Professional Documents

Culture Documents

Tex2TexT RPET Technical Data Sheet

Tex2TexT RPET Technical Data Sheet

Uploaded by

Talha NafeesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tex2TexT RPET Technical Data Sheet

Tex2TexT RPET Technical Data Sheet

Uploaded by

Talha NafeesCopyright:

Available Formats

Test Type: XQ-S Test #: 30 Temperature: 25°C

Test Material: RPET Staple Black Fiber Spec: 1.4D x 38mm Test Humidity: 50%RH

Intensity at a

Breaking Breaking

Breaking Elongation Breaking Force Breaking Time Initial Modulus Elastic Modulus Definite

Item Strength Elongation

(mm) (cN/dtex) (S) (cN/dtex) (cN/dtex) Elongation

(cN) Rate (%)

(cN)

Average 6.79 2.89 4.52 28.87 8.68 81.45 29.36 4.93

Test Type: XQ-S Test #: 30 Temperature: 25°C

Test Material: RPET Staple Ecru Fiber Spec: 1.50Denier x 38mm Test Humidity: 50%RH

Intensity at a

Breaking Breaking Breaking

Breaking Force Breaking Time Initial Modulus Elastic Modulus Definite

Item Strength Elongation Elongation

(cN/dtex) (S) (cN/dtex) (cN/dtex) Elongation

(cN) (mm) Rate (%)

(cN)

Average 8.48 3.18 5.11 31.77 9.55 15.86 27.65 4.77

Test Type: EM8.6-02 Test #: 30 Temperature: 25°C

Test Material: RPET Staple RW Fiber Spec: See below Test Humidity: 50%RH

Breaking Double Length Linear Density Length Deviation Crimps Moisture

Breaking Tenacity Over Length Fiber Crimp Percentage Oil Content

Item Elongation Fiber Deviation Rate Rate /25mm Regain

(cN/dtex) (%) (%) (%)

(%) (mg/100g) (%) (%) (%)

Tex2Tex™ Pure RW

5.11 28.5 0 0 +2.1 -1.30 9.80 12.30 0.48 0.16

1.4D*38mm

Tex2Tex™ Pure RW

5.68 28.5 0 0 +1.86 -1.60 10.20 12.10 0.55 0.17

1.2D*38mm

You might also like

- Fabric Specification Form: Please Refer To Pretest Guide For TestingDocument5 pagesFabric Specification Form: Please Refer To Pretest Guide For TestingHemel Khan100% (1)

- Omniplus-I Brochure 2020 enDocument24 pagesOmniplus-I Brochure 2020 ensubramanianNo ratings yet

- Ultrasonic Thickness Gauge A&B Scan For Testing Rubber Thickness TM281 SeriesDocument6 pagesUltrasonic Thickness Gauge A&B Scan For Testing Rubber Thickness TM281 SeriesNeilbarth Morales100% (1)

- Overview Standards For TextilesDocument25 pagesOverview Standards For TextilesanoniemenclubNo ratings yet

- USTER HVI Spectrum Measuring PrinciplesDocument45 pagesUSTER HVI Spectrum Measuring PrinciplesRAMARAMRAM100% (2)

- Im SWP L 002fDocument42 pagesIm SWP L 002fHotib PerwiraNo ratings yet

- Uniaxial GeogridsDocument1 pageUniaxial Geogridskoko kNo ratings yet

- Ansys Fluent Simulation ReportDocument10 pagesAnsys Fluent Simulation Reportot6onxh0wsNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- TN 120RE10ceDocument1 pageTN 120RE10ceAna AnaNo ratings yet

- Matam Multifiber MILLS LTD. (Denim Unit-2) : Quality Control DepartmentDocument1 pageMatam Multifiber MILLS LTD. (Denim Unit-2) : Quality Control DepartmentTowfic Aziz KanonNo ratings yet

- NEET Information Courses Company: NEET Help On Whatsapp ChatDocument1 pageNEET Information Courses Company: NEET Help On Whatsapp Chat15919688moazNo ratings yet

- TDS - Pla Pro HT - Rev 2.0Document2 pagesTDS - Pla Pro HT - Rev 2.0okta wijayaNo ratings yet

- Effective Stress Triaxial Compression: Consolidated UndrainedDocument2 pagesEffective Stress Triaxial Compression: Consolidated UndrainedgomesNo ratings yet

- Anexo 1 - Resultados Ensayos Geomembrana - TRIDocument9 pagesAnexo 1 - Resultados Ensayos Geomembrana - TRIVictor Junior Guadalupe AguilarNo ratings yet

- Mil HDBK 17 2FDocument11 pagesMil HDBK 17 2FprodianNo ratings yet

- Ansys Fluent Simulation Report - PDF 1Document9 pagesAnsys Fluent Simulation Report - PDF 1Manjunath D RNo ratings yet

- Tear Strength - H&M - Shirt Dress Cleopatra S-03 - Black - Bulk Initial (After 3rd Time) - AJL - PassDocument2 pagesTear Strength - H&M - Shirt Dress Cleopatra S-03 - Black - Bulk Initial (After 3rd Time) - AJL - Passkhanh18No ratings yet

- NBR 6240 TdsDocument2 pagesNBR 6240 TdsYorgieNo ratings yet

- THS4131CD: Analog Devices Process Technology: 2.5um 2 Bipolar (AD8672, AD829, AD620)Document15 pagesTHS4131CD: Analog Devices Process Technology: 2.5um 2 Bipolar (AD8672, AD829, AD620)ikperha jomafuvweNo ratings yet

- Ansys Fluent Simulation ReportDocument5 pagesAnsys Fluent Simulation ReportNeil RodriguesNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- ADSS 48SME Tension & Sagging SpecificationsDocument1 pageADSS 48SME Tension & Sagging SpecificationsChahreddine KOUMENJINo ratings yet

- Zhongqi HE, Ke Zhou, Shupan YINDocument6 pagesZhongqi HE, Ke Zhou, Shupan YINChandrasekarNo ratings yet

- E ResinsDocument2 pagesE ResinsmajimojoNo ratings yet

- Ansys - Fluent - Simulation - Faraj RahilDocument13 pagesAnsys - Fluent - Simulation - Faraj RahilFaraj RahilNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Dynamic Mechanical Analysis (DMA) Basics and BeyondDocument53 pagesDynamic Mechanical Analysis (DMA) Basics and BeyondJessica HatfieldNo ratings yet

- Volltext (PDF) Tpu95a (Ref3)Document4 pagesVolltext (PDF) Tpu95a (Ref3)namasse.medamineNo ratings yet

- PANA 22x36x178 Static 1 1Document10 pagesPANA 22x36x178 Static 1 1cristi.nicolaehotmail.comNo ratings yet

- ZylonDocument2 pagesZylongumustuNo ratings yet

- Araldite Av138 hv998Document7 pagesAraldite Av138 hv998Nautique SolutionsNo ratings yet

- 9844 - Techdata RS 485Document2 pages9844 - Techdata RS 485Anonymous zMWvcTNo ratings yet

- N2M1Document1 pageN2M1Lê Nguyễn Ánh DươngNo ratings yet

- NEET Information Courses Company: NEET Help On Whatsapp ChatDocument1 pageNEET Information Courses Company: NEET Help On Whatsapp Chat15919688moazNo ratings yet

- ISO Test Method en (1509 R3)Document16 pagesISO Test Method en (1509 R3)alokaNo ratings yet

- UL2586 2-Core D-Conductor Shielding Outdoor Power Cable: Cross Section Mechanical and Physical CharacteristicsDocument3 pagesUL2586 2-Core D-Conductor Shielding Outdoor Power Cable: Cross Section Mechanical and Physical CharacteristicsAlejandro BuriticaNo ratings yet

- Spring-In - Simulation in Fiber-Composite ManufacturingDocument15 pagesSpring-In - Simulation in Fiber-Composite ManufacturingkarthikNo ratings yet

- Informe Perdida de Carga Tuberia 4 Pulgadas Con by PassDocument7 pagesInforme Perdida de Carga Tuberia 4 Pulgadas Con by PassAMADEUSWALNo ratings yet

- GS-Input DataDocument1 pageGS-Input DataIrihs OthaiminNo ratings yet

- Dynamic Mechanical AnalysisDocument22 pagesDynamic Mechanical Analysisrudy ammeNo ratings yet

- Ansys Fluent Simulation ReportDocument11 pagesAnsys Fluent Simulation ReportNarayana Addanki Machine DesignNo ratings yet

- Properties of Common Optical Polymers: F D C DDocument1 pageProperties of Common Optical Polymers: F D C DHugo MakNo ratings yet

- Spec SheetDocument6 pagesSpec SheettristanNo ratings yet

- Analysis of Ocean Structures Tutorial 5Document18 pagesAnalysis of Ocean Structures Tutorial 5Victor DaggersNo ratings yet

- 32.768 KHZ Crystal Unit SMD 6.9X1.4X1.3Mm Type: Mxt7 SeriesDocument2 pages32.768 KHZ Crystal Unit SMD 6.9X1.4X1.3Mm Type: Mxt7 SeriesMohammad AhamdNo ratings yet

- Tear Strength - H&M - Vintage Slim Ankle HW Conscious Cream S-04 - Ecru - FTD (As Received) - Pass - AGLDocument2 pagesTear Strength - H&M - Vintage Slim Ankle HW Conscious Cream S-04 - Ecru - FTD (As Received) - Pass - AGLkhanh18No ratings yet

- Direct Measurement of Crosslink Density: Core Technology Research, Development and TestingDocument1 pageDirect Measurement of Crosslink Density: Core Technology Research, Development and TestingMd Saifur RahamanNo ratings yet

- N236 - SpecDocument2 pagesN236 - SpecSrikanth KrishnamurthyNo ratings yet

- System Information Idler Set DataDocument98 pagesSystem Information Idler Set DataHasan arif KısaalioğluNo ratings yet

- Informe Perdida de Carga Tuberia 6 Pulgadas Con by PassDocument7 pagesInforme Perdida de Carga Tuberia 6 Pulgadas Con by PassAMADEUSWALNo ratings yet

- Sloshing EffectDocument7 pagesSloshing EffectA-31 Abhinav VermaNo ratings yet

- Rise Time BudgetDocument11 pagesRise Time Budgetsectiona100% (5)

- S/N Desiccant Shape Bulk Density Particle Size Bulk Density (KG/M) (Ibm/f)Document16 pagesS/N Desiccant Shape Bulk Density Particle Size Bulk Density (KG/M) (Ibm/f)SHINo ratings yet

- Comparison GBX11 TriAxDocument1 pageComparison GBX11 TriAxjordiNo ratings yet

- Cement TestDocument1 pageCement TestSunil MayengbamNo ratings yet

- Development of BNCT TPSDocument17 pagesDevelopment of BNCT TPSJunGyuYiNo ratings yet

- 75D-72F SIM COA (Hengyi)Document1 page75D-72F SIM COA (Hengyi)vikashNo ratings yet

- Caracteristicas Cable Utp Con MensajeroDocument2 pagesCaracteristicas Cable Utp Con MensajeroOsvaldo Riquelme FloresNo ratings yet

- Arkema Nano Strength BlockDocument4 pagesArkema Nano Strength BlockGunjan GadodiaNo ratings yet

- STC53K SeriesDocument4 pagesSTC53K SeriesonallpelinNo ratings yet

- Liquid Chromatography - Mass Spectrometry: An IntroductionFrom EverandLiquid Chromatography - Mass Spectrometry: An IntroductionNo ratings yet

- RR 2493 10921 30-Dec-22Document5 pagesRR 2493 10921 30-Dec-22Talha NafeesNo ratings yet

- Grade Thresholds - June 2023: Cambridge O Level Bengali (3204)Document1 pageGrade Thresholds - June 2023: Cambridge O Level Bengali (3204)Talha NafeesNo ratings yet

- Grade Thresholds - November 2018: Cambridge O Level Food and Nutrition (6065)Document1 pageGrade Thresholds - November 2018: Cambridge O Level Food and Nutrition (6065)Talha NafeesNo ratings yet

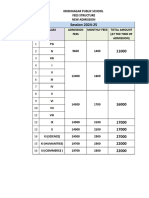

- Fees Structure 2024-25Document1 pageFees Structure 2024-25Talha NafeesNo ratings yet

- Updated IBA Math Main Book Answers 2022-23 (18-8-22)Document4 pagesUpdated IBA Math Main Book Answers 2022-23 (18-8-22)Talha NafeesNo ratings yet

- Gul Ahmed Non Denim ApparelDocument37 pagesGul Ahmed Non Denim ApparelTalha NafeesNo ratings yet

- Cambridge International AS Level: Arabic Language 8680/32Document4 pagesCambridge International AS Level: Arabic Language 8680/32Talha NafeesNo ratings yet

- Cambridge International Project QualificationDocument2 pagesCambridge International Project QualificationTalha NafeesNo ratings yet

- Cambridge International AS Level: Arabic 8680/31 October/November 2022Document3 pagesCambridge International AS Level: Arabic 8680/31 October/November 2022Talha NafeesNo ratings yet

- Cambridge International AS LevelDocument20 pagesCambridge International AS LevelTalha NafeesNo ratings yet

- YTML Newsletter - July-Sep'23Document41 pagesYTML Newsletter - July-Sep'23Talha NafeesNo ratings yet

- F AY 12091 Naia RenewDocument2 pagesF AY 12091 Naia RenewTalha NafeesNo ratings yet

- Amazing Sharm El SheikhDocument2 pagesAmazing Sharm El SheikhTalha NafeesNo ratings yet

- Denim Brochures 2Document7 pagesDenim Brochures 2Talha NafeesNo ratings yet

- End Breaks in The Spinning and Weaving of Weavable Singles YarnsDocument5 pagesEnd Breaks in The Spinning and Weaving of Weavable Singles Yarnsapi-3733260No ratings yet

- Centara Standart Room Set Up - Dec 2011 - OperationsDocument10 pagesCentara Standart Room Set Up - Dec 2011 - OperationsdamianuskrowinNo ratings yet

- Report PDFDocument45 pagesReport PDFmuskan KhanNo ratings yet

- Pilling-Fabric Defect: Mechanism ofDocument6 pagesPilling-Fabric Defect: Mechanism ofনাজীম সরোয়ারNo ratings yet

- IS 15351 StandardsDocument17 pagesIS 15351 StandardsCHIRAG PATELNo ratings yet

- Evince Textile Limited: Internship ExperienceDocument9 pagesEvince Textile Limited: Internship ExperienceAnik IslamNo ratings yet

- TexturingDocument25 pagesTexturingRtr Hasan MahmudNo ratings yet

- CottonDocument65 pagesCottondrskathirrveluNo ratings yet

- ReportDocument45 pagesReportabhijith msNo ratings yet

- Sewing Threads: Standard Test Methods ForDocument12 pagesSewing Threads: Standard Test Methods ForAbdul HameedNo ratings yet

- Automobile TextileDocument45 pagesAutomobile TextileShamima akter100% (1)

- Twill Weave 165001-08 2 PDFDocument19 pagesTwill Weave 165001-08 2 PDFNadim MahmudNo ratings yet

- LinenDocument15 pagesLinenswarna swarna100% (1)

- BRFL Textiles PVT LTD: Sample DescriptionDocument1 pageBRFL Textiles PVT LTD: Sample DescriptionNarendraSinghNo ratings yet

- 纺纱学双语Document653 pages纺纱学双语Gizachew Zeleke100% (1)

- Rearing TechnologyDocument142 pagesRearing TechnologyAdita AgarwalNo ratings yet

- ApplicationManual - KopieDocument61 pagesApplicationManual - KopieJohn GoezNo ratings yet

- Effect of Spindle Speed of Ring Frame On Yarn Quality: December 2018Document5 pagesEffect of Spindle Speed of Ring Frame On Yarn Quality: December 2018gizex2013No ratings yet

- Cut Resistant GlovesDocument29 pagesCut Resistant GloveshelloNo ratings yet

- Uster Quantum ClearerDocument27 pagesUster Quantum ClearerMd. Humayun KabirNo ratings yet

- Journal of Photochemistry & Photobiology, B: Biology: ArticleinfoDocument9 pagesJournal of Photochemistry & Photobiology, B: Biology: ArticleinfoFranklynElardNo ratings yet

- Textile Calculations and EquationsDocument1 pageTextile Calculations and Equationsarsh thakurNo ratings yet

- VortexIII870 e PDFDocument10 pagesVortexIII870 e PDFMd. Humayun KabirNo ratings yet

- 10 Chapter 1Document44 pages10 Chapter 1rohini soniNo ratings yet

- Project Planning For WeaversDocument18 pagesProject Planning For WeaversDhrubajyoti Panigrahi100% (1)

- Blend Dyeing (NEW BOOK) (Upload 28-06 - 2007)Document232 pagesBlend Dyeing (NEW BOOK) (Upload 28-06 - 2007)ibayraktar775208100% (1)