 3 ) 6 . 5 9 . 3 1 9 0 - 1 3 0 )

1 . O2 . 7 1 1 4 - 3 7 1 9 . 4 - 1 4 . 1 30 (86) 1 . O - 2 . 31 1 4 , 3 2 t A 1 - 1 3 . 5

(131-196) ( r2 1 _ 1 8 8 )

14 (19) 1 80 (2s1) (104) 1.2 2.2111-31) 10.5 16.7

(146_2331

1t

Downloaded from www.Manualslib.com manuals search engine

Group87 Ah conditioning

Modilications

Modifications

1976 modelyear

New evapoEtor housing covel

Butyl taps usedto seal evaporatoroutl€t, coverand eva-

valvemustnot be insulated.

NOTEIExpansion

'l 1978 modelyear

Receive/dryer relocated

movedto lront panelnextto engineradi-

Receiv€r/dry€r

us€don 240 and260 seies.

6tor.Samereceiver/dryer

240 expansion valve and thermostat

fitted on 260.

Expansion anddischarge pressursvalveson2 60 wersdis-

continued in 1978. Thevalves,whichw€rs incoporated

in the r€ceiver/dryer,havebsen replacedby the 24o ex-

Samethemostat{B) is usedfor 24O and 260 series.

Compressordoes not opsrateconstantlybut only when

temperatursof evaporatorexce€dsa predeterminedlevel.

't2

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ah conditioning

Modificatlons

1979 model year

Adjustable

thermostat

Prevlouslythethermostatcouldbe switchedon by means

oi a rocker switch, and the temperatureadjusteo oy a

lever. 1979- modes now have an adjustableknoo.

The capillarytube now leadsfrom the themostat io the

evaporatorouter. The function of the thermostat is rhe

Notel The orange secton beyond MAX shoutd onry oe

usedwhen quick coolingis required,.nd in exrretrreoon-

ditionssuch as drivingin desen regions,otheNise warer

which has condensedon the evaporatorw I freeze and

obstructrhe passageof air.

p

240

Rubbermountedcompressor{apptiesto vehicteswmour

Largercapacity compressor1240 petrol,/gasolreon,y,.

Y o r kA 2 1 0 . C a p a c i t y1 6 4 c m 3 ( 1 Oi n 3 )( p r e v i o u s tiy4 7

c m J ( 9 . Oi n r ) .

Refrigerantvolume increasedaccordingty:

2 4 O : 1 . 3k s ( 2 . 9 l b s )

2 6 0 : 1 . 5k g ( 3 . 3 t b s )

Newtype ot AC compensationfor engine

Operates n principleby supplyingexrrafuelair (caburet-

ted enginesor air(injectedengines)toenginewhen com-

The system comprisesa solenoidvalve, a vacuum valve

See AC compensarion,pages61-67

t3

Downloaded from www.Manualslib.com manuals search engine

Gnup 87 Ai conditioning

1980 modelyear

260 compressor

(mm)threads

[4illimetfe bolts,pre'

usedfor mounting 0)

Diesel 0

Sankyocompressorused, m m threads

Notel Dieselenginesdo not have an AC compensation

system (idlespeed compensation)

Delayed engagement of compressor

Delayrelayiitted to 1I8G- vehicles.engagescompressor

approx. 10 secondsafter enginesrdr ard relay receiv's

1981 model year

Cut-outswitch on receiver/dryer

(USA only)

Sensesthe rcceiver,/dryer prcssure.lfthis is too low, the

switch cuts offthe curenttothe compressot,thus preven_

rmg oamage.

Downloaded from www.Manualslib.com manuals search engine

Gtoup87 At conditioning

Drciningrcfigennt

A. Drainingrefrigerant

Specialtool:5143

Readthe safety precautionson page 7.

TheAC systemmustbe drainedif the refrigerant

circuitis disconnected

or ifone or moreof the components

is replaced.

Thepressure

gaugesetonfillingstation15143)shouldbe used;makesurethatthepressure gaugesareclosedbeforecon-

Connections

Nipplesshouldbe fingerrightonly.

Disconnectthe batterynegativelead.

240 Pet.ol/gasoline

and diesel

Removethe cover nuts and connectthe btue hoseto the

compressor"suction" side and the red hoseto the outtet

side marked"disch .

A2

2601975-1977

Remove rheredhose(high

the covernutsandconnect

pressure)tothe (small

compressor pipe)andthebtuehose

llow pressure)ro the equallsrngvalve on the suspensron

A3

260 1978-

Removethe cover nuts and connectthe red hose (high

pressure)tothe compressor(smallpipe)a nd the bluehose

{low pressure)to the compressor(largepipe).

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ah conditioning

A4

The short centre hoseshouldbe placedin an exhaustgas

extraclorhose as a safety precaunon.

Openthe gaugevalvesand lhe valveson the components.

Openthevalveonthe centrehosevery carefullysothatthe

refrigerantslowlYflows o!t.

0

CautionI lf the relrigerant flows out too quick ly

lubricating oilwill be drawn out of the system

Closethe valveswhen the gaugesIndcate zero.

0 (

B. Fillingrefrigerant

Specialtools:5143,5144,5153,9942

0 (

Beadthe safety precauiionson page 7.

Equipment required 0)

Fillingstation 5143

I Ii

5144

Nipple 5153

9942

Rubbersloves, safery slasses.

0

5143

0

Evacuating system,

filling measuringcylinder

Bl

Disconnectthe battery negativelead.

Check that:

- hosesand pressuregaugesarc coftecnyconnected

allvalves arc closed

- venr screw on vacuum pump ]s ooseo.

Makesurethat spacersarefitted to the endsofthe hoses.

The spacers,which open lhe valves,should be placed in

the nipplesat the end of each hose.

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ai conditioning

B2

connect hosesto component

S e e p a g e1 5 .

B3

Connectcentreshon hoseto vacuumDumD

B4

Make surethat measuringcylinderis empty

This can be checkedat the liquidindicatorin the centreof

the cylinder.lf empty. it must be evacuatedat the same

Method:

Openthe outlet valve on the measu ng cylinder,see fig.

o Cautionl Do not open the valve until the cylinderis

B5

Fully open gaugevalves and valves at compo-

nents

B6

Sun vacuumpump

B7

Openthe vacuumpumpvalveslowly (the cente valvebe-

low the pressuregaugesl.

1l

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ah conditioning

B8

Turnvent screwon vacuumpumponeturn clock-

L e a v e t h ep u m p o n 1 , / 2 - 1 m i n u l ea n d t h e nc l o s e t h ev e n t {,

This sperformedto renrovemoisturefromthe system and

from the oil in the pump. A hlgherdepressioncan be ob

B9

(

Evacuatesystem until low pressure gauge (on

left) indicatesnearly- l bar (-14 psi), then run

vacuumpumpfor a further 30 minutes,

Note! lf the temperatureis below 3OoC {86oFl the vac

uum pump shouldbe left runningfor a further 20 minuies, (

all together 50 minules.

TheabovevaluesarevaLidai (orcloseto)sealevel.

Pressurcsshouldbe reducedby 0.034 bar (O.47

psl)forevery3OOmetres984 ft abovesealeve

E.s. 1 5OO metres (4 920 ft) above sea evel

=5xO.034+O.17 bar (2.37 osi) reducedpres

su'e+ aop'o\.- 0.82 b"

6

Bto

C l o s et h e v a c u u mp u m p v a l v e a n da l s o t h eo u t l e t v a l v o

en

the measuringcylinder(if evacuated).

Switch off the vacuum pump.

lf the specifieddepressioncannotbe obtainedor if it drops

on closingthe valves,there is a leak in the systern.

Find and coffect the leak and evacuat€the system once ei (

0 I

Btl

The following procedures only apply iI the

measudng cylinder has been evacuated or ifthere

is less than 1 600, 1 800 or 2 000 grammesrre-

frigerant in it (depends on year and vehicle type).

In othercasesproceedto leaktesting,816

6 0 0 s = 3 . 6 l b s ,1 8 O O s = 4 l b s , 2 O O O g = 4 . 5

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Bt2

Open

I - valve on refrigerantcontainer

- valvefor input refrigeranton measuringcylinder

Bt3

Open the upper valve above the measurlngcy inder and

transferaf€w hundredgrammesof refrigerant.Cose the

B t4

Record pressure and set scale on measuring

cylinder.

T u r ni h e s c a L e

{ m a r k e dR 1 2 ) t o t h e s a m ep r e s s u r a

es l n

dicatedon the pressure9auge.

E.g. pressuregauge shows 4.9 Set the measLringcyl-

inderwith the 4.9 scale abovethe refrigeranlindicaror.

Open upper valve on measuring cylinder and rransfer

1600 {3.6 lbsl, 18OO (4 lbsl or 2ooo {4.5 lbsl

srammes refriseranr (dependinson modelyear and ve-

hicle type).

1 1O0 {2.5 lbs), I3OO (2.9 bs) or 15oo (3 4 lbs)

g€mmes n system p !s 200 grammesfor eak test and

moisture remov3l.The rest is necessaryto prevent the

meas!.ingcy indersfromdra ningcomp erelywh ch would

3 necesstate evac!aringthe cylnder beforethe next filllng

Close valve.

B t5

Close

- va ve for input refilgerant

va ve on reirigerantcontain€r

Bt6

Leak test

Openthe ouiletvalveon the measuringcyl nderand trans_

fer 2oo grammes (O.4 lb) of refrigerantto the system

:c

t9

Downloaded from www.Manualslib.com manuals search engine

Gtoup87 Air conditioning

Fi ing refrigercnt

Bt7

Checkall connectionswith leak detector5144

field(buzzes

Setthe detectorto the mostsensitive nearlv

allthetime).Rectit anyleaksandperfoma newleaktest

Bt8

Filling

Beforeaddingrcf gerantto the system,the refrigerant

usedfor the lsak test must be drainedand the system

Method:

hosefrcmthevatuumpumpandplacethe

Disconnectthe

endofthehosein an exhaustgas {safetyprecau-

extractor

Openthevalveonthe centrehoseverycarefullysothatthe

refrigeEntslowly flows out.

flowsouttooquicklylubricating

Note!lf the refrigerant oil

will be drawnout of the compressor.

Closethe valvewhenthe gaugesindicateapproxamately

Bt9

cente hoseto vacuumpump.

Reconnect

Switchon the vacuumpumpand openthe pumpvalve

Leavethe pump runningfor 10 minutesafterthe low

pressuregaugeindicatesnearly-1 bar ( 14 psi).

820

Closevacuum pumpvalve

pump

Switch off vacuum

821

Fill refrigerant

Opentheoutlelvalveonthe measuring cylinder andtlans-

fer 1 1OO,1 30Oor 1 50Ogrammesof refrigerant to the

system.{Amountdepends on modelyearandvehiclerype,

seepages2-4).

Switchon the heaterunitforthe cylinderif it is difficultto

seethe last30MOO grammes.

Note!lfthe measuringcylinderis drained it

completely

must be evacuatedbeforethe next filling,

Closeboththegaugevalvesandmakesurethattheother

valvesareclosed.Reconnectthe batteryearthlead.

Testthe system,seenextpage.

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Performancetest

822

C Testcondition

s l24O,260l

197+1978 1979-

Open Closed

Open Closed

s3 t/s \2 00O l-rlinl 33 t/s l2ooo l[]'in)

C O N T R O LS E T T I N G S

3 (max) 3

Cool Cool

o

FLOOR Closed Closed

DEF Closed Closed

Open Open

Air conditioningswitch On

Recordedoperatingconditions24O

Appliesto vehices equippedwith a viscouscouplingfan.

Note I Pressuresreferio sea level,and can vary depend

ing on altitude,equipment,test conditionsetc.

823

240 Petrol/Gasoline

1975-1978

Ambienttemp in front of car oC (oF) 20 {68)

824

24O Petrol/Gasoline

1979-

Ambient temp in front ot car oC (oF) 20 1681 30 (86) 40 {104}

Air temp at panelvents oC (oF) 9 12 {48-54) 9-12 (48-54) 9-12l4e-541

Prcssure

at compressorinlet

(large

connedion)MPa .... o.t24.26 o.t44.26 o.13

p s i. . . . . . 11-31 20-37 18

Pressure

at compressor

outlet

(small

connection)

MPa..... o.65-O.90 o.80-1.20 1.48

psr...... 92 128 114 111 210

21

Downloaded from www.Manualslib.com manuals search engine

Group87 Air conditioning

Momance test,Diesel,260

240 Diesel198G

Ambisnt temp in tront of car oC {oF) 20 1681 30 (86) /tO (lO4)

Air tempat panelventsoc {oF) 8-12 {46-54) U12@6-541 8-t2|.46-541

Pressureat compressorinlet

{large MPa ....

connection) o.14.27 o.14.27 0.14

p s i. . . . . . 14-38 ft44 20

Pressure outlet

at compressor

MPa.....

connection}

{small o.67-1.09 o.94-1.41 1.4

psi ....-. 95-155 134-200

Recordedoperatingconditions260

fan

with a viscouscoupling

Appliesto vehiclesequipped

NoteI Pressures referto sealevel,andcanvarydepend-

ingon aftitude,€quipment, etc.

test conditions

826

@

1975-1978

260 Petrol/Gasoline

Ambient temp in front of car oC (oF) 20168t 30 (86) 40 (1()4)

Airtemp at panelvents oC (oFl 8-r2 (46-54) 14-20 {57-68) 20-28 {68-€2

Evaporatorpressureat reliefvalve MPa 0.1s-o.20 o.224.27 o.2g-0.35

p s i. . . 27-24 31-38 40-50

Highpressure MPa .

at compressor o.9-1.3 1 . 5 - 1. I 1.9-2.3

p s i. . . 130-185 2 to-256 270-320

260 1979- Petrol/Gasoline

Ambient temo in front of car oC (oF) 20 {68) 30 {s6) iro (1o4)

Air tempar panelventsoC(8oFl 9-12 {48-54) 9-12 @a-541 9-12 (48-54}

P.essure

at comprcssorinlet

MPa ....

connection)

{large 0.10-o.24 o.10-o.23 o.124.22

p s r' . . . . 14-34 17-32

Pressureat compressoroutlet

(small

connection)MPa..... o.65-O.93 0.87-'t.35 1.0F1.67

psi ...... 92-132 124-192 149237

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

York compressor B 20 engine

Q

C. York compressor- B 2O engine

Removing- fitting - belt adiustment

Notel Checkoil levelbeforefitting a new or reconditionedcompressor,see page 26.

o Removing

Drainrefrigemnt

from system,seepage15.

CI

Disconnectlrom compressorl

- refrigerant

hoses{plusendsimmediately).

Detachthe compressorfromthe mountlngblacket

c2

(|

4 Fitting

Posltionthe compressor,do nottightenthe retainingbolts

Fit the stay betweenthe centre and lower brackets.

1 Tightenthe bohs in the order indicaiedadjacent

Tighteningtorques:

Compressor boltsmax.30 Nm (22 ft. lbs)

Remainlnsbolts33-41 Nm (24-30ft. lbs.)

o

C3

Fit belt

Adjustthe behtensonby meansofthe air pump,/roller.

It sho!ldnotbe posslble

to depressthe beltby morerhan

6 8 mm (measured betweenair pump compressor).

Connectthe refrigerant

hoses.UsenewO rings,smeared

Tishteningtorque30 Nm (22 ft. lbs).

rf Replacereceiver/dryer

Add refrigerant

or dryingagent.See page58.

to the svstem,seepageI6.

23

Downloaded from www.Manualslib.com manuals search engine

Gtoup87 Air conditioning

Yo comprcssor- 817-B 23 engines

0

York compressor- B 17-B 23 engines

Bemoving- fitting - cleaning

Notel Checkoil levelbeforcfitting a new or reconditionedcompressor,see page 26.

*$t (

Removing

fromsystem,seepage15.

Dminrefrigerant

Cars with power deering

Detachthepowerpumpandhangitfrcm thewheelhous-

I

ins.

Carswith twin drive belts

c5

a

Uft off the drive belts by removingthe crankshaftpulley.

c6

All cars:

Disconnect f rcm compre$sor: (

- rcfrigeGnt

hoses(plugsendsimmedeitely).

andmountingbracket.

Removethe compressor

Fitting

o (

c7

Carswithout power steering

anddrivebelt(s).

Fitthecompressor

Reconne€,t hoses.Use new Orings,

the refrigerant

smearedwith compressotoil.

Tightening torqle 30 Nm {22 ft. lbs)

Set belt tensionby moving the compressot.lt should not

be possibleto depressthe belt by more than $-1O mm

or dryingagent, see

Replacethe receiver/dryer o"n' o)

Add rcf gerantto the system,seepage16.

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

- B 174 23

Yotkcomprcssor

c8

Carswith power steeringand twin drive belts

0 Fitthe compressor,

c9

Fit:

I studs oppositeeach other

2 - inner pulley

4 compressordrive belt and outer pulley

6 - screws and nuts.

Note!The crankshaftshouldbe rotatedwhilst tight-

eningthe pullevbohs.and alsowhen lrttrngrhe belr.

(2-3 tulns).

ct0

Check belt tension: lt should not be possjbleto depress

t h e b e l tb y m o r et h a n3 - l 0 m m ( O . 1 2 - O . 4i n ) , ( 8 O 1 0 0

N=l8 22 lbs).

VA Incorrect belt tension

Placewasher (s) betweenthe pulleyhalvesto slackenthe

p

belts. Removewasher(s)to tighten the belts.

Onewasheraltersthe belttensionby about5 mm {0-2 in).

Reconnect the refrigelant hoses. Use new O-nngs,

smearedwiih comprcssoroil.

Tightenins torque 30 Nm (22 ft. lbs.)

Heplacerhe receiver/dryeror drying agent. See page

54.

Add refrigerantto the s)€tem, see page 16.

cll

Carswith powersteeringandonedrivebelt

ct2

Fit drive b€lt

Fit the belt ovef the crankshaft. and power

compressor

Tightenthe belt by moving the power pump.

Checkthe belt tensionas follows:

Attachtool5l9T to the beltbetweenthecrankshaftpulley

The belt tensionshould be 17-18 units.

Reconnect the refrigerant hoses. Use new O-rings,

smearedwathcompressoroil.

Tightenins torque 30 Nm (22 {t. lbs.}.

Replace the receiver/dryeror drying agent. See page

Add refrigerantto the system,see page 16.

25

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ah conditioning

Yo* comprcssot - oil level check

Oil levelcheck- York compressor

ct3

Normaly t is not necessaryto check lhe oil level on in (

{

staLl€dcompressors,but new or reconddonedunits musl

be checkedbefore instalalion and refrigerantis added

New compressoBare chargedwith oil durins manufac

@r I

W AR NI NG

lfihe ol levelin an instaled compressoris checked

it is mportantthatthe refigerant is drainedfromthe

systembeforethe oi plug is !nscrewed. lf this pre

A d pstick can be made to measurethe levelof oil in the

cauton is not fo owed the reftgerant wil sprayoll

compressor.The dlpstickcan be shapedfrom a 3 mm dF

of hole,taking the oil in the compressoralong with

ameter brasswire, and graduatedwlh 1Ox3 mm ma*s

it

as 5hown above Tdch dvisior cotrespondsto dpp'ori

m a t e l yO . 0 3 d m 3 , / ( O . 0 6U S p i n t )

0

ct4

Checking

T h e g r a d u a t e dp a r t o f t h e d i p s t i c ks h o u l d b e h e d a t (

r i g h t a n g l e st o t h e b o t t o r no f l h e c o m p r e s s o rT. h e c o r

r e c t o i l e v e l f o r n e w c o m p r e s s o r si s 2 8 2 9 m m ( 0 . 3d m 3

= 0 . 0 6U S p i n 0 .

On installedcompressorswhich have been run, so some

of the olLwillhave beencirculatedin the system and con-

sequentlythe levelof oil in the compressorwill be consider

a b l y l o w e r { 2 02 5 m m = 0 . 8 - l . O i n ) t h a ns p e c i f i eadb o v e .

0 (

f t h e l e v e ls l e s st h a n2 0 m m ( O . 8i n ) t o p u p t o 2 0 m m

ct5

Adding oil

Only compressoroils may be used to top up the system,

Beforeunscrewingthe oil p ug checkthat lhe Oiing is in-

tad and that the sealingsurfaceson the plug and crank

caseare unclamaged.The o pllg shoud be tightenedto

approximatey5 Nm (4 tt. lbs.)

0

26

Downloaded from www.Manualslib.com manuals search engine

Group87 Ah conditioning

York compressor, clutch reDlacement

Q

York compressor,clutch replacement(on car)

(Not necessaryto d@inrcfrigetant)

ct6

Removing

Lock clutch and remove pulley centre bolt

Turn on the ignitionto engagethe electrcmagneticclutch

a nd counterholdthe pulleywith the drivebelt. Removethe

bolt and free the pulley from the shaft by screwing in a

5,/8" UNC (A) bolt in the centre.

ct7

Remove magnet

lead(2).

Disconnect

- fourbolts(1).

magnet(3).

c/8

Fitting

Fit the magnetwith the lead turned upward, and connect

t h e c a b l eM

. akesurethatthekeyislocatedcoiiectlyinthe

groove.Attach the pulley.

ct9

Fit centreboh

Tum on the ignition and counterholdthe pulley with the

d ve belt when tighteningthe bolt.

Tigttening torque 25-30 Nm (18-€O tt. lbs.)

Turn the pulleyand make surethat it does not contactthe

c20

andpage25 for 821.

Seepase24 for 820 engines,

21

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Yo* comprcssor,disassembly

York compressor

Disassembling

Off car)

t, (

Not€ lThe valveplateisonlyavarlableas a complete

unrr Includrngvalves.and can be replacedwrthout

removlng the compressorfrom the vehicle. See

ope'atronsC24-25. C38. lr ,s however necessary

to drain the rcfrigeranlfrom lhe system, see page

c2l

Remove clutch and magnet

Lockthe clutch by connectinga battery.Counte old the

0 I

pulleyas illustmtedand removethe centre boll.

Screw in a 5,/8' UNC bolt and removethe pulley.

Lift out the magnet.

I

c22

Remove kev and end washer

c23

Remove seal

Carefullylift out the seal with the aid of a sreelwirc. Make

surethatthere are no burrsorscoreson the shaft, and that

0r I

the innersealingsufaces are clean.

f' (

D]

c24

Removeseruicevalvesand boltsretainingcom-

pressofrcp

Removecompressortop

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ait conditioning

York comprcssor, disassembly

c25

,D Remove:

- guide pin

- valveplate(ifnecessarytapthesideslighnywith a plastic

Carefu yscrapeoffpiecesofgasket(ifany)f rom the crank-

*--.--'

Valve plate replacement only, see page 3l operation

c3B.

c26

ljnscrew and remove bottom cover and clean

crankcaseand covermatingsurfaces,

c27

ldentify con rods and caps

c28

Removecon rod bolts. lift oft cap and pressout

con rod and pistonthroughcylinder.

(f

c29

Remove bearing cover plate

Cleananddrythecrankcase

andshaftto removealltraces

c30

Removecrankshaftbearing

Heatthecrankcase (300'F)in an oven.

to 150"C

( T h i s m a k e s i t e a s i e r t o r e m o v e t h e c r a n k s h a f ta n d

bearing.)

lfthe crankshaftis undamaged,and only the bearingis to

be replaced,clampthe centresectionofthe shaft in a vice

and Leveroff the bearingwith two screwdriverc.

rf

29

Downloaded from www.Manualslib.com manuals search engine

Group87 Ah conditioning

YorkcomprcssoLassembly

AssemblingYork compressor

c31

Fit cEnkshaftrear bearing

Fitthebeangbyexsrtingpressure

ontheinnerrace.

'lF:'

c32

Fit crankshatt front bearing

Ivlakesurethatthebearingseatisfreefrombunsandclin.

Heatthe crankcase to l50oc {3oooF)in an oven.

Pressin the bearing.

c33

Fit crankshaft

Afterthe crankcase hascooledplaceit in a pressas illus

trated restingthe front end on a support.

Insertthecrankshaft itin relationto the

andcarcfullyalign

bearinginnerrace.

Pressin the shaftuntilthebeainginnerracecontactsthe

a

lmpoftam lf the crankshaft

doesnot contactthe

bearinginnerrace,damagewill result.

Downloaded from www.Manualslib.com manuals search engine

Group 87 Air conditioning

Yotk compressoL assembly

c34

Fit new rubbersealto rearcoverDlate

0

c35

Lightlypressoncoverplateandtightenallscrews

Tightento a torque of 20 Nm (15 ft. lbs.).

0 Fit pistons and con rods

c36

NotelThe lockpin (A) in thegudgeonpin must point

towards the cenlre of the compressor.

Assemble con rods and caps and tighten to alorque of

20 Nm {15 ft. lbs.l.

Checkfor smooth operationby turning the shaft a few

c37

Fit bottom cover whh new gasket and tighten

if crosswise to 20-30 Nm (15-30 ft. lbs.)

c38

D Fit valve cover and top cover

Smearcompressoroilonto the crankcase,valvecoverand

top coversea ing surfaces.

Fit the crankcaseguide pins,

P l a c ea n e w g a s k e t o n t h ec r a n k c a s e a nm

d a k es u r ew h e n

fining the valve plate that the nuts point upwards.

Placea newgasketbetweenthe valvecoverandtop cover.

SmearthesealingsLrrfacesoftheseruicevalveswth com

pressoroil and place new sealsin the top cover.

Securethe valveswlth the four long bolts and tighten the

remainingbolts in theoder indic.ted adjacenttoa torque

o f 2 G 3 0 N m ( 1 5 - 3 Of t . l b s . ) .

31

Downloaded from www.Manualslib.com manuals search engine

I

Gtoup 87 Ah conditioning

Yotk compressoa assembly

c39

Check new seal

Compress seala few times.

(1)

The lugs mustbe ableto movein andout of the re

I

Fit seal

c40

0 (

oll andpresst on to the

lmmercethe sealin compressor

Placethe

f.ce {A)facins

upward.

finelygroundsur

plstonringin itsholderwiththe

c4l

0 (

Press down seal with end washer

i.t c42

::, '

Fit end washer

.'.,

.l &, Fita newsealunderthe washer'Oilthe sealingsurfaces

wnh compressoroil andcentreit beforetightenlng

c43

Fit cover washer

Thewashercanbe pressed on by hand.lt shdesonto the

wher ll_eLlLlchis

pocrl.on

shatrdrd rakesup theco-recl

f,tted.

@

d',

q

Fit clutch

Tightenthe centreboltto 25-30 Nm (18-22 ft. lbs l

c45

Add 30o cm3 {0.6 Us pintl compressor

oil

Seepase26 for oil levelcheck.

32

Downloaded from www.Manualslib.com manuals search engine

igroup87 Ait conditloning

Sankyo compressor on diesel engines

D. SankyocompressorSD S08, b1O

Removing- fitting - belt adjustment

D1

Removing

Drainrefrigerant,

seepage15.

Disconnectf rcm compressor:

- rcfrigerant

hoses(plugendsimmediatety).

D2

Slackenthe mountingbolts,arowed.

D3

Lift off the d ve belt, removethe mounting botts and lift

away the compressot

D4

Fitting - belt adjustment

lf the compressorhasbeenrcplacedor repairedrhe oil level

Mdhod:

Drainthe old compressofoilinto a measuringcylinderand

Add the sameamountof new oilto the comprcssorbeforc

insralljngit.

The a mountof oil addedmust be morethan 40 cm3 (0.08

US pint).

Smearthe plugO ring with compressoroil and tightenthe

p l u st o a t o r q u eo f 1 0 i 2 N m ( 7 . 4 1 1 . 5 f t . l b s . l .

lf for instancea hose has burst and refrigeranthas been

lost very quickly,add 135 cm3 oilto the compressor.

D5

Atach the compressorloosely. Adjustthe behtensionand

tightenthe mountingbolts-ltshould notbe possibleto de

pressthe belt by more than 5-10 mm (O.2-O.4 in).

Reconnect the refdgerant hoses. lJse new O-rings,

smearedwith compressoroil.

0 Tighteningtorque 30 Nm (22 ft. lbs.)

Replace receiver/dryeror drying agent, see page 58.

Fill refrige€nt, see page 16.

33

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Sankyo compressoL parts replacement

Clutch replacement,SankyocompressorSD 5O8, 51O

Includesreplacementof pulley,carbonseal,bearings(2x),magnet

Specialtools: 1801,2261,5137,

5142,9175

Disassembly

0' (

D6

Mount compressorin vice

Use protectivejaws to avoid damagingthe compressor.

@r (

D7

Removenut (19 mm) from clutch

U s e a h o o k w r e n c h t o c o u n t e r h o i dl h e c l u t c l , .

o, o)

Pull off clutch

A$ach puller22Sl with 3 x 1,/4" x l bolts and pulloff

@rI

0 I

D9

Remove retainer and felt seal

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ah conditioning

Sanlcfo comprcssor. parts replacement

Dt0

Remove:

I

- Oiing.

I Dtl

Bemovecarbonseallrom shaft

Usepuller

9175.

I Dt2

Remove inner circlip

D

I

Dt3

Removepulley

Usea universa

puler.

Remov€the circlipsecuringthe bearing

i0

35

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air condhioning

SankyocompressoLparts replacement

Dt4

Pressout bearings

Supportthepulleyon block5142. Pressoutthetwo bear_

ingswithdriftl gor and5137. NOTETherearetwobeaF

ings.

Remove magnet

Removethe scrcwsandlift out the magnet-

o)

Assembly

Specialtools:at085,5142 and9175

Fit magnet

Securethe lead to the clamp.

Downloaded from www.Manualslib.com manuals search engine

Group87 Air conditioning

SankyocompressoLpans replacement

Dt7

Pressin bearings

! Usepresstool5095andblock5142.

Fit the bearingsone at a time.

D t8

Fit circlip

D19

Attach pulley to compressor

Useblock5142.

o

5142

Carefullytapthe

pulleyinto position

witha ptasric

ma er_

D20

Fit innercirclip

t D2l

Fit carbon seal

Firstattachthe seattotoot9175.

D22

SmearO-ringwith compressoroil beforeplacing

in compressor

{Raised

section

of O-rinsupward.)

(D

37

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Sanll/ocomprcssoaparts replacement

D23

Fit:

- circlip

{

felt sealandretainer

*

,I

t

D24 (

Fit clutch

5142 Alignthe clutchto the keyway.

Carefullytapon theclutchwitha plasticmalletuntilone

two of the threadsarevisible.Useblock5142.

Fit nut

or

CI(

torque3a Nm {29 ft. lbs.)

Tiqhtening

seePage33.

Fit compressor,

I

(

ll

{

38

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Ai conditioning

Sankyo compressoL valve plate rcplacement

0

Valve plate on Sankyocompressor,replacement

(Oft cat)

lF

i

I

Removing

t Mount compressorin vice

(valvecoverup.)

D25

M a r k t h e p o s i t i o no f t h e c o v e r .

D26

Bemovescrewsand cover

Carefullyleveroff the cover wllh a screwdriver.

D27

Free valve plate

Carefullyleveroff the valve platewithout scoringthe sur-

I Cleanthe compressorbody and valve plate.

Fifting

D28

Place new gasket and valve plate on bod,,

Makesurethat the guidepin fits in to ihe coffecthole,

otheMisethe retaining

screwswillnot fit propeny.

I

D29

Placenew gasketbetweenvalveplateand cover

I Positionthe coveraccodingto the indenrificatton

marks.

Tightenthe boltscrosswise.

\

I Tightening torque15 2 Nm (lltl.5 ft. tbs.l.

N O T E I fo i l h a s b e e ns p i l t d u r i n gt h e r e p a i r , t h eo i l

plug should be removed and the compressor

o i l d r a i n e d i n t o a m e a s u r i n gc y l i n d e r .C o n e c t

a m o u n r = 1 3 5 c m 3 .( 0 . 3U S p i n r ) .

R e t u r nt h e o i l a n d t i g h i e n i h e o i l p t u g t o 1 0 N m

(7.4 ft. lbs.).

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Delcocomprcssoton 827, 828 engines

E. Delco compressor

Removing- fitting - belt adjustment

Specialtool514l

I

h is not necessarytodischargeref gerantfrcm the

system ifthe compressoris only moved to one sde

to obtain accesstothe enginevalvese.t.c. In such

a casefollow E2 and hangthe compressorfromthe

bonnet hinge

EI

Removing

Drain ref gerantfrcm the system, see page 1 5.

Disconnectthe connectionplatefor rhe compressorhoses.

'fl

6,1

Fit:

protecuveplugs on plate

- adaptor5141 to compressor.

{ l

E2

Removecompressor

Disconnecr

the lead.

Moveasidethe upperradiatorhoseandte it to a suitabte

CI)

a

- mountinsbolts{4 x)

Lft awaythe compressor. 0)l

E3

Fifting - belt adiustment

Positionthe comp.essorand drive belt.

Adjusl the belt tension and tighten the coi,pressor

m o u n l i n gb o l t s .l t s h o u l d n o t b e p o s s i b t e t od e p r e s st h e

b e l t b y m o r e t h a n 5 - 1 0 m m ( 0 . 2 - 0 . 4i n ) .

Remove adaptor 5 14 1 and fit the connecrionplate.

Tishrening torque 12F34 Nm {10-25 ft. tbs.}

Replace receiver/dryeror drying agem, see page 58.

0 ) l

Fill reirigerant,see page 16.

40

Downloaded from www.Manualslib.com manuals search engine

Grcup87 Air conditioning

Delcocomprcssor,parts replacement

0

Clutch replacement,Delco compressor

Includesreplacementof pulley,bearing.magnet

E4

oblain accessto clutch

Disconnectthe negativeteadfrom the batrery.

Detachthe compressorfrom the mountingbracketsand

Bend the upper radiatorhose underthe compressorand

placea pieceof wood abovethe hoseto supportrhecom

t E5

For removalof components,see pages42-43, E7-13.

Forfitting of solenoid,see page48, E36-39.

For fining the remainingcomponents,see pages49-50,

E40-45.

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air condhioning

Delcocomprcssor, disassembly

{ ) {

DisassemblingDelcocompressor

Specialtools:1801,5132,5133,5134,5135,5137,5139,5140,5142

(Off cat)

MountJixture5132 in vice

E6 cl

Supportthe compressorin the fixture.

E7

@ l

9/16"

Remove clutch nut

Cou.terholdtheclutchwith5133 andremovethenutwith

a 9,/16" socket.

{) (

FB

- circlip

E9

Withdraw clutch

Usepuller5134.

ol

E|0

Remove:

- circlip

- sleeve(leverout with screwdiver)

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ai conditioning

Delcocomprcssoadisassemw

Pull ofi pulley

0 Usea suitablepuller.

Usetool5135 to supportthe centrcspindteof the purer.

Et2

Removepulleycirclipand driveout bearhrg

80t+5t37 Usedrift513?andhandle

1a01.

Placesupport5142 beneaththe pulley.

I Et3

Remove magnet

ldentifythe positionof rhe magnet.

- rrlagnet.

Et4

Bemove circlip and ceramic sleeve

Bemovethe circlipandfrcntcollar.

Withdrawthe sleevewith puller5139.

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Delco comprcssor, disassembly

Et5

RemoveO-ring

Use a pieceo{ steelwiro, shapedas illustrated.

Et6 @t,

I

Removesealwith 5140

Pressthe toolagainstthe sealandtum it untilthe lug grips

Pull out the tool and seal. o)e

Et7

Turn compressorand fixture so that bottom end

o a

porntsup

Bemovethe safety valve, O-dngsand rcar cover.

@)a

ldentify location of oil pump gear and collar

outerO r ng.

Et9

Lift off rearvalve housingand valve plate

U s ea p a i r o fl o c k i n gp l i e l sa n d g r i p t h et w o d r i t t e dh o t e si n

the housing. o

Downloaded from www.Manualslib.com manuals search engine

Grcup 87 Ai conddoning

D elco compressor, disassembly

E20

Remove oil pump suction pipe and O-ring

I E2l

Detach compressorfrom fixture

Supportcompressor

on 5142, fronr end up

E22

Lift off outer housing {rom cylinder unit

0 E23

Pull out front end O-ring

E24

Lift off front section

E25

Removelront valvehousingand valveplatefrom

cylinder unit

E26

Clean and check all parts

E27

Replace seals and worn parts

0

f*." t* "*."** ir"t "in

ararat'te

asa c.-neresna*

l

Downloaded from www.Manualslib.com manuals search engine

Group87 Air condhioning

Delco compressor, assembly

{)

AssemblingDelcocompressor

Specialtools:1801,5132,5133.5138.5139,5144,5/ 42,5152

F2B

Support cylinder unit on 5142 and fit lront valve

0,e

plate and valve housing

trTl-"i:1rrT111.il l O' f

5142

829 r), t

Fit {ront sectionand O-ringon valve housing

Smear the O-ing with compressoroil.

0e

0)a

E30

Position outer housing above cylinder unit

Turnthehousingsothatthe holein theplateabovethe oil

sumpalignswith thesuctionpipehoLein thecylinderunt.

{)a

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ai conditioning

Delco compressor, assembly

E3l

Moum compressorin tixtures5132 as illustrated

0 and fit suctionpipeand O-ring

Thecylinderunitshoutd

rhenberurned

sothatthesucnon

prpe|s centredin the hole jn the ojtsump ptate_

E32

Fit rear valve plate

Alignthe pl6tewith the cytinderunit.

I E33

Fiti

- O{ing

oil pump(alisnidenrification

ma*s).

Fit sieve in rear section

0

47

Downloaded from www.Manualslib.com manuals search engine

Gtoup87 Air conditioning

Delcoconprcssor, assembly

E35

Fit rear section

Note The locationof the two guide pins.

Tighteningtorquefornuts= 2&-34 Nm {l9-25ft. lbs.)

Fit:

- satetyvalve,tighteningroque = I 4-1 I N m ll (Fl 4 ft

lbs.l

- O-ringsfor hoseconnections.

E36

Fit magnet

Fitth€ magnetaccordingtothepreviouslymadeidentifica

NOTETheplugfor the etectricleadsshouldpoint to

10 o clockwhen the serviceplateon the

comDressor Dointsto 12 o clock.

Thefixtureshouldbe heldin thevicewiththefrontend

facingup.

E37 O

Fit circliptor magnet

E38

Fit shaft seal

Attachthe s€alto 5140.

Insertthetoolinthefrontendcollarandtum

ituntiltheseal

Th€nprsssdownthe springandtum the tool anti-clock

wiseto releasethe sealfiomthe tool.

E39

- O-ringin innergroovein collar

- ceramicrjng(usepuller5139)

circlipfor ceramicdng.

o

48

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ah conditioning

D elco compressor, assembly

Fit bearing and circlip on pulley

rN Used ft 513a andhandle 1a01.

E4l

Fit pulley

Used ft 5138andhandle

r8O1.

0 E42

Fhl

I

E4s

Fit:

- new sleevefor felt seal

- key in shaft key\,vay.

(f

49

Downloaded from www.Manualslib.com manuals search engine

-

II

GroupB7 Ah conditioning

Evaporctor,rcplacement

E44

Fit clutchwith presstool 5152

T t ' e t h r L s t b e a r r g m . s r b e l o - r r e o o e r w F e n r h e c r u r c h dnn o

5152 v

NOTEDo not ovenightenthe cl|rtchotherwiselt will con

Fit:

E45 @e

- washer and circlipin clr.rtchcentre

- n u t ( m a c h i n e de n d f a c i n g w a s h e d .

Tightenthe nut:

0)a

Tishteningtorque 19-35 {14-26 tt. lbs.l

Use a 9,/16" socket and countefiold with 5133.

0,, {

F. Evaporator,replacement 0De

0te

Removing

Disconnectthe battery negativelead.

Drain refrigerantfrcm the sysiem, see page 15.

- g l o v ec o m p a r t m e n t

- p a n e b e n e a t hg l o v e c o m p a d m e n t

s i d e p a n e ln e x t t o h e a t e r .

Removethe rlght defrostervent and air duct.

(

50

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ai conditioning

EvaporctoL rcplacement

Remove thermostat {rom cover

0 Applies to 24O | 975-1978)

N o t e t h a t t h e p o s i t i o no f t h e t h e r m o s t a t{ 1 ) c a n

v a r y a n d t h a t t h e c a p i l l a r y t L r boen 1 9 7 9 -m o d e l s

i s m o u n t e d o n t h e e v a p o r a t o rp i p e .

cover (2).

F3

I Unscrew conneqtions and carefully pull out eva-

porator

Fifting

Frt:

- new evaporatorseal

0 Fit (as applicable):

F5

0 Connect refrigerant hoses

Usenew O rings,smearedwith compressor

o.

e\, Tightenins

torque30 Nm {22 ft. lbs.)

Replacereceiver/dryer

Frllsystem

or dryinsagerr, seepase 58.

with ref gerantandteakrest,seepage16.

Insulatehosesand connecttons

NOTE The expansionvatvemusr not be ins!tated.

- glovecompartmenr

Downloaded from www.Manualslib.com manuals search engine

Grcup 87 Ar condiion;ng

Evaporatot thermostat, replacement

Evaporatorthermostat,replacement c 0

Thermostatlocationvarieswith modeltype and year

The folowins variationsoccur:

24O 1975-197A,260 !978: The thermostatis locatedin the evaporatorcovera nd

the caDlllarvtube {heat sensod is insertedin the evaporator.

26O 1975-1977: No themostatfitted. The temperatureofthe refrigerantlsregulated

For replacement

insteadby a suctiondlschargevalve,incorporatedin rhe receiver,/dryer'

s e e p a g e5 6 , o p € G t i o nH 1 - 5 .

240,260 1979 earlytypes: Adiustablethermostatlocatedon the controlpanel.The

0)a

caoilLarv tube is insertedin the evaporator.lf prcbLemsarise, e.g iregul.r cvcling,the

thermostat should be replacedand lhe capillarytub€ placed on the evaporatoroutlet

( s a m ea s f o r L a t eW p e s ) I. h e r m o s t a tP , / N 1 2 5 9 6 1 7 7 .

240 , 260 1 97 9 late types : Adjlslable thermosratlocatedon the controlpanel The

caDilarvtube is mounted on the evaporatoroullet.

0)e

to changeto the adlustable

On replacingthermostatson old rype models it is advisabLe

tvpe, see instructionsbelow A specialkLtP/N 1129O90-5 is availabLe

Fitting new type adtustablethermostat 0ll f

F s0 e

- glove compartment

panel beneathglove compartment

- side panelsnear heater.

0a

Ft0

Loosenthermostat. cut off capillary tube

tubein evaporator.

Leaverestof capillary

Clean evaporator outlet

6) I

52

Downloaded from www.Manualslib.com manuals search engine

Group87 Air condhioning

Evaporator them ostat rcpIacement

Connect thermostat across AC rclay and @m-

pEssor solenoid

105 Compressor sol€noid

106 Solenoid

107 Thermostat+ switch

129AC relay

107 129

Ft3

Attach thermostat to comrol oanel

Bend capillary tube and attach h to evafrorator

outlet

Bendthscapillarylubeapproximately40 mm{1.5 in)trom

its endarounda 10 mm (O.4in) diam€terpipe.

Attach the tubs to the evaporatoroutlet pipe with two

clampslP,/N944267-4).

Insulateevaporator outlet

Useinsulation tapeP,/N591235-7.

R€fit parts removed.

53

Downloaded from www.Manualslib.com manuals search engine

Gtoup87 Air conditioning

EvaDorctor thermostat inspection

Evaporatorthermostat, inspection

Allvehiclss,apartfrom 260197F1977models,areequipp€dwith ovaporatorthermo-

stats.The purposeoftheth€rmostatisto cycleli.e.engage/disengage)

the compress-

or, A defectivethermostatcanusuallycaus€ths evaporatortoiceup which blocksthe

air flow and consequently€uses poor cooling.

The tvDeand locationof the thermostatvariesas follows:

240 197+1974.260

Adjustable tlpe mounted on evaporator cover.

24O,260 1579-t Non adjustablethermostatmountedon dashboad controlpanel.

Fl6

Inspectthermostat as follows: DASHBOARDCONTBOLSETTING

TESTCONDITIONS

- Bonnet{hood)open. Doorsand windows closed - Temperature

controlat COOL

- Enginespeedapprox.33 r/s (2,000/min) - FloorandDEFshuttersclosed(pushbuttonsout)

-An additionalfanmustbe usedto coolthecondenser. - REC(recirculation)

buttondepr€ssed

- An-condswitchON (1975-1978)

- 1979- modelswith adjustabl€

typethermostarset ad-

justerknobto blues€ction.

Fl7

Check that compre5aorcrycles the compressor

doesnot cyclee.g. becauseof higham-

checkthatthethermostat

After5-1Ominoperation cycles bienttemperatures,

a roadtestshouldbe carriedout.See

clutch.lf

the mov€msntof the compressor

by obseruing F 18.

Ft8

Boad test Notethe lowesttemp€rature

at whichthethermostatdis-

(Ambient temperature should not exceod 25oC = engagesthe compressor,This should be 5o-8oc

77OFJ (41o-46oF)dependins

on the temperature

of the coolins

an.

Drivethevehiclsarapproximatsly50 km,/h(3o mph)and

measurethetemperatur€ ofthe air fiom the cen-

releas€d

Ft9 F20

lf temperature b allove 8'C (46oF) It temperatureis lower than soc (41oF)

240 1975- 1978,260 1978: 240 1975 - 1978, 260 1978

Removethe soundproofing and panelon the sid€of the and panelon the sideof the

Removethe soundproofing

Turn the thermostatscrew slightlyclockwise. Tumthe thermostatscrewslightlyanticlockwise.

240, 260 1979- 240,2601979-

Thethermostatcannotbe adiust€d6nd mustthereforebe Thethemostatcannotbe adjusted

andmuntherefor€be

54

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ai conditioning

Expansion valve rcplacement

G. Expansionvalve (nearevaporator),replacement

( 2 4 0 a n d2 6 0 1 9 7 8 - m o d e s )

on 260 1s75 1977 modelsthe expansionvalve is incorporatedwith a dischargeprcssurevatve and is mounteclon the

receiver,/dwer.see oveneaf.

t Removing

Disconnectthe battery negativelead.

0 Drain .efrigerantfrcm the system, see page 15.

Remove:

- soundproofingpanel

G2

Removel

- evaporatoroutler ins!lation

NOTE Thermostatlocationvarieswith model type

0 G3

Fit new expansion valve

Usenew O-ings,smearedwith compressoroil.

Tightenins

torque30 Nm {22 ft. lbs.}.

G4

Fit:

Insulatethe evaporator

outletpipe.

NOTE Do not insulatethe expansionva ve.

G5

Replacereceiver/dryer

or dryingagent,see page

58.

Fillsystem with refrgerant,see page 16.

Refit side panels and soundproo{ing.

Downloaded from www.Manualslib.com manuals search engine

Group87 Ah condhioning

Eryansionvafue- suctiondischaryevalve,rcplacement

H, Expansion

valve,sustiondischargevalve in receiver/dryeJ

, re-

placement

Onlvfifted to 260 1975-1977models

Removing

Disconnectthe batterynegativetead.

Drainrefrigerantfrom tho system,see page 1 5 .

Ivlarkpositionof valve body cov6r.

H2

Bemove:

- retainingbolts

-Gring.

H3

Remove:

- bolts and lock washsrs

- expansion

valveO-ring.

Smearnew O-ringswith compressor oil.

Fittwo O-dngsto expansionvalveand oneto suctiondis-

PlaceoneO-ringin expansion

valveseatin valvebody.

H5

Fit:

- lockwashersandmountingbolts

- coverO-ring(oil fitst)

- covor,according to proviously

mademarks.

Replacedryingagent,s€epage59, operationK3.

seepage16.

Fillsystemwith refdgerant,

56

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ait conditianing

Condenser.replacement

c

J. Condenser,

replacement

Removing

Disconnectthe baltery negativelead.

Dra n refigerant from the system,see page 15.

J2

i0 obtain accessto compressor

- radialorgrilleand headamp frames

- r g h t h e a da m p , 2 6 0 a n d 2 4 O 1 9 7 9

- electnccoo n9 fan (if fitted)

Disconnectrefrgerant hoses(plug ends mmedtarety).

Remove condenser

0

Fitting

J3

Fit condenser

i0 Reconnecrreftigeranthoses.

Us€new O rings,smearedwlh compressor

o

Tghtening

torque17 Nm {12 ft. tbs_).

Q

Beplacereceiver/dryeror drying agent, see next page.

Fill system with refrigerant,see page I6.

51

Downloaded from www.Manualslib.com manuals search engine

Group87 Ah conditioning

Receiver/ dryeL replacement

Receiver/dryer.replacement

NOTEThe receiver/dryer containsa desiccant(dryingagent)thepurposeofwhich is to absorbanv moisturein the

is not exposedto air (moisture).

refrigerantcircuit.Becauseof this it is very importantthat the receiver/dryer

Receive/dryerlocationand type varieswith enginetype and model

NOTEFollowing anyreparrswhichinvolveinleF

rupringthe.eirigersnlcircuilor if moistureis

suspectedin the system,the receive/dryeror

desiccant(dryingagenl)must be replaced.

KI

Replacingreceive/dryer

240. | 975-t 977

24, 260 1978-

Disconnect leadfromthobattery.

thenegative

fromthe syslem,seepage15.

Drainrefrigerant

Disconnectthe hosss(plugendsimmediately)-

refrigerant

Replace receiver/dryer

NoTE Measurethe amountof oil in the receiver,/dryer.

Thesameamountof newoilmustbeaddedtothereplac*.

ment receiver,/dryer(260 and Diesel)or York compressor

(240).

240 1975-1977

K2 o

Fitting

lvlakesurethattheevaporator

hoseis connected

to the

OUTconnection on the rcceivet/dryet.

Reconnectthe refrigeranthoses. Use new O-rings

smearedwith compressor oil.

Tishteninstorque25 Nm (18 ft lbs.l.

Add r€frig€rantto the system, seepage I 6, Reconnect

240, 260 1978-

Replacingdrying agent

K3

260 1975-1977

Removing

Disconnectthe batterynegativelead.

Drainrcf gerantfrom the system.seepage15.

Disconnectre"frigeranthoses{plug endsimmediately as

wellas in valvebody)

ldentifyvalvebodyposition

in relation

10mounting

bracket.

Ot

58

Downloaded from www.Manualslib.com manuals search engine

1

Group87 Air conditioning

Beceiver/dryeLreplacement

K4

Removereceiver/drver

(ldeftify the position of the body first. )

K5

Removethe O-rings.Cleanthe sieveandremoverneDag

containing

the dryingagent.

Smearthe new O-ringswith compressor oitbeforefitting.

Place new bag oI drying agent in receiver/dryer.

K6

Fit receiver/dryer

Reconnectthe refrigeranthoses. Use new O-rings,

smearedwith compressor oit.

Tishtening torque,seofig. (41 Nm = 30ft. tbs.24 Nm =

18 ft. lbs,17 Nm = 12 ft. tbs)

Add refrigerantto the system,seepage16.

Beconnect the battery.

59

Downloaded from www.Manualslib.com manuals search engine

Gtoup 87 Air conditioning

Refrigercnt hoset heater control valve

L. Refrigeranthoses,replacement

l f o n e o r m o r e o l t h e r e f r i g e r a n th o s e s h a s b u r s t ,c a u s i n gr a p i d l o s s o f t h e r e f r i g e r a n t i,t i s v e r y p r o b a b l et h a t

c o m p r e s s o ro i l h a s b e e n l o s t . T h i s o i l m u s i b e r e p a c e dw i t h n e w o i l - S e e p a g e 7 .

I n p r i n c i pe t h e m e t h o df o r r e p l a c i n gh o s e s i s t h e s a m e f o r a l l l y p e s . l t s h o u l db e n o t e dh o w e v e r t h a t t h eh o s e sa r e o f

v a r y i n g l e n g t h a n d t h a t e a c h h o s e i s i n t e n d e df o r a s p e c i a lp a r t o f t h e r e f r i g e r a ncl i r c u i l .

LI

Replacement

Disconnectthe battery negativeLead.

Drain refrigerantfrom the system, see page 15.

Replacethe defectivehose.

lf necessary,add new comprcssoroil (does not apply to

systems with York compressor). Use new O rinss,

smearedwith compressoroil. Tighten all connecnonsto

toque, see specificationson page 2 4.

Replacereceiver/dryef or drying agent, see page 58.

Add refrigerantto the system, see page I6.

Reconnectthe battery.

M. Inspectionof mechanicalheatercontrolvalve

s!€tem is unableto keeppassengercompartmentcool in hot weather,the heaterconlrolvalveshould

tfthe air condirioning be

oa

'COOL i

inspectedand if necessaryadjusted.The problemmay be due to the valvenot closingwhen the heatercontrolis at

Inspectionand adjustment

Remove:

- soundproofingpanel beneathsteeing wheel

- side panelsnext to heater

o{|

Warm up the engine.

Move rhe heatercontrolto ofi (closed)andcheckthat the

input hose from the engineto the heater control valve is

cold. lf not. tum the adjusterscrew (arrcwed)3,/4 tum

Checkthat the hose coos down after a few minuteswith

the engineidling.

Aso check that the heater control valve lever boftoms

"COOL'

when ihe temperaturecontrcl is set to

Apply sealerto the adjusterscrew.

Refit side panel and soundproofing.

0 (

60

Downloaded from www.Manualslib.com manuals search engine

Group 87 Ait conditioning

AC compensatian.cafturrcted engines

N. AC compensation- idle speed compensation

0 T h e p u r p o s eo f t h e A c c o m p e n s a t i o n s v s t e mi s r o c o u n t e r a clrh e r n c r e a s e tdo a do n r h ee n g i n ea l r d e s p e e d s w h e nt h e

c o m o r - e s s oi sr e n g a g e o .l r f J r c t i o n s I n p r i r L i p t €o y s r , o p t y1 g a d d i l r o l d t, u e t - a. r r i " r r r e i c a

o u . r e t e oe n q i n e s ro r a . r

U l j e c r e oe r g r r e s j o a s tt h e l h . o t r ' Fv d t v ew h e l r t , ec o m p . e q s o ri s e r g a g e d .

An alternative c o m p e n s a t i n gs v s t e mi s f i t t e dr o c e r r a i nv e h i c t e s( 8 2 j A 8 2 - s w e d e n ,A u s t r ai a ,c a n a d a ) a , n df u n c t i o n s

b y a d v a n c i n gt h e i g n i t i o nw h e n r h e c o m p r e s s o ri s e n g a g e d .

Carburretedengines

All 1975-1 978 modets

ldle speed s kepr constanrwhen th€ compressoris en-

gagedby nreansof a solenoidvalve mounied on rhe caF

0 Wher rhe romp.-.ror s "rqageo t." tocd or tre "r9rr"

rncreases. On sensingthis ihe sotenoidvatveopensaoo al

l o w sa n a d d i to n a l a m o u not f f u e ta i r m x l u r et o b y p a s sr h e

lhrottle valve and maintaina consta.r ide speeo

The solenoidvalve closes rhe bypass channetwnen me

compressor|s drsengaged.

0

(0

-,o)

4-cylinder1979-

{ E x c lS. w e d e n ,A u s i r a l i aC, a n a d a8, 2 t A 1 9 8 2 _ )

The compressor,when engaged, acrualesthe soenoo

v a l v e( 1 ) w h i c hi nt u r no p e n st h e v a c u u m

v a v el 2 ) d o w r n s

mofe fuelair mixtureto bypassthethrort e vatve The id €

speed s Increasedby a pproxinrarely3 5 r,/s (2OOr,/min)

r l e " o t a c p l r i l l u s r r " r , oc n

l-"*' *1.'" '"" h*-. *" I

L o - ' n d c l e d . I h e F io c .utr l o o f r r - - o s " , , m a v r o w - |

P v e rb F d , f - r . r ,

I

Downloaded from www.Manualslib.com manuals search engine

Group87 Air condi[oning

AC comparsation, carbutetEd engines

N3

B21A'1982 - (Sweden, Austlalia, Canada)

Theidlespeedcompensationsystemfunctionsby aclvan-

cingthe ignitionwhenthe compressor is engaged.

Compr€ssordis€ngaged:The depressionin front of the

throttlevalveis low andconsequentlvthe distributoris not

Compr€ssorengaged: The depressionafter the thmttle

andidlespeedis kept

valveishigh,theignitionis advanced

Theadjacent showswhsrethehosesare

illustration