Professional Documents

Culture Documents

4F27 Ford

4F27 Ford

Uploaded by

Andrei valençaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4F27 Ford

4F27 Ford

Uploaded by

Andrei valençaCopyright:

Available Formats

SF99 Servo Bore Repair System:

4F27

Rotunda Tool # NRL4F27

This tool is for use on Ford 4F27E (FN4A-EL) transaxles.

READ ALL APPLICABLE INSTRUCTIONS

BEFORE ATTEMPTING TO USE THE TOOL

U.S. Patent # 6,192,567 12-27-12

1. Install the drill jig into the case by setting the jig into the

servo. Install the included 6mm bolts in the case, through

the jig.

2. Drop the 7/16” guide into the jig. It doesn’t matter which

one of the lands on the guide you use, as long as one of

the lands is under the 3/8” Allen screw.

3. Ream out the bore using the 7/16” reamer, applying ample

lubrication.* DO NOT REAM ABOVE 500 RPM.

4. Replace the 7/16” reamer guide with the 1/2” guide, and

the 7/16” reamer with the 1/2” reamer.

5. Ream the bore out using the 1/2” reamer with ample

lubrication.* Take care not to either push too hard on the

reamer or turn the reamer faster than 500 RPM when

reaming. Either one can overly enlarge the bore, causing a

loose bushing.

6. Clean the case before proceeding to step number seven.

*- CUTTING OIL must be used for lubrication. The use of substitutes,

particularly ATF, may result in an over-sized bore.

Loctite® is a registered trademark of the Loctite Corporation of Rocky Hill, CT

7. Apply Loctite® (preferably green #680) or equivalent to the bushing and align the

hole drilled in the side of the bushing with the v shaped notch cast into the case. Drive

the bushing in by hitting the driver until the bushing bottoms.

8. Insert the provided sizing pin into the bore, chamfer first. It may be necessary to start

the pin in the bushing with a rubber mallet. Once the pin is inside the bushing, use a

punch to drive the pin all the way through the bushing. The included sizing pin is larger

than the factory servo pin, so repeat until the factory servo pin moves freely through

the bushing.

**ALWAYS CHECK PIN FINISH FOR **

**BURS AND COARSNESS**

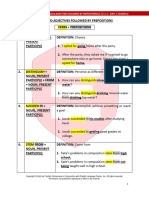

Important Reamer Info

Reamers are like drills, if you use them repeatedly in aluminum

Inspect for aluminum buildups they develop build-ups on the cutting edges. These build-ups

on the cutting edges as pictured effectively make the reamer larger, causing a larger hole. This

left.

larger hole then robs the bushing you’re installing of

interference needed to properly crush the bushing. This causes

the pin to be loose in the bushing, which defeats the entire

purpose . To prevent this, you need to (1) keep your reamers

sharp and (2) use plenty of CUTTING OIL when reaming.

You must use a cutting oil, i.e. Tap Magic, for

Lubrication when reaming.

DO NOT SUBSTITUTE WITH ATF!!!

Replacement bushings are available through Rotunda, Part # NRL4834

Rotunda Technician Tool Program

1-800-ROTUNDA (768-8632)

Option #6

You might also like

- Hot Rod Ford RoadsterDocument34 pagesHot Rod Ford RoadsterJuanRodriguez94% (17)

- You Re Designing It All Wrong Tal Florentin WebydoDocument116 pagesYou Re Designing It All Wrong Tal Florentin WebydoLucia Codreanu83% (6)

- NP5011 Ed8 2020Document84 pagesNP5011 Ed8 2020RaFi Ibna Asad100% (2)

- BRH 625 Sandvi̇k BreakerDocument87 pagesBRH 625 Sandvi̇k BreakerSerkanAl100% (1)

- Dokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFDocument4 pagesDokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFMabrouk GuezatiNo ratings yet

- Media 24-BetooghoofdeDocument72 pagesMedia 24-BetooghoofdeNetwerk24SakeNo ratings yet

- Flexible Impeller GuideDocument10 pagesFlexible Impeller GuideRaymondNo ratings yet

- Kf22Qt Sec4 FRDDocument21 pagesKf22Qt Sec4 FRDMauro PerezNo ratings yet

- Green Panther Earth Auger 2 Men Op GP 2m With Power Head 14 GP 2m 2Document24 pagesGreen Panther Earth Auger 2 Men Op GP 2m With Power Head 14 GP 2m 2muneebNo ratings yet

- Instructions: Installation Instructions For Oil Restrictors (FORD 302 & 351W ENGINES)Document3 pagesInstructions: Installation Instructions For Oil Restrictors (FORD 302 & 351W ENGINES)Adauto PersonNo ratings yet

- Tap SPDOpInstDocument6 pagesTap SPDOpInstjschaudtNo ratings yet

- Air Driven Tube Cleaner: SpecificationsDocument8 pagesAir Driven Tube Cleaner: SpecificationswahyuspecNo ratings yet

- Toolzone WhitworthDocument5 pagesToolzone WhitworthJanice WilliamsNo ratings yet

- SM95C AgDocument7 pagesSM95C AghernanNo ratings yet

- FX-375 ServiceDocument21 pagesFX-375 ServiceMauro PerezNo ratings yet

- DTR Tokarka 330x600-800Document36 pagesDTR Tokarka 330x600-800riegerautoNo ratings yet

- Colibri SampleDocument26 pagesColibri SampleGergő Attila TóthNo ratings yet

- Snow Blower Impeller Kit™ Modifies Two-Stage Snow BlowersDocument9 pagesSnow Blower Impeller Kit™ Modifies Two-Stage Snow BlowersFreedom InlfuencerNo ratings yet

- Snow Blower Impeller Kit™ Modifies Two-Stage Snow BlowersDocument9 pagesSnow Blower Impeller Kit™ Modifies Two-Stage Snow BlowersFreedom InlfuencerNo ratings yet

- Polymer80 RJ556U Build InstructionsDocument14 pagesPolymer80 RJ556U Build InstructionsAW GehrsNo ratings yet

- Bellows Specifications: 4-φ MAX MIN LDocument2 pagesBellows Specifications: 4-φ MAX MIN LharryNo ratings yet

- Drilling System RB-208-3 RB-214-3 ManualDocument50 pagesDrilling System RB-208-3 RB-214-3 ManualCleverson MoreiraNo ratings yet

- Installation Instructions Oil Filter Relocation Kit PART # 15749Document2 pagesInstallation Instructions Oil Filter Relocation Kit PART # 15749Alex BernalNo ratings yet

- TimkenTT en Vol1 Iss3Document2 pagesTimkenTT en Vol1 Iss3grupa2904No ratings yet

- 4032 Installation Tips: Piston To Cylinder Wall ClearanceDocument2 pages4032 Installation Tips: Piston To Cylinder Wall ClearanceMihneaStefanNo ratings yet

- Brother Hi TapDocument6 pagesBrother Hi TapMohd Asri TaipNo ratings yet

- PDFDocument10 pagesPDFPaul HuaraychiriNo ratings yet

- 1.0.4 Manual Tron 7.0 ADVANCEDocument41 pages1.0.4 Manual Tron 7.0 ADVANCEfaizan7996No ratings yet

- FSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsDocument6 pagesFSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsEzequiel CeccarelliNo ratings yet

- Jih 20 24 英文說明書 標準機+護罩 (Auto)Document28 pagesJih 20 24 英文說明書 標準機+護罩 (Auto)Michał JabłońskiNo ratings yet

- Bi Center BitDocument8 pagesBi Center BitAntonio Jose da CostaNo ratings yet

- P-3009-Bg Manual de Servicio Serie 700Document24 pagesP-3009-Bg Manual de Servicio Serie 700PatoCOBRANo ratings yet

- 7 - Lubrification and RepairsDocument5 pages7 - Lubrification and RepairsGabriel vieiraNo ratings yet

- Sealey SA649 NoticeDocument3 pagesSealey SA649 NoticeSEMONNo ratings yet

- Stick - 3.86 MDocument3 pagesStick - 3.86 Mcristian chuquicondor torresNo ratings yet

- SUXR341stage 1 Yoshi Cam SpecsDocument2 pagesSUXR341stage 1 Yoshi Cam SpecsGarry BlakeNo ratings yet

- AT 401 - OM 6 LubricationDocument2 pagesAT 401 - OM 6 LubricationricardozafraNo ratings yet

- AT 401 - OM 6 Lubrication PDFDocument2 pagesAT 401 - OM 6 Lubrication PDFRICARDO ZAFRANo ratings yet

- Kit de Instalación 1250RO-4 para OL500 SeriesDocument1 pageKit de Instalación 1250RO-4 para OL500 SeriesHarold VasquezNo ratings yet

- 4839 30 JK0094 V4Document49 pages4839 30 JK0094 V4Kamy SamuelsonNo ratings yet

- Dummy 1.5Document4 pagesDummy 1.5Durvis Joel Romero LopezNo ratings yet

- HALCO DTH Drill Tools User GuideDocument12 pagesHALCO DTH Drill Tools User GuideApril LongNo ratings yet

- Komatsu Liner KitDocument34 pagesKomatsu Liner KitMANCHING MOKNo ratings yet

- Gen 6 998 WebDocument27 pagesGen 6 998 WebbujleagaNo ratings yet

- MN3085 - 0222 (W)Document12 pagesMN3085 - 0222 (W)mariamalloney1730No ratings yet

- Street Series: CBR-1000RRDocument3 pagesStreet Series: CBR-1000RR김재치No ratings yet

- Pa 1408141Document12 pagesPa 1408141callcott2006No ratings yet

- Dokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFDocument4 pagesDokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFMabrouk GuezatiNo ratings yet

- KIC e-CATALOG - 2018 PDFDocument60 pagesKIC e-CATALOG - 2018 PDFjONATHAN100% (1)

- Iin Ns ST TR Ru Uc CT Tiio On Ns SH He Ee Et TF Fo or R# #9 96 68 83 30 0 - 5 51 1Document1 pageIin Ns ST TR Ru Uc CT Tiio On Ns SH He Ee Et TF Fo or R# #9 96 68 83 30 0 - 5 51 1ЮрийNo ratings yet

- Dodge ALL-STEEL Pillow Blocks: Instruction Manual ForDocument2 pagesDodge ALL-STEEL Pillow Blocks: Instruction Manual ForWisnu BharataNo ratings yet

- Boston Gear Oil RecommendationDocument19 pagesBoston Gear Oil Recommendationangel de mi guardaNo ratings yet

- VJMillDocument57 pagesVJMillpelowisNo ratings yet

- Hand Grease GunDocument8 pagesHand Grease GunPranjal ChakrabortyNo ratings yet

- Drive Shaft Installation InstructionDocument7 pagesDrive Shaft Installation InstructionYonas MuluNo ratings yet

- Agroinform 20170609165551 Geo Efcg Efgch ManualDocument12 pagesAgroinform 20170609165551 Geo Efcg Efgch ManualRosohaticaNo ratings yet

- User Manual Milling Machine: BF 50digDocument17 pagesUser Manual Milling Machine: BF 50diggkyankielNo ratings yet

- Mesin RumputDocument32 pagesMesin Rumputaep77No ratings yet

- Milling Guidlines in DrillingDocument1 pageMilling Guidlines in DrillingJevi SeptiawanNo ratings yet

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- Tragedy of CommonsDocument4 pagesTragedy of CommonsminhaajNo ratings yet

- Encendido MultichispaDocument21 pagesEncendido MultichispaRicardo Diaz100% (1)

- Kobold Quarterly 02Document45 pagesKobold Quarterly 02angelknight_13100% (5)

- D3756-97 (2010) Standard Test Method For EvaluationDocument6 pagesD3756-97 (2010) Standard Test Method For Evaluationastewayb_964354182No ratings yet

- Thirty Days To Change Your LifeDocument103 pagesThirty Days To Change Your Lifekanna45100% (1)

- RJ45 Patch Panel Installation SheetDocument6 pagesRJ45 Patch Panel Installation SheetRomeo BalingaoNo ratings yet

- Verbs and Adjectives Followed by Prepositions - Lesson 1Document4 pagesVerbs and Adjectives Followed by Prepositions - Lesson 1Franklin Horacio Colmenares PérezNo ratings yet

- Test Bank For The Strategic Management of Health Care Organizations 7th Edition Peter M GinterDocument13 pagesTest Bank For The Strategic Management of Health Care Organizations 7th Edition Peter M Ginteradjacent.longan1v799t100% (38)

- LIP Doctrines PDFDocument5 pagesLIP Doctrines PDFTracey FraganteNo ratings yet

- ANSYS ICEM CFD Programmers GuideDocument202 pagesANSYS ICEM CFD Programmers GuideSaif EvonyNo ratings yet

- 14 Keren! 3 & 4 Indonesian Course BookDocument213 pages14 Keren! 3 & 4 Indonesian Course BookTimNo ratings yet

- Format Guidelines and Integrated Script 090112Document75 pagesFormat Guidelines and Integrated Script 090112Mer Coronejo CondrillonNo ratings yet

- Global Information Society Watch Report On Access To Online Information and KnowledgeDocument232 pagesGlobal Information Society Watch Report On Access To Online Information and KnowledgeICTdocsNo ratings yet

- Canon CH4-6501 DIGIC5+ Image Processor FAR-1206-803 TOC PDFDocument5 pagesCanon CH4-6501 DIGIC5+ Image Processor FAR-1206-803 TOC PDFOsama YaseenNo ratings yet

- Dye History From 2600 BC To The 20th CenturyDocument8 pagesDye History From 2600 BC To The 20th CenturySalahuddin SaikotNo ratings yet

- Test Bank For Essentials of Corporate Finance Mcgraw Hill Irwin Series in Finance Insurance and Real Estate 9th EditionDocument21 pagesTest Bank For Essentials of Corporate Finance Mcgraw Hill Irwin Series in Finance Insurance and Real Estate 9th Editionnoticehyoideal.iyjt100% (48)

- Datasheet (LT1074)Document16 pagesDatasheet (LT1074)HermesSanchezNo ratings yet

- Introduction To Latin Answer Key SecondDocument118 pagesIntroduction To Latin Answer Key SecondYinuo ZhangNo ratings yet

- lsf9.1.3 Quick Reference PDFDocument20 pageslsf9.1.3 Quick Reference PDFccchanNo ratings yet

- Samiam v. Coopersburg - Order On MSJDocument29 pagesSamiam v. Coopersburg - Order On MSJSarah BursteinNo ratings yet

- Datasheet 31038Document5 pagesDatasheet 31038gerson evandro hanauerNo ratings yet

- Novel Companion Britlit SeDocument384 pagesNovel Companion Britlit SeAndreea SavulescuNo ratings yet

- Service Bulletin Atr72: Transmittal Sheet Revision No. 02Document9 pagesService Bulletin Atr72: Transmittal Sheet Revision No. 02Pradeep K sNo ratings yet

- Trigger Point Massage GuideDocument82 pagesTrigger Point Massage Guideula100% (6)

- Rounding 100 S Place PacketDocument20 pagesRounding 100 S Place PacketFrederichNietszcheNo ratings yet