Professional Documents

Culture Documents

Si 1724 Efishere

Si 1724 Efishere

Uploaded by

hufuentsCopyright:

Available Formats

You might also like

- Liebherr T264 SpecificationsDocument24 pagesLiebherr T264 Specificationsbas100% (1)

- RP554 ManualDocument3 pagesRP554 ManualAdolfo Angulo100% (1)

- Cook Compression PackingDocument2 pagesCook Compression PackingMuhammad Imran100% (1)

- Fin FanDocument4 pagesFin FanPuchit SpkNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- RTL Sleevoil Instruction Manual 499970Document11 pagesRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाNo ratings yet

- Manuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFDocument8 pagesManuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFAnonymous T7zEN6iLHNo ratings yet

- Poly Hopper Inverted Vee Kit 95970: Parts ListDocument2 pagesPoly Hopper Inverted Vee Kit 95970: Parts List77ztfNo ratings yet

- Installing The Delta Ring Assembly & The Barrel Into The Upper ReceiverDocument2 pagesInstalling The Delta Ring Assembly & The Barrel Into The Upper Receiverpronet8686No ratings yet

- QD Bushings CatalogDocument5 pagesQD Bushings CatalogYuri OrellanoNo ratings yet

- Mte13ii Oc77 - 1331 X009 06 299 1 001 - 0Document3 pagesMte13ii Oc77 - 1331 X009 06 299 1 001 - 0Miguel Puma SuclleNo ratings yet

- IOM 40 Fugitive Emissions Packing PDFDocument4 pagesIOM 40 Fugitive Emissions Packing PDFTedi SutansahNo ratings yet

- Angle Type Blowdown ValveDocument7 pagesAngle Type Blowdown ValverikumohanNo ratings yet

- The Highest Level of Reloading PrecisionDocument3 pagesThe Highest Level of Reloading PrecisionToxophilus TheLuckyNo ratings yet

- Standard TorqueDocument12 pagesStandard TorqueEDY AZHARINo ratings yet

- Kennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualDocument11 pagesKennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualttyNo ratings yet

- Descarga Riva VXR 18Document7 pagesDescarga Riva VXR 18lucasNo ratings yet

- Technical Data: DescriptionDocument3 pagesTechnical Data: DescriptionSyaefah FaizNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- Repair ManualDocument2 pagesRepair ManualKleiton Silveira de CastroNo ratings yet

- Installation of Packing: How To Install PackingDocument1 pageInstallation of Packing: How To Install PackingChandra SekarNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- Eich Split Bearing Instruction Manual 07 19Document5 pagesEich Split Bearing Instruction Manual 07 19huseyinNo ratings yet

- Bonded Sump Entry Fitting Termination Style Spec Sheet-2Document4 pagesBonded Sump Entry Fitting Termination Style Spec Sheet-2Enrique ArmandoNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- Lead Seal Casing Patches: Instruction Manual 6400Document9 pagesLead Seal Casing Patches: Instruction Manual 6400Ragui StephanosNo ratings yet

- BOPV Section 6 - Assembly InstructionsDocument4 pagesBOPV Section 6 - Assembly InstructionsusamakhattakNo ratings yet

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 pagesInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNo ratings yet

- WWP 40 HDocument13 pagesWWP 40 HHEMANTKHERANo ratings yet

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 pagesValves S&S B Series 8-Inch Globe: Instruction ManualpedroNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- Renold Hi-Tec - RB Flywheel Mount Coupling Assembly InstructDocument12 pagesRenold Hi-Tec - RB Flywheel Mount Coupling Assembly InstructJorge ContrerasNo ratings yet

- Stock "QD" Bushings: RemovalDocument2 pagesStock "QD" Bushings: RemovalmecanicoNo ratings yet

- Operation Manual Cast Iron ValvesDocument48 pagesOperation Manual Cast Iron ValvesRobert LazaroNo ratings yet

- AR-15 Receiver Lapping Tool Usage Instructions Product #156757 Instruction #1024572Document2 pagesAR-15 Receiver Lapping Tool Usage Instructions Product #156757 Instruction #1024572Dean MillerNo ratings yet

- Kbu KBZ5Document6 pagesKbu KBZ5Andrew VNo ratings yet

- FTS 425 InstallDocument2 pagesFTS 425 InstalldedypunyaNo ratings yet

- Kidde ECS Advanced Delivery Fire Suppression System: Component DescriptionDocument2 pagesKidde ECS Advanced Delivery Fire Suppression System: Component DescriptionkiuNo ratings yet

- VE5C VE Commodore Hard Lid ManualDocument13 pagesVE5C VE Commodore Hard Lid ManualmathewNo ratings yet

- AsasasasasasasDocument1 pageAsasasasasasasmateoNo ratings yet

- SKF SAF and SAFS Installation and Maintenance OMs English 1 PDFDocument4 pagesSKF SAF and SAFS Installation and Maintenance OMs English 1 PDFjaime San Martin PulgarNo ratings yet

- GIH Section 6 - Assembly InstructionsDocument3 pagesGIH Section 6 - Assembly InstructionsLawrence FernandesNo ratings yet

- SEPCO 14 Procedimiento para La InstalaciónDocument1 pageSEPCO 14 Procedimiento para La InstalaciónVictor Flores ResendizNo ratings yet

- Marley ValveDocument4 pagesMarley ValveM Fadli AzhariNo ratings yet

- Die Form Ring PackingDocument8 pagesDie Form Ring Packingjim_tuckerNo ratings yet

- 2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuideDocument2 pages2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuidemajoNo ratings yet

- Er 96 5 14Document3 pagesEr 96 5 14DIEGO YECID MILLAN MENDOZANo ratings yet

- Service: Ualiru... TobeDocument3 pagesService: Ualiru... TobeTomas MalyNo ratings yet

- Chesterton 1600 - 1601 Empaquetadura Prensoestopa-FUNDICIONDocument10 pagesChesterton 1600 - 1601 Empaquetadura Prensoestopa-FUNDICIONpcesar777No ratings yet

- Instruction Manual 6460: Lead Seal Cementing Type Casing PatchDocument10 pagesInstruction Manual 6460: Lead Seal Cementing Type Casing PatchRagui StephanosNo ratings yet

- BearingDocument11 pagesBearingThanh Luan NguyenNo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- Freedom Flyer: For Single & Double Treadle Joy Spinning WheelsDocument2 pagesFreedom Flyer: For Single & Double Treadle Joy Spinning WheelsSad ElfNo ratings yet

- 37 1 606Document26 pages37 1 606khalafNo ratings yet

- Type 3500 DatasheetDocument12 pagesType 3500 DatasheetrendymulyadiNo ratings yet

- Accum Re AssemblyDocument1 pageAccum Re AssemblyrezandriansyahNo ratings yet

- Halcyon Tankbands02Document2 pagesHalcyon Tankbands02viboralunaNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- Ohlins DTC Einbauanleitung Fgba 1884 EnglischDocument7 pagesOhlins DTC Einbauanleitung Fgba 1884 EnglischKFZ - TECHNIKNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- HCMM026EDocument1 pageHCMM026EhufuentsNo ratings yet

- Krauss-Maffai 3200T ROIDocument3 pagesKrauss-Maffai 3200T ROIhufuentsNo ratings yet

- ROI 3.1 Magna Exterior Injection MoldingDocument2 pagesROI 3.1 Magna Exterior Injection MoldinghufuentsNo ratings yet

- HCAU006EDocument1 pageHCAU006EhufuentsNo ratings yet

- 2022 New Broaband Sensor Approach For Condition MonitoringDocument17 pages2022 New Broaband Sensor Approach For Condition MonitoringhufuentsNo ratings yet

- HCAU005EDocument1 pageHCAU005EhufuentsNo ratings yet

- HCAU007EDocument1 pageHCAU007EhufuentsNo ratings yet

- Application Success Story:: Food Processing Corn Mash Mechanical SealDocument1 pageApplication Success Story:: Food Processing Corn Mash Mechanical SealhufuentsNo ratings yet

- Application Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostsDocument1 pageApplication Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostshufuentsNo ratings yet

- Solutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationsDocument1 pageSolutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationshufuentsNo ratings yet

- 442HP Small and Large SizeDocument2 pages442HP Small and Large SizehufuentsNo ratings yet

- SpiralTrac S SuccessDocument1 pageSpiralTrac S SuccesshufuentsNo ratings yet

- Intelliflow: Chestertont-30 Intelliflow Water SaverDocument2 pagesIntelliflow: Chestertont-30 Intelliflow Water SaverhufuentsNo ratings yet

- 370 in A Sprout Waldon Twin Flow Refiner: IndustryDocument1 page370 in A Sprout Waldon Twin Flow Refiner: IndustryhufuentsNo ratings yet

- ILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammableDocument1 pageILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammablehufuentsNo ratings yet

- Sbpln53a ENDocument2 pagesSbpln53a ENhufuentsNo ratings yet

- ILK-M18-AB: Electrical Design Ac / DC Output Normally OpenDocument1 pageILK-M18-AB: Electrical Design Ac / DC Output Normally OpenhufuentsNo ratings yet

- Solutions: Sealing High ViscositiesDocument2 pagesSolutions: Sealing High ViscositieshufuentsNo ratings yet

- ES V1 I7 Moyno SolutionsDocument2 pagesES V1 I7 Moyno SolutionshufuentsNo ratings yet

- ES V1 I8 Positive DisplacementDocument2 pagesES V1 I8 Positive DisplacementhufuentsNo ratings yet

- Case History Steel Trap Live Load 2Document1 pageCase History Steel Trap Live Load 2hufuentsNo ratings yet

- EN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindersDocument1 pageEN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindershufuentsNo ratings yet

- Lube Oil System - Alco & HHP - 2Document43 pagesLube Oil System - Alco & HHP - 2kiran kumarNo ratings yet

- Basic Concepts, Rectangular and T Beams PDFDocument49 pagesBasic Concepts, Rectangular and T Beams PDFAhmed Hussein KamelNo ratings yet

- Hardness Testing Technologies: AdvancedDocument20 pagesHardness Testing Technologies: AdvancedramalingamNo ratings yet

- L958FDocument2 pagesL958FUbaldo Enrique Caraballo EstradaNo ratings yet

- Moog CartridgeValves DBD04 Catalog enDocument8 pagesMoog CartridgeValves DBD04 Catalog enTejas MahadikNo ratings yet

- AP Physics Study GuideDocument96 pagesAP Physics Study GuideBenjamin GroffNo ratings yet

- 2012 Fifth Wheel Selection GuideDocument96 pages2012 Fifth Wheel Selection GuideAbrar HussainNo ratings yet

- Capstan & Turret LatheDocument27 pagesCapstan & Turret LatheMuraliNo ratings yet

- Admiral ManualDocument36 pagesAdmiral ManualJulian Bermudez HernandezNo ratings yet

- Install Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Document13 pagesInstall Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Mauriece CarrilloNo ratings yet

- Bomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualDocument66 pagesBomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualSwiduNo ratings yet

- RulmanKatalogu 2018 05 18 15 - 24 - 59Document336 pagesRulmanKatalogu 2018 05 18 15 - 24 - 59Alvaro Felipe CharlinNo ratings yet

- Mak Freezol 68 OilDocument1 pageMak Freezol 68 OilshobhaNo ratings yet

- Lifting LugDocument8 pagesLifting LugEnrique BarajasNo ratings yet

- Dynamics Review Package (Key)Document19 pagesDynamics Review Package (Key)Arlo SeasenNo ratings yet

- Fatigue Testing - Ignacio ArtamendiDocument26 pagesFatigue Testing - Ignacio ArtamendiRoque3RNo ratings yet

- Bahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A BuildingDocument11 pagesBahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A Buildingrjchp100% (1)

- Rocket Engines - Origin, Developments and FutureDocument13 pagesRocket Engines - Origin, Developments and FutureDeepak Rawat100% (1)

- r7210305 ThermodynamicsDocument4 pagesr7210305 ThermodynamicssivabharathamurthyNo ratings yet

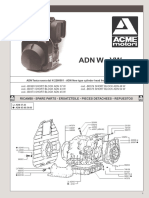

- Acme AdnDocument21 pagesAcme AdnbaiardimircoNo ratings yet

- Komatsu PC200-6 Shop ManualDocument711 pagesKomatsu PC200-6 Shop ManualMạnh Dũng100% (1)

- Chapter 5 Centrifugal Compressor (Complete Slide)Document17 pagesChapter 5 Centrifugal Compressor (Complete Slide)Azhan FikriNo ratings yet

- Em12r1u PDFDocument482 pagesEm12r1u PDFAnwar ZaibNo ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- Duraflex WiresDocument1 pageDuraflex WiresjaqiriNo ratings yet

- Ahm-1C Hopper Mount Dryer Operating Manual: Dri-AirDocument22 pagesAhm-1C Hopper Mount Dryer Operating Manual: Dri-AirYenireé MedinaNo ratings yet

- Som 1Document8 pagesSom 1Sachin SainiNo ratings yet

- So21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocument156 pagesSo21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdBazzie100% (1)

- Mid Term Paper 3 Heat TransferDocument2 pagesMid Term Paper 3 Heat TransferAbdul GhaffarNo ratings yet

Si 1724 Efishere

Si 1724 Efishere

Uploaded by

hufuentsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Si 1724 Efishere

Si 1724 Efishere

Uploaded by

hufuentsCopyright:

Available Formats

CHESTERTON ®

1724E Installation Instructions

Fisher Live Load Kit for Fisher Valve Body Design E

1. Precaution: System should be shut down, depressurized, 7. Install the new gland studs provided. Verify the B7 studs

drained, and cool before valve is handled. Observe all plant and the 2H nuts provided are of the same or better grade

safety requirements. than the studs and nuts being replaced.

2. Check the condition of the valve for the following: 8. Install the packing follower and packing gland flange.

• A 10 to 32 RMS (7.5 to 24 Ra) stem finish is required. Make sure the packing follower enters into the stuffing box.

• The stuffing box bore should be 125 RMS (94 Ra) or Note: If the Fisher Packing Gland Flange is of the older

better finish. type, the two raised surfaces on the top of the flange

• The stem run out should not exceed ±0.010 TIR/FT. should be machined flat to permit the proper installation

of the live loading assemblies.

• The Fisher Packing Box Ring should be in the bottom

of the stuffing box. 9. Lubricate the studs, bottom of the nuts, and live loading

3. The stuffing box must be clean, i.e. completely free of any assembly components (belleville springs and flat washer)

previous packing or foreign material. The valve stem must with CHESTERTON Nickel Anti-Seize Compound. Verify

be clean, free of nicks, scratches and burrs. the springs and flat washers are properly stacked as

shown in the drawing.

4. Verify the split sleeve height provided is correct. The

height of the sleeve should be 0.187" shorter than the 10. Install a live loading assembly on each stud. The cut away

calculated height. The calculated height is the difference portion of the outer guide should face the stem.

between the stuffing box depth and the measured 11. Install the two packing gland nuts. Tighten each nut until

packing set height. The packing height is approximately finger tight. Alternately tighten the gland nuts until the top

five times the cross section for the 1724 packing set. surface of the flat washer is flush or even with the top, flat

Install the Split Sleeve in the bottom of the stuffing box. surface of the outer guide. Verify that the packing gland is

Make sure the two halves align and are seated properly square and perpendicular to the stem.

on the stuffing box bottom.

12. To properly consolidate the packing: Actuate the valve 10

5. Valve stems with minor pitting may be lightly coated with times, retighten the packing gland nuts at the end of the

an approved lubricant to help reduce packing wear. last down/in-stroke. Actuate the valve 10 more times,

Chesterton recommends 725 or 772 Nickel Anti-Seize retighten the packing gland nuts at the end of the last

Compound, or a silicone lubricant be applied to the I.D. down/in-stroke.

of the rings and valve stem for ease of actuation.

13. Follow normal safety precautions when returning the valve

Compatibility of lubricants should be evaluated in highly

to service.

oxidative chemical environments.

14. It is advisable to check gland adjustment after a few

6. Install one ring of 1724 packing using a Chesterton Valve

hours of service. Take up as necessary.

Tamping Tool. Care must be taken to insure the skive-cut

ends are properly mated. Firmly tamp the ring to the bottom If the valve does not actuate properly at the compressed

of the box. Install remaining rings in the same manner assembly height, release all packing gland load completely.

staggering joints 90 degrees. See drawing. Then gradually tighten the packing gland nuts until no leakage

is observed. Do not tighten to the point where the stem will

not actuate. Reference the Fisher Kit Table.

225 Fallon Road

Stoneham, Massachusetts 02180 -2904 USA

Tel: 781- 438 -7000 • Fax: 781- 438 -8971

www.chesterton.com

© A.W. CHESTERTON CO., 2004. All rights reserved.

® Registered trademark owned and licensed by A. W. CHESTERTON CO.

FORM NO. 071011 in USA and other countries. PRINTED IN USA 9/04

A.W. Chesterton 1724E Packing Configuration

Spring assembly Replacement B7

with outer guide Studs and 2H Nuts

compressed.

Top of flat washer Spring assembly

is flush with top with outer guide

of outer guide. uncompressed.

Packing Rings

Style 1724

Split Sleeve

Fisher Packing

Box Ring

Radial Axial Uncomp. Compress. AWC Live Load

Needed Needed Height Height Bolt Dia. Configuration Item #

0.480" 0.787" 0.787" 0.688" 0.312" 1 in par/8 in ser 030776

0.480" 0.835" 0.835" 0.764" 0.437" 1 in par/8 in ser 030912

0.650" 0.977" 0.977" 0.883" 0.562" 1 in par/8 in ser 030959

0.650" 1.007" 1.077" 0.883" 0.562" 1 in par/8 in ser 031023

Torque and Friction Values 1724E Fisher Kits Valve Body Design E

BODY RATING : CLASS 150 & 300

Bolt/Stud Bolt/Stud Box Predicted

Valve Size Stem O.D. Box I.D. Dia. Length Depth LL Complete Kit Packing Friction Torque

Inches Inches/mm Inches/mm Inches/mm Inches/mm Inches Item # Item # Lbs. / kg Ft-lbs / N.m

1"-1.5" 0.375 / 9,5 0.875 / 22,2 0.312 / 7,9 2.750 / 69,9 2.562 030776 148004 87.0 / 39,5 5.0 / 6,8

2" / 3" / 4" 0.500 / 12,7 1.000 / 25,4 0.437 / 11,1 3.250 / 82,5 3.500 030912 148005 132.3 / 60,0 6.5 / 8,8

6" / 8" 0.750 / 19,0 1.375 / 34,9 0.562 / 14,3 4.250 / 108,0 3.812 030959 148006 159.4 / 72,3 8.5 / 11,5

BODY RATING : CLASS 600

Bolt/Stud Bolt/Stud Box Predicted

Valve Size Stem O.D. Box I.D. Dia. Length Depth LL Complete Kit Packing Friction Torque

Inches Inches/mm Inches/mm Inches/mm Inches/mm Inches Item # Item # Lbs. / kg Ft-lbs / N.m

6" / 8" 0.750 / 19,0 1.375 / 34,9 0.562 / 14,3 4.250 / 108,0 3.812 031023 148007 193.2 / 86,6 13.0 / 17,6

Includes Designs EAC, EAD, EC, ED, EHAT, EHD, EHT, EJ, EP, ES, ENC, END, ENJ, EWPP, AND ENS.

You might also like

- Liebherr T264 SpecificationsDocument24 pagesLiebherr T264 Specificationsbas100% (1)

- RP554 ManualDocument3 pagesRP554 ManualAdolfo Angulo100% (1)

- Cook Compression PackingDocument2 pagesCook Compression PackingMuhammad Imran100% (1)

- Fin FanDocument4 pagesFin FanPuchit SpkNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- RTL Sleevoil Instruction Manual 499970Document11 pagesRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाNo ratings yet

- Manuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFDocument8 pagesManuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFAnonymous T7zEN6iLHNo ratings yet

- Poly Hopper Inverted Vee Kit 95970: Parts ListDocument2 pagesPoly Hopper Inverted Vee Kit 95970: Parts List77ztfNo ratings yet

- Installing The Delta Ring Assembly & The Barrel Into The Upper ReceiverDocument2 pagesInstalling The Delta Ring Assembly & The Barrel Into The Upper Receiverpronet8686No ratings yet

- QD Bushings CatalogDocument5 pagesQD Bushings CatalogYuri OrellanoNo ratings yet

- Mte13ii Oc77 - 1331 X009 06 299 1 001 - 0Document3 pagesMte13ii Oc77 - 1331 X009 06 299 1 001 - 0Miguel Puma SuclleNo ratings yet

- IOM 40 Fugitive Emissions Packing PDFDocument4 pagesIOM 40 Fugitive Emissions Packing PDFTedi SutansahNo ratings yet

- Angle Type Blowdown ValveDocument7 pagesAngle Type Blowdown ValverikumohanNo ratings yet

- The Highest Level of Reloading PrecisionDocument3 pagesThe Highest Level of Reloading PrecisionToxophilus TheLuckyNo ratings yet

- Standard TorqueDocument12 pagesStandard TorqueEDY AZHARINo ratings yet

- Kennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualDocument11 pagesKennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualttyNo ratings yet

- Descarga Riva VXR 18Document7 pagesDescarga Riva VXR 18lucasNo ratings yet

- Technical Data: DescriptionDocument3 pagesTechnical Data: DescriptionSyaefah FaizNo ratings yet

- Maintenance Instruction Manual: Severe Service Control ValvesDocument9 pagesMaintenance Instruction Manual: Severe Service Control Valvesابزار دقیقNo ratings yet

- Repair ManualDocument2 pagesRepair ManualKleiton Silveira de CastroNo ratings yet

- Installation of Packing: How To Install PackingDocument1 pageInstallation of Packing: How To Install PackingChandra SekarNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- Eich Split Bearing Instruction Manual 07 19Document5 pagesEich Split Bearing Instruction Manual 07 19huseyinNo ratings yet

- Bonded Sump Entry Fitting Termination Style Spec Sheet-2Document4 pagesBonded Sump Entry Fitting Termination Style Spec Sheet-2Enrique ArmandoNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- Lead Seal Casing Patches: Instruction Manual 6400Document9 pagesLead Seal Casing Patches: Instruction Manual 6400Ragui StephanosNo ratings yet

- BOPV Section 6 - Assembly InstructionsDocument4 pagesBOPV Section 6 - Assembly InstructionsusamakhattakNo ratings yet

- Instruction Manual: Bharat Heavy Electricals Limited TiruchirapalliDocument7 pagesInstruction Manual: Bharat Heavy Electricals Limited TiruchirapalliUJJAL KUMAR BHATTACHARYAYNo ratings yet

- WWP 40 HDocument13 pagesWWP 40 HHEMANTKHERANo ratings yet

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 pagesValves S&S B Series 8-Inch Globe: Instruction ManualpedroNo ratings yet

- Trailer Buddy VaultDocument10 pagesTrailer Buddy VaultjeffNo ratings yet

- Renold Hi-Tec - RB Flywheel Mount Coupling Assembly InstructDocument12 pagesRenold Hi-Tec - RB Flywheel Mount Coupling Assembly InstructJorge ContrerasNo ratings yet

- Stock "QD" Bushings: RemovalDocument2 pagesStock "QD" Bushings: RemovalmecanicoNo ratings yet

- Operation Manual Cast Iron ValvesDocument48 pagesOperation Manual Cast Iron ValvesRobert LazaroNo ratings yet

- AR-15 Receiver Lapping Tool Usage Instructions Product #156757 Instruction #1024572Document2 pagesAR-15 Receiver Lapping Tool Usage Instructions Product #156757 Instruction #1024572Dean MillerNo ratings yet

- Kbu KBZ5Document6 pagesKbu KBZ5Andrew VNo ratings yet

- FTS 425 InstallDocument2 pagesFTS 425 InstalldedypunyaNo ratings yet

- Kidde ECS Advanced Delivery Fire Suppression System: Component DescriptionDocument2 pagesKidde ECS Advanced Delivery Fire Suppression System: Component DescriptionkiuNo ratings yet

- VE5C VE Commodore Hard Lid ManualDocument13 pagesVE5C VE Commodore Hard Lid ManualmathewNo ratings yet

- AsasasasasasasDocument1 pageAsasasasasasasmateoNo ratings yet

- SKF SAF and SAFS Installation and Maintenance OMs English 1 PDFDocument4 pagesSKF SAF and SAFS Installation and Maintenance OMs English 1 PDFjaime San Martin PulgarNo ratings yet

- GIH Section 6 - Assembly InstructionsDocument3 pagesGIH Section 6 - Assembly InstructionsLawrence FernandesNo ratings yet

- SEPCO 14 Procedimiento para La InstalaciónDocument1 pageSEPCO 14 Procedimiento para La InstalaciónVictor Flores ResendizNo ratings yet

- Marley ValveDocument4 pagesMarley ValveM Fadli AzhariNo ratings yet

- Die Form Ring PackingDocument8 pagesDie Form Ring Packingjim_tuckerNo ratings yet

- 2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuideDocument2 pages2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuidemajoNo ratings yet

- Er 96 5 14Document3 pagesEr 96 5 14DIEGO YECID MILLAN MENDOZANo ratings yet

- Service: Ualiru... TobeDocument3 pagesService: Ualiru... TobeTomas MalyNo ratings yet

- Chesterton 1600 - 1601 Empaquetadura Prensoestopa-FUNDICIONDocument10 pagesChesterton 1600 - 1601 Empaquetadura Prensoestopa-FUNDICIONpcesar777No ratings yet

- Instruction Manual 6460: Lead Seal Cementing Type Casing PatchDocument10 pagesInstruction Manual 6460: Lead Seal Cementing Type Casing PatchRagui StephanosNo ratings yet

- BearingDocument11 pagesBearingThanh Luan NguyenNo ratings yet

- Storz ManualDocument7 pagesStorz Manualhijodebudas100% (1)

- Freedom Flyer: For Single & Double Treadle Joy Spinning WheelsDocument2 pagesFreedom Flyer: For Single & Double Treadle Joy Spinning WheelsSad ElfNo ratings yet

- 37 1 606Document26 pages37 1 606khalafNo ratings yet

- Type 3500 DatasheetDocument12 pagesType 3500 DatasheetrendymulyadiNo ratings yet

- Accum Re AssemblyDocument1 pageAccum Re AssemblyrezandriansyahNo ratings yet

- Halcyon Tankbands02Document2 pagesHalcyon Tankbands02viboralunaNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- Ohlins DTC Einbauanleitung Fgba 1884 EnglischDocument7 pagesOhlins DTC Einbauanleitung Fgba 1884 EnglischKFZ - TECHNIKNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- HCMM026EDocument1 pageHCMM026EhufuentsNo ratings yet

- Krauss-Maffai 3200T ROIDocument3 pagesKrauss-Maffai 3200T ROIhufuentsNo ratings yet

- ROI 3.1 Magna Exterior Injection MoldingDocument2 pagesROI 3.1 Magna Exterior Injection MoldinghufuentsNo ratings yet

- HCAU006EDocument1 pageHCAU006EhufuentsNo ratings yet

- 2022 New Broaband Sensor Approach For Condition MonitoringDocument17 pages2022 New Broaband Sensor Approach For Condition MonitoringhufuentsNo ratings yet

- HCAU005EDocument1 pageHCAU005EhufuentsNo ratings yet

- HCAU007EDocument1 pageHCAU007EhufuentsNo ratings yet

- Application Success Story:: Food Processing Corn Mash Mechanical SealDocument1 pageApplication Success Story:: Food Processing Corn Mash Mechanical SealhufuentsNo ratings yet

- Application Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostsDocument1 pageApplication Success Story:: Excessive Flush and Leakage 1200 - 1500 GPH / High Maintenance CostshufuentsNo ratings yet

- Solutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationsDocument1 pageSolutions Solutions Solutions Solutions: 442 Split Seals in Vacuum ApplicationshufuentsNo ratings yet

- 442HP Small and Large SizeDocument2 pages442HP Small and Large SizehufuentsNo ratings yet

- SpiralTrac S SuccessDocument1 pageSpiralTrac S SuccesshufuentsNo ratings yet

- Intelliflow: Chestertont-30 Intelliflow Water SaverDocument2 pagesIntelliflow: Chestertont-30 Intelliflow Water SaverhufuentsNo ratings yet

- 370 in A Sprout Waldon Twin Flow Refiner: IndustryDocument1 page370 in A Sprout Waldon Twin Flow Refiner: IndustryhufuentsNo ratings yet

- ILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammableDocument1 pageILK-M18-FR: Electrical Design DC PNP/NPN Output Normally Open / Closed ProgrammablehufuentsNo ratings yet

- Sbpln53a ENDocument2 pagesSbpln53a ENhufuentsNo ratings yet

- ILK-M18-AB: Electrical Design Ac / DC Output Normally OpenDocument1 pageILK-M18-AB: Electrical Design Ac / DC Output Normally OpenhufuentsNo ratings yet

- Solutions: Sealing High ViscositiesDocument2 pagesSolutions: Sealing High ViscositieshufuentsNo ratings yet

- ES V1 I7 Moyno SolutionsDocument2 pagesES V1 I7 Moyno SolutionshufuentsNo ratings yet

- ES V1 I8 Positive DisplacementDocument2 pagesES V1 I8 Positive DisplacementhufuentsNo ratings yet

- Case History Steel Trap Live Load 2Document1 pageCase History Steel Trap Live Load 2hufuentsNo ratings yet

- EN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindersDocument1 pageEN36616 - CS034 - FP - Non-Metallic Hydraulic Wear Rings Increase Lateral Load Handling of Shear CylindershufuentsNo ratings yet

- Lube Oil System - Alco & HHP - 2Document43 pagesLube Oil System - Alco & HHP - 2kiran kumarNo ratings yet

- Basic Concepts, Rectangular and T Beams PDFDocument49 pagesBasic Concepts, Rectangular and T Beams PDFAhmed Hussein KamelNo ratings yet

- Hardness Testing Technologies: AdvancedDocument20 pagesHardness Testing Technologies: AdvancedramalingamNo ratings yet

- L958FDocument2 pagesL958FUbaldo Enrique Caraballo EstradaNo ratings yet

- Moog CartridgeValves DBD04 Catalog enDocument8 pagesMoog CartridgeValves DBD04 Catalog enTejas MahadikNo ratings yet

- AP Physics Study GuideDocument96 pagesAP Physics Study GuideBenjamin GroffNo ratings yet

- 2012 Fifth Wheel Selection GuideDocument96 pages2012 Fifth Wheel Selection GuideAbrar HussainNo ratings yet

- Capstan & Turret LatheDocument27 pagesCapstan & Turret LatheMuraliNo ratings yet

- Admiral ManualDocument36 pagesAdmiral ManualJulian Bermudez HernandezNo ratings yet

- Install Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Document13 pagesInstall Instructions ! Billet Power Blocks (BPB) ! 2013-2017 Subaru Crosstrek / 2012-2016 Impreza 2.0i !Mauriece CarrilloNo ratings yet

- Bomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualDocument66 pagesBomag BPR 35 - 42 D, BPR 35 - 60 D Operators and Maintenance ManualSwiduNo ratings yet

- RulmanKatalogu 2018 05 18 15 - 24 - 59Document336 pagesRulmanKatalogu 2018 05 18 15 - 24 - 59Alvaro Felipe CharlinNo ratings yet

- Mak Freezol 68 OilDocument1 pageMak Freezol 68 OilshobhaNo ratings yet

- Lifting LugDocument8 pagesLifting LugEnrique BarajasNo ratings yet

- Dynamics Review Package (Key)Document19 pagesDynamics Review Package (Key)Arlo SeasenNo ratings yet

- Fatigue Testing - Ignacio ArtamendiDocument26 pagesFatigue Testing - Ignacio ArtamendiRoque3RNo ratings yet

- Bahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A BuildingDocument11 pagesBahrain World Trade Center BWTC The First Large-Scale Integration of Wind Turbines in A Buildingrjchp100% (1)

- Rocket Engines - Origin, Developments and FutureDocument13 pagesRocket Engines - Origin, Developments and FutureDeepak Rawat100% (1)

- r7210305 ThermodynamicsDocument4 pagesr7210305 ThermodynamicssivabharathamurthyNo ratings yet

- Acme AdnDocument21 pagesAcme AdnbaiardimircoNo ratings yet

- Komatsu PC200-6 Shop ManualDocument711 pagesKomatsu PC200-6 Shop ManualMạnh Dũng100% (1)

- Chapter 5 Centrifugal Compressor (Complete Slide)Document17 pagesChapter 5 Centrifugal Compressor (Complete Slide)Azhan FikriNo ratings yet

- Em12r1u PDFDocument482 pagesEm12r1u PDFAnwar ZaibNo ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- Duraflex WiresDocument1 pageDuraflex WiresjaqiriNo ratings yet

- Ahm-1C Hopper Mount Dryer Operating Manual: Dri-AirDocument22 pagesAhm-1C Hopper Mount Dryer Operating Manual: Dri-AirYenireé MedinaNo ratings yet

- Som 1Document8 pagesSom 1Sachin SainiNo ratings yet

- So21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocument156 pagesSo21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdBazzie100% (1)

- Mid Term Paper 3 Heat TransferDocument2 pagesMid Term Paper 3 Heat TransferAbdul GhaffarNo ratings yet