Professional Documents

Culture Documents

Other Shank Styles Showa D-F-C System (BBT) : Merit With Dual Face Contact System

Other Shank Styles Showa D-F-C System (BBT) : Merit With Dual Face Contact System

Uploaded by

santhoshkumar.sOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Other Shank Styles Showa D-F-C System (BBT) : Merit With Dual Face Contact System

Other Shank Styles Showa D-F-C System (BBT) : Merit With Dual Face Contact System

Uploaded by

santhoshkumar.sCopyright:

Available Formats

SHOWA

D-F-C SYSTEM (BBT)

Merit with dual face contact system

●Improve preciousness of processing surface and

Contact

Gap

dimension

●Extend life of cutting tools

●Control color change(fretting) on the taper side under

heavy duty processingh

SHOWA

●Improve repetition preciousness of ATC D-F-C Shank Standard Shank

(Taper Contact Only)

(BBT)

●Stability for Z direction at the time of high-speed

precessing

●Impreove of roundness of the boring processing

SHOWA BBT TOOL SYSTEM

Dual face require drawing allowance space for contact 【Example of BT50】

BBT HOLDER BBT HOLDER

BEFORE CLAMPING AFTER CLAMPING

SPACE CONTACT

ELASTIC DEFORMATION BBT SPINDLE

CLAMPING BBT HOLDER

BT SPINDLE

The Showa BBTTool System offers simultaneous dual 【Reference value】

contact between the machine spindle face and toolholder Spindle size Clamping force AXIAL MOVEMENT AMOUNT

flange face, as well as the machine spindle taper and

long toolholder taper shank.

*The value of the table is for reference only

and axial movement amount depends on the

clamping mechanism and spindle shape.

(The numerical values in the machining center

owned by the Company)

*BIG-PLUS system is Daishowa Seiki licensed products

DIMENSIONS BT P.37-92

29

You might also like

- Merlo p40.17 Plus Service From c237523 - 086893 Man - Ass.serie Pano-Merlin-CdcDocument386 pagesMerlo p40.17 Plus Service From c237523 - 086893 Man - Ass.serie Pano-Merlin-CdcRene Krebs100% (13)

- FS-612 Sep2016Document70 pagesFS-612 Sep2016Lucas MonteiroNo ratings yet

- Mece307 - Sertaç ŞimşekDocument18 pagesMece307 - Sertaç ŞimşekErtürk ErdiNo ratings yet

- A320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericDocument6 pagesA320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericJivendra KumarNo ratings yet

- JCB HM380 Hammermaster - RetroexcavadoraDocument2 pagesJCB HM380 Hammermaster - RetroexcavadoraYvan100% (2)

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- General Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual BitDocument1 pageGeneral Data: Pictures May Not Show Every (All) Optional Feature (S) On Actual BitDaniel NavarroNo ratings yet

- Profile & Cutter Placement: Reference Photo: 17 1/2" FC619Document1 pageProfile & Cutter Placement: Reference Photo: 17 1/2" FC619Hendra SiswantoNo ratings yet

- Product Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Document1 pageProduct Specifications:: Bhitrackpage ("Bit","Bit Stylesheet") %Joe CruzNo ratings yet

- Vibratory Compactors: S S L M T L C T L C W LDocument4 pagesVibratory Compactors: S S L M T L C T L C W LPAUL FRANKLIN ANGULO CABANILLASNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- GTD+ FC MC RC For PartingDocument8 pagesGTD+ FC MC RC For Partingtuananhngo19096No ratings yet

- 6 '' STX-40Document1 page6 '' STX-40REGHIS HaouesNo ratings yet

- 6'' VMG-55DVHX2Document1 page6'' VMG-55DVHX2REGHIS HaouesNo ratings yet

- Standard Models: Ke-368Jsga/Ke-368Jsg/Ke-368JDocument8 pagesStandard Models: Ke-368Jsga/Ke-368Jsg/Ke-368JHabib NurNo ratings yet

- CNC Tapping CenterDocument6 pagesCNC Tapping CenterJovelyn MillaresNo ratings yet

- PNC 10catalogueDocument2 pagesPNC 10catalogueParlin PasbarNo ratings yet

- Catalog Blade EDocument7 pagesCatalog Blade ECorey StrongNo ratings yet

- BHDFC BHMFCDocument2 pagesBHDFC BHMFCdimaszanonNo ratings yet

- Beroni Maxx Reversible MB Plough (Hydraulic)Document1 pageBeroni Maxx Reversible MB Plough (Hydraulic)as.linkedin20No ratings yet

- Geotech Sales Data SheetDocument2 pagesGeotech Sales Data SheetAbdi AnsharyNo ratings yet

- DG2/40 HS: Flat Transmission Belts Technical Data SheetDocument2 pagesDG2/40 HS: Flat Transmission Belts Technical Data Sheetdirkz26No ratings yet

- Bevel Gears - KHK PDFDocument50 pagesBevel Gears - KHK PDFSantiago MolinaNo ratings yet

- Tri ConeDocument2 pagesTri ConeANo ratings yet

- 12 1/4'' RWD2S510.625Z: Reference PhotoDocument1 page12 1/4'' RWD2S510.625Z: Reference PhotoJoe CruzNo ratings yet

- 13.5 RWD2X60512.25X - E19039Document1 page13.5 RWD2X60512.25X - E19039Joe CruzNo ratings yet

- RAM ConnectionreportDocument8 pagesRAM Connectionreportahmed fathiNo ratings yet

- ISCAR. Turning and Threading ToolsDocument466 pagesISCAR. Turning and Threading ToolsJuan Carlos Encalada100% (2)

- Mimake DB40270-07 - CFL-605RT - ENDocument2 pagesMimake DB40270-07 - CFL-605RT - ENsunnyNo ratings yet

- HC506ZDocument1 pageHC506ZLeonardo BarriosNo ratings yet

- Okuma Multi TareasDocument17 pagesOkuma Multi Tareasrafael bautista MejiaNo ratings yet

- Sinumerik 840dDocument713 pagesSinumerik 840dmiguel de carvalhoNo ratings yet

- nc20 Nano Cut TurningDocument5 pagesnc20 Nano Cut TurningferNo ratings yet

- Mill Quad FeedDocument12 pagesMill Quad FeedMartin huntNo ratings yet

- BOSCHERT - CompactDocument2 pagesBOSCHERT - CompactNachoLarreaNo ratings yet

- E-Cat HT PDFDocument2 pagesE-Cat HT PDFArif Hidayat ViscaNo ratings yet

- SXP-2 Point Series - 2023Document4 pagesSXP-2 Point Series - 2023isgectraineeNo ratings yet

- Vibratory Contractors - AEHQ5837-01 08-08Document2 pagesVibratory Contractors - AEHQ5837-01 08-08Carlo PoliNo ratings yet

- Ncommonness With The Usual Machine: Parts Name ZAXIS200 EX200 EX200 EX200 UH083 Engine AA-6BG1T A-6BG1T 6BD1TDocument23 pagesNcommonness With The Usual Machine: Parts Name ZAXIS200 EX200 EX200 EX200 UH083 Engine AA-6BG1T A-6BG1T 6BD1TMd Kasim KhanNo ratings yet

- Measurements of Gaps at SEJDocument11 pagesMeasurements of Gaps at SEJdharmpalbhartiyaNo ratings yet

- 14.75 RWD2C512.250 - E18716Document1 page14.75 RWD2C512.250 - E18716Joe CruzNo ratings yet

- Product Presentation: LL 20T L3Document13 pagesProduct Presentation: LL 20T L3PRASANNAKUMAR THANGARAJNo ratings yet

- 1 PDFDocument20 pages1 PDFRacem RebaiNo ratings yet

- Directional: 12 1/4in Sdi519 PDCDocument1 pageDirectional: 12 1/4in Sdi519 PDCKhairatul Nada BurhanuddinNo ratings yet

- FANUC R-2000iB-200T PDFDocument2 pagesFANUC R-2000iB-200T PDFSalvador BarrónNo ratings yet

- ARP SeriesDocument12 pagesARP Seriest.meynoldsNo ratings yet

- Hi-TECH 230-4 (9.0)Document100 pagesHi-TECH 230-4 (9.0)Ойген ЁхNo ratings yet

- PUMA MX SeriesDocument44 pagesPUMA MX SeriesAbdul HananNo ratings yet

- Hoerbiger - Blocker Ring Bre-BroschureDocument6 pagesHoerbiger - Blocker Ring Bre-BroschureR KathirasanNo ratings yet

- Lecture 4 Metal Cutting ProcessDocument14 pagesLecture 4 Metal Cutting ProcessDhiraj DhimanNo ratings yet

- SXLSXHDocument11 pagesSXLSXHJuan carlos 200797No ratings yet

- pts830 DatasheetDocument4 pagespts830 DatasheetteehoweNo ratings yet

- SAKAE - Non Linear PotentiometerDocument2 pagesSAKAE - Non Linear PotentiometerdanilonavNo ratings yet

- 10" Birotor Models B111, B113, B114, B115: DescriptionDocument2 pages10" Birotor Models B111, B113, B114, B115: DescriptionMekar MeinaNo ratings yet

- KORLOYDocument12 pagesKORLOYAlexandre SouzaNo ratings yet

- CNC Cylindrical Grinder: EGP, EGA & EPA-A SeriesDocument10 pagesCNC Cylindrical Grinder: EGP, EGA & EPA-A SeriesLộc HuỳnhNo ratings yet

- Drill: Mitsubishi CarbideDocument8 pagesDrill: Mitsubishi CarbideĐồng Đăng HảiNo ratings yet

- 4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeDocument2 pages4 Different Base Assemblies For Added Versatility: Easy-to-CustomizeOnagro XNo ratings yet

- Iadc Dull GradingDocument2 pagesIadc Dull GradingSamsung J7No ratings yet

- Core Balance Current Transformer CBCT: FeaturesDocument1 pageCore Balance Current Transformer CBCT: FeaturesKiran KarthikNo ratings yet

- 8 1/2'' MX-30DXDH: Product SpecificationsDocument1 page8 1/2'' MX-30DXDH: Product SpecificationsMohamed Mahmoud Rezk DimoNo ratings yet

- Ik72t Pga Eng WebDocument2 pagesIk72t Pga Eng WebMazin MohammadNo ratings yet

- Pmi Linear Guide Msa 3.5mDocument59 pagesPmi Linear Guide Msa 3.5mToàn ĐứcNo ratings yet

- KELCH - Tool HoldersDocument71 pagesKELCH - Tool Holderssanthoshkumar.sNo ratings yet

- 7 CL500Document4 pages7 CL500santhoshkumar.sNo ratings yet

- FBB - Harmonic - Catalogue - DifferentialGearDocument39 pagesFBB - Harmonic - Catalogue - DifferentialGearsanthoshkumar.sNo ratings yet

- The Design and Manufacturing of Machine Tapered Shaft Measuring ToolDocument5 pagesThe Design and Manufacturing of Machine Tapered Shaft Measuring Toolsanthoshkumar.sNo ratings yet

- Tolerancing in Mold Design - Part 1Document7 pagesTolerancing in Mold Design - Part 1santhoshkumar.sNo ratings yet

- Features and Characteristics of Motorized and Non-Motorized Milling SpindlesDocument6 pagesFeatures and Characteristics of Motorized and Non-Motorized Milling Spindlessanthoshkumar.sNo ratings yet

- Technical Explanation of Rotary EncodersDocument6 pagesTechnical Explanation of Rotary Encoderssanthoshkumar.sNo ratings yet

- Research On The Assembly Process of Spindle System of Precision Lathe, Y. ZhangDocument5 pagesResearch On The Assembly Process of Spindle System of Precision Lathe, Y. Zhangsanthoshkumar.sNo ratings yet

- Origin of Dividing A Circle Into 360 Parts: THE P.DevarajDocument5 pagesOrigin of Dividing A Circle Into 360 Parts: THE P.Devarajsanthoshkumar.sNo ratings yet

- Heidenhain Modular Angle Encoders Scale Drum TapeDocument45 pagesHeidenhain Modular Angle Encoders Scale Drum Tapesanthoshkumar.sNo ratings yet

- DFM Slides USDocument54 pagesDFM Slides USsanthoshkumar.sNo ratings yet

- Bearing TolerancesDocument11 pagesBearing Tolerancessanthoshkumar.sNo ratings yet

- Dissertation KelvinFinalVersionDocument101 pagesDissertation KelvinFinalVersionsanthoshkumar.sNo ratings yet

- Sluder SWW2017Document34 pagesSluder SWW2017santhoshkumar.sNo ratings yet

- Defining PCB ConstraintsDocument20 pagesDefining PCB Constraintssanthoshkumar.sNo ratings yet

- Pelton Wheel ExamplesDocument14 pagesPelton Wheel ExamplesSakhile Nhlakanipho ZithaNo ratings yet

- At03084 GD825Document10 pagesAt03084 GD825Jackson PhinniNo ratings yet

- Hystory Card Press 2021 Update Maret 2021Document14 pagesHystory Card Press 2021 Update Maret 2021slamet supriyadiNo ratings yet

- Cross Head PDFDocument1 pageCross Head PDFganesh916No ratings yet

- Gasgas FSE EC SM 400 450 2005 Manual de Reparatie WWW - Manuale-Reparatie - Eu PDFDocument34 pagesGasgas FSE EC SM 400 450 2005 Manual de Reparatie WWW - Manuale-Reparatie - Eu PDFRobi Junc100% (1)

- Properties of Philippine Woods at 50Document4 pagesProperties of Philippine Woods at 50Sylvious Jason HequilanNo ratings yet

- Life Without Black PeopleDocument7 pagesLife Without Black PeopleMosi Ngozi (fka) james harrisNo ratings yet

- Pipe 0.5 Inch SCH, XXSDocument3 pagesPipe 0.5 Inch SCH, XXSreniNo ratings yet

- Lvmdp-Model - Bali Tukad UndaDocument1 pageLvmdp-Model - Bali Tukad UndaHaries KurniawanNo ratings yet

- EVRO Honey Sigh 9.21Document25 pagesEVRO Honey Sigh 9.21Iurie PlescaNo ratings yet

- 5555 Back Pressure Valve, Double Seated (Balanced) : SeriesDocument3 pages5555 Back Pressure Valve, Double Seated (Balanced) : SeriesJohnf PreciadoNo ratings yet

- 1 - The Levers of The Human BodyDocument25 pages1 - The Levers of The Human Bodybreinfout fotosNo ratings yet

- Oil Pump System: Operation Diagram Structure and ComponentsDocument2 pagesOil Pump System: Operation Diagram Structure and ComponentsRadamirNo ratings yet

- Panel Synchron 600 KvaDocument2 pagesPanel Synchron 600 KvaHerman Lam'zNo ratings yet

- Basic Chinese To English 2Document10 pagesBasic Chinese To English 2luisNo ratings yet

- MJ - JL: Female Joint / JointDocument6 pagesMJ - JL: Female Joint / JointArmando SgabeiNo ratings yet

- GSH 27 VC Professional Manual 162091 PDFDocument125 pagesGSH 27 VC Professional Manual 162091 PDFCostyGsm0% (1)

- Resume For The Post of Tank /welding / Piping Inspector.Document28 pagesResume For The Post of Tank /welding / Piping Inspector.AJMAL KAREEMNo ratings yet

- Pneumatic KnockerDocument1 pagePneumatic KnockerramaNo ratings yet

- RENR7312 D3G, D4G and D5G Track-Type Tractors 1Document91 pagesRENR7312 D3G, D4G and D5G Track-Type Tractors 1Rob BeersNo ratings yet

- Filtro Rotatorio DesparafinacionDocument8 pagesFiltro Rotatorio DesparafinacionPabel LemaNo ratings yet

- External Shrinkage Restraint For Multi-Story Concrete StructuresDocument6 pagesExternal Shrinkage Restraint For Multi-Story Concrete Structuresramadani karaNo ratings yet

- Pneumatic Connectors PDFDocument95 pagesPneumatic Connectors PDFYuDiNo ratings yet

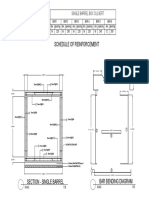

- Reinforced Line CanalDocument1 pageReinforced Line CanalJoefel BessatNo ratings yet

- Process Isolation Methods & ProcedureDocument37 pagesProcess Isolation Methods & ProcedureJayaseelan GNo ratings yet

- Drip Tube Type Surge Vessel For Waste Water - Detail PDFDocument3 pagesDrip Tube Type Surge Vessel For Waste Water - Detail PDFtrueavatharNo ratings yet