Professional Documents

Culture Documents

John Deer JD 6020 TEST & OPS

John Deer JD 6020 TEST & OPS

Uploaded by

michaljurkiewicz1982Copyright:

Available Formats

You might also like

- JD 6020 Diagnostics PDFDocument1,496 pagesJD 6020 Diagnostics PDFjwd100% (8)

- John Deere 27D Compact Excavator Technical Service Repair Manual TM2356Document31 pagesJohn Deere 27D Compact Excavator Technical Service Repair Manual TM2356Equipment ManualsNo ratings yet

- Manual Mazda CX5 PDFDocument277 pagesManual Mazda CX5 PDFLUIS ALEJANDRO100% (2)

- Manual Reparacion Motor K25 PDFDocument135 pagesManual Reparacion Motor K25 PDFRojasDura.83% (41)

- 8120, 8220, 8320, 8420, and 8520 Tractors Operation and TestDocument3,386 pages8120, 8220, 8320, 8420, and 8520 Tractors Operation and TestBakas AthanasiosNo ratings yet

- Mid 222 2Document36 pagesMid 222 2danecuprija100% (1)

- Sample Class C Drivers Written Test 1Document3 pagesSample Class C Drivers Written Test 1Emmanuel Ike Okolo100% (4)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Man 175d Imo Tier II Imo Tier III MarineDocument440 pagesMan 175d Imo Tier II Imo Tier III MarineSea Man Mkt100% (3)

- Template Marketing Plan For InsuranceDocument13 pagesTemplate Marketing Plan For InsuranceOmar-Ayah ShakerNo ratings yet

- TM110219Document5 pagesTM110219Alejandro DhoNo ratings yet

- Liebherr R904C Litronic Crawler Excavator Service Repair Manual SN23072 PDFDocument70 pagesLiebherr R904C Litronic Crawler Excavator Service Repair Manual SN23072 PDFjfjkskemmdm0% (4)

- Manual de Fallas MBE4000 PDFDocument429 pagesManual de Fallas MBE4000 PDFhecazorla100% (1)

- John Deere 586YDocument23 pagesJohn Deere 586YIvan Fernandez PérezNo ratings yet

- JD 6020 - 6920S Operations and Tests TM4741Document3,477 pagesJD 6020 - 6920S Operations and Tests TM4741ElcoteamNo ratings yet

- Quantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User ManualDocument36 pagesQuantum With Unity Pro: 141 MMS 425 01, 141 MMS 535 02 SERCOS Multi-Axis Motion Controller User Manualrmorenodx4587No ratings yet

- Mazda Cx7 2007 Workshop ManualDocument20 pagesMazda Cx7 2007 Workshop Manualtyrone100% (60)

- John Deere 580YDocument23 pagesJohn Deere 580YPOBRETÃO CrNo ratings yet

- Premium 7130 To 7530 Diagn-Tm400019 PDFDocument5,433 pagesPremium 7130 To 7530 Diagn-Tm400019 PDFandis_a100% (7)

- LUST Frequency InverterDocument346 pagesLUST Frequency InverterMuhammad Ahmad0% (1)

- Kioti Daedong CS2210, CS2410, CS2410N, CS2510 (US), CS2610 (EU, AU) Tractors Service ManualDocument19 pagesKioti Daedong CS2210, CS2410, CS2410N, CS2510 (US), CS2610 (EU, AU) Tractors Service ManualLisakolyNo ratings yet

- Manual TM10686Document1,244 pagesManual TM10686Juan Mesa0% (1)

- Engine General Information and Diagnosis (G16-J20 Engines)Document141 pagesEngine General Information and Diagnosis (G16-J20 Engines)Rezha Maulana Azhar100% (1)

- Kioti Daedong DK4520-EU, DK5020-EU, DK6020-EU Tractors Service Manual WM201231Document19 pagesKioti Daedong DK4520-EU, DK5020-EU, DK6020-EU Tractors Service Manual WM201231LisakolyNo ratings yet

- TM262L10MESE8T Notice RDocument48 pagesTM262L10MESE8T Notice RJulian MNo ratings yet

- Kioti Daedong K9 2400, K9 2440 UTV (Utility Vehicle) Service ManualDocument19 pagesKioti Daedong K9 2400, K9 2440 UTV (Utility Vehicle) Service ManualLisakolyNo ratings yet

- Firmware Compatibility Rules: Modicon M580, Modicon Momentum, Modicon MC80, and Modicon X80 I/O ModulesDocument13 pagesFirmware Compatibility Rules: Modicon M580, Modicon Momentum, Modicon MC80, and Modicon X80 I/O ModulesMonty SinghNo ratings yet

- BT50 - Uny0 3 - 8564-1a-06h PDFDocument138 pagesBT50 - Uny0 3 - 8564-1a-06h PDFAnonymous qP4h5VMNo ratings yet

- BT 50 2012Document269 pagesBT 50 2012Phạm An Bình100% (4)

- Cda 3000Document276 pagesCda 3000Anders-Pehr GidlundNo ratings yet

- Gensys Technical Documentation PDFDocument126 pagesGensys Technical Documentation PDFaupNo ratings yet

- Magnetbalken Ausgabe 7 - ENDocument72 pagesMagnetbalken Ausgabe 7 - ENChin Wei SteNo ratings yet

- Movitrac B SeriesDocument252 pagesMovitrac B SeriesJackson BarbosaNo ratings yet

- SINUMERIK 808D ADVANCED Service Manual 022016 EngDocument42 pagesSINUMERIK 808D ADVANCED Service Manual 022016 Englatifesil2No ratings yet

- SIEP C71061627C 02 YAS+A1000+UsersManual PDFDocument544 pagesSIEP C71061627C 02 YAS+A1000+UsersManual PDFJorge MorenoNo ratings yet

- Tech Man 6110-6510s TR Op Test-TM4572Document1,884 pagesTech Man 6110-6510s TR Op Test-TM4572BarryNo ratings yet

- 4 D ServiceDocument61 pages4 D Servicehosseindrm44No ratings yet

- YASKAWA AC Drive A1000: Technical ManualDocument590 pagesYASKAWA AC Drive A1000: Technical ManualJavier MartínezNo ratings yet

- Mazda CX-7Document4 pagesMazda CX-7Marco LunaNo ratings yet

- MAZDA 2,0 and 2,3 L3 LF Engines SMDocument60 pagesMAZDA 2,0 and 2,3 L3 LF Engines SMOmar MahmoudNo ratings yet

- System Manual: Movidrive MDX60B / 61BDocument32 pagesSystem Manual: Movidrive MDX60B / 61Balin grecuNo ratings yet

- SINUMERIK 808D ADVANCED Commissioning Manual 012015 EngDocument188 pagesSINUMERIK 808D ADVANCED Commissioning Manual 012015 EngAleksa GajićNo ratings yet

- Ethernet Modbus X80 Gateway Device Type Manager: User ManualDocument40 pagesEthernet Modbus X80 Gateway Device Type Manager: User ManualVladNo ratings yet

- z41 180320234327Document101 pagesz41 180320234327Avaa AmgaaNo ratings yet

- Installation and Maintenance LSF46.2 AlternatorDocument20 pagesInstallation and Maintenance LSF46.2 AlternatorTrung Quan Vo100% (1)

- Air Dryer - ED750ADocument26 pagesAir Dryer - ED750AcrafzaclubNo ratings yet

- Caterpillar CCM ForDieselEngines PDFDocument87 pagesCaterpillar CCM ForDieselEngines PDFAnonymous M0OEZEKoGi100% (1)

- EPower HA179769 1Document206 pagesEPower HA179769 1Aristóteles Terceiro NetoNo ratings yet

- Mid 222Document32 pagesMid 222danecuprijaNo ratings yet

- 8430 TractorDocument5,645 pages8430 TractorJohnathan LarkanNo ratings yet

- Sinumerik Sinumerik 808D Advanced PLC Subroutines Manual: User Manual Legal InformationDocument74 pagesSinumerik Sinumerik 808D Advanced PLC Subroutines Manual: User Manual Legal InformationBALDEV SINGHNo ratings yet

- NC30F2 From JM0 NC30F2 0 203419Document148 pagesNC30F2 From JM0 NC30F2 0 203419Alexe Victor100% (1)

- AC Drive E1000Document448 pagesAC Drive E1000Sơn NguyễnNo ratings yet

- 524K 4WD Loader Engine 6068HDW74 (T3) Operation and TestDocument51 pages524K 4WD Loader Engine 6068HDW74 (T3) Operation and TestKleiton Francisco PereiraNo ratings yet

- Kioti Daedong PX9530, PX9030, PX1053, PX1153, PX1103, PX1303 Tractors Service Manual 04-2020Document19 pagesKioti Daedong PX9530, PX9030, PX1053, PX1153, PX1103, PX1303 Tractors Service Manual 04-2020LisakolyNo ratings yet

- Kda 3.3 150 3 A00w Servo Drive Indramat ManualDocument48 pagesKda 3.3 150 3 A00w Servo Drive Indramat ManualjhonNo ratings yet

- Dynojet Research Motorcycle Accessories 250Document31 pagesDynojet Research Motorcycle Accessories 250cesarNo ratings yet

- Ba Scalance-X-000 76 PDFDocument54 pagesBa Scalance-X-000 76 PDFRodrigo RodriguesNo ratings yet

- Kioti Daedong LX500L Tractors Service ManualDocument19 pagesKioti Daedong LX500L Tractors Service ManualLisakolyNo ratings yet

- Nonlinear Traction Control Design for Parallel Hybrid VehiclesFrom EverandNonlinear Traction Control Design for Parallel Hybrid VehiclesNo ratings yet

- Electronic Automotive Transmission Troubleshooter Honda Acura vehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Honda Acura vehiclesNo ratings yet

- The Industry HandbookDocument34 pagesThe Industry HandbookslpypndaNo ratings yet

- 07-Ev-2020 07 16 PDFDocument278 pages07-Ev-2020 07 16 PDFFernando BautistaNo ratings yet

- Ford Scorpio Engine ManualDocument4 pagesFord Scorpio Engine Manualkristy100% (57)

- Product Catalogue: Axle ComponentsDocument10 pagesProduct Catalogue: Axle ComponentsNibin OdukkathilNo ratings yet

- Owner's Manual: Water Pump WH15X/WH20XDocument64 pagesOwner's Manual: Water Pump WH15X/WH20XFayeez MukadamNo ratings yet

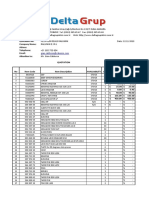

- ESTIMATEDocument2 pagesESTIMATEazharNo ratings yet

- Fueling System of SI and CI Engines: by Zewdie Alemayehu (Automotive Eng.)Document67 pagesFueling System of SI and CI Engines: by Zewdie Alemayehu (Automotive Eng.)ahmed jemalNo ratings yet

- Shop Manual Allis-Chalmers: IviodelsDocument78 pagesShop Manual Allis-Chalmers: IviodelsDmitryNo ratings yet

- 2019 New Product From WintomDocument6 pages2019 New Product From WintomVictorNo ratings yet

- Seal Kit - KGDocument6 pagesSeal Kit - KGEsra DemirNo ratings yet

- I-Mold Flyer Interflon Grease ENDocument1 pageI-Mold Flyer Interflon Grease ENKamila AriasNo ratings yet

- Schedule May 6 - May 11 2019Document16 pagesSchedule May 6 - May 11 2019Alexander IbrahimNo ratings yet

- Report - CarVerticalDocument13 pagesReport - CarVerticalRebaz Jamal AhmedNo ratings yet

- Engine Indicators: OutlineDocument7 pagesEngine Indicators: Outlinechristianvan100% (1)

- Varroc InplantDocument55 pagesVarroc Inplantaamna_shaikh01No ratings yet

- 045220X56ZDocument1 page045220X56ZIrina VarzouNo ratings yet

- Shapotools O & M Manual (S) R2Document21 pagesShapotools O & M Manual (S) R2Thennarasan GNo ratings yet

- F10 Oversize Piston RingsDocument2 pagesF10 Oversize Piston RingsDPNo ratings yet

- Group 4 AutomobileDocument6 pagesGroup 4 AutomobilePuneet KakkarNo ratings yet

- MECHANICS OF MACHINES-Lecture7-1Document43 pagesMECHANICS OF MACHINES-Lecture7-1Abdul RahmanNo ratings yet

- CP Battery Impact WrenchesDocument2 pagesCP Battery Impact WrenchesBe HappyNo ratings yet

- Fuel Pressure TestDocument3 pagesFuel Pressure TestPoma KritNo ratings yet

- Yamaha Nmax Smart Key SystemDocument1 pageYamaha Nmax Smart Key Systemmotley crewzNo ratings yet

- ReadmeDocument3 pagesReadmeLộc Trịnh XuânNo ratings yet

- Escogear CouplingsDocument31 pagesEscogear CouplingsMohamed ElfeilNo ratings yet

- Ficha Técnica Krupp HB 32Document4 pagesFicha Técnica Krupp HB 32Alejo CarboneNo ratings yet

- LR3 Stop Lamp Circuit LRL183853501 (LR3-Wiring)Document1 pageLR3 Stop Lamp Circuit LRL183853501 (LR3-Wiring)fionaNo ratings yet

- Common Winding Schemes: Homebuilt Electric MotorsDocument2 pagesCommon Winding Schemes: Homebuilt Electric MotorsLAliNo ratings yet

John Deer JD 6020 TEST & OPS

John Deer JD 6020 TEST & OPS

Uploaded by

michaljurkiewicz1982Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

John Deer JD 6020 TEST & OPS

John Deer JD 6020 TEST & OPS

Uploaded by

michaljurkiewicz1982Copyright:

Available Formats

6020 to 6920S

Tractors

Created by free version of DocuFreezer

and SE Tractors

Diagnostics

TECHNICAL MANUAL

6020 to 6920S Tractors

and SE Tractors

Diagnostics

TM4726 01NOV03 (ENGLISCH)

For complete service information also see:

6020 to 6920S Tractors and SE Tractors

Operation and Tests . . . . . . . . . . . . . . . . . . . TM4741

6020 to 6620 Tractors and SE Tractors

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TM4750

Tractors 6820, 6920 and 6920S

Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TM4756

Front Wheel Drive Axles - AS and MS

Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CTM4687

Front Wheel Drive Axles (700 Series) . . . . . CTM4820

POWERTECH Diesel Engines . . . . . . . . . . . CTM104

Mechanical Fuel Injection Systems . . . . . . . CTM207

Electronic Fuel Injection Systems (Level

4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CTM170

Electronic Fuel Injection Systems (Level

1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CTM284

Electronic Fuel Injection Systems (Level

11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CTM220

Electronic Fuel Injection Systems (Level

12). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CTM331

Alternators and Starting Motors

(available in English only). . . . . . . . . . . . . . . CTM77

John Deere Werke Mannheim

European Version

Printed in Germany

Introduction

Foreword

This diagnostics manual is valid for the following

This is the safety-alert symbol. When you see this

tractor types:

symbol on the machine or in this manual, be alert to

the potential for personal injury.

6020, 6120, 6220, 6320, 6420, 6420S, 6520, 6620,

6820, 6920 and 6920S.

Technical Manuals are concise guides for specific

machines. They are on-the-job guides containing only

SE tractors: 6020, 6120, 6220, 6320, 6420 and 6520.

the vital information needed for diagnosis, analysis,

testing and repair.

This manual is written for an experienced technician.

Essential tools required in performing certain service

Fundamental service information is available from

work are identified in this manual and are

other sources covering basic theory of operation,

recommended for use.

fundamentals of troubleshooting, general maintenance,

and basic type of failures and their causes.

Live with safety: Read the safety messages in the

introduction of this manual and the cautions presented

throughout the text of the manual.

LX24888,0000410 –19–01OCT02–1/1

TM4726 (01NOV03) 6020 to 6920S tractors

022204

PN=2

Contents

210

SECTION 210—GENERAL INFORMATION

Group 05—Safety Information

SECTION 211—DIAGNOSTIC TROUBLE CODES

Group ATC—ATC Diagnostic Trouble Codes

211

Group BCU—BCU Diagnostic Trouble Codes

Group BIF—BIF Diagnostic Trouble Codes

Group ECU—ECU Diagnostic Trouble Codes

Group EPC—EPC Diagnostic Trouble Codes

Group JDL—JDL Diagnostic Trouble Codes

Group PLC—PLC Diagnostic Trouble Codes 212

Group PRF—PRF Diagnostic Trouble Codes

Group SFA—SFA Diagnostic Trouble Codes

Group SIC—SIC Diagnostic Trouble Codes

Group SSU—SSU Diagnostic Trouble Codes

Group TCU—TCU Diagnostic Trouble Codes

213

Group TEC—TEC Diagnostic Trouble Codes

Group UIC—UIC Diagnostic Trouble Codes

SECTION 212—OBSERVABLE SYMPTOMS

Group 20—Engine

Group 40—Electrical System INDX

Group 50—SyncroPlus Transmission

Group 51—Power Reverser Transmission

Group 53—AutoPowr/IVT Transmission

Group 55—PowrQuad, PowrQuad Plus and

AutoQuad Transmissions

Group 56—Drive Systems

Group 60—Steering and Brakes

Group 70—Hydraulic System

Group 90—Operator’s Cab

SECTION 213—SYSTEM DIAGNOSTICS

Group 45—Electronics

All information, illustrations and specifications in this manual are based on

the latest information available at the time of publication. The right is

reserved to make changes at any time without notice.

COPYRIGHT 2003

DEERE & COMPANY

European Office Mannheim

All rights reserved

A John Deere ILLUSTRUCTION Manual

Previous Editions

Copyright 2002, 2001

TM4726 (01NOV03) i 6020 to 6920S tractors

022204

PN=1

Contents

210

211

212

213

INDX

TM4726 (01NOV03) ii 6020 to 6920S tractors

022204

PN=2

210

Section 210

GENERAL INFORMATION

Contents

Page

Group 05—Safety Information

Recognize Safety Information . . . . . . . . . . . . .210-05-1

“Important” - Information . . . . . . . . . . . . . . . . .210-05-1

“Note” - Information . . . . . . . . . . . . . . . . . . . . .210-05-1

Prevent Machine Runaway . . . . . . . . . . . . . . .210-05-1

Handle Fluids Safely—Avoid Fires . . . . . . . . .210-05-2

Prevent Battery Explosions . . . . . . . . . . . . . . .210-05-2

Prepare for Emergencies. . . . . . . . . . . . . . . . .210-05-2

Prevent Acid Burns . . . . . . . . . . . . . . . . . . . . .210-05-3

Avoid High-Pressure Fluids . . . . . . . . . . . . . . .210-05-4

Service Cooling System Safely . . . . . . . . . . . .210-05-4

Remove Paint Before Welding or Heating . . . .210-05-5

Avoid Heating Near Pressurized Fluid

Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210-05-5

Work In Ventilated Area . . . . . . . . . . . . . . . . .210-05-6

Wear Protective Clothing. . . . . . . . . . . . . . . . .210-05-6

Practice Safe Maintenance . . . . . . . . . . . . . . .210-05-7

Park Machine Safely . . . . . . . . . . . . . . . . . . . .210-05-7

Use Proper Lifting Equipment . . . . . . . . . . . . .210-05-8

Construct Dealer-Made Tools Safely . . . . . . . .210-05-8

Support Machine Properly . . . . . . . . . . . . . . . .210-05-8

Work in Clean Area. . . . . . . . . . . . . . . . . . . . .210-05-9

Illuminate Work Area Safely . . . . . . . . . . . . . .210-05-9

Service Machines Safely . . . . . . . . . . . . . . . . .210-05-9

Use Proper Tools . . . . . . . . . . . . . . . . . . . . .210-05-10

Service Tires Safely . . . . . . . . . . . . . . . . . . .210-05-10

Service Front-Wheel Drive Tractor Safely . . .210-05-11

Safety Information - Air Brake System. . . . . .210-05-11

Avoid Eye Contact With Radar . . . . . . . . . . .210-05-12

Keep ROPS Installed Properly . . . . . . . . . . .210-05-12

Replace Safety Signs . . . . . . . . . . . . . . . . . .210-05-12

Dispose of Waste Properly . . . . . . . . . . . . . .210-05-13

Live With Safety . . . . . . . . . . . . . . . . . . . . . .210-05-13

Safety Measures on Electronic Control

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . .210-05-14

TM4726 (01NOV03) 210-1 6020 to 6920S tractors

022204

PN=1

Contents

210

TM4726 (01NOV03) 210-2 6020 to 6920S tractors

022204

PN=2

Group 05

Safety Information

210

Recognize Safety Information 05

1

This is a safety-alert symbol. When you see this symbol

on your machine or in this manual, be alert to the

potential for personal injury.

–UN–07DEC88

Follow recommended precautions and safe operating

practices.

T81389

DX,ALERT –19–29SEP98–1/1

“Important” - Information

Information marked as IMPORTANT points out problems

that may lead to machine damage. By following the

directions given, these problems can be avoided.

LX,CRA05 002885 –19–09APR92–1/1

“Note” - Information

When marked with NOTE the information given is more

detailed or contains restrictions to directions given

previously. On the other hand useful information may be

given belonging to certain instructions without being

directly connected to them.

LX,CRA05 002886 –19–09APR92–1/1

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway.

Do not start engine by shorting across starter terminals.

Machine will start in gear if normal circuitry is bypassed.

–UN–11JAN89

NEVER start engine while standing on ground. Start

engine only from operator’s seat, with transmission in

neutral or park.

TS177

DX,BYPAS1 –19–29SEP98–1/1

TM4726 (01NOV03) 210-05-1 6020 to 6920S tractors

022204

PN=7

Safety Information

210

05 Handle Fluids Safely—Avoid Fires

2

When you work around fuel, do not smoke or work near

heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not

incinerate or puncture pressurized containers.

–UN–23AUG88

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn

TS227

spontaneously.

DX,FLAME –19–29SEP98–1/1

Prevent Battery Explosions

Keep sparks, lighted matches, and open flame away from

the top of battery. Battery gas can explode.

Never check battery charge by placing a metal object

across the posts. Use a volt-meter or hydrometer.

–UN–23AUG88

Do not charge a frozen battery; it may explode. Warm

battery to 16°C (60°F).

TS204

DX,SPARKS –19–03MAR93–1/1

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

–UN–23AUG88

hospital, and fire department near your telephone.

TS291

DX,FIRE2 –19–03MAR93–1/1

TM4726 (01NOV03) 210-05-2 6020 to 6920S tractors

022204

PN=8

Safety Information

210

Prevent Acid Burns 05

3

Sulfuric acid in battery electrolyte is poisonous. It is strong

enough to burn skin, eat holes in clothing, and cause

blindness if splashed into eyes.

Avoid the hazard by:

1. Filling batteries in a well-ventilated area.

2. Wearing eye protection and rubber gloves.

3. Avoiding breathing fumes when electrolyte is added.

4. Avoiding spilling or dripping electrolyte.

5. Use proper jump start procedure.

If you spill acid on yourself:

1. Flush your skin with water.

2. Apply baking soda or lime to help neutralize the acid.

3. Flush your eyes with water for 15—30 minutes. Get

medical attention immediately.

–UN–23AUG88

If acid is swallowed:

1. Do not induce vomiting.

2. Drink large amounts of water or milk, but do not

TS203

exceed 2 L (2 quarts).

3. Get medical attention immediately.

DX,POISON –19–21APR93–1/1

TM4726 (01NOV03) 210-05-3 6020 to 6920S tractors

022204

PN=9

Safety Information

210

05 Avoid High-Pressure Fluids

4

Escaping fluid under pressure can penetrate the skin

causing serious injury.

Avoid the hazard by relieving pressure before

–UN–23AUG88

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure.

Search for leaks with a piece of cardboard. Protect hands

X9811

and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid

injected into the skin must be surgically removed within a

few hours or gangrene may result. Doctors unfamiliar with

this type of injury should reference a knowledgeable

medical source. Such information is available from Deere

& Company Medical Department in Moline, Illinois, U.S.A.

DX,FLUID –19–03MAR93–1/1

Service Cooling System Safely

Explosive release of fluids from pressurized cooling

system can cause serious burns.

Shut off engine. Only remove filler cap when cool enough

to touch with bare hands. Slowly loosen cap to first stop

–UN–23AUG88

to relieve pressure before removing completely.

TS281

DX,RCAP –19–04JUN90–1/1

TM4726 (01NOV03) 210-05-4 6020 to 6920S tractors

022204

PN=10

Safety Information

210

Remove Paint Before Welding or Heating 05

5

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated

by welding, soldering, or using a torch.

–UN–23AUG88

Remove paint before heating:

• Remove paint a minimum of 100 mm (4 in.) from area

to be affected by heating. If paint cannot be removed,

TS220

wear an approved respirator before heating or welding.

• If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

• If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or

paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Do not use a chlorinated solvent in areas where welding

will take place.

Do all work in an area that is well ventilated to carry toxic

fumes and dust away.

Dispose of paint and solvent properly.

DX,PAINT –19–24JUL02–1/1

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near

pressurized fluid lines, resulting in severe burns to

yourself and bystanders. Do not heat by welding,

soldering, or using a torch near pressurized fluid lines or

other flammable materials. Pressurized lines can be

–UN–15MAY90

accidentally cut when heat goes beyond the immediate

flame area.

TS953

DX,TORCH –19–03MAR93–1/1

TM4726 (01NOV03) 210-05-5 6020 to 6920S tractors

022204

PN=11

Safety Information

210

05 Work In Ventilated Area

6

Engine exhaust fumes can cause sickness or death. If it is

necessary to run an engine in an enclosed area, remove

the exhaust fumes from the area with an exhaust pipe

extension.

–UN–23AUG88

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area

TS220

DX,AIR –19–17FEB99–1/1

Wear Protective Clothing

Wear close fitting clothing and safety equipment

appropriate to the job.

Prolonged exposure to loud noise can cause impairment

or loss of hearing.

–UN–23AUG88

Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable or

uncomfortable loud noises.

TS206

Operating equipment safely requires the full attention of

the operator. Do not wear radio or music headphones

while operating machine.

DX,WEAR –19–10SEP90–1/1

TM4726 (01NOV03) 210-05-6 6020 to 6920S tractors

022204

PN=12

Safety Information

210

Practice Safe Maintenance 05

7

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from

power-driven parts. Disengage all power and operate

controls to relieve pressure. Lower equipment to the

ground. Stop the engine. Remove the key. Allow machine

to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed. Fix

damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On self-propelled equipment, disconnect battery ground

cable (-) before making adjustments on electrical systems

–UN–23AUG88

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

TS218

welding on machine.

DX,SERV –19–17FEB99–1/1

Park Machine Safely

Before working on the machine:

• Lower all equipment to the ground.

• Stop the engine and remove the key.

• Disconnect the battery ground strap.

–UN–24MAY89

• Hang a "DO NOT OPERATE" tag in operator station.

TS230

DX,PARK –19–04JUN90–1/1

TM4726 (01NOV03) 210-05-7 6020 to 6920S tractors

022204

PN=13

Safety Information

210

05 Use Proper Lifting Equipment

8

Lifting heavy components incorrectly can cause severe

injury or machine damage.

Follow recommended procedure for removal and

installation of components in the manual.

–UN–23AUG88

TS226

DX,LIFT –19–04JUN90–1/1

Construct Dealer-Made Tools Safely

Faulty or broken tools can result in serious injury. When

constructing tools, use proper, quality materials, and good

workmanship.

–UN–01JUL97

Do not weld tools unless you have the proper equipment

and experience to perform the job.

LX1016749

DX,SAFE,TOOLS –19–10OCT97–1/1

Support Machine Properly

Always lower the attachment or implement to the ground

before you work on the machine. If the work requires that

the machine or attachment be lifted, provide secure

support for them. If left in a raised position, hydraulically

supported devices can settle or leak down.

–UN–23AUG88

Do not support the machine on cinder blocks, hollow tiles,

or props that may crumble under continuous load. Do not

work under a machine that is supported solely by a jack. TS229

Follow recommended procedures in this manual.

When implements or attachments are used with a

machine, always follow safety precautions listed in the

implement or attachment operator’s manual.

DX,LOWER –19–24FEB00–1/1

TM4726 (01NOV03) 210-05-8 6020 to 6920S tractors

022204

PN=14

Safety Information

210

Work in Clean Area 05

9

Before starting a job:

• Clean work area and machine.

• Make sure you have all necessary tools to do your job.

–UN–18OCT88

• Have the right parts on hand.

• Read all instructions thoroughly; do not attempt

shortcuts.

T6642EJ

DX,CLEAN –19–04JUN90–1/1

Illuminate Work Area Safely

Illuminate your work area adequately but safely. Use a

portable safety light for working inside or under the

machine. Make sure the bulb is enclosed by a wire cage.

The hot filament of an accidentally broken bulb can ignite

spilled fuel or oil.

–UN–23AUG88

TS223

DX,LIGHT –19–04JUN90–1/1

Service Machines Safely

Tie long hair behind your head. Do not wear a necktie,

scarf, loose clothing, or necklace when you work near

machine tools or moving parts. If these items were to get

caught, severe injury could result.

–UN–23AUG88

Remove rings and other jewelry to prevent electrical

shorts and entanglement in moving parts.

TS228

DX,LOOSE –19–04JUN90–1/1

TM4726 (01NOV03) 210-05-9 6020 to 6920S tractors

022204

PN=15

Safety Information

210

05 Use Proper Tools

10

Use tools appropriate to the work. Makeshift tools and

procedures can create safety hazards.

Use power tools only to loosen threaded parts and

fasteners.

–UN–08NOV89

For loosening and tightening hardware, use the correct

size tools. DO NOT use U.S. measurement tools on

metric fasteners. Avoid bodily injury caused by slipping

TS779

wrenches.

Use only service parts meeting John Deere specifications.

DX,REPAIR –19–17FEB99–1/1

Service Tires Safely

Explosive separation of a tire and rim parts can cause

serious injury or death.

Do not attempt to mount a tire unless you have the proper

equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate

the tires above the recommended pressure. Never weld or

heat a wheel and tire assembly. The heat can cause an

increase in air pressure resulting in a tire explosion.

Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and extension

hose long enough to allow you to stand to one side and

NOT in front of or over the tire assembly. Use a safety

cage if available.

Check wheels for low pressure, cuts, bubbles, damaged

rims or missing lug bolts and nuts.

–UN–23AUG88

TS211

DX,RIM –19–24AUG90–1/1

TM4726 (01NOV03) 210-05-10 6020 to 6920S tractors

022204

PN=16

Safety Information

210

Service Front-Wheel Drive Tractor Safely 05

11

When servicing front-wheel drive tractor with the rear

wheels supported off the ground and rotating wheels by

engine power, always support front wheels in a similar

manner. Loss of electrical power or transmission/

–UN–06AUG94

hydraulic system pressure will engage the front driving

wheels, pulling the rear wheels off the support if front

wheels are not raised. Under these conditions, front drive

wheels can engage even with switch in disengaged

L124515

position.

LX,MFWD2 –19–01MAY91–1/1

Safety Information - Air Brake System

CAUTION: Compressed air tank is pressurized!

Always relieve pressure before working on the air brake

system. Do not carry out any welding jobs on the air

brake system.

–UN–24APR96

LX008009

LX,AIRBRAKES –19–03MAR94–1/1

TM4726 (01NOV03) 210-05-11 6020 to 6920S tractors

022204

PN=17

Safety Information

210

05 Avoid Eye Contact With Radar

12

Radar ground speed sensor emits a very low intensity

microwave signal. It will not cause any ill effects during

normal use. Although intensity is low, DO NOT look

directly into face of sensor while in operation, to avoid any

possible eye damage.

–UN–23AUG88

TS266

RX,SAFTY,RADAR1 –19–21SEP92–1/1

Keep ROPS Installed Properly

Make certain all parts are reinstalled correctly if the

roll-over protective structure (ROPS) is loosened or

removed for any reason. Tighten mounting bolts to proper

torque.

–UN–23AUG88

The protection offered by ROPS will be impaired if ROPS

is subjected to structural damage, is involved in an

overturn incident, or is in any way altered by welding,

bending, drilling, or cutting. A damaged ROPS should be

TS212

replaced, not reused.

DX,ROPS3 –19–03MAR93–1/1

Replace Safety Signs

Replace missing or damaged safety signs. See the

machine operator’s manual for correct safety sign

placement.

–UN–23AUG88

TS201

DX,SIGNS1 –19–04JUN90–1/1

TM4726 (01NOV03) 210-05-12 6020 to 6920S tractors

022204

PN=18

Safety Information

210

Dispose of Waste Properly 05

13

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful waste used

with John Deere equipment include such items as oil, fuel,

coolant, brake fluid, filters, and batteries.

–UN–26NOV90

Use leakproof containers when draining fluids. Do not use

food or beverage containers that may mislead someone

into drinking from them.

TS1133

Do not pour waste onto the ground, down a drain, or into

any water source.

Air conditioning refrigerants escaping into the air can

damage the Earth’s atmosphere. Government regulations

may require a certified air conditioning service center to

recover and recycle used air conditioning refrigerants.

Inquire on the proper way to recycle or dispose of waste

from your local environmental or recycling center, or from

your John Deere dealer.

DX,DRAIN –19–03MAR93–1/1

Live With Safety

Before returning machine to customer, make sure

machine is functioning properly, especially the safety

systems. Install all guards and shields.

–19–07OCT88

TS231

DX,LIVE –19–25SEP92–1/1

TM4726 (01NOV03) 210-05-13 6020 to 6920S tractors

022204

PN=19

Safety Information

210

05 Safety Measures on Electronic Control Units

14

IMPORTANT: Do not use a test lamp on any

CAUTION: Before installing test equipment

control unit. Only use a multimeter

on tractor, always shut off the engine and

(JT05791A).

turn the key switch “OFF”.

IMPORTANT: To protect electronic circuits,

CAUTION: Always engage the park lock disconnect the battery and alternator

when performing tests with the engine before performing any welding on

running. the tractor.

CAUTION: When testing is performed with

the engine running, there is a risk of injury

from rotating parts.

LX25599,0000243 –19–01JAN01–1/1

TM4726 (01NOV03) 210-05-14 6020 to 6920S tractors

022204

PN=20

Section 211

DIAGNOSTIC TROUBLE CODES

Contents 211

Page Page

Group ATC—ATC Diagnostic Trouble Codes Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-36

ATC 000170.03 — Sending Unit for Inside ATC 000923.03 — Driver Unit for the Fan

Air Temperature, Shorted or Open Motors, Shorted Circuit . . . . . . . . . . . . . 211-ATC-37

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-37

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-1 ATC 000923.04 — Fan Motor Driver Unit,

ATC 000170.04 — Sending Unit for Inside Grounded or Open Circuit . . . . . . . . . . . 211-ATC-40

Air Temperature, Short to Ground . . . . . . 211-ATC-3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-40

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-4 ATC 000923.12 — Fan Motors,

ATC 000171.03 — Sending Units for Malfunction . . . . . . . . . . . . . . . . . . . . . . 211-ATC-42

Ambient Air Temperature, Shorted or Open Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-42

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-6 ATC 001079.03 — 5-volt Power Supply,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-7 Shorted or Open Circuit . . . . . . . . . . . . . 211-ATC-45

ATC 000171.04 — Sending Units for Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-45

Ambient Temperature, Short to ATC 001079.04 — 5-volt Power Supply,

Ground . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-11 Grounded Circuit . . . . . . . . . . . . . . . . . . 211-ATC-47

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-11 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-47

ATC 000628.12 — Controller, Internal

ATC 001546.03 — Potentiometer for

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-15

Position of Water Valve, Shorted or Open

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-15

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-49

ATC 000630.02 — Controller, Internal

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-50

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-16

ATC 001546.04 — Potentiometer for

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-16

Water Valve Position, Grounded

ATC 000639.14 — 29-bit CAN BUS, High

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-52

Error Rate . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-17

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-17 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-53

ATC 000871.03 — Refrigerant Pressure ATC 001547.03 — Sending Units for

Sending Unit, Shorted Circuit. . . . . . . . . 211-ATC-18 Evaporator Core Temperature, Shorted or Open

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-18 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-55

ATC 000871.04 — Refrigerant Pressure Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-56

Sending Unit, Grounded or Open ATC 001547.04 — Sending Unit for

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-20 Evaporator Core Temperature, Short to

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-21 Ground . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-58

ATC 000876.03 — Air-Conditioning Relay, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-58

Shorted or Open Circuit . . . . . . . . . . . . . 211-ATC-23 ATC 001548.03 — Sending Unit for Actual

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-24 Outlet Air Temperature, Shorted or Open

ATC 000876.04 — Air-Conditioning Relay, Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-60

Grounded Circuit . . . . . . . . . . . . . . . . . . 211-ATC-27 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-61

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-27 ATC 001548.04 — Sending Unit for Actual

ATC 000876.10 — Compressor Clutch Outlet Air Temperature, Grounded

Engages and Disengages Too Often . . . 211-ATC-30 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-63

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-30 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-63

ATC 000876.14 — Compressor Switches ATC 001549.03 — Water Valve Motor,

Off Due to Engine Overheating . . . . . . . 211-ATC-35 Shorted Circuit. . . . . . . . . . . . . . . . . . . . 211-ATC-65

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-35 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-66

ATC 000919.03 — Solar Sensor

Activated . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-36 Continued on next page

TM4726 (01NOV03) 211-1 6020 to 6920S tractors

022204

PN=1

Contents

Page Page

ATC 001549.04 — Water Valve Motor, ATC 523860.02 — Defog Sensor,

Grounded Circuit . . . . . . . . . . . . . . . . . . 211-ATC-68 Frequency out of Valid Range . . . . . . . 211-ATC-103

211 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-69 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-103

ATC 001549.07 — Water Valve,

Malfunction . . . . . . . . . . . . . . . . . . . . . . 211-ATC-71 Group BCU—BCU Diagnostic Trouble Codes

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-72 BCU 000070.31 — Handbrake Failure . . . . 211-BCU-1

ATC 001549.13 — Water Valve Not Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-1

Calibrated . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-74 BCU 000084.02 — Wheel Speed Sender,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-75 Circuit Fault . . . . . . . . . . . . . . . . . . . . . . 211-BCU-2

ATC 001552.03 — Temperature Control, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-2

Shorted or Open Circuit . . . . . . . . . . . . . 211-ATC-76 BCU 000168.16 — System Voltage Too High

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-76 (Engine Running). . . . . . . . . . . . . . . . . . . 211-BCU-4

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-4

ATC 001552.04 — Temperature Control,

BCU 000168.17 — System Voltage Too

Grounded Circuit . . . . . . . . . . . . . . . . . . 211-ATC-77

Low (Engine Speed Over 1500 rpm) . . . . 211-BCU-5

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-78

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-5

ATC 001553.03 — Fan Speed Control,

BCU 000168.18 — System Voltage Too

Shorted or Open Circuit . . . . . . . . . . . . . 211-ATC-79 Low (Engine Speed Up to 1500 rpm). . . . 211-BCU-6

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-79 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-7

ATC 001553.04 — Fan Speed Control, BCU 000186.02 — Rear PTO Speed Sender,

Grounded Circuit . . . . . . . . . . . . . . . . . . 211-ATC-80 Circuit Fault . . . . . . . . . . . . . . . . . . . . . . 211-BCU-8

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-80 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-8

ATC 002000.09 — Engine Control Unit is BCU 000186.17 — Rear PTO Speed Not

not Transmitting any Data (Coolant Registered . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-9

Temperature) . . . . . . . . . . . . . . . . . . . . . 211-ATC-81 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-10

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-82 BCU 000190.02 — Engine Speed Sender,

ATC 523848.03 — Potentiometer for Circuit Fault . . . . . . . . . . . . . . . . . . . . . 211-BCU-11

Position of Air Distribution Flaps, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-12

Shorted or Open Circuit . . . . . . . . . . . . . 211-ATC-84 BCU 000629.12 — Control Unit, Internal

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-84 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-13

ATC 523848.04 — Potentiometer for Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-13

Position of Air Distribution Flaps, Grounded BCU 000639.12 — Control Unit, Internal

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-87 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-13

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-87 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-13

ATC 523848.05 — Adjusting Motor for Air BCU 000639.13 — 29-bit CAN BUS, High

Distribution, Shorted Circuit . . . . . . . . . . 211-ATC-89 Error Rate . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-14

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-90 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-14

BCU 000639.19 — 29-bit CAN BUS, Very

ATC 523848.06 — Adjusting Motor for Air

High Error Rate . . . . . . . . . . . . . . . . . . . 211-BCU-15

Distribution, Grounded Circuit . . . . . . . . 211-ATC-92

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-16

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-92

BCU 000746.31 — Differential Lock

ATC 523848.07 — Air Distribution,

Solenoid Valve, Circuit Fault . . . . . . . . . 211-BCU-17

Malfunction . . . . . . . . . . . . . . . . . . . . . . 211-ATC-94 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-17

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-95 BCU 000980.07 — Rear PTO, Switch

ATC 523848.13 — Adjusting Motor for Air Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-18

Distribution, Not Calibrated . . . . . . . . . . 211-ATC-97 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-19

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-97 BCU 001676.31 — Relay for LTC Coolant

ATC 523860.03 — Defog Sensor, Shorted or Pump, Circuit Fault . . . . . . . . . . . . . . . . 211-BCU-20

Open Circuit . . . . . . . . . . . . . . . . . . . . . 211-ATC-98 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-20

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-99 BCU 001882.02 — Front PTO Speed

ATC 523860.04 — Defog Sensor, Sender, Circuit Fault . . . . . . . . . . . . . . . 211-BCU-21

Grounded Circuit . . . . . . . . . . . . . . . . . 211-ATC-101

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-ATC-101 Continued on next page

TM4726 (01NOV03) 211-2 6020 to 6920S tractors

022204

PN=2

Contents

Page Page

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-21 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-38

BCU 001882.17 — Front PTO Speed Not BCU 302122.31 — Air Brake Solenoid Valve,

Registered . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-22 Circuit Fault . . . . . . . . . . . . . . . . . . . . . . 211-BCU-39 211

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-23 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-40

BCU 001893.07 — Front PTO, Switch BCU 302123.31 — Forward/Reverse Switch

Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-25 Signal Doesn’t Match Signal of Not-Neutral

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-25 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-41

BCU 299780.07 — Malfunction at Turn Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-41

Signal Switch . . . . . . . . . . . . . . . . . . . . . 211-BCU-26 BCU 302124.31 — Alternator Relay,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-27 Circuit Fault . . . . . . . . . . . . . . . . . . . . . . 211-BCU-43

BCU 302001.31 — INFORMATION FOR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-43

OPERATOR: 250-Hour Service . . . . . . . 211-BCU-28 BCU 302131.31 — Fault in Turn Signal

BCU 302002.31 — INFORMATION FOR Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-44

OPERATOR: 500-Hour Service . . . . . . . 211-BCU-28 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-44

BCU 302003.31 — INFORMATION FOR BCU 302132.31 — Hazard Warning Light

OPERATOR: 750-Hour Service . . . . . . . 211-BCU-28 Fuse F03/03 and/or F03/04 Defective . . 211-BCU-45

BCU 302004.31 — INFORMATION FOR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-46

OPERATOR: 1500-Hour Service . . . . . . 211-BCU-28 BCU 302133.31 — Rear PTO Preselector,

BCU 302071.31 — INFORMATION FOR Switch Error . . . . . . . . . . . . . . . . . . . . . . 211-BCU-47

OPERATOR: Turn Off the Rear PTO Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-48

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-29 BCU 302134.31 — HMS Program Switch

BCU 302073.31 — Rear PTO Solenoid, Defective . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-49

Circuit Fault . . . . . . . . . . . . . . . . . . . . . 211-BCU-29 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-49

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-29 BCU 302135.31 — Rear PTO Remote

BCU 302077.31 — INFORMATION FOR Control, Switch Error Left. . . . . . . . . . . . 211-BCU-50

OPERATOR: Sit on Seat or Turn Off the Rear Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-50

PTO. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-31 BCU 302136.31 — Rear PTO Remote

BCU 302080.31 — Differential Lock, Control, Switch Error Right . . . . . . . . . . 211-BCU-51

Switch Error . . . . . . . . . . . . . . . . . . . . . . 211-BCU-31 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-52

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-31 BCU 302139.31 — INFORMATION FOR

BCU 302082.31 — INFORMATION FOR OPERATOR: Rear PTO can now be

OPERATOR: Actuate the Front-Wheel Drive Switched On at the Remote Control

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-33 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-53

BCU 302085.31 — Front Wheel Drive, BCU 302240.31 — Control Unit

Switch Error . . . . . . . . . . . . . . . . . . . . . . 211-BCU-33 Connected to Wrong Wiring Harness

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-33 Connector . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-54

BCU 302086.31 — Front-Wheel Drive Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-54

Clutch Solenoid, Circuit Fault. . . . . . . . . 211-BCU-35 BCU 303027.31 — Calibration of Hitch

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-35 Control Unit Not Successful . . . . . . . . . . 211-BCU-55

BCU 302087.31 — INFORMATION FOR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-56

OPERATOR: Tractor is Moving BCU 303028.31 — Hitch Control Unit Not

Although Handbrake is On. . . . . . . . . . . 211-BCU-36 Calibrated . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-56

BCU 302088.31 — INFORMATION FOR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-57

OPERATOR: Handbrake is On and a Gear is BCU 303037.03 — 5-Volt Supply Voltage

Selected . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-37 Too High . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-58

BCU 302089.31 — INFORMATION FOR Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-58

OPERATOR: Turn Off the Rear PTO BCU 303037.04 — 5-Volt Supply Voltage

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-37 Too Low . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-59

BCU 302106.31 — Control Unit, Internal Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-60

Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-37 BCU 303041.02 — Stepper Motor Coil 1,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-38 Open Lead . . . . . . . . . . . . . . . . . . . . . . 211-BCU-61

BCU 302120.31 — Front PTO Solenoid

Valve, Circuit Fault . . . . . . . . . . . . . . . . 211-BCU-38 Continued on next page

TM4726 (01NOV03) 211-3 6020 to 6920S tractors

022204

PN=3

Contents

Page Page

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-62 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-90

BCU 303042.02 — Stepper Motor Coil 2, BCU 303055.03 — Position Sensor,

211 Open Lead. . . . . . . . . . . . . . . . . . . . . . . 211-BCU-63 Signal Voltage Too High . . . . . . . . . . . . 211-BCU-92

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-64 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-92

BCU 303043.02 — Stepper Motor Coil 1, BCU 303055.04 — Position Sensor,

Circuit Fault . . . . . . . . . . . . . . . . . . . . . 211-BCU-65 Signal Voltage Too Low. . . . . . . . . . . . . 211-BCU-93

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-66 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-94

BCU 303044.02 — Stepper Motor Coil 2, BCU 303056.03 — Raise Limit

Circuit Fault . . . . . . . . . . . . . . . . . . . . . 211-BCU-67 Potentiometer, Signal Voltage Too

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-68 High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-95

BCU 303045.04 — System Voltage Too

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-96

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-69

BCU 303056.04 — Raise Limit

BCU 303047.03 — System Voltage Too

Potentiometer, Signal Voltage Too

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-70

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-98

BCU 303049.02 — Conflicting Signals

from Quick Raise/Lower Switch and Remote Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-98

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-70 BCU 303057.03 — Rate-of-Drop

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-70 Potentiometer, Signal Voltage Too

BCU 303049.03 — Rapid Raise/Lower High. . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-100

Rocker Switch, Signal Voltage Too Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-100

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-72 BCU 303057.04 — Rate-of-Drop

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-72 Potentiometer, Signal Voltage Too

BCU 303049.04 — Rapid Raise/Lower Low . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-102

Rocker Switch, Signal Voltage Too Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-103

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-73 BCU 303058.02 — Remote Control Switch,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-74 Erroneous Signal . . . . . . . . . . . . . . . . . 211-BCU-105

BCU 303051.03 — Left Draft Sender, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-105

Signal Voltage Too High . . . . . . . . . . . . 211-BCU-75 BCU 303060.02 — Stepper Motor

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-76 Deadband Out of Range . . . . . . . . . . . 211-BCU-107

BCU 303051.04 — Left Draft Sender, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-107

Signal Voltage Too Low. . . . . . . . . . . . . 211-BCU-77 BCU 303177.18 — Oil Temperature

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-78 During Calibration Too Low . . . . . . . . . 211-BCU-109

BCU 303052.03 — Right Draft Sender, BCU 303251.02 — Left Draft Sender,

Signal Voltage Too High . . . . . . . . . . . . 211-BCU-79 Disrupted Signal During Calibration . . . 211-BCU-109

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-80 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-110

BCU 303052.04 — Right Draft Sender,

BCU 303251.03 — Left Draft Sender,

Signal Voltage Too Low. . . . . . . . . . . . . 211-BCU-81

Signal Voltage Too High During

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-82

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-111

BCU 303053.03 — Sensitivity

BCU 303251.04 — Left Draft Sender,

Potentiometer, Signal Voltage Too

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-83 Signal Voltage Too Low During

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-84 Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-111

BCU 303053.04 — Sensitivity BCU 303252.02 — Right Draft Sender,

Potentiometer, Signal Voltage Too Disrupted Signal During Calibration . . . 211-BCU-111

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-85 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-112

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-85 BCU 303252.03 — Right Draft Sender,

BCU 303054.03 — Hitch Height Control Signal Voltage Too High During

Potentiometer, Signal Voltage Too Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-113

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-87 BCU 303252.04 — Right Draft Sender,

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-87 Signal Voltage Too Low During

BCU 303054.04 — Hitch Height Control Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-113

Potentiometer, Signal Voltage Too

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BCU-89 Continued on next page

TM4726 (01NOV03) 211-4 6020 to 6920S tractors

022204

PN=4

Contents

Page Page

BCU 303255.03 — Position Sender, BIF 000127.00 — Transmission Oil

Signal Voltage Too High During Pressure Low. . . . . . . . . . . . . . . . . . . . . . 211-BIF-24

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-114 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-24 211

BCU 303255.04 — Position Sender, BIF 000167.16 — D+ Voltage High (Engine

Signal Voltage Too Low During Running) . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-26

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-114 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-27

BCU 303260.16 — Stepper Motor Raising BIF 000167.17 — D+ Voltage Too Low

Deadband Above Valid Range During (Engine Speed Over 1500 rpm) . . . . . . . . 211-BIF-28

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-115 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-28

BCU 303260.18 — Stepper Motor Raising BIF 000167.18 — D+ Voltage Too Low

Deadband Below Valid Range During (Engine Speed Up to 1500 rpm) . . . . . . . 211-BIF-30

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-115 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-30

BCU 303261.16 — Stepper Motor BIF 000168.16 — System Voltage Too High

Lowering Deadband Above Valid Range During (Engine Running). . . . . . . . . . . . . . . . . . . 211-BIF-31

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-116 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-32

BCU 303261.18 — Stepper Motor BIF 000168.17 — System Voltage Too

Lowering Deadband Below Valid Range During Low (Engine Speed Over 1500 rpm) . . . . 211-BIF-33

Calibration . . . . . . . . . . . . . . . . . . . . . . 211-BCU-116 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-33

BIF 000168.18 — System Voltage Too

Group BIF—BIF Diagnostic Trouble Codes Low (Engine Speed Up to 1500 rpm). . . . 211-BIF-35

BIF 000096.03 — Fuel Gauge Sender, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-35

Shorted or Open Circuit . . . . . . . . . . . . . . . 211-BIF-1 BIF 000177.00 — Transmission Oil

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-1 Temperature Very High . . . . . . . . . . . . . . 211-BIF-37

BIF 000096.04 — Fuel Gauge Sender, Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-37

Grounded Circuit . . . . . . . . . . . . . . . . . . . . 211-BIF-2 BIF 000177.03 — Transmission Oil

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-3 Temperature Sender, Shorted or Open

BIF 000096.17 — Low Fuel Level . . . . . . . . . 211-BIF-4 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-40

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-5 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-40

BIF 000100.00 — Engine Oil Pressure BIF 000177.04 — Transmission Oil

Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-6 Temperature Sender, Grounded

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-7 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-42

BIF 000107.16 — Engine Air Cleaner Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-42

Clogged . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-8 BIF 000177.16 — Transmission Oil

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-8 Temperature High . . . . . . . . . . . . . . . . . . 211-BIF-44

BIF 000110.00 — Coolant Temperature Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-44

Very High. . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-9 BIF 000186.16 — INFORMATION FOR

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-10 OPERATOR: Warning, Rear PTO

BIF 000110.03 — Coolant Temperature Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-47

Sender, Short or Open Circuit . . . . . . . . . 211-BIF-12 BIF 000190.02 — No Signal From Engine

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-13 Speed Sender . . . . . . . . . . . . . . . . . . . . . 211-BIF-47

BIF 000110.04 — Coolant Temperature Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-47

Sender, Short to Ground . . . . . . . . . . . . . 211-BIF-15 BIF 000628.02 — Control Unit, Internal

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-15 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-49

BIF 000110.16 — Coolant Temperature Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-49

High. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-17 BIF 000639.02 — 29-Bit CAN BUS, Open

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-17 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-49

BIF 000126.15 — Hydraulic Oil Filter Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-50

Dirty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-19 BIF 301141.31 — INFORMATION FOR

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-20 OPERATOR: Switch Off Worklights

BIF 000126.16 — Transmission/Hydraulic Oil While Driving on Road . . . . . . . . . . . . . . . 211-BIF-51

Filter Dirty . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-21

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-22 Continued on next page

TM4726 (01NOV03) 211-5 6020 to 6920S tractors

022204

PN=5

Contents

Page Page

BIF 301143.31 — INFORMATION FOR ECU 000105.03 — Manifold Air

OPERATOR: Preheat Time Temperature Input Voltage High . . . . . . 211-ECU-53

211 Remaining . . . . . . . . . . . . . . . . . . . . . . . . 211-BIF-52 ECU 000105.04 — Manifold Air

Temperature Input Voltage Low . . . . . . . 211-ECU-55

Group ECU—ECU Diagnostic Trouble Codes ECU 000105.16 — Manifold Air Temperature

ECU 000028.03 — Cruise Control Moderately High. . . . . . . . . . . . . . . . . . . 211-ECU-57

Potentiometer Input Voltage High . . . . . . 211-ECU-1 ECU 000110.00 — Engine Coolant

ECU 000028.04 — Cruise Control Temperature Extremely High . . . . . . . . . 211-ECU-59

Potentiometer Input Voltage Low . . . . . . . 211-ECU-5 ECU 000110.03 — Engine Coolant

ECU 000029.03 — Hand Throttle Temperature Input Voltage High . . . . . . 211-ECU-62

Potentiometer Input Voltage High . . . . . . 211-ECU-9 ECU 000110.04 — Engine Coolant

ECU 000029.04 — Hand Throttle Temperature Input Voltage Low . . . . . . . 211-ECU-66

Potentiometer Input Voltage Low . . . . . . 211-ECU-13 ECU 000110.15 — Engine Coolant

ECU 000084.31 — Vehicle Speed Temperature Slightly High . . . . . . . . . . . 211-ECU-70

Mismatch . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-17 ECU 000110.16 — Engine Coolant

ECU 000091.03 — Accelerator Pedal Temperature Moderately High . . . . . . . . 211-ECU-73

Potentiometer Input Voltage High . . . . . 211-ECU-19 ECU 000158.17 — ECU Power Down

ECU 000091.04 — Accelerator Pedal Error . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-76

Potentiometer Input Voltage Low . . . . . . 211-ECU-23 ECU 000160.02 — Wheel Speed Sensor

ECU 000091.07 — Hand Throttle or Input Noise . . . . . . . . . . . . . . . . . . . . . . 211-ECU-79

Accelerator Pedal Not Calibrated ECU 000174.00 — Fuel Temperature

Correctly . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-26 Extremely High . . . . . . . . . . . . . . . . . . . 211-ECU-81

ECU 000091.13 — Hand Throttle or ECU 000174.03 — Fuel Temperature Input

Accelerator Pedal, Calibration Voltage High . . . . . . . . . . . . . . . . . . . . . 211-ECU-82

Interrupted . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-27 ECU 000174.04 — Fuel Temperature Input

ECU 000094.01 — Fuel Supply Pressure

Voltage Low. . . . . . . . . . . . . . . . . . . . . . 211-ECU-84

Extremely Low . . . . . . . . . . . . . . . . . . . . 211-ECU-28

ECU 000174.15 — Fuel Temperature

ECU 000094.03 — Fuel Supply Pressure

Slightly High . . . . . . . . . . . . . . . . . . . . . 211-ECU-86

Input Voltage High . . . . . . . . . . . . . . . . . 211-ECU-29

ECU 000174.16 — Fuel Temperature

ECU 000094.04 — Fuel Supply Pressure

Moderately High. . . . . . . . . . . . . . . . . . . 211-ECU-87

Input Voltage Low . . . . . . . . . . . . . . . . . 211-ECU-31

ECU 000174.31 — Fuel Temperature Sensor

ECU 000094.10 — Fuel Rail Pressure Loss

Faulty . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-90

Detected . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-33

ECU 000189.00 — Engine Speed

ECU 000094.13 — Fuel Rail Pressure Higher

Than Expected . . . . . . . . . . . . . . . . . . . 211-ECU-35 Derate . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-91

ECU 000094.17 — Fuel Rail Pressure Not ECU 000190.00 — Engine Racing

Developed . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-37 Excessively . . . . . . . . . . . . . . . . . . . . . . 211-ECU-93

ECU 000094.18 — Fuel Supply Pressure ECU 000190.02 — Engine Speed Input

Moderately Low . . . . . . . . . . . . . . . . . . . 211-ECU-38 Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-96

ECU 000097.03 — Input Voltage from ECU 000190.16 — Engine Speed Slightly

Water-in-Fuel Sensor High. . . . . . . . . . . 211-ECU-39 High. . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-97

ECU 000097.04 — Input Voltage from ECU 000611.03 — Electronic Injector

Water-in-Fuel Sensor Low . . . . . . . . . . . 211-ECU-41 Wiring Shorted To Power Source. . . . . 211-ECU-100

ECU 000097.16 — Water in Fuel ECU 000611.04 — Electronic Injector

Detected . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-43 Wiring Shorted To Ground . . . . . . . . . . 211-ECU-102

ECU 000100.01 — Engine Oil Pressure ECU 000620.03 — Sensor Supply 2

Extremely Low . . . . . . . . . . . . . . . . . . . . 211-ECU-45 Voltage High . . . . . . . . . . . . . . . . . . . . 211-ECU-104

ECU 000100.03 — Engine Oil Pressure Input ECU 000620.04 — Sensor Supply 2

Voltage High . . . . . . . . . . . . . . . . . . . . . 211-ECU-47 Voltage Low. . . . . . . . . . . . . . . . . . . . . 211-ECU-106

ECU 000100.04 — Engine Oil Pressure Input ECU 000627.01 — Electronic Injector Supply

Voltage Low. . . . . . . . . . . . . . . . . . . . . . 211-ECU-49 Voltage Problem . . . . . . . . . . . . . . . . . 211-ECU-108

ECU 000100.18 — Engine Oil Pressure

Moderately Low . . . . . . . . . . . . . . . . . . . 211-ECU-51 Continued on next page

TM4726 (01NOV03) 211-6 6020 to 6920S tractors

022204

PN=6

Contents

Page Page

ECU 000627.04 — ECU Unswitched ECU 000656.05 — Cylinder No. 6 EI

Power Missing . . . . . . . . . . . . . . . . . . . 211-ECU-109 Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-162

ECU 000629.13 — ECU Error. . . . . . . . . 211-ECU-110 ECU 000656.06 — Cylinder No. 6 EI Circuit 211

ECU 000629.19 — ECU to Pump Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-164

Communication Error . . . . . . . . . . . . . . 211-ECU-113 ECU 000656.07 — Cylinder No. 6 EI Fuel

ECU 000632.02 — Fuel Shutoff Error . . . 211-ECU-114 Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-166

ECU 000632.05 — Fuel Shutoff ECU 000676.03 — Glow Plug Relay

Non-Functional . . . . . . . . . . . . . . . . . . 211-ECU-115 Voltage High . . . . . . . . . . . . . . . . . . . . 211-ECU-168

ECU 000636.02 — Pump Position Sensor ECU 000676.05 — Glow Plug Relay

Input Noise . . . . . . . . . . . . . . . . . . . . . 211-ECU-116 Voltage Low. . . . . . . . . . . . . . . . . . . . . 211-ECU-170

ECU 000636.08 — Pump Position Sensor ECU 000729.03 — Inlet Air Heater Signal

Input Missing . . . . . . . . . . . . . . . . . . . . 211-ECU-118 High. . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-172

ECU 000636.10 — Pump Position Sensor ECU 000729.05 — Inlet Air Heater Signal

Input Pattern Error . . . . . . . . . . . . . . . . 211-ECU-120 Low . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-174

ECU 000637.02 — Crank Position Input ECU 000810.02 — Calculated Vehicle

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-122 Speed Input Signal Noise . . . . . . . . . . 211-ECU-176

ECU 000637.07 — Crank Position/Pump ECU 000898.09 — Engine Speed or Torque

Position Timing Moderately Out of Message Invalid. . . . . . . . . . . . . . . . . . 211-ECU-178

Sync . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-125 ECU 000931.02 — Pump Current

ECU 000637.08 — Crank Position Input Instability . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-180

Missing . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-127 ECU 000931.03 — Pump Current

ECU 000637.10 — Crank Position Input Feedback Input Voltage High. . . . . . . . 211-ECU-181

Pattern Error . . . . . . . . . . . . . . . . . . . . 211-ECU-129 ECU 000931.04 — Pump Current

ECU 000651.05 — Cylinder No. 1 EI Feedback Input Voltage Low . . . . . . . . 211-ECU-182

Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-132 ECU 000931.15 — Pump Current Out of

ECU 000651.06 — Cylinder No. 1 EI Circuit

Range (Engine OFF) . . . . . . . . . . . . . . 211-ECU-183

Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-134

ECU 000931.31 — Pump Current Not

ECU 000651.07 — Cylinder No. 1 EI Fuel

Controllable . . . . . . . . . . . . . . . . . . . . . 211-ECU-184

Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-136

ECU 001041.02 — Start Signal

ECU 000652.05 — Cylinder No. 2 EI

Missing . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-185

Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-138

ECU 001041.03 — Start Signal Always

ECU 000652.06 — Cylinder No. 2 EI Circuit

Active . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-186

Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-140

ECU 001069.02 — Tire Size Error . . . . . 211-ECU-186

ECU 000652.07 — Cylinder No. 2 EI Fuel

Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-142 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-187

ECU 000653.05 — Cylinder No. 3 EI ECU 001069.09 — Tire Size Invalid . . . . 211-ECU-188

Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-144 ECU 001069.31 — Tire Size Error . . . . . 211-ECU-190

ECU 000653.06 — Cylinder No. 3 EI Circuit ECU 001076.00 — Pump Control Valve

Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-146 Closure Too Long . . . . . . . . . . . . . . . . 211-ECU-192

ECU 000653.07 — Cylinder No. 3 EI Fuel ECU 001076.01 — Pump Control Valve

Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-148 Closure Too Short . . . . . . . . . . . . . . . . 211-ECU-194

ECU 000654.05 — Cylinder No. 4 EI ECU 001076.02 — Pump Detected

Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-150 Defect . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-196

ECU 000654.06 — Cylinder No. 4 EI Circuit ECU 001076.03 — Pump Solenoid

Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-152 Current High . . . . . . . . . . . . . . . . . . . . 211-ECU-197

ECU 000654.07 — Cylinder No. 4 EI Fuel ECU 001076.05 — Pump Solenoid Circuit

Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-154 Open . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-199

ECU 000655.05 — Cylinder No. 5 EI ECU 001076.06 — Pump Solenoid Circuit

Circuit Open . . . . . . . . . . . . . . . . . . . . 211-ECU-156 Severely Shorted . . . . . . . . . . . . . . . . . 211-ECU-201

ECU 000655.06 — Cylinder No. 5 EI Circuit ECU 001076.07 — Pump Control Valve

Shorted . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-158 Closure Not Detected . . . . . . . . . . . . . 211-ECU-203

ECU 000655.07 — Cylinder No. 5 EI Fuel

Delivery Failure . . . . . . . . . . . . . . . . . . 211-ECU-160 Continued on next page

TM4726 (01NOV03) 211-7 6020 to 6920S tractors

022204

PN=7

Contents

Page Page

ECU 001076.10 — Pump Solenoid Circuit EPC 000639.13 — 29-bit CAN BUS, High

Moderately Shorted . . . . . . . . . . . . . . . 211-ECU-205 Error Rate . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-5

211 ECU 001076.13 — Current Drop - Time Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-5

Fault . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-207 EPC 000639.19 — 29-bit CAN BUS, Very

ECU 001077.07 — Attempting to Fuel High Error Rate . . . . . . . . . . . . . . . . . . . . 211-EPC-6

Without Command . . . . . . . . . . . . . . . . 211-ECU-208 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-6

ECU 001077.11 — Pump Supply Voltage Out EPC 306014.02 — Clutch Pedal

Of Range . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-209 Potentiometer, Incorrect Voltage Ratio

ECU 001077.12 — Pump Self-Test at Channel 1 and 2 . . . . . . . . . . . . . . . . . 211-EPC-7

Error . . . . . . . . . . . . . . . . . . . . . . . . . . 211-ECU-210 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-7

ECU 001077.19 — Communication Error EPC 306015.03 — Clutch Pedal

between ECU and Pump Detected . . . 211-ECU-211 Potentiometer, Voltage at Channel 1 Too

ECU 001077.31 — Pump Initiated Engine High. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-8

Protection . . . . . . . . . . . . . . . . . . . . . . 211-ECU-212 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-9

ECU 001078.07 — ECU/Pump Timing EPC 306016.04 — Clutch Pedal

Moderately Out of Sync . . . . . . . . . . . . 211-ECU-213 Potentiometer, Voltage at Channel 1 Too

ECU 001078.11 — ECU/Pump Engine Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-10

Speed Out of Sync . . . . . . . . . . . . . . . 211-ECU-214 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 211-EPC-11

ECU 001078.31 — ECU/Pump Timing EPC 306020.31 — Control Unit, Wrong