Professional Documents

Culture Documents

Annexure B

Annexure B

Uploaded by

Utkarsh DabhadeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure B

Annexure B

Uploaded by

Utkarsh DabhadeCopyright:

Available Formats

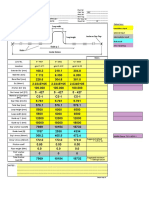

ANNEXURE B

PROJECT: IOCL AJMER W.O NO. FPRO-474

EQUIPMENT: LPG MOUNDED BULLETS

DESIGN INPUTS

Internal Design Pressure P kg/cm2(g) 15.5050 psi 220.5323 N/mm2 1.521

Material Designation IS 2041 GR355

Maximum Allowable Stress S kg/cm2(g) 2090.42 psi 29732.6708 N/mm2 205.000

Corrosion allowance CA inch 0.059 mm 1.500

Inside Diameter ( Un Corroded) inch 283.465 mm 7200.000

Inside Diameter ( Corroded) D inch 283.583 mm 7203.000

Inside Radius ( Un Corroded) inch 141.732 mm 3600.000

Inside Radius ( Corroded) R inch 141.791 mm 3601.500

Joint Efficiency E 1.00

COMPARISON BETWEEN CODES FOR THICKNESS

ASME SEC VIII DIV 1 ASME SEC VIII DIV 2 PD 5500 : 2015

PR

t =

(SE − 0 .6 P ) t= P*Di/(2*f-P)

1.052 inch 1.056 inch 1.056 inch

t= t= t=

26.721 mm 26.812 mm 26.812 mm

Uncorrod 1.111 inch Uncorrod 1.115 inch Uncorrod 1.115 inch

ed thk t = 28.221 mm ed thk t = 28.312 mm ed thk t = 28.312 mm

Nominal thickness of shell as per drawing 30 mm

ANNEXURE B

PROJECT: IOCL GUWAHATI W.O NO. FPRO-472

EQUIPMENT: LPG MOUNDED BULLETS

TAG NO: 07-T-103C/D

DESIGN INPUTS

Internal Design Pressure P kg/cm2(g) 17.8400 psi 253.7437 N/mm2 1.750

Material Designation SA 516 GR 60

Maximum Allowable Stress S kg/cm2(g) 1440.90 psi 20494.3530 N/mm2 141.304

Corrosion allowance CA inch 0.118 mm 3.000

Inside Diameter ( Un Corroded) inch 270.079 mm 6860.000

Inside Diameter ( Corroded) D inch 270.315 mm 6866.000

Inside Radius ( Un Corroded) inch 135.039 mm 3430.000

Inside Radius ( Corroded) R inch 135.158 mm 3433.000

Joint Efficiency E 1.00

COMPARISON BETWEEN CODES FOR SHELL THICKNESS

ASME SEC VIII DIV 1 ASME SEC VIII DIV 2 PD 5500 : 2015

PR

t =

(SE − 0 .6 P ) t= P*Di/(2*f-P)

1.674 inch 1.684 inch 1.684 inch

t= t= t=

42.527 mm 42.769 mm 42.769 mm

Uncorrod 1.792 inch Uncorrod 1.802 inch Uncorrod 1.802 inch

ed thk t = 45.527 mm ed thk t = 45.769 mm ed thk t = 45.769 mm

Nominal thickness of shell as per drawing 46 mm

ANNEXURE B

PROJECT: HMEL BHATINDA W.O no. FPRO-471

EQUIPMENT: OFF-SPEC PROPYLENE

TAG NO: 967-TL-003

DESIGN INPUTS

Internal Design Pressure P kg/cm2(g) 23.4282 psi 333.2263 N/mm2 2.298

Material Designation SA 537 CL.1

Maximum Allowable Stress S kg/cm2(g) 2049.63 psi 29152.5024 N/mm2 201.000

Corrosion allowance CA inch 0.059 mm 1.500

Inside Diameter ( Un Corroded) inch 275.591 mm 7000.000

Inside Diameter ( Corroded) D inch 275.709 mm 7003.000

Inside Radius ( Un Corroded) inch 137.795 mm 3500.000

Inside Radius ( Corroded) R inch 137.854 mm 3501.500

Joint Efficiency E 1.00

COMPARISON BETWEEN CODES FOR THICKNESS

ASME SEC VIII DIV 1 ASME SEC VIII DIV 2 PD 5500 : 2015

PR

t =

(SE − 0 .6 P ) t= P*Di/(2*f-P)

1.576 inch 1.585 inch 1.585 inch

t= t= t=

40.043 mm 40.253 mm 40.254 mm

Uncorrod 1.636 inch Uncorrod 1.644 inch Uncorrod 1.644 inch

ed thk t = 41.543 mm ed thk t = 41.753 mm ed thk t = 41.754 mm

Nominal thickness of shell as per drawing 42 mm

ANNEXURE B

PROJECT: HMEL BHATINDA W.O NO. FPRO-471

EQUIPMENT: ISOBUTANE

TAG NO: 983-TL-004

DESIGN INPUTS

Internal Design Pressure P kg/cm2(g) 7.6000 psi 108.0971 N/mm2 0.745

Material Designation SA 516 GR.70

Maximum Allowable Stress S kg/cm2(g) 1713.40 psi 24370.2022 N/mm2 168.027

Corrosion allowance CA inch 0.059 mm 1.500

Inside Diameter ( Un Corroded) inch 275.591 mm 7000.000

Inside Diameter ( Corroded) D inch 275.709 mm 7003.000

Inside Radius ( Un Corroded) inch 137.795 mm 3500.000

Inside Radius ( Corroded) R inch 137.854 mm 3501.500

Joint Efficiency E 1.00

COMPARISON BETWEEN CODES FOR THICKNESS

ASME SEC VIII DIV 1 ASME SEC VIII DIV 2 PD 5500 : 2015

PR

t =

(SE − 0 .6 P ) t= P*Di/(2*f-P)

0.612 inch 0.613 inch 0.613 inch

t= t= t=

15.534 mm 15.566 mm 15.566 mm

Uncorrod 0.671 inch Uncorrod 0.672 inch Uncorrod 0.672 inch

ed thk t = 17.034 mm ed thk t = 17.066 mm ed thk t = 17.066 mm

Nominal thickness of shell as per drawing 32 mm

ANNEXURE B

PROJECT: HMEL BHATINDA W.O NO. FPRO-471

EQUIPMENT: BUTENE-1

TAG NO: 967-TL-002A/B

DESIGN INPUTS

Internal Design Pressure P kg/cm2(g) 7.0000 psi 99.5631 N/mm2 0.686

Material Designation SA 516 GR.70

Maximum Allowable Stress S kg/cm2(g) 1713.40 psi 24370.2022 N/mm2 168.027

Corrosion allowance CA inch 0.059 mm 1.500

Inside Diameter ( Un Corroded) inch 275.591 mm 7000.000

Inside Diameter ( Corroded) D inch 275.709 mm 7003.000

Inside Radius ( Un Corroded) inch 137.795 mm 3500.000

Inside Radius ( Corroded) R inch 137.854 mm 3501.500

Joint Efficiency E 1.00

COMPARISON BETWEEN CODES FOR THICKNESS

ASME SEC VIII DIV 1 ASME SEC VIII DIV 2 PD 5500 : 2015

PR

t =

(SE − 0 .6 P ) t= P*Di/(2*f-P)

Corroded 0.563 inch Corroded 0.564 inch Corroded 0.564 inch

thk t = 14.308 mm thk t = 14.334 mm thk t = 14.334 mm

Uncorrode 0.622 inch Uncorrod 0.623 inch Uncorrod 0.623 inch

d thk t = 15.808 mm ed thk t = 15.834 mm ed thk t = 15.834 mm

Nominal thickness of shell as per drawing 32 mm

You might also like

- The Secrets of AstrologyDocument192 pagesThe Secrets of Astrologyskballenm92% (26)

- Blind Flange Design Calculation As Per Asme Section Vii Division - 1Document4 pagesBlind Flange Design Calculation As Per Asme Section Vii Division - 1mukesh100% (2)

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocument117 pagesThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNo ratings yet

- Saddle-Design-Operating - FinalDocument17 pagesSaddle-Design-Operating - FinalSiva baalan75% (4)

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- Backing Ring CalculationDocument11 pagesBacking Ring CalculationAhmad FaujiNo ratings yet

- LP Scrubber OnwjDocument1 pageLP Scrubber Onwjpanji uteNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- VSL CalDocument50 pagesVSL CalEmrahCayboyluNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Flange Input CalcDocument12 pagesFlange Input CalcdharwinNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- 10in Titanium Flange-235psi - Ring Gasket PDFDocument5 pages10in Titanium Flange-235psi - Ring Gasket PDFmo444444No ratings yet

- Api - 650 2008Document27 pagesApi - 650 2008WinsonLimHuiWahNo ratings yet

- Min. Required Thickness Due To Internal PresdescriptionDocument3 pagesMin. Required Thickness Due To Internal PresdescriptionRobby Ardi NugrohoNo ratings yet

- 23132-E1A-XL-M: Spherical Roller BearingDocument2 pages23132-E1A-XL-M: Spherical Roller BearingvivianaNo ratings yet

- Engineering Services LTD: CalculationDocument29 pagesEngineering Services LTD: CalculationtomNo ratings yet

- Tank WT & Volume ConvertoreDocument11 pagesTank WT & Volume ConvertorenileshNo ratings yet

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 pageChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanNo ratings yet

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- Calculation AC-1 SunjinDocument3 pagesCalculation AC-1 SunjinJoulee NurimanNo ratings yet

- Spur Gears Component GenDocument6 pagesSpur Gears Component GendexterisNo ratings yet

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Candle Plate ThicknessDocument2 pagesCandle Plate ThicknessAnkur KumarNo ratings yet

- Separator 01 OnwjDocument1 pageSeparator 01 Onwjpanji uteNo ratings yet

- IBR Calualations (28.12.22)Document10 pagesIBR Calualations (28.12.22)Sumit MishraNo ratings yet

- Superheated Steam SeparatorDocument4 pagesSuperheated Steam SeparatorGanesh BhardwajNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- Clien:: Design Calculation of Expansion Bellow As Per App. 5 & 26 of Asme Sec. Viii, Div 1 2004edDocument4 pagesClien:: Design Calculation of Expansion Bellow As Per App. 5 & 26 of Asme Sec. Viii, Div 1 2004edvijay10484No ratings yet

- Nozzle & FlangeDocument14 pagesNozzle & FlangeRaghNo ratings yet

- Approved - Orifice - C650037Document3 pagesApproved - Orifice - C650037Hemanath CENo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- Load Calculation Sheet at Expansion LoopsDocument8 pagesLoad Calculation Sheet at Expansion LoopsTushar Choudhary0% (1)

- Insert Plate: Forging Projection Calculations Div.1Document5 pagesInsert Plate: Forging Projection Calculations Div.1Mudasir MughalNo ratings yet

- 4.2.5.RS ConnectionDocument14 pages4.2.5.RS ConnectionAnh KyNo ratings yet

- Design Calculations For Pressure VesselsDocument43 pagesDesign Calculations For Pressure VesselsMoises Alvarez LeandroNo ratings yet

- Weight Estimation of Vessels AppsDocument39 pagesWeight Estimation of Vessels Appsmacwan23No ratings yet

- v756373001xb - Mds Sludge Decant TankDocument50 pagesv756373001xb - Mds Sludge Decant TankInamullah KhanNo ratings yet

- Separator 02 OnwjDocument1 pageSeparator 02 Onwjpanji uteNo ratings yet

- Bea XL K MB1Document2 pagesBea XL K MB1Teguh TirtayasaNo ratings yet

- Flange Input Data Values Description: FLGDocument4 pagesFlange Input Data Values Description: FLGAnonymous AyDvqgNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- TK-ALCOZAP-2020-01-06-Rev. DDocument65 pagesTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- U NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Document14 pagesU NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Anh KyNo ratings yet

- API 650 Storage Tank 2400Document34 pagesAPI 650 Storage Tank 2400PANOLI PROJECTNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (2)

- POT Design R0Document9 pagesPOT Design R0VB665No ratings yet

- Moment Connection DesignDocument2 pagesMoment Connection DesignmaheshbandhamNo ratings yet

- 23252-BEA-XL-K-MB1-C3: Spherical Roller BearingDocument2 pages23252-BEA-XL-K-MB1-C3: Spherical Roller BearingPhan Tuan AnhNo ratings yet

- Part-Uhx (U-Tube) .Document5 pagesPart-Uhx (U-Tube) .AKSHAY BHATKARNo ratings yet

- Design of Flanges Tongue Groove TypeDocument19 pagesDesign of Flanges Tongue Groove TypeJunaid MateenNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Wall Thickness 2Document18 pagesWall Thickness 2Imam Zulfir RamandhaNo ratings yet

- Solution - Astrophysics - D - Test - IB 2016, 2017 2018, 2019 and 2023Document17 pagesSolution - Astrophysics - D - Test - IB 2016, 2017 2018, 2019 and 2023Đạt NguyễnNo ratings yet

- NRCC 53261Document18 pagesNRCC 53261MEHDI FARROKHINo ratings yet

- Actual Let Exam Gen Ed March 2023Document24 pagesActual Let Exam Gen Ed March 2023joseglennbalondro4No ratings yet

- Option d1 PagesDocument9 pagesOption d1 PagesMohammad SuliemanNo ratings yet

- Aits 2021 PT I Jeem Sol PDFDocument17 pagesAits 2021 PT I Jeem Sol PDFmehul pant100% (1)

- (Full Topic) Ielts Speaking 9-12 - Ielts Quoc SonDocument21 pages(Full Topic) Ielts Speaking 9-12 - Ielts Quoc SonHien NguyenNo ratings yet

- PUCARO Triflexil M 2-PlyDocument2 pagesPUCARO Triflexil M 2-PlyUmang DhanukaNo ratings yet

- War Otv 00 GDC 0001 BDocument10 pagesWar Otv 00 GDC 0001 BOmar ATENo ratings yet

- WORKSHEET Phy lab-IIDocument12 pagesWORKSHEET Phy lab-IIzithNo ratings yet

- Pacific Plate Movement Worksheet March 2020Document3 pagesPacific Plate Movement Worksheet March 2020John OsborneNo ratings yet

- BOARD EXAM QUESTIONS ON ArraysDocument6 pagesBOARD EXAM QUESTIONS ON ArraysAD SOLUTIONSNo ratings yet

- UTS Module 1Document13 pagesUTS Module 1Mark Christian BrlNo ratings yet

- 3189 PDFDocument5 pages3189 PDFVln SekharNo ratings yet

- D Đoán 7Document21 pagesD Đoán 7Hải NgọcNo ratings yet

- Gr.4 LaboratoryExercise No.3 Establishment of Horizontal ControlDocument18 pagesGr.4 LaboratoryExercise No.3 Establishment of Horizontal ControlCahulogan KateNo ratings yet

- Cambridge International AS & A Level: Information Technology 9626/04 February/March 2022Document10 pagesCambridge International AS & A Level: Information Technology 9626/04 February/March 2022jesuNo ratings yet

- Experiment 2 - Torsion TestDocument3 pagesExperiment 2 - Torsion TestNabiella AtieraNo ratings yet

- K550X Sputter Coater Instruction ManualDocument32 pagesK550X Sputter Coater Instruction ManualCHARLES MICHAEL ALBERT -No ratings yet

- Home Tuitions 870Document68 pagesHome Tuitions 870maxisinc.inNo ratings yet

- Sampling Distribution and Simulation in RDocument10 pagesSampling Distribution and Simulation in RPremier PublishersNo ratings yet

- BriefingDocument2 pagesBriefingmiguelambarahonaNo ratings yet

- Audit Plan - PT IRSDocument30 pagesAudit Plan - PT IRSHeru Wijaya MassosorangNo ratings yet

- QQQ - Pureyr2 - Chapter 3 - Sequences & Series (V2) : Total Marks: 42Document4 pagesQQQ - Pureyr2 - Chapter 3 - Sequences & Series (V2) : Total Marks: 42Medical ReviewNo ratings yet

- Cohen 1967Document14 pagesCohen 1967Easa YahiyaNo ratings yet

- NEC READING PRACTICE TEST 6 SsDocument9 pagesNEC READING PRACTICE TEST 6 SsB Vu HoangNo ratings yet

- English For Scie Nce and Techno LogyDocument15 pagesEnglish For Scie Nce and Techno Logynur ainun lubisNo ratings yet

- 385W PERC Module: JAM72S01 365-385/PRDocument2 pages385W PERC Module: JAM72S01 365-385/PRAmreican PrideNo ratings yet

- Before Listening: Finding The LibraryDocument4 pagesBefore Listening: Finding The LibraryPhạm Tuấn TàiNo ratings yet

- Physics:: JEE-ADVANCED-2012-P1-Model IDocument1 pagePhysics:: JEE-ADVANCED-2012-P1-Model IJohn CarterNo ratings yet