Professional Documents

Culture Documents

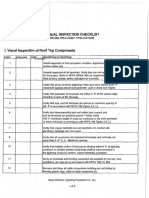

Electrical Inspection Checklist Clickable

Electrical Inspection Checklist Clickable

Uploaded by

Diana BenavidesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Inspection Checklist Clickable

Electrical Inspection Checklist Clickable

Uploaded by

Diana BenavidesCopyright:

Available Formats

Electrical Inspection

Checklist

Preparation:

Review job requirements and documentation.

Gather necessary tools and equipment.

Safety Devices:

Test GFCI outlets and breakers.

Replace malfunctioning devices.

Safety Measures:

Verify proper use and ratings of splices and terminations.

Check temperature ratings of terminations.

Look for arc flash protection warning signs.

Verify enclosure markings and ratings.

Ensure adequate working clearances, dedicated spaces, and headroom.

Select suitable PPE for protection against arc flash.

Ensure the availability of appropriate arc-rated PPE.

General Inspection:

Check panels for damage.

Verify circuit labeling.

Inspect wiring for damage.

Confirm continuity of grounded conductors in multiwire branch circuits.

Verify the adequate length of free conductors in boxes.

Ensure proper installation of boxes at designated points.

Switches and Outlets:

Test switches and outlets.

Check for wear or damage.

Verify grounding.

Installation Compliance:

Identify installations or components covered by NEC regulations.

Verify that installations adhere to manufacturer instructions and labeling.

Identify installations or equipment needing special approval or investigation.

Inspect fixtures for installation.

Check for damage or malfunction.

Appliances and Equipment:

Test appliances and equipment.

Inspect cords and plugs.

Identify the voltage of the equipment to be inspected.

Determine the approach boundaries for shock protection.

Conduct an incident energy analysis for the equipment.

Ensure awareness of short-circuit current and clearing times.

Define the Arc Flash Boundary and evaluate associated risks.

Grounding and Bonding:

Inspect grounding and bonding systems.

Check for damage or wear.

Electrical Wiring:

Inspect wiring installation.

Check for damage or wear.

Ensure all conductors of a circuit are grouped together.

Inspect insulation values where different system conductors

share enclosures.

Verify protection of wiring methods from framing edges, nails, and screws.

Equipment Integrity:

Verify closure of unused openings.

Check for damage or contamination.

Confirm secure mounting and adequate ventilation.

Conductor Installation:

Check for insulating bushings or grommets in specific installations.

Verify protection, cover, and allowances for ground movement in

underground installations.

Ensure continuity and completeness in metal raceways and enclosures.

Securely fasten wiring methods and support independently of

suspended ceilings.

Documentation:

Record findings.

Provide detailed reports to customer.

Inspection Review:

Pass: Meets standards

Flag: Attention needed

Fail: Immediate action required

Automate workflows, ensure timely service deliveries

with Zuper's Electrical Business Software.

Invest in your success today!

Book a Free Demo

You might also like

- Anuhazi Lexicon (Not Exhaustive) - Before Anu TranslationsDocument10 pagesAnuhazi Lexicon (Not Exhaustive) - Before Anu TranslationsfarahNo ratings yet

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Module 2 1 Math 10 Graphs of Polynomial Functions FinalDocument29 pagesModule 2 1 Math 10 Graphs of Polynomial Functions FinalJacob Sanchez100% (1)

- Electrical Wiring Methods and Check ListDocument3 pagesElectrical Wiring Methods and Check Listssb100% (1)

- Ecg EkgDocument3 pagesEcg EkgrochimNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Preventive MaintenanceDocument6 pagesPreventive MaintenanceMay Ann DuronNo ratings yet

- Inspection and Testing of Electrical InstallationsDocument7 pagesInspection and Testing of Electrical InstallationsOdoch HerbertNo ratings yet

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- Edoc-Switchgear and Switchboard Inspection and Testing GuideDocument16 pagesEdoc-Switchgear and Switchboard Inspection and Testing GuideEl Comedor Benedict100% (1)

- SLPG - Emergency Light Fixture-1yDocument2 pagesSLPG - Emergency Light Fixture-1yAshraf MohammedNo ratings yet

- Testing LectureDocument22 pagesTesting Lectureketan chandrakarNo ratings yet

- Electrical Hazards ChecklistDocument3 pagesElectrical Hazards ChecklistKunju MathewsNo ratings yet

- EDOC - 10 Critical Tests For New Power Circuit BreakersDocument7 pagesEDOC - 10 Critical Tests For New Power Circuit BreakersEl Comedor BenedictNo ratings yet

- SLPG - Distribution Board-2yDocument2 pagesSLPG - Distribution Board-2yAshraf MohammedNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument12 pagesComprehensive Electrical System Maintenance ChecklistsFarrukh Nadeem100% (1)

- Comprehensive Electrical System Maintenance ChecklistsDocument5 pagesComprehensive Electrical System Maintenance ChecklistsAshwinSiddaramaiahNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument6 pagesTesting and Commissioning of Electrical EquipmentGreeshma PuttannaNo ratings yet

- MS - Installation - Testing - Power Cables and Wires - QC - REV - 2Document7 pagesMS - Installation - Testing - Power Cables and Wires - QC - REV - 2irfan vpNo ratings yet

- HS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineDocument7 pagesHS418 Portable Electrical Equipment Inspection Testing and Tagging GuidelineAmit BhattNo ratings yet

- WS-Periodic Inspection 9 2008Document10 pagesWS-Periodic Inspection 9 2008NATHANNo ratings yet

- Visual and Technical Checking of Instrumentation and Control SystemDocument13 pagesVisual and Technical Checking of Instrumentation and Control SystemzhangyiliNo ratings yet

- Thermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andDocument3 pagesThermographic Scanning of Electrical Equipment Kindly Put A Mark in The Box If This Is Included andCollen Noel MabasaNo ratings yet

- Control Gears and Switch Gear TasksDocument12 pagesControl Gears and Switch Gear TasksBit CoinNo ratings yet

- Inspection of Electrical Installations in HomesDocument10 pagesInspection of Electrical Installations in HomesHans De KeulenaerNo ratings yet

- Pvtrin Checklist Practical Tips On PV Installations enDocument22 pagesPvtrin Checklist Practical Tips On PV Installations enyavuz772100% (1)

- Electrical Work ProcedureDocument18 pagesElectrical Work ProcedureUmar Adamu100% (2)

- Photo Voltaic Plant Routine Operation & Maintenance Manual: Prepared By-Sunil Singh (DGM D&E)Document7 pagesPhoto Voltaic Plant Routine Operation & Maintenance Manual: Prepared By-Sunil Singh (DGM D&E)Sunil SinghNo ratings yet

- SLPG - HT Motor-4yDocument4 pagesSLPG - HT Motor-4yAshraf MohammedNo ratings yet

- Electrical Hazards ChecklistDocument2 pagesElectrical Hazards ChecklistPatrick Julius100% (1)

- Install Process Instrumentation and Control Cabling and TubingDocument9 pagesInstall Process Instrumentation and Control Cabling and TubingAbela DrrsNo ratings yet

- CH 11 Maintenance and RepairDocument18 pagesCH 11 Maintenance and RepairRiyadh SalehNo ratings yet

- Electrical Safety No VideoDocument31 pagesElectrical Safety No VideoJulios Charl Panuncialman TagupaNo ratings yet

- EIM IATOOLS CORE No. 3Document20 pagesEIM IATOOLS CORE No. 3Zhiany CardelNo ratings yet

- LVDocument43 pagesLVMuhamed Elsayed - ZalatNo ratings yet

- Cable Glands in Hazardous Areas CCG PresentationDocument59 pagesCable Glands in Hazardous Areas CCG PresentationAwotiku Abimbola100% (2)

- HorticaElectricalMaintenance ProgramDocument9 pagesHorticaElectricalMaintenance ProgramManibalanNo ratings yet

- Msra - 999Document2 pagesMsra - 999Mahmoud IdrisNo ratings yet

- Welding MC ChecklistDocument1 pageWelding MC ChecklistBalakumarNo ratings yet

- Earth Loop Impedance TestsDocument18 pagesEarth Loop Impedance TestsKedarnath Sastry susarlaNo ratings yet

- Annual Inspection Form HearybrosDocument4 pagesAnnual Inspection Form HearybrostelecttNo ratings yet

- BS7671 17th Edition Electrical InstallDocument4 pagesBS7671 17th Edition Electrical InstallAnthony WilliamsNo ratings yet

- Assembling Power Lines - A Step-by-Step GuideDocument3 pagesAssembling Power Lines - A Step-by-Step Guidegavina3187No ratings yet

- Wire and Cable InstallationDocument9 pagesWire and Cable InstallationqaqcmepteamNo ratings yet

- Method Statement: For Electrical Inspection & TestingDocument1 pageMethod Statement: For Electrical Inspection & TestingJustin SanchezNo ratings yet

- Electrical Inspection ChecklistsDocument13 pagesElectrical Inspection ChecklistsNuraisyah BatrisyiaNo ratings yet

- Processmeter: Safety InformationDocument4 pagesProcessmeter: Safety InformationVICROENo ratings yet

- Electrical Panel Inspection & MaintenanceDocument4 pagesElectrical Panel Inspection & MaintenanceFawaaz KhurwolahNo ratings yet

- The Most Important Precautions During Commissioning and Start Up of LV SwitchgearDocument8 pagesThe Most Important Precautions During Commissioning and Start Up of LV SwitchgearMarian MarianNo ratings yet

- Electrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQDocument6 pagesElectrical Method of Statement For Installation & Termination of Cables and Wires - Method Statement HQRahul Raj SinghNo ratings yet

- Installing Process Instrumentation and Controlling Cabling and TubingDocument48 pagesInstalling Process Instrumentation and Controlling Cabling and TubingAbela DrrsNo ratings yet

- Electrical CommissioningDocument19 pagesElectrical CommissioningLuis EnriqueNo ratings yet

- D00 Cat0001 02Document3 pagesD00 Cat0001 02Muhammad Ibad AlamNo ratings yet

- Electrical Work ProcedureDocument18 pagesElectrical Work ProcedureWilliam Berrospi Garcia100% (3)

- Testing Ex EquipmentDocument10 pagesTesting Ex EquipmentscaranoNo ratings yet

- Guidelines For High Potential (Hi-Pot) DC Testing of Medium Voltage Cables - EEPDocument11 pagesGuidelines For High Potential (Hi-Pot) DC Testing of Medium Voltage Cables - EEPSheraz Khan100% (2)

- Relay Testing ProcedureDocument6 pagesRelay Testing ProcedureScribdTranslationsNo ratings yet

- Commissioning: Commissioning High Voltage EquipmentDocument14 pagesCommissioning: Commissioning High Voltage Equipment2091979No ratings yet

- 3.1 Installation of Wires and Cables & TestingDocument5 pages3.1 Installation of Wires and Cables & TestingMedrouaNo ratings yet

- Electrical Panel Inspection ChecklistDocument2 pagesElectrical Panel Inspection ChecklisthafizahNo ratings yet

- IW27 Electrical Walk Down PDFDocument2 pagesIW27 Electrical Walk Down PDFJaldoNo ratings yet

- ThesisDocument129 pagesThesisOvaid MehmoodNo ratings yet

- Tutor Marked Assignment (TMA) SR Secondary 2018 19Document98 pagesTutor Marked Assignment (TMA) SR Secondary 2018 19kanna2750% (1)

- Polyphenol Oxidase Activity and Browning of Three Avocado VarietiesDocument6 pagesPolyphenol Oxidase Activity and Browning of Three Avocado VarietiesMiguelArceMonroyNo ratings yet

- Mesología BERQUEDocument6 pagesMesología BERQUEPanchita PonisioNo ratings yet

- Crawling Under A Broken Moon 05Document28 pagesCrawling Under A Broken Moon 05Maxim BorisovNo ratings yet

- Ácido Sulfurico Ligas CompatíveisDocument2 pagesÁcido Sulfurico Ligas CompatíveisGuilherme Augusto de OliveiraNo ratings yet

- Energetica 09 Septembrie2020Document73 pagesEnergetica 09 Septembrie2020Ion DutescuNo ratings yet

- Private Peaceful EssayDocument7 pagesPrivate Peaceful Essayb6zm3pxh100% (2)

- Task 2 Overview and Instructions 2021Document3 pagesTask 2 Overview and Instructions 2021alindafitrotNo ratings yet

- Variables On Both Sides of EquationsDocument17 pagesVariables On Both Sides of EquationsShatakshi DixitNo ratings yet

- UNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestDocument21 pagesUNITS 1-17 Diagnostic Test 8E (Standard) : You Have ONE HOUR To Complete This TestNayem Hossain HemuNo ratings yet

- Dampak Bencana Alam Bagi Sektor Pariwisata Di Bali Ni Ketut Sutrisnawati AKPAR DenpasarDocument10 pagesDampak Bencana Alam Bagi Sektor Pariwisata Di Bali Ni Ketut Sutrisnawati AKPAR DenpasarRihar KoharNo ratings yet

- Biological Bases of BehaviorDocument7 pagesBiological Bases of BehaviorSANTHOSH KUMAR T MNo ratings yet

- Irjet V3i4441 PDFDocument5 pagesIrjet V3i4441 PDFnisaNo ratings yet

- Quail Farming Business Plan PDF OverviewDocument5 pagesQuail Farming Business Plan PDF OverviewhenrymcdoNo ratings yet

- Global Warming (Word Formation)Document2 pagesGlobal Warming (Word Formation)EvaNo ratings yet

- Appendix O Contents of The Health and Safety FileDocument5 pagesAppendix O Contents of The Health and Safety Fileaaktgt MepNo ratings yet

- Jul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New MexicoDocument16 pagesJul-Sep 2008 Voice For Native Plants Newsletter, Native Plant Society of New Mexicofriends of the Native Plant Society of New MexicoNo ratings yet

- 11thMachAutoExpo 2022Document112 pages11thMachAutoExpo 2022Priyanka KadamNo ratings yet

- Pronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalDocument4 pagesPronoun Reference - Exercise 5: Correction Should Sound Natural and Be LogicalPreecha ChanlaNo ratings yet

- LESSON 2 Occupational Safety and Health LawsDocument6 pagesLESSON 2 Occupational Safety and Health LawsMELCHOR CASTRONo ratings yet

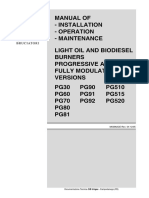

- Manual of - Installation - Operation - Maintenance Light Oil and Biodiesel Burners Progressive and Fully Modulating Versions PG30 PG90 PG510 PG60 PG91 PG515 PG70 PG92 PG520 PG80 PG81Document52 pagesManual of - Installation - Operation - Maintenance Light Oil and Biodiesel Burners Progressive and Fully Modulating Versions PG30 PG90 PG510 PG60 PG91 PG515 PG70 PG92 PG520 PG80 PG81OSAMANo ratings yet

- Mobile Division: Service Parts ListDocument20 pagesMobile Division: Service Parts Listwag008No ratings yet

- Siskyou Bombing RangeDocument114 pagesSiskyou Bombing RangeCAP History LibraryNo ratings yet

- Interviw With Martin DavisDocument12 pagesInterviw With Martin DavisraktimddkNo ratings yet

- Balsa Wood BridgeDocument31 pagesBalsa Wood BridgeAlvin WongNo ratings yet

- WEEK 8 VentilationDocument39 pagesWEEK 8 VentilationNURIN ADLINA TAJULHALIMNo ratings yet