Professional Documents

Culture Documents

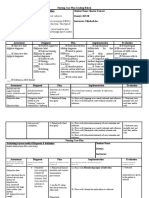

Practice Questions - Set 1 Answers

Practice Questions - Set 1 Answers

Uploaded by

grc.lehaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practice Questions - Set 1 Answers

Practice Questions - Set 1 Answers

Uploaded by

grc.lehaCopyright:

Available Formats

1.(a) Identify the key stages of a workplace risk assessment.

(5)

Identify the hazards

Decide who might be harmed and how

Evaluate the risks and decide on precaution

Record your findings and implement them

Review your assessment and update if necessary

(b) Outline the meaning of `as low as reasonably practicable' (ALARP). (3)

In essence, making sure a risk has been reduced ALARP is about weighing the risk

against the sacrifice needed to further reduce it. The decision is weighted in favour of

health and safety because the presumption is that the duty-holder should implement the

risk reduction measure. To avoid having to make this sacrifice, the duty-holder must be

able to show that it would be grossly disproportionate to the benefits of risk reduction

that would be achieved. Thus, the process is not one of balancing the costs and benefits of

measures but, rather, of adopting measures except where they are ruled out because they

involve grossly disproportionate sacrifices. Extreme examples might be:

To spend Lim to prevent five staff suffering bruised knees is obviously

grossly disproportionate; but

To spend £lm to prevent a major explosion a major explosion capable of

killing 150 people is obviously proportionate.

2. Many major oil / gas incidents have occurred in recent years, eg Piper Alpha,

Texas City, Mumbai High.

(a) Outline reasons why such incidents should be investigated by employers. (6)

Establish Causes of incident

Establish process failures

Establish Lessons learnt to prevent similar occurrences

(b) Identify TWO parties, other than the employer, who may want to

investigate these types of incident. (2)

Authorities

Insurance Companies

3. (a) Outline the term Flash Point. (3)

Point at which something is ready explode

A measure of a fuels flammability

The temperature where by enough vapor is produced to create a flammable

mixture

The temperature at which a combustible liquid gives off enough vapour to

produce a vapour / air mixture that will ignite v, when a flame is applied

(b) List the Hazards associated with LNG (4)

Pool Fires

LGN Spills on water

Terrorism

Explosion in confined space

4. An employee was seriously injured in an accident at work within an oil and gas

installation.

Identify the documented information that might be used by the investigating team to

determine the causes of this accident.(8)

PTW

Photographs

CCTV Footage

Previous Health and Safety Meeting Minutes

Risk Assessments / JSA's

Method Statements

Individual Capabilities (Stress, Mental Health)

Control Room Data

Q5. Give the meaning of the following terms:

(a) upper flammable limit (UFL) (2);

UFL refers to the richest mixture at which the substance is still flammable

(b) lower flammable limit (LFL); (2)

LFL refers to the leanest mixture at which the substance is flammable (i.e. the

smallest fraction of combustible gas)

(c) flashpoint; (2)

Flashpoint is the lowest temperature at which the vapour of a combustible

liquid can ignite in air

(d) Highly flammable liquids. (2)

Substances which, when hot, catch fire in contact with air at ambient

temperature without any energy input.

Q6. Identify the information that might be included on a checklist for an

investigation following an accident. (8)

Obtain basic facts — names of injured, witnesses, place, date and time,

persons in area. Ascertain substances / chemicals involved, injuries, damage

to equipment

Establish circumstances — What happened? Causes, events leading to

incident Competence, Supervision, Behaviour

Preventive Measures - Review the risk assessment for the activity. What

precautions should have been in force? What training should those carrying

out the activity have received? What precautions were actually taken?

Compare them with those which should have been taken. What training was

actually given? Compare it with training which should have been given.

Was the initial response adequate? — Firefighting, first aid, containment and

spillage

Identify underlying causes - Management or supervision failure? Lack of

competence?

Inadequate training? Shortcomings in original design of equipment of

facilities. Absence of a system for maintenance.

Determine action needed to prevent a recurrence - improve physical

safeguards, introduce better test and maintenance arrangements, improve

work methods, provide and use personal protective equipment, make changes

to supervision and training arrangements, review procedures involving

outside contractors, improve inspection systems

Q7. Following preparation of a vessel for maintenance within an oil and gas

installation a low specific activity (LSA) radioactive sludge was encountered.

(a) Identify hazards associated with the sludge. (2)

Risk of fire, explosion, detonation if ignited.

Toxicity to Divers

(b) Outline FOUR control measures to reduce the risk to workers exposed to the

sludge. (4)

Wearing of correct PPE

Monitoring devices and personal sensors Explosion proof certified equipment

Safety procedures, training etc

(c) Identify TWO other pieces of workplace equipment where the sludge may be

found. (2)

Shale Shakers

Mud Pits

You might also like

- SITXFSA002 Student Assessment PackDocument50 pagesSITXFSA002 Student Assessment Packneetu shukla17% (6)

- NEBOSH IOG1 ExaminersFeedback PDFDocument24 pagesNEBOSH IOG1 ExaminersFeedback PDFAyoola Ayodeji100% (7)

- Arson Prevention PlanDocument13 pagesArson Prevention PlanrasanavaneethanNo ratings yet

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Nebosh: Management of Health and Safety Unit Ig1Document5 pagesNebosh: Management of Health and Safety Unit Ig1Shagufta Mallick100% (2)

- Nssa - Si 68 - 1990Document187 pagesNssa - Si 68 - 1990Courage50% (2)

- Avoiding Explosions by Means of Inerting SystemsDocument14 pagesAvoiding Explosions by Means of Inerting SystemsRicky Menon100% (1)

- Fire Protection Plan - 1Document11 pagesFire Protection Plan - 1prince100% (1)

- Exams Papers Q & AsDocument29 pagesExams Papers Q & Asnowondery86% (7)

- Guidelines for Combustible Dust Hazard AnalysisFrom EverandGuidelines for Combustible Dust Hazard AnalysisNo ratings yet

- Q&a Refaie IogDocument38 pagesQ&a Refaie Iogmohamed refaieNo ratings yet

- Nebosh-Iogc Q&A: Questions AnswersDocument22 pagesNebosh-Iogc Q&A: Questions AnswersabouhashmNo ratings yet

- Oil and Gas SafetyDocument32 pagesOil and Gas SafetyAlhaj MassoudNo ratings yet

- SPE 46610 The Hazard Register: Thomas J. Dujmovich/ConocoDocument5 pagesSPE 46610 The Hazard Register: Thomas J. Dujmovich/ConocoBagas JuniarNo ratings yet

- 431 - 15 Exothermic ReactionsDocument7 pages431 - 15 Exothermic ReactionsAdriana Reyes Cordoba100% (1)

- Nebosh Accidents PDFDocument6 pagesNebosh Accidents PDFfedaretNo ratings yet

- Accident Investigation Procedure - Safety NotesDocument5 pagesAccident Investigation Procedure - Safety NotesVipin Kumar JaiswalNo ratings yet

- Advanced Fire Fighting New Book - TS RahamanDocument168 pagesAdvanced Fire Fighting New Book - TS RahamanFateh SinghNo ratings yet

- FPFF CapsuleDocument80 pagesFPFF CapsuleClash Of Clans with the heroNo ratings yet

- Igc1 Element 4 & 5 - Rev 0Document17 pagesIgc1 Element 4 & 5 - Rev 0VickyJeeNo ratings yet

- General Fire and Explosion ConsiderationsDocument5 pagesGeneral Fire and Explosion Considerationsmohammed naeemNo ratings yet

- 899 Howto LOPADocument5 pages899 Howto LOPAkumar_chemical100% (1)

- Fire Risk AssessmentDocument39 pagesFire Risk AssessmentMutu PalembangNo ratings yet

- 2nd Assignment Progress-HoangThanh (May 31)Document97 pages2nd Assignment Progress-HoangThanh (May 31)Nguyễn Hoàng ThànhNo ratings yet

- PHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Document7 pagesPHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Zack MalikNo ratings yet

- Safety in Chemical Process IndustriesDocument40 pagesSafety in Chemical Process IndustriesDevendra SharmaNo ratings yet

- Fire Management Plan 1681606896Document7 pagesFire Management Plan 1681606896dikdikNo ratings yet

- Element 1Document37 pagesElement 1Htoo Htoo KyawNo ratings yet

- Element 5 AnswersDocument3 pagesElement 5 AnswersNabeel KhanNo ratings yet

- Coursework Enm302 Salim-GDocument14 pagesCoursework Enm302 Salim-GgaddasalimNo ratings yet

- Factors: Root Cause AnalysisDocument2 pagesFactors: Root Cause Analysisnsy2204100% (1)

- Summative Assessments 244383Document9 pagesSummative Assessments 244383Nomsa ZunguNo ratings yet

- Nsn-Hse035 Emergency Preparedness & Response e MwapDocument5 pagesNsn-Hse035 Emergency Preparedness & Response e MwapAngeloNo ratings yet

- TD SbaDocument7 pagesTD SbaMarlon FordeNo ratings yet

- Nebosh Important Q SDocument137 pagesNebosh Important Q SAmani Gasim Eljack100% (2)

- Oisd RP 233 DraftDocument66 pagesOisd RP 233 DraftvijaygalaxyNo ratings yet

- Emergency Planning and Preparedness - On-Site & Off-SiteDocument17 pagesEmergency Planning and Preparedness - On-Site & Off-SiteDebasis MishraNo ratings yet

- Pub 59Document7 pagesPub 59Rahul ShrivastavaNo ratings yet

- The Problem: Fire & Emergency EvacuationDocument6 pagesThe Problem: Fire & Emergency EvacuationChand RajNo ratings yet

- NeboshDocument6 pagesNeboshsuphi05No ratings yet

- Safety and Hazards in Chemical Industries: (Module I)Document16 pagesSafety and Hazards in Chemical Industries: (Module I)shrutiNo ratings yet

- Sample Written Program Fire Prevention PlanDocument17 pagesSample Written Program Fire Prevention Plantanbqtb03No ratings yet

- Formal Safety Assessment and Risk Analysis of Offshore StructuresDocument25 pagesFormal Safety Assessment and Risk Analysis of Offshore StructuresDrAbdoz EngineeroNo ratings yet

- Practical 01 (Emergency and Laboratory Safety)Document28 pagesPractical 01 (Emergency and Laboratory Safety)Mr. GoogleNo ratings yet

- Safety and The EnvironmentDocument10 pagesSafety and The EnvironmentYong Kai MingNo ratings yet

- HSE Assessment of Explosion Risk Analysis in Offshore Safety CasesDocument16 pagesHSE Assessment of Explosion Risk Analysis in Offshore Safety CasesMichał MakuchNo ratings yet

- Chapter 9.safetyDocument47 pagesChapter 9.safetyMuhamad Baihakhi ShamsudinNo ratings yet

- Fire Risk Assessment: A Guide For BusinessesDocument33 pagesFire Risk Assessment: A Guide For Businesseskhalid najjarNo ratings yet

- Emergency PreparednessDocument15 pagesEmergency PreparednessDaniel67% (3)

- Elements of PSM Terry Hardy.51145540Document12 pagesElements of PSM Terry Hardy.51145540Syed Mujtaba Ali Bukhari100% (1)

- Sample Written Program Fire Prevention PlanDocument17 pagesSample Written Program Fire Prevention PlanAljun GullesNo ratings yet

- Spe 46642 MSDocument17 pagesSpe 46642 MSanaghaNo ratings yet

- Development of Emergency Response Procedures For Incidents Involving Dangerous GoodsDocument5 pagesDevelopment of Emergency Response Procedures For Incidents Involving Dangerous GoodsJulius Ceasar SanorjoNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Recognizing Catastrophic Incident Warning Signs in the Process IndustriesFrom EverandRecognizing Catastrophic Incident Warning Signs in the Process IndustriesNo ratings yet

- Essential Practices for Creating, Strengthening, and Sustaining Process Safety CultureFrom EverandEssential Practices for Creating, Strengthening, and Sustaining Process Safety CultureNo ratings yet

- Personal Protective Equipment for Chemical, Biological, and Radiological Hazards: Design, Evaluation, and SelectionFrom EverandPersonal Protective Equipment for Chemical, Biological, and Radiological Hazards: Design, Evaluation, and SelectionNo ratings yet

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesFrom EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesNo ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- Aviation Instructor's Handbook (2024): FAA-H-8083-9BFrom EverandAviation Instructor's Handbook (2024): FAA-H-8083-9BRating: 3.5 out of 5 stars3.5/5 (4)

- Understanding Your Scores On The Emotional Intelligence Self-Assessment ScaleDocument2 pagesUnderstanding Your Scores On The Emotional Intelligence Self-Assessment ScaleFarhat MansuriNo ratings yet

- Smallholder Vegetable Packhouses: Establishing and ManagingDocument50 pagesSmallholder Vegetable Packhouses: Establishing and ManagingMeet ShahNo ratings yet

- Reading Comprehension Class 12 CbseDocument4 pagesReading Comprehension Class 12 CbseCbse AccountNo ratings yet

- CPR WebDocument222 pagesCPR WebANo ratings yet

- Annalyn B. Forio, RN, ManDocument23 pagesAnnalyn B. Forio, RN, Manjay kusain100% (1)

- Mid Term Examination: Physical Activity and The Stages of Behavior Change ModelDocument8 pagesMid Term Examination: Physical Activity and The Stages of Behavior Change Modelapi-457299309No ratings yet

- Assignment Overview: Worksheet: Emotional IntelligenceDocument4 pagesAssignment Overview: Worksheet: Emotional IntelligenceKaranja Wa Njuguna CyclistNo ratings yet

- Should Universal Healthcare Be Free To All Americans?Document7 pagesShould Universal Healthcare Be Free To All Americans?movys musicNo ratings yet

- Nursing Care Plan Template and Grading RubricDocument4 pagesNursing Care Plan Template and Grading RubricSharon TanveerNo ratings yet

- Perception of The Students Towards LGBTQIA+Document10 pagesPerception of The Students Towards LGBTQIA+Vergel PadugaNo ratings yet

- 5 Sciatica Exercises For Pain Relief (With Pictures) : Back IntelligenceDocument26 pages5 Sciatica Exercises For Pain Relief (With Pictures) : Back Intelligenceanand sahu100% (1)

- Keywords To RememberDocument2 pagesKeywords To RememberMajolika Syakira DeviNo ratings yet

- Careergoals2023 PortfolioDocument8 pagesCareergoals2023 Portfolioapi-662464269No ratings yet

- Answer Sheet For Module 8Document4 pagesAnswer Sheet For Module 8DashiKONICNo ratings yet

- Microbiological TestDocument33 pagesMicrobiological TestSaufi MuhammadNo ratings yet

- Cattle Annual Cow Cost SpreadsheetDocument4 pagesCattle Annual Cow Cost SpreadsheetSushil JangirNo ratings yet

- Bachelor of Hospital ManagementDocument5 pagesBachelor of Hospital ManagementsurajyellowkiteNo ratings yet

- Dentistry 10 00222Document18 pagesDentistry 10 00222kittyNo ratings yet

- Moving Meditation of SilambamDocument4 pagesMoving Meditation of SilambamGabrielNo ratings yet

- Katrina Pope-Argument Essay Final DraftDocument6 pagesKatrina Pope-Argument Essay Final Draftapi-548846091No ratings yet

- RS OnlineDocument28 pagesRS OnlineAnugrah Prasetyo AjiNo ratings yet

- A Machine Learning Framework Involving EEG Based Functional Connectivity To Diagnose Major Depressive Disorder (MDD)Document14 pagesA Machine Learning Framework Involving EEG Based Functional Connectivity To Diagnose Major Depressive Disorder (MDD)asma khanNo ratings yet

- DRRM Week 5Document12 pagesDRRM Week 5Shy SubijanoNo ratings yet

- How Do You Actually Develop A Growth MindsetDocument3 pagesHow Do You Actually Develop A Growth MindsetacmcNo ratings yet

- Emed - BLS - FBAO - First Aid Part2Document87 pagesEmed - BLS - FBAO - First Aid Part2Princess Cate MercadoNo ratings yet

- The 12 Golden Rules: Safety at WorkDocument11 pagesThe 12 Golden Rules: Safety at WorkStacey FejerNo ratings yet

- 358 Developmental DomainsDocument2 pages358 Developmental Domainsapi-285147481No ratings yet