Professional Documents

Culture Documents

SOP-HA-028 SOP On Out of Trend Results

SOP-HA-028 SOP On Out of Trend Results

Uploaded by

bhullram736Copyright:

Available Formats

You might also like

- SOP On Handling of DeviationsDocument10 pagesSOP On Handling of Deviationschemist_tma100% (1)

- SOP For Corrective Action and Preventive Action (CAPA)Document5 pagesSOP For Corrective Action and Preventive Action (CAPA)Juan Manuel Jaurez100% (5)

- Excavadora CDM6065Document109 pagesExcavadora CDM6065Leandro DietrichNo ratings yet

- SOP-QA-002-00-Document Preparation, Control and RetentionDocument7 pagesSOP-QA-002-00-Document Preparation, Control and RetentionNgoc Sang HuynhNo ratings yet

- Handling of OOTDocument18 pagesHandling of OOTjameer80100% (2)

- SOP QA 010 00 Handling of DeviationDocument17 pagesSOP QA 010 00 Handling of Deviationnetelsrt129875% (4)

- Corrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateDocument5 pagesCorrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateAlmario SagunNo ratings yet

- Tandard Perating Rocedure: TitleDocument5 pagesTandard Perating Rocedure: TitlevishalstjsNo ratings yet

- Sop Qa 037 00 OosDocument19 pagesSop Qa 037 00 OosAnand H S100% (3)

- SOP On Handling of DeviationsDocument9 pagesSOP On Handling of DeviationsBlueSaga100% (1)

- L0-Sqe-Pro-055 (5) Drug and Alcohol Testing ProcedureDocument14 pagesL0-Sqe-Pro-055 (5) Drug and Alcohol Testing ProcedureCK TangNo ratings yet

- SOP For Handling of Out of Trend (OOT)Document3 pagesSOP For Handling of Out of Trend (OOT)Mubarak Patel100% (1)

- SOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical ResultsDocument5 pagesSOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical Resultsد.عمر خليل العباسي100% (2)

- SOP On Handling of OOT and OOS-impDocument16 pagesSOP On Handling of OOT and OOS-impAkshita100% (1)

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument3 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesArup Chakraborty100% (1)

- PR-GM 09 Identification and Control Ofnon Conformance ProcedureDocument5 pagesPR-GM 09 Identification and Control Ofnon Conformance ProcedureFULGENCE RUHARARANo ratings yet

- Dev HanDocument9 pagesDev HanTuriyo AnthonyNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta100% (2)

- BRSM Form 009 - QMS MDD IsvDocument16 pagesBRSM Form 009 - QMS MDD IsvAnonymous q8lh3fldWMNo ratings yet

- Handling Data Yang Oos (Yola)Document6 pagesHandling Data Yang Oos (Yola)Ghifari Eka NugrohoNo ratings yet

- QCD-036-01 Good Chromatography PracticesDocument12 pagesQCD-036-01 Good Chromatography Practicesarnab rayNo ratings yet

- Oos Out of SpecificationDocument12 pagesOos Out of SpecificationShumaila Iftikhar100% (1)

- AC QA 004-01 (Deviation)Document30 pagesAC QA 004-01 (Deviation)Vijay Singh100% (1)

- Personnel Competencies Manual: Quality Assurance & Safety Quality System & Auditing TQ - (01 To 06) - 07Document5 pagesPersonnel Competencies Manual: Quality Assurance & Safety Quality System & Auditing TQ - (01 To 06) - 07Ananda FitrianiNo ratings yet

- Handling of Oot ResultsDocument5 pagesHandling of Oot ResultstghonsNo ratings yet

- SOP-QA-013-00-corrective and Preventive ActionDocument10 pagesSOP-QA-013-00-corrective and Preventive ActionNgoc Sang HuynhNo ratings yet

- SOP For Raw Material Release PG PDFDocument2 pagesSOP For Raw Material Release PG PDFMosub Al.DirdiryNo ratings yet

- SOP-QA-048 RoundingDocument3 pagesSOP-QA-048 RoundingchalicevitalchemNo ratings yet

- DELL - PSU - QPA - Rev 7 0 2Document116 pagesDELL - PSU - QPA - Rev 7 0 2Michael WuNo ratings yet

- SOP of Change ControlDocument24 pagesSOP of Change ControlPaolo PiccoliniNo ratings yet

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument4 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesGanesh KashinathNo ratings yet

- 30-99-90-1615 Rev 1 Internal and External Audits ProcedureDocument10 pages30-99-90-1615 Rev 1 Internal and External Audits ProcedureEswar ReddyNo ratings yet

- Product Formulation DevelopmentDocument3 pagesProduct Formulation DevelopmentAnonymous mBOujo5No ratings yet

- PRODUCT-Bank of Investment and Development of Cambodia: Test Case Result DocumentDocument8 pagesPRODUCT-Bank of Investment and Development of Cambodia: Test Case Result DocumentBIDC EmailNo ratings yet

- Qa003 15Document7 pagesQa003 15Sridhar NandipatiNo ratings yet

- ReprocessingDocument3 pagesReprocessingswanandkul86% (7)

- MICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFDocument4 pagesMICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFalnzeer omerNo ratings yet

- G-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Document17 pagesG-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Ahmad HidayatNo ratings yet

- Sop For Analytical Method Validqation and VerificationDocument7 pagesSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- CTFL2018 05 Testmanagement Quiz 1.01Document35 pagesCTFL2018 05 Testmanagement Quiz 1.01Giang- B17DCCN188 Nguyễn Thị HươngNo ratings yet

- Sop 003 For Analysis of Rinse SampleDocument3 pagesSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- Evaluation Reporting of ResultsDocument16 pagesEvaluation Reporting of ResultspurnachandrashekarNo ratings yet

- Pharmaguidesop Com 2021 03 Sop On Supplier Qualification VenDocument14 pagesPharmaguidesop Com 2021 03 Sop On Supplier Qualification VenTuriyo AnthonyNo ratings yet

- Evaluation Reporting of Results Core Document PDFDocument6 pagesEvaluation Reporting of Results Core Document PDFParkhomyukNo ratings yet

- End To End Testing Procedure: Issue 1.0Document9 pagesEnd To End Testing Procedure: Issue 1.0Sushant NarvekarNo ratings yet

- Sop-Qa-038-00-Stability StudiesDocument22 pagesSop-Qa-038-00-Stability Studiesnareshph28No ratings yet

- WWW Pharmaguideline Com 2010 03 Sop For Out of SpecificationDocument8 pagesWWW Pharmaguideline Com 2010 03 Sop For Out of SpecificationTuriyo AnthonyNo ratings yet

- Qua-Dmt-G-001 Guideline For Root Cause Analysis InvestigationsDocument61 pagesQua-Dmt-G-001 Guideline For Root Cause Analysis InvestigationsSuresh GollaNo ratings yet

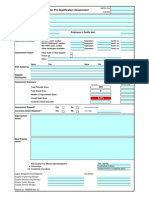

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- XXX Test Summary and Sign OffDocument9 pagesXXX Test Summary and Sign OffMark FriazNo ratings yet

- XXX Test Summary and Sign OffDocument9 pagesXXX Test Summary and Sign OffMarkNo ratings yet

- ETE:MR:02Document3 pagesETE:MR:02pranesh kadamNo ratings yet

- SOP On SOPDocument7 pagesSOP On SOPRaja AbhilashNo ratings yet

- SOP Internal AUditDocument8 pagesSOP Internal AUditAnmolNo ratings yet

- Management ReviewDocument2 pagesManagement Reviewpranesh kadamNo ratings yet

- Calibration of Friability Test ApparatusDocument4 pagesCalibration of Friability Test Apparatusashishchandan13No ratings yet

- 38) PFMEA ProcedureDocument3 pages38) PFMEA ProcedureSagar DaundNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- ISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012From EverandISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012No ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- Comparative Analysis and Optimization of Active Power and Delay of 1-Bit Full Adder at 45 NM TechnologyDocument3 pagesComparative Analysis and Optimization of Active Power and Delay of 1-Bit Full Adder at 45 NM TechnologyNsrc Nano ScientifcNo ratings yet

- OSHA Office of Training & Education 1Document78 pagesOSHA Office of Training & Education 1AmeerUlHaqNo ratings yet

- Probity Audit PolicyDocument7 pagesProbity Audit PolicyMahmud Toha100% (1)

- Lecture Three Actuators ObjectivesDocument5 pagesLecture Three Actuators ObjectivesKenani SaningaNo ratings yet

- Villaba 26Document205 pagesVillaba 26villaba14No ratings yet

- HMT306 Food Processing and PreservationDocument431 pagesHMT306 Food Processing and Preservationgumnani.rewachandNo ratings yet

- Elitmus Syllabus and Question Paper PatternDocument5 pagesElitmus Syllabus and Question Paper PatternAbhishek MohanNo ratings yet

- Jay Van Patten - Executive Resume - August 2019Document4 pagesJay Van Patten - Executive Resume - August 2019api-472622610No ratings yet

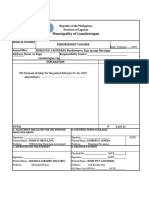

- Municipality of Camalaniugan: Amounting ToDocument3 pagesMunicipality of Camalaniugan: Amounting ToMelody Frac ZapateroNo ratings yet

- PNS BAFS 184.2016. GAHP Chicken Broilers LayersDocument22 pagesPNS BAFS 184.2016. GAHP Chicken Broilers LayersFelix Albit Ogabang IiiNo ratings yet

- Baires Dev PreentrevistaDocument3 pagesBaires Dev PreentrevistaCarlos Gonzalo Maravi ArensNo ratings yet

- Grade 6 SLK Arts Q1 Week 3 FinalDocument14 pagesGrade 6 SLK Arts Q1 Week 3 FinalNalyn AdameNo ratings yet

- Philippine Rabbit v. People of The Philippines DigestDocument2 pagesPhilippine Rabbit v. People of The Philippines DigestDonvidachiye Liwag CenaNo ratings yet

- Fluid Mechanics - ProblemsDocument4 pagesFluid Mechanics - ProblemsClement Chima50% (2)

- Construction Planning 2019 MemoDocument6 pagesConstruction Planning 2019 MemoNtokozo JiyanaNo ratings yet

- Short Circuit Currents.Document11 pagesShort Circuit Currents.Shiju Kp.No ratings yet

- Jump To Navigationjump To Search: EuroplugDocument5 pagesJump To Navigationjump To Search: EuroplugqwertyNo ratings yet

- Outline of ISF2024Document10 pagesOutline of ISF2024Matias JavierNo ratings yet

- Piping & Instrumentation DiagramDocument15 pagesPiping & Instrumentation Diagramplanet123No ratings yet

- Tanzania Transport Master Plan (Vol. 1)Document33 pagesTanzania Transport Master Plan (Vol. 1)Julius Enock Moshi100% (1)

- 2021 Exam BramhastraDocument5,530 pages2021 Exam BramhastraRed VelvetNo ratings yet

- Amazon API GatewayDocument307 pagesAmazon API GatewayMinoru Osorio Garcia0% (1)

- FCJJ37 Power ES StudentDocument9 pagesFCJJ37 Power ES StudentMateo AlvarezNo ratings yet

- Usando MessageBox C BuilderDocument3 pagesUsando MessageBox C BuilderFernando Luiz Do AmaralNo ratings yet

- Polaris InfoDocument4 pagesPolaris InfoSankuri RamNo ratings yet

- Ca360b - Brochure BiotechDocument2 pagesCa360b - Brochure BiotechHawerasNo ratings yet

- Check List No. 12 - Creation of MortgageDocument2 pagesCheck List No. 12 - Creation of MortgageATIKUR RAHMANNo ratings yet

- 1 s2.0 S1044580316303412 MainDocument15 pages1 s2.0 S1044580316303412 MainShariful IslamNo ratings yet

- CBEprom Data BookDocument65 pagesCBEprom Data BookChelle2100% (2)

SOP-HA-028 SOP On Out of Trend Results

SOP-HA-028 SOP On Out of Trend Results

Uploaded by

bhullram736Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP-HA-028 SOP On Out of Trend Results

SOP-HA-028 SOP On Out of Trend Results

Uploaded by

bhullram736Copyright:

Available Formats

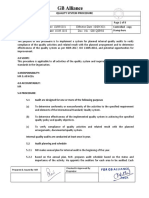

Acme Formulation Pvt Ltd, Nalagarh (H.P.

)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 1 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

1.0 PURPOSE

To lay down a procedure for handling of Out of Trend with respect to analytical result

process parameter and environment monitoring.

2.0 SCOPE

This SOP is applicable for handling of out of trend (within specification) results observed

in Hormone Block at Acme Formulation Pvt. Ltd.

3.0 RESPONSIBILITY

3.1 Officer/Executive (User Department) shall be responsible for investigation of OOT

and communication to respective HOD and QA.

3.2 HOD of user department and QA shall be responsible for investigation and

identification of root cause and proposal of CAPA.

3.3 Head QA/Designee shall be responsible for review of investigation and evaluation of

CAPA.

4.0 ACCOUNTABILITY

4.1 Head-QC and Head-QA shall be accountable for compliance of this SOP.

5.0 PROCEDURE

5.1 Criteria for OOT Result

Following criteria shall be used to consider result as out of trend after consultation

with QA.

5.1.1 If the critical parameter analyzed shows an abnormal result in comparison to

the other unit (of different batches) of the same strength`.

5.1.2 If the critical parameter analyzed shows an abnormal result in comparison to

the previous station sample of the same storage condition. (Stability sample

results)

5.1.3 Trend shall be prepared for minimum 10 batches and determine the UCL &

LCL on the basis of trend. APQR trends shall be followed to get the OOT

limits based on 2 sigma and 3 sigma approaches.

5.1.4 If finished assay release specification limit is 90-110, OOT shall be raised in

case observed results values <92 or >108.

5.1.5 If finished assay release specification limit is 95-105, observed results within

95-105 shall be reported as such. QA can take decision to investigate for any

uneven results based on product trend data and behavior.

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

Acme Formulation Pvt Ltd, Nalagarh (H.P.)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 2 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

5.1.6 In cases of blend assay where release specification limit is 95-105, if

composite assay results found out of limit but within 90-110, then blend

uniformity shall be performed. If BU results and RSD found well within the

limit and average within 95-105 then average of BU shall be reported as assay.

OOS shall be raised if BU average shall not be within 95-105

5.1.7 In case of finished product testing where average of content uniformity shall

be reported as assay. If observed CU results average shall not be within 95-

105, then proceed for L2 stage where next 20 tablets will be analyzed and

average of 30 tablets shall be within release specification limit 95-105. OOS

shall be raised if CU average shall not be within 95-105

5.1.8 OOT shall be raised if Dissolution shall go for S3 stage.

5.1.9 In case of Stability assay, OOT shall be raised if there is a ±5% variation from

initial results.

5.1.10 In case of related substance test, for impurities NMT 0.5% and NMT 1.0%,

OOT shall be raised if an impurity crosses 80% of the specification limit or

based on historical trend data as applicable.

5.1.11 OOT shall not be raised for impurities having specification limit below 0.5%

5.1.12 OOT shall not be raised for established trends (in case of stability study)

5.1.13 The result shall be declared as OOT only after consultation with Head QA.

5.1.14 Only chemical parameter shall be treated as critical.

5.2 Handling of OOT Result

5.2.1 Whenever any OOT result observed, same shall be recorded as per (Format

No. HA028/F01) & further processing shall be done as per flow mentioned in

format number (HA028/F04).

5.2.2 Each OOT shall be investigated as per (Format No. HA028/F02) and SOP on

Root cause Analysis Tools (SOP/HA/087) if required.

5.2.3 Investigation team shall initiate investigation and final approval to be done by

Head QA/Designee.

5.2.4 Each OOT result shall be assigned a unique number as OOT/XX/YYY, e.g.

first OOT of year 2019 shall be assigned as OOT/19/001

Where:

OOT stands for Out of Trend

The 4th character / is a forwarding slash

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

Acme Formulation Pvt Ltd, Nalagarh (H.P.)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 3 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

XX will be two digits of current year

The 7th character / is a forwarding slash

Last three numeric characters shall be the sequential no. for OOT (i.e.

001,002,003 and so on).

5.2.5 QC team shall refer SOP on Out of Specification results (SOP/HA/018) to

perform Phase-I investigation.

5.2.6 If the investigation reveals an assignable cause, then the analysis shall be

repeated in duplicate and the mean value shall be considered for reporting.

5.2.7 If the cause is not assigned, then an experimental plan will be designed in

consultation with QA and manufacturing investigation shall be carried out

accordingly.

5.2.8 The reporting/corrective action shall be carried out based on the outcome of

the above study.

5.2.9 An OOT investigation shall be completed within 30 working days.

5.1.1 In case the investigation exceeds more than 30 days then interim report shall

be generated by QC Head /designee and extension shall be taken for

investigation after authorization by Quality Assurance Head/Designee.

5.1.2 Wherever applicable Quality Assurance head shall notify the OOT results to

Head of RA, Manufacturing Head/customer as defined in respective

agreement.

5.3 Trend of OOT

5.3.1 OOT trend shall be prepared and reviewed on half yearly basis.

5.3.2 Content of Trend to be covered as below:

5.3.2.1 Objective

5.3.2.2 Scope

5.3.2.3 Total Number of OOT during the review period with closure status.

5.3.2.4 Month wise review of OOT during the review period.

5.3.2.5 Review of OOT based on the classification i.e. analytical

error/Manufacturing error.

5.3.2.6 Categorization of Analytical error

(a) Dilution error

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

Acme Formulation Pvt Ltd, Nalagarh (H.P.)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 4 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

(b) Sample preparation error

(c) Procedural error

(d) Contamination

(e) Procedural non compliance

(f) Instrument performance error

5.3.2.7 Manufacturing error

(a) Procedural non compliance

(b) Procedure not follow

(c) Raw Material issue

5.3.2.8 Review of OOT for closure status with open/closed beyond time line

with justification.

5.3.2.9 CAPA review for OOT.

5.3.2.10 Review of Repeated OOT.

5.3.2.11 CAPA review status for repeated OOT.

5.3.2.12 Comparison with previous trend for OOT.

5.3.2.13 Department and section/stage wise review of OOT.

5.3.2.14 Review of Root Cause wise OOT

5.3.2.15 Effective analysis tools shall be used for trend analysis (pie chart, Bar

chart, Pareto analysis, any other statistically shall be used) during

trend analysis.

6.0 PRECAUTION

NA

7.0 RELATED DOCUMENTS

7.1 SOP on Out of Specification (OOS) Result

8.0 LIST OF FORMATS

S.

Title of Format Format Number

No.

8.1 Log book for out of trend result HA028/F01

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

Acme Formulation Pvt Ltd, Nalagarh (H.P.)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 5 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

8.2 Out of trend test result investigation form HA028/F02

8.3 Trend Analysis Discontinued

8.4 Flow chart for OOT test result HA028/F04

9.0 REFERENCES

9.1 ICH guidelines handling OOT.

10.0 ABBREVIATIONS

Abbreviation Description

ICH International conference on harmonization

LOD Loss on drying

OOT Out of trend

RSD Relative standard deviation

RS Related substances

LCL Lower Control Limit

UCL Upper Control Limit

HA Hormone Block Quality Assurance

SOP Standard operating procedure

°C Degree Celsius

11.0 REVISION HISTORY

Revision No. Effective Date Change Control No. Reason of revision

02 09 Jan 2018 NA Scheduled Revision

The format of SOP has been revised to in line

E0 23/04/2019 HB/CC/HA/18/319

with EDCS software.

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

Acme Formulation Pvt Ltd, Nalagarh (H.P.)

Standard Operating Procedure

Originating Department: Quality Assurance

Title: SOP on Out of Trend Results

SOP No.: SOP/HA/028 Version No.: E2 Page 6 of 6

Effective Date: 15/03/21 Review Date: 15/03/23

HB/CC/HA/20/202 Procedure and Attachments of the SOP has been

E1 08/10/2020

reframed.

1. Responsibility for QA and QC has been

updated.

2. Criterion for OOT Results has been

elaborated.

3. Procedure for Handling of OOT Results has

been elaborated.

4. Procedure for Trending of OOT has been

E2 15/03/21 HB/CC/HA/21/018

updated.

5. Format of Out of trend test result investigation

form (HA028/F02) has been reframed.

6. Flow chart for OOT test result (HA028/F04)

has been reframed.

7. Format for Trend Analysis (HA028/F03) has

been discontinued.

Prepared By Checked By Approved By

202589 on 12/03/21 17:28:52 202432 on 12/03/21 17:39:34 201044 on 13/03/21 10:03:20

Format No. HA001/F01

You might also like

- SOP On Handling of DeviationsDocument10 pagesSOP On Handling of Deviationschemist_tma100% (1)

- SOP For Corrective Action and Preventive Action (CAPA)Document5 pagesSOP For Corrective Action and Preventive Action (CAPA)Juan Manuel Jaurez100% (5)

- Excavadora CDM6065Document109 pagesExcavadora CDM6065Leandro DietrichNo ratings yet

- SOP-QA-002-00-Document Preparation, Control and RetentionDocument7 pagesSOP-QA-002-00-Document Preparation, Control and RetentionNgoc Sang HuynhNo ratings yet

- Handling of OOTDocument18 pagesHandling of OOTjameer80100% (2)

- SOP QA 010 00 Handling of DeviationDocument17 pagesSOP QA 010 00 Handling of Deviationnetelsrt129875% (4)

- Corrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateDocument5 pagesCorrective and Preventive Action (Capa) Procedure: Rev. No. Page No. Revision History Originator DateAlmario SagunNo ratings yet

- Tandard Perating Rocedure: TitleDocument5 pagesTandard Perating Rocedure: TitlevishalstjsNo ratings yet

- Sop Qa 037 00 OosDocument19 pagesSop Qa 037 00 OosAnand H S100% (3)

- SOP On Handling of DeviationsDocument9 pagesSOP On Handling of DeviationsBlueSaga100% (1)

- L0-Sqe-Pro-055 (5) Drug and Alcohol Testing ProcedureDocument14 pagesL0-Sqe-Pro-055 (5) Drug and Alcohol Testing ProcedureCK TangNo ratings yet

- SOP For Handling of Out of Trend (OOT)Document3 pagesSOP For Handling of Out of Trend (OOT)Mubarak Patel100% (1)

- SOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical ResultsDocument5 pagesSOP - QA-007 SOP For Out of Specification (OOS) For Pharmaceutical Resultsد.عمر خليل العباسي100% (2)

- SOP On Handling of OOT and OOS-impDocument16 pagesSOP On Handling of OOT and OOS-impAkshita100% (1)

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument3 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesArup Chakraborty100% (1)

- PR-GM 09 Identification and Control Ofnon Conformance ProcedureDocument5 pagesPR-GM 09 Identification and Control Ofnon Conformance ProcedureFULGENCE RUHARARANo ratings yet

- Dev HanDocument9 pagesDev HanTuriyo AnthonyNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta100% (2)

- BRSM Form 009 - QMS MDD IsvDocument16 pagesBRSM Form 009 - QMS MDD IsvAnonymous q8lh3fldWMNo ratings yet

- Handling Data Yang Oos (Yola)Document6 pagesHandling Data Yang Oos (Yola)Ghifari Eka NugrohoNo ratings yet

- QCD-036-01 Good Chromatography PracticesDocument12 pagesQCD-036-01 Good Chromatography Practicesarnab rayNo ratings yet

- Oos Out of SpecificationDocument12 pagesOos Out of SpecificationShumaila Iftikhar100% (1)

- AC QA 004-01 (Deviation)Document30 pagesAC QA 004-01 (Deviation)Vijay Singh100% (1)

- Personnel Competencies Manual: Quality Assurance & Safety Quality System & Auditing TQ - (01 To 06) - 07Document5 pagesPersonnel Competencies Manual: Quality Assurance & Safety Quality System & Auditing TQ - (01 To 06) - 07Ananda FitrianiNo ratings yet

- Handling of Oot ResultsDocument5 pagesHandling of Oot ResultstghonsNo ratings yet

- SOP-QA-013-00-corrective and Preventive ActionDocument10 pagesSOP-QA-013-00-corrective and Preventive ActionNgoc Sang HuynhNo ratings yet

- SOP For Raw Material Release PG PDFDocument2 pagesSOP For Raw Material Release PG PDFMosub Al.DirdiryNo ratings yet

- SOP-QA-048 RoundingDocument3 pagesSOP-QA-048 RoundingchalicevitalchemNo ratings yet

- DELL - PSU - QPA - Rev 7 0 2Document116 pagesDELL - PSU - QPA - Rev 7 0 2Michael WuNo ratings yet

- SOP of Change ControlDocument24 pagesSOP of Change ControlPaolo PiccoliniNo ratings yet

- SOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesDocument4 pagesSOP For Corrective Action and Preventive Action (CAPA) - Pharmaceutical GuidelinesGanesh KashinathNo ratings yet

- 30-99-90-1615 Rev 1 Internal and External Audits ProcedureDocument10 pages30-99-90-1615 Rev 1 Internal and External Audits ProcedureEswar ReddyNo ratings yet

- Product Formulation DevelopmentDocument3 pagesProduct Formulation DevelopmentAnonymous mBOujo5No ratings yet

- PRODUCT-Bank of Investment and Development of Cambodia: Test Case Result DocumentDocument8 pagesPRODUCT-Bank of Investment and Development of Cambodia: Test Case Result DocumentBIDC EmailNo ratings yet

- Qa003 15Document7 pagesQa003 15Sridhar NandipatiNo ratings yet

- ReprocessingDocument3 pagesReprocessingswanandkul86% (7)

- MICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFDocument4 pagesMICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFalnzeer omerNo ratings yet

- G-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Document17 pagesG-20-Interpretation and Guidance On The Estimation of Uncertainty of Measurement in Testing (EN)Ahmad HidayatNo ratings yet

- Sop For Analytical Method Validqation and VerificationDocument7 pagesSop For Analytical Method Validqation and Verificationvasant ugale100% (3)

- CTFL2018 05 Testmanagement Quiz 1.01Document35 pagesCTFL2018 05 Testmanagement Quiz 1.01Giang- B17DCCN188 Nguyễn Thị HươngNo ratings yet

- Sop 003 For Analysis of Rinse SampleDocument3 pagesSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- KSA-POP-010-General Guidelines For Sampling For Laboratory TestingDocument7 pagesKSA-POP-010-General Guidelines For Sampling For Laboratory TestingASHJANNo ratings yet

- Evaluation Reporting of ResultsDocument16 pagesEvaluation Reporting of ResultspurnachandrashekarNo ratings yet

- Pharmaguidesop Com 2021 03 Sop On Supplier Qualification VenDocument14 pagesPharmaguidesop Com 2021 03 Sop On Supplier Qualification VenTuriyo AnthonyNo ratings yet

- Evaluation Reporting of Results Core Document PDFDocument6 pagesEvaluation Reporting of Results Core Document PDFParkhomyukNo ratings yet

- End To End Testing Procedure: Issue 1.0Document9 pagesEnd To End Testing Procedure: Issue 1.0Sushant NarvekarNo ratings yet

- Sop-Qa-038-00-Stability StudiesDocument22 pagesSop-Qa-038-00-Stability Studiesnareshph28No ratings yet

- WWW Pharmaguideline Com 2010 03 Sop For Out of SpecificationDocument8 pagesWWW Pharmaguideline Com 2010 03 Sop For Out of SpecificationTuriyo AnthonyNo ratings yet

- Qua-Dmt-G-001 Guideline For Root Cause Analysis InvestigationsDocument61 pagesQua-Dmt-G-001 Guideline For Root Cause Analysis InvestigationsSuresh GollaNo ratings yet

- 01 Supplier Pre-Qualification AssessmentDocument18 pages01 Supplier Pre-Qualification AssessmentChinh Lê Đình100% (1)

- XXX Test Summary and Sign OffDocument9 pagesXXX Test Summary and Sign OffMark FriazNo ratings yet

- XXX Test Summary and Sign OffDocument9 pagesXXX Test Summary and Sign OffMarkNo ratings yet

- ETE:MR:02Document3 pagesETE:MR:02pranesh kadamNo ratings yet

- SOP On SOPDocument7 pagesSOP On SOPRaja AbhilashNo ratings yet

- SOP Internal AUditDocument8 pagesSOP Internal AUditAnmolNo ratings yet

- Management ReviewDocument2 pagesManagement Reviewpranesh kadamNo ratings yet

- Calibration of Friability Test ApparatusDocument4 pagesCalibration of Friability Test Apparatusashishchandan13No ratings yet

- 38) PFMEA ProcedureDocument3 pages38) PFMEA ProcedureSagar DaundNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- ISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012From EverandISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012No ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- Comparative Analysis and Optimization of Active Power and Delay of 1-Bit Full Adder at 45 NM TechnologyDocument3 pagesComparative Analysis and Optimization of Active Power and Delay of 1-Bit Full Adder at 45 NM TechnologyNsrc Nano ScientifcNo ratings yet

- OSHA Office of Training & Education 1Document78 pagesOSHA Office of Training & Education 1AmeerUlHaqNo ratings yet

- Probity Audit PolicyDocument7 pagesProbity Audit PolicyMahmud Toha100% (1)

- Lecture Three Actuators ObjectivesDocument5 pagesLecture Three Actuators ObjectivesKenani SaningaNo ratings yet

- Villaba 26Document205 pagesVillaba 26villaba14No ratings yet

- HMT306 Food Processing and PreservationDocument431 pagesHMT306 Food Processing and Preservationgumnani.rewachandNo ratings yet

- Elitmus Syllabus and Question Paper PatternDocument5 pagesElitmus Syllabus and Question Paper PatternAbhishek MohanNo ratings yet

- Jay Van Patten - Executive Resume - August 2019Document4 pagesJay Van Patten - Executive Resume - August 2019api-472622610No ratings yet

- Municipality of Camalaniugan: Amounting ToDocument3 pagesMunicipality of Camalaniugan: Amounting ToMelody Frac ZapateroNo ratings yet

- PNS BAFS 184.2016. GAHP Chicken Broilers LayersDocument22 pagesPNS BAFS 184.2016. GAHP Chicken Broilers LayersFelix Albit Ogabang IiiNo ratings yet

- Baires Dev PreentrevistaDocument3 pagesBaires Dev PreentrevistaCarlos Gonzalo Maravi ArensNo ratings yet

- Grade 6 SLK Arts Q1 Week 3 FinalDocument14 pagesGrade 6 SLK Arts Q1 Week 3 FinalNalyn AdameNo ratings yet

- Philippine Rabbit v. People of The Philippines DigestDocument2 pagesPhilippine Rabbit v. People of The Philippines DigestDonvidachiye Liwag CenaNo ratings yet

- Fluid Mechanics - ProblemsDocument4 pagesFluid Mechanics - ProblemsClement Chima50% (2)

- Construction Planning 2019 MemoDocument6 pagesConstruction Planning 2019 MemoNtokozo JiyanaNo ratings yet

- Short Circuit Currents.Document11 pagesShort Circuit Currents.Shiju Kp.No ratings yet

- Jump To Navigationjump To Search: EuroplugDocument5 pagesJump To Navigationjump To Search: EuroplugqwertyNo ratings yet

- Outline of ISF2024Document10 pagesOutline of ISF2024Matias JavierNo ratings yet

- Piping & Instrumentation DiagramDocument15 pagesPiping & Instrumentation Diagramplanet123No ratings yet

- Tanzania Transport Master Plan (Vol. 1)Document33 pagesTanzania Transport Master Plan (Vol. 1)Julius Enock Moshi100% (1)

- 2021 Exam BramhastraDocument5,530 pages2021 Exam BramhastraRed VelvetNo ratings yet

- Amazon API GatewayDocument307 pagesAmazon API GatewayMinoru Osorio Garcia0% (1)

- FCJJ37 Power ES StudentDocument9 pagesFCJJ37 Power ES StudentMateo AlvarezNo ratings yet

- Usando MessageBox C BuilderDocument3 pagesUsando MessageBox C BuilderFernando Luiz Do AmaralNo ratings yet

- Polaris InfoDocument4 pagesPolaris InfoSankuri RamNo ratings yet

- Ca360b - Brochure BiotechDocument2 pagesCa360b - Brochure BiotechHawerasNo ratings yet

- Check List No. 12 - Creation of MortgageDocument2 pagesCheck List No. 12 - Creation of MortgageATIKUR RAHMANNo ratings yet

- 1 s2.0 S1044580316303412 MainDocument15 pages1 s2.0 S1044580316303412 MainShariful IslamNo ratings yet

- CBEprom Data BookDocument65 pagesCBEprom Data BookChelle2100% (2)