Professional Documents

Culture Documents

3954 010 JSA Trench Prep Rev 1

3954 010 JSA Trench Prep Rev 1

Uploaded by

Khalid IrfanCopyright:

Available Formats

You might also like

- OceanofPDF - Com King of Ruin - Sasha Leone Jade RoweDocument374 pagesOceanofPDF - Com King of Ruin - Sasha Leone Jade Roweelizandra040601No ratings yet

- JHA DrillingDocument4 pagesJHA Drillingjay RNo ratings yet

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- JSA Hydro ExcavateDocument3 pagesJSA Hydro Excavatearnel_ado4412100% (3)

- JSA Fall ProtectionDocument2 pagesJSA Fall ProtectionAli SadiqinNo ratings yet

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger2250% (2)

- Red-Haired Girl Leelu: Julia LitvinDocument21 pagesRed-Haired Girl Leelu: Julia LitvinNatalia Lozada Campos100% (2)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- JSA 115 Slip New Drill-Line On BlocksDocument4 pagesJSA 115 Slip New Drill-Line On BlocksanhlhNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Rocky Mountain National Park Page of Job Hazard Analysis (Jha)Document3 pagesRocky Mountain National Park Page of Job Hazard Analysis (Jha)John Carlo MuÑoz MacahiligNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- Mechanical Maintenance ActivitesDocument7 pagesMechanical Maintenance ActivitesJhun Aquino50% (2)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (4)

- Player's Guide To D&ZDocument25 pagesPlayer's Guide To D&ZTGR M100% (4)

- 35 - Method Statements For Erection of Steel PDFDocument1 page35 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- RA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualyDocument1 pageRA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualySaifulNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- 1 - R.A. - 004 - ShutteringDocument4 pages1 - R.A. - 004 - ShutteringmahmoudabidaliNo ratings yet

- Demolition of Civil StructureDocument3 pagesDemolition of Civil StructureSikandar MasoodNo ratings yet

- 1 - R.A. - 005 - De-ShutteringDocument4 pages1 - R.A. - 005 - De-ShutteringmahmoudabidaliNo ratings yet

- Trenches: Am I in Danger?Document1 pageTrenches: Am I in Danger?Alizamin SyedNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisMark DizonNo ratings yet

- Activity Hazard Analysis For Soil ExcavationDocument3 pagesActivity Hazard Analysis For Soil Excavationanoopanil16No ratings yet

- OSI EHS 002 B - SWMS Floor Chipping WorkDocument2 pagesOSI EHS 002 B - SWMS Floor Chipping Workranjithroshan143No ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- 3954-009-JSA-Cold Field Bending Rev 0Document4 pages3954-009-JSA-Cold Field Bending Rev 0Viron BaxhiaNo ratings yet

- Reducing Brush & Trees With Wood Chipper: Job Safety AnalysisDocument3 pagesReducing Brush & Trees With Wood Chipper: Job Safety AnalysisRetselisitsoeNo ratings yet

- Risk Assessment/ JSA Lifting &rigging OperationDocument5 pagesRisk Assessment/ JSA Lifting &rigging Operationuz9143895No ratings yet

- Jsa Brick ShiftingDocument4 pagesJsa Brick ShiftingRavi thokalNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Safety Analysis: Gas Powered ChainsawDocument4 pagesJob Safety Analysis: Gas Powered ChainsawJuztin NovalNo ratings yet

- VacuumDocument2 pagesVacuumShah MuzzamilNo ratings yet

- Jha UnloadingDocument4 pagesJha UnloadingRavi thokalNo ratings yet

- 45 - Method Statements For Erection of Steel PDFDocument1 page45 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- 025 Mec. Excav. Copressor ShelterDocument4 pages025 Mec. Excav. Copressor ShelterViron BaxhiaNo ratings yet

- Removing Rig Floor PlatesDocument1 pageRemoving Rig Floor Platesmadjid bobNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- Equipment ErectionDocument4 pagesEquipment Erectionsunil tiwariNo ratings yet

- 3954-009-JSA-NDT Rev 0Document3 pages3954-009-JSA-NDT Rev 0Viron BaxhiaNo ratings yet

- Hazard Analysis-FEATURE: Mobilization: Driving To JobsiteDocument3 pagesHazard Analysis-FEATURE: Mobilization: Driving To Jobsiteavaldez1972No ratings yet

- Final Risk AssessmentDocument8 pagesFinal Risk Assessmentapi-514194726No ratings yet

- Job Hazard Analysis: Minimum Required Personal Protective Equipment For This JobDocument3 pagesJob Hazard Analysis: Minimum Required Personal Protective Equipment For This JobvalerieNo ratings yet

- 001 Mech. - Manual Excavation JSADocument4 pages001 Mech. - Manual Excavation JSAKiên Đinh VănNo ratings yet

- JHA Power Hand Tool Use - ROMODocument3 pagesJHA Power Hand Tool Use - ROMOMohd AleemNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- Breaking Out The MastDocument1 pageBreaking Out The MastDQE040 HSSENo ratings yet

- TA - Converting Office SpacesDocument8 pagesTA - Converting Office SpacesShannon MooreNo ratings yet

- Excavation Dtra - MechanicalDocument6 pagesExcavation Dtra - MechanicalShahid AlamNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Risk Assessment For Above Ground Drainage SystemDocument2 pagesRisk Assessment For Above Ground Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- BULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15Document5 pagesBULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15hechame TamerhouletNo ratings yet

- Haunter Grey Deception, Seven Book Boxed Set: Includes Upheaval, Evolution, and the PrequelsFrom EverandHaunter Grey Deception, Seven Book Boxed Set: Includes Upheaval, Evolution, and the PrequelsNo ratings yet

- 22-Heat StressDocument22 pages22-Heat StressKhalid IrfanNo ratings yet

- Jsp-Concrete Pipes DemolitionDocument13 pagesJsp-Concrete Pipes DemolitionKhalid IrfanNo ratings yet

- Risk Asses 65 Piping Fabricated and Assembly H03Document13 pagesRisk Asses 65 Piping Fabricated and Assembly H03Khalid IrfanNo ratings yet

- JOB SAFETY ANALYSIS Steel ErectionDocument9 pagesJOB SAFETY ANALYSIS Steel ErectionKhalid IrfanNo ratings yet

- Job Safety AnalysisDocument16 pagesJob Safety AnalysisKhalid IrfanNo ratings yet

- How To Talk Dirty and Influence PeopleDocument151 pagesHow To Talk Dirty and Influence PeopleAnindya Nandi100% (3)

- SindhI Culture by Ajaz KhattakDocument27 pagesSindhI Culture by Ajaz KhattakAjaz AhmadNo ratings yet

- Chapter4-Nouns and PronounsDocument20 pagesChapter4-Nouns and PronounsDNIndri100% (1)

- Free Download Cursed Shadows Silvercrest Academy Book 3 KC Kean Full Chapter PDFDocument51 pagesFree Download Cursed Shadows Silvercrest Academy Book 3 KC Kean Full Chapter PDFclifford.vazquez593100% (16)

- Taeny in 2013 PDFDocument1,205 pagesTaeny in 2013 PDFgodkimtaeyeon100% (1)

- Sustainability Report Baby Diapers and Incontinence Products PDFDocument60 pagesSustainability Report Baby Diapers and Incontinence Products PDFOsvaldo GonçalvesNo ratings yet

- BharatTex2024 BrochureDocument15 pagesBharatTex2024 Brochureveenaenterprises1324No ratings yet

- Pascal MDocument134 pagesPascal MLili LiliNo ratings yet

- Rules and Regulations News CatingDocument3 pagesRules and Regulations News CatingFirman HidayatNo ratings yet

- Exegetical Notes For Ruth 3 1 5 Tony A BartolucciDocument21 pagesExegetical Notes For Ruth 3 1 5 Tony A BartolucciTimothy DamilareNo ratings yet

- BowlingDocument44 pagesBowlingMohd FaezNo ratings yet

- Iris On Rainy DaysDocument245 pagesIris On Rainy DaysJose Salas100% (1)

- WJM Student Handbook 2022-2023Document15 pagesWJM Student Handbook 2022-2023angelinaNo ratings yet

- English Let Review 2015Document92 pagesEnglish Let Review 2015Rennel Mallari89% (9)

- Ruins Ronin PDF PDFDocument80 pagesRuins Ronin PDF PDFPablo Parzanini100% (2)

- Evidence Consolidation Activity RESUELTADocument6 pagesEvidence Consolidation Activity RESUELTAShirley PrietoNo ratings yet

- JamesHeal TestMaterials 24ppDocument13 pagesJamesHeal TestMaterials 24pp郭哲宏No ratings yet

- Frequency: by Stacey DayDocument4 pagesFrequency: by Stacey Dayvania furtadoNo ratings yet

- Reynella Neighbourhood Centre 2016 NewsletterDocument4 pagesReynella Neighbourhood Centre 2016 NewsletterReynella East CollegeNo ratings yet

- MTH 3 ModuleDocument13 pagesMTH 3 ModuleJasmin Lastimoso AjoNo ratings yet

- Julian K Jarboe Everyone On The Moon Is Essential Personnel Lethe Press - 2020Document173 pagesJulian K Jarboe Everyone On The Moon Is Essential Personnel Lethe Press - 2020Marcos Arthur VianaNo ratings yet

- Chihuahua CFDocument8 pagesChihuahua CFMaria Elisa Balestrini100% (3)

- Bojack Horseman Spec - Second DraftDocument32 pagesBojack Horseman Spec - Second DraftRory DiamondNo ratings yet

- AirPod CozyDocument2 pagesAirPod CozyHenriette KnitNo ratings yet

- Módulo 2 - Texto 08 - M. V. Antiguidade Clássica - Gisela Richter - Polychromy in Greek SculptureDocument12 pagesMódulo 2 - Texto 08 - M. V. Antiguidade Clássica - Gisela Richter - Polychromy in Greek SculptureIvair ReinaldimNo ratings yet

- Warframe (Critique Copy)Document33 pagesWarframe (Critique Copy)KibblesnbitsNo ratings yet

3954 010 JSA Trench Prep Rev 1

3954 010 JSA Trench Prep Rev 1

Uploaded by

Khalid IrfanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3954 010 JSA Trench Prep Rev 1

3954 010 JSA Trench Prep Rev 1

Uploaded by

Khalid IrfanCopyright:

Available Formats

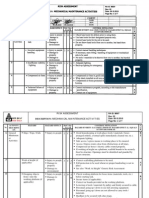

SANTOS LTD JSA NUMBER 3954-010

SCOTIA FIELD DEVELOPMENT DATE 13.12.01

REVISION 1

JOB SAFETY ANALYSIS PAGE 1 of 5

ACTIVITY TRENCH PREPARATION

Crew Name: TRENCHING Job Title: TRENCH PREPARATION APPROVAL

Job Location: Persons Carrying out this Job: Project Manager:

LENGTH OF THE RIGHT OF WAY TRENCHING FOREMAN, MACHINERY OPERATORS AND LABOURERS

Job Supervisor:

Job Supervisor: Colin Howard

BASIC PPE REQUIRED FOR THIS JOB

X Long Shirt Sleeves X Long Trousers X Hard Hat X Safety Footwear Overalls X Dust Mask X Ear Plugs X Safety Glasses Goggles X Gloves

EXTRA PPE REQUIRED FOR THIS JOB (As identified in the Recommended Procedures below)

Personal Protective Equipment including: Safety Footwear, hard hats, overalls, dust mask, ear protection, safety glasses.

JOB DESCRIPTION

Carry out trench excavation as per drawing specifications using Excavators, Cleveland’s and other digging machines.

JOB FREQUENCY

X Daily Weekly Once Off As Required Emergency

File: 753439296.doc Printed Date: 11/05/24

JOB SAFETY ANALYSIS TRENCH PREPARATION JSA NO: 3954-JSA-009

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

Be vigilant when approaching trench or ditching machine

Do not walk close to edge of trench (stay 2-3m away from

Fall into trench due to edge collapse, or unawareness of

1. Advance to ditching machine straddling trench edge when walking beside trench)

trench falling

Check area for any collapsed sections overnight and

advise supervisor

Exit ramps to be cut in ditch to allow escape of animals

trapped in trench

Clear trench of animals / snakes before starting work (in

case anyone should fall in)

Have snake nooses on hand for safely getting snakes out

Animals/Snakes trapped in trench.

of the trench (long pole with a noose at the end operated

by pulling a cord)

When releasing snakes or other animals from the noose

do so on the other side of the trench to the one that the

work party is on (No horse play)

Visually inspect ditcher prior to starting, report to

supervisor anything not correct

Be especially vigilant in isolated areas

Unexpected snakes escape trench via machine Foreman to make regular checks on operators

Care to be taken when working around the machine in the

morning as Snakes may have existed trench via bucket

wheel and be present on machine

Ensure that the correct PPE is worn when changing the

teeth or working on the buckets (gloves, eye protection

and hard hat to prevent knocking head on bucket teeth in

Sharp edges on cutting teeth or buckets causing cuts to

2. Machine maintenance confined space)

personnel whilst being changed

Use only correct tools, ensure tools in good condition

especially when undoing bolts which have become stuck

due to digging action

Ensure suitable access to repair service

Cover / protect sharp edges if possible

Falling / Striking injury due to restricted access. Personnel to ensure that their footing base is sound when

working on equipment (especially when working on

bucket wheel near trench area)

Ensure machine is isolated when servicing

No work to proceed until instructed to do so by supervisor

Ditcher in motion whilst servicing or unexpected start up prior

to service completion If machine does have to be active, (e.g. lubricating wheel

chain) supervisor to ensure all non essential personnel

removed from contact area with moving components

Slip / fall due to oil / grease spills causing poor foothold. Clean up all spills and report any leaks to supervisor

3. Operate ditcher and excavate trench. Person too close to machine, struck/crushed by ditcher or Supervisor to ensure all personnel clear of machine prior

File: 753439296.doc Page 2 of 5 Printed Date: 11/05/24

JOB SAFETY ANALYSIS TRENCH PREPARATION JSA NO: 3954-JSA-009

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

to starting

Experienced / assessed personnel to operate machine

only

spoil. Check spoil belt and spoil are clear and spoil discharge

area is clear

All pipeline personnel warned in their induction not to

approach within a safe distance a ditching machine

Beware of conveyor belt trapping fingers

Do not wear Loose clothing, long hair when working on or

Person becomes entangled in conveyor spoil belt / rollers. near rollers

Do not interfere with belt / spoil discharge in any way if

the machine is in motion

Ensure only experienced and compatent persons are to

be on the Right of Way near operating trenching

machines

All non-essential workers to be removed from work area

Operators not to work alone (especially when in isolated

areas)

Person in front of machine run over

Operator and trenching assistant to enforce non-essential

personnel keeping their distance

All persons around ditching machine to assume that the

operator cannot hear or see them

Persons setting ranging poles to be aware of the ditcher

behind him and monitor separation distance

No one to ride on ditcher when operating

Persons on ditcher become entangled in machine / push

Always seek operators permission to climb onto ditcher

control levers

and never attempt to climb on whilst ditcher is moving

Exercise extreme care when approaching the trench

4. Checking depth / size of trench Trench collapse, causing persons to fall in trench Select area with stable / firm Soil, before leaning over

approaching the trench

5. Excavator rock / steep sections using excavators Rock breaker noise level damaging the operators heating Operator to wear hearing PPE

Operator to ensure that no personnel come close enough

to be struck by rock chips etc

Splintering rock injuring persons

Operator to operate from behind a windscreen

Operator to wear the correct PPE from the job

Always reverse straight up & down inclines not across

If in doubt about slope safety, consult supervisor prior to

Steep inclines cause excavator to slip / skid striking person or starting

overturning causing plant damage. Be aware of overturning when swinging machine to tip

load

Be aware of the excavator’s reduced ability to dig or lift

File: 753439296.doc Page 3 of 5 Printed Date: 11/05/24

JOB SAFETY ANALYSIS TRENCH PREPARATION JSA NO: 3954-JSA-009

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

when on a steep incline

Ensure no persons working down hill of the excavator

should the excavator start to slip. If you have a problem,

sound the horn to warn others. Ensure excavator is

secured, to ensure independent operation. Supervisor to

check rope/set up is correct for operation and suitable

communication is available with winch operator.

Ensure explosives and detonators stored and in suitable

containers.

DO not leave explosives unattended at any stage

Only suitably qualified blasting personnel to handle

Premature explosion due to proximity of explosives and

6. Blasting undigable sections of Rock using explosives explosives (Blasting subcontractor)

detonators.

Blasting site to include warning signs, fire extinguishers

and warning lights etc

Movements of explosive charge to be co-ordinated with

Client through Road safe

Only suitably qualified / assessed operators to operate

drill rig

Ensure Air Drill is serviced regularly and has daily pre

(Drilling holes using air drill) Personnel hearing damage or start checks

7. Drilling holes for explosives

entanglement with revolving drill Correct PPE to be worn

Only essential personnel are present

Beware of entrapment of loose clothing or hair in

revolving machinery

Only supervisor / blasting foreman to remove explosives

from containers and only sufficient explosives to be

8. Charging holes prior to blasting. Loss of explosives & premature explosion

removed (Any outstanding explosive to be returned to

Magazine)

All non essential personnel to be held back to a suitable

perimeter by flagman

All radios to be turned off in blast area

No incoming or outgoing messages

Size of blast area to be determined by an experienced

supervisor

Injury to persons walking through blast zone.

Flagman to have whistles to be blown, should any person

break the perimeter and walk into blast area

Flagman to be visible to blast initiator and hold green

flags aloft if perimeter maintained. Blast supervisor to

confirm all flagman have green flags raised prior to

blasting.

Blaster to retire to blast perimeter set at expected fly rock

9. Firing of blast Fly rock injures persons

limit

File: 753439296.doc Page 4 of 5 Printed Date: 11/05/24

JOB SAFETY ANALYSIS TRENCH PREPARATION JSA NO: 3954-JSA-009

BASIC JOB STEP POTENTIAL HAZARD RECOMMENDED ACTION OR PROCEDURE

Blast to be covered with blasting mat prior to firing

All persons to locate suitable cover before blast

Blasting supervisor to check the blast site for unexploded

Unexploded charge may be detonated if later struck by an charges (No one else to encroach within the blast

10. Inspection of blast site after firing.

excavator perimeter until the all clear signal is given by blasting

supervisor)

Subject of individual JSA at each location

11. Hand expose existing services Danger for hand digging personnel from services

Personnel to hand dig carefully

No one is to enter trench without the foremans approval

12. Entry into excavated trench Trench collapses trapping persons

and without a spotter

NAMES / SIGNATURES OF CREW MEMBERS

NAME POSITION SIGNATURE NAME POSITION SIGNATURE

File: 753439296.doc Page 5 of 5 Printed Date: 11/05/24

You might also like

- OceanofPDF - Com King of Ruin - Sasha Leone Jade RoweDocument374 pagesOceanofPDF - Com King of Ruin - Sasha Leone Jade Roweelizandra040601No ratings yet

- JHA DrillingDocument4 pagesJHA Drillingjay RNo ratings yet

- Backfilling Compaction JSADocument2 pagesBackfilling Compaction JSArashid zaman84% (25)

- JSA Hydro ExcavateDocument3 pagesJSA Hydro Excavatearnel_ado4412100% (3)

- JSA Fall ProtectionDocument2 pagesJSA Fall ProtectionAli SadiqinNo ratings yet

- Skid Steer (Generic) : Job Safety AnalysisDocument2 pagesSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNo ratings yet

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger2250% (2)

- Red-Haired Girl Leelu: Julia LitvinDocument21 pagesRed-Haired Girl Leelu: Julia LitvinNatalia Lozada Campos100% (2)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- JSA 115 Slip New Drill-Line On BlocksDocument4 pagesJSA 115 Slip New Drill-Line On BlocksanhlhNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Rocky Mountain National Park Page of Job Hazard Analysis (Jha)Document3 pagesRocky Mountain National Park Page of Job Hazard Analysis (Jha)John Carlo MuÑoz MacahiligNo ratings yet

- Excavation Job Safety AnalysisDocument1 pageExcavation Job Safety AnalysisVishal Upadhyay100% (3)

- Mechanical Maintenance ActivitesDocument7 pagesMechanical Maintenance ActivitesJhun Aquino50% (2)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (4)

- Player's Guide To D&ZDocument25 pagesPlayer's Guide To D&ZTGR M100% (4)

- 35 - Method Statements For Erection of Steel PDFDocument1 page35 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- RA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualyDocument1 pageRA of Grass Cutting by Strimmer Brushcutter & Removing Weeds MannualySaifulNo ratings yet

- Joinery Carpentry Risk AssessmenmtDocument4 pagesJoinery Carpentry Risk Assessmenmtadeniyi abiolaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- 1 - R.A. - 004 - ShutteringDocument4 pages1 - R.A. - 004 - ShutteringmahmoudabidaliNo ratings yet

- Demolition of Civil StructureDocument3 pagesDemolition of Civil StructureSikandar MasoodNo ratings yet

- 1 - R.A. - 005 - De-ShutteringDocument4 pages1 - R.A. - 005 - De-ShutteringmahmoudabidaliNo ratings yet

- Trenches: Am I in Danger?Document1 pageTrenches: Am I in Danger?Alizamin SyedNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisMark DizonNo ratings yet

- Activity Hazard Analysis For Soil ExcavationDocument3 pagesActivity Hazard Analysis For Soil Excavationanoopanil16No ratings yet

- OSI EHS 002 B - SWMS Floor Chipping WorkDocument2 pagesOSI EHS 002 B - SWMS Floor Chipping Workranjithroshan143No ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- 3954-009-JSA-Cold Field Bending Rev 0Document4 pages3954-009-JSA-Cold Field Bending Rev 0Viron BaxhiaNo ratings yet

- Reducing Brush & Trees With Wood Chipper: Job Safety AnalysisDocument3 pagesReducing Brush & Trees With Wood Chipper: Job Safety AnalysisRetselisitsoeNo ratings yet

- Risk Assessment/ JSA Lifting &rigging OperationDocument5 pagesRisk Assessment/ JSA Lifting &rigging Operationuz9143895No ratings yet

- Jsa Brick ShiftingDocument4 pagesJsa Brick ShiftingRavi thokalNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Safety Analysis: Gas Powered ChainsawDocument4 pagesJob Safety Analysis: Gas Powered ChainsawJuztin NovalNo ratings yet

- VacuumDocument2 pagesVacuumShah MuzzamilNo ratings yet

- Jha UnloadingDocument4 pagesJha UnloadingRavi thokalNo ratings yet

- 45 - Method Statements For Erection of Steel PDFDocument1 page45 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- 025 Mec. Excav. Copressor ShelterDocument4 pages025 Mec. Excav. Copressor ShelterViron BaxhiaNo ratings yet

- Removing Rig Floor PlatesDocument1 pageRemoving Rig Floor Platesmadjid bobNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- Equipment ErectionDocument4 pagesEquipment Erectionsunil tiwariNo ratings yet

- 3954-009-JSA-NDT Rev 0Document3 pages3954-009-JSA-NDT Rev 0Viron BaxhiaNo ratings yet

- Hazard Analysis-FEATURE: Mobilization: Driving To JobsiteDocument3 pagesHazard Analysis-FEATURE: Mobilization: Driving To Jobsiteavaldez1972No ratings yet

- Final Risk AssessmentDocument8 pagesFinal Risk Assessmentapi-514194726No ratings yet

- Job Hazard Analysis: Minimum Required Personal Protective Equipment For This JobDocument3 pagesJob Hazard Analysis: Minimum Required Personal Protective Equipment For This JobvalerieNo ratings yet

- 001 Mech. - Manual Excavation JSADocument4 pages001 Mech. - Manual Excavation JSAKiên Đinh VănNo ratings yet

- JHA Power Hand Tool Use - ROMODocument3 pagesJHA Power Hand Tool Use - ROMOMohd AleemNo ratings yet

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajNo ratings yet

- Breaking Out The MastDocument1 pageBreaking Out The MastDQE040 HSSENo ratings yet

- TA - Converting Office SpacesDocument8 pagesTA - Converting Office SpacesShannon MooreNo ratings yet

- Excavation Dtra - MechanicalDocument6 pagesExcavation Dtra - MechanicalShahid AlamNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Risk Assessment For Above Ground Drainage SystemDocument2 pagesRisk Assessment For Above Ground Drainage Systemمقاول تكييف كهرباء وصحيNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- AHA-003, ExcavationDocument5 pagesAHA-003, ExcavationBuddhika100% (2)

- BULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15Document5 pagesBULLDOZER - C52JSA-044 - Using Bulldozer Ripper - 25-Feb-15hechame TamerhouletNo ratings yet

- Haunter Grey Deception, Seven Book Boxed Set: Includes Upheaval, Evolution, and the PrequelsFrom EverandHaunter Grey Deception, Seven Book Boxed Set: Includes Upheaval, Evolution, and the PrequelsNo ratings yet

- 22-Heat StressDocument22 pages22-Heat StressKhalid IrfanNo ratings yet

- Jsp-Concrete Pipes DemolitionDocument13 pagesJsp-Concrete Pipes DemolitionKhalid IrfanNo ratings yet

- Risk Asses 65 Piping Fabricated and Assembly H03Document13 pagesRisk Asses 65 Piping Fabricated and Assembly H03Khalid IrfanNo ratings yet

- JOB SAFETY ANALYSIS Steel ErectionDocument9 pagesJOB SAFETY ANALYSIS Steel ErectionKhalid IrfanNo ratings yet

- Job Safety AnalysisDocument16 pagesJob Safety AnalysisKhalid IrfanNo ratings yet

- How To Talk Dirty and Influence PeopleDocument151 pagesHow To Talk Dirty and Influence PeopleAnindya Nandi100% (3)

- SindhI Culture by Ajaz KhattakDocument27 pagesSindhI Culture by Ajaz KhattakAjaz AhmadNo ratings yet

- Chapter4-Nouns and PronounsDocument20 pagesChapter4-Nouns and PronounsDNIndri100% (1)

- Free Download Cursed Shadows Silvercrest Academy Book 3 KC Kean Full Chapter PDFDocument51 pagesFree Download Cursed Shadows Silvercrest Academy Book 3 KC Kean Full Chapter PDFclifford.vazquez593100% (16)

- Taeny in 2013 PDFDocument1,205 pagesTaeny in 2013 PDFgodkimtaeyeon100% (1)

- Sustainability Report Baby Diapers and Incontinence Products PDFDocument60 pagesSustainability Report Baby Diapers and Incontinence Products PDFOsvaldo GonçalvesNo ratings yet

- BharatTex2024 BrochureDocument15 pagesBharatTex2024 Brochureveenaenterprises1324No ratings yet

- Pascal MDocument134 pagesPascal MLili LiliNo ratings yet

- Rules and Regulations News CatingDocument3 pagesRules and Regulations News CatingFirman HidayatNo ratings yet

- Exegetical Notes For Ruth 3 1 5 Tony A BartolucciDocument21 pagesExegetical Notes For Ruth 3 1 5 Tony A BartolucciTimothy DamilareNo ratings yet

- BowlingDocument44 pagesBowlingMohd FaezNo ratings yet

- Iris On Rainy DaysDocument245 pagesIris On Rainy DaysJose Salas100% (1)

- WJM Student Handbook 2022-2023Document15 pagesWJM Student Handbook 2022-2023angelinaNo ratings yet

- English Let Review 2015Document92 pagesEnglish Let Review 2015Rennel Mallari89% (9)

- Ruins Ronin PDF PDFDocument80 pagesRuins Ronin PDF PDFPablo Parzanini100% (2)

- Evidence Consolidation Activity RESUELTADocument6 pagesEvidence Consolidation Activity RESUELTAShirley PrietoNo ratings yet

- JamesHeal TestMaterials 24ppDocument13 pagesJamesHeal TestMaterials 24pp郭哲宏No ratings yet

- Frequency: by Stacey DayDocument4 pagesFrequency: by Stacey Dayvania furtadoNo ratings yet

- Reynella Neighbourhood Centre 2016 NewsletterDocument4 pagesReynella Neighbourhood Centre 2016 NewsletterReynella East CollegeNo ratings yet

- MTH 3 ModuleDocument13 pagesMTH 3 ModuleJasmin Lastimoso AjoNo ratings yet

- Julian K Jarboe Everyone On The Moon Is Essential Personnel Lethe Press - 2020Document173 pagesJulian K Jarboe Everyone On The Moon Is Essential Personnel Lethe Press - 2020Marcos Arthur VianaNo ratings yet

- Chihuahua CFDocument8 pagesChihuahua CFMaria Elisa Balestrini100% (3)

- Bojack Horseman Spec - Second DraftDocument32 pagesBojack Horseman Spec - Second DraftRory DiamondNo ratings yet

- AirPod CozyDocument2 pagesAirPod CozyHenriette KnitNo ratings yet

- Módulo 2 - Texto 08 - M. V. Antiguidade Clássica - Gisela Richter - Polychromy in Greek SculptureDocument12 pagesMódulo 2 - Texto 08 - M. V. Antiguidade Clássica - Gisela Richter - Polychromy in Greek SculptureIvair ReinaldimNo ratings yet

- Warframe (Critique Copy)Document33 pagesWarframe (Critique Copy)KibblesnbitsNo ratings yet