Professional Documents

Culture Documents

64002EN

64002EN

Uploaded by

Carlos OlivaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

64002EN

64002EN

Uploaded by

Carlos OlivaCopyright:

Available Formats

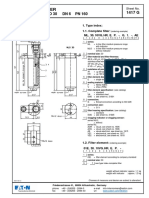

Oil Filter FF

64002EN.doc 03.10.05

OIL FILTER FF1087, FF1088

Order example

Fig. 1

FF1087.Q020.BS16.GT16-M

magnet pack

connecting thread

- GT16 = G1

- GT24 = G1½

seal material

- B = nitrile

- V = viton

degree of filtration

(table 2)

filter type

Table 1. Dimensions [mm]

Type P A D F L H G E J K M N

FF1087 71 150 G1 170 275 83 27 13 125 45 9 108

FF1088 106 190 G1½ 230 350 112 38 16 170 64 13 148

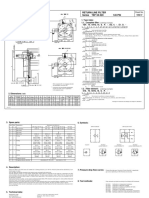

- depressurize the filter

1. Technical data - open the bottom plug of the filter housing

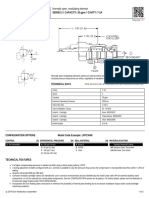

- maximum operating pressure 40 bar (4000 kPa) - open the cap of the filter housing

- max flow 300 l/min - lift the filter element with the filter holder out of the

- connecting threads G1 or G1½ housing

- filtration material: - special fiber glass mixture - remove the element from its holder

(see table 2) - clean the filter housing and the holder and check the

- operating pressure of by-pass valve 1.6 ± 0.2 bar condition of the seals. Change them into new ones if

(0.16 MPa) necessary.

- visual contamination indicator as for Metso Drives’ - oil the seals and the threads of the filter

standard delivery - fasten the new filter element into its holder

- electrical contamination indicator optionally available - install the element with its holder into place in the filter

- filter housing material GRP housing

- fasten the filter cap back into place

Table 2. Degree of filtration according to ISO 16889 - let the filter fill with oil and drain the system

Type Micron rating sizes x for Final loss of - check the tightness of the filter housing when

ß-value pressure, ∆p pressure is on

ßx = 100 ßx = 200 ßx ≥ 1000 (bar)

DISPOSE OF THE USED FILTER ELEMENT

Q010 9 10 12 4.0 PROPERLY!

Q020 18 20 22 4.0

2. Filter maintenance

Replace the old filter element after the pressure

difference indication, after certain intervals or at least

twice a year according to the following instructions:

Moventas Oy 1(1)

You might also like

- Minox 35GT Repair ManualDocument28 pagesMinox 35GT Repair ManualKjell PerssonNo ratings yet

- Daikin Manual BookDocument42 pagesDaikin Manual Bookamsal koto0% (2)

- Cat Filter and Filter Application GuideDocument255 pagesCat Filter and Filter Application GuideSixto Guarniz Anticona83% (6)

- Shogun 2001 Fuel ProblemDocument6 pagesShogun 2001 Fuel ProblemJose GilmerNo ratings yet

- Thu06 Pentair MembranefiltrationDocument29 pagesThu06 Pentair MembranefiltrationdagNo ratings yet

- Filter Media StandardsDocument8 pagesFilter Media StandardsSaeed Kazemi100% (1)

- Filter Unit, Series UM 80 58 PSIDocument2 pagesFilter Unit, Series UM 80 58 PSIAzmi AhmadNo ratings yet

- ds-tmf-5848-engDocument2 pagesds-tmf-5848-engely wagnerNo ratings yet

- Filter Unit, Series UM 125 58 PSIDocument2 pagesFilter Unit, Series UM 125 58 PSIhadNo ratings yet

- Return Line - FRE - 07.001 - R4Document8 pagesReturn Line - FRE - 07.001 - R4neerajlokhande05No ratings yet

- Series TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LDocument4 pagesSeries TNRS 101 DN25 PN10: RETURN LINE FILTER, With Suction Connection Sheet No. 1070 LRaid BekaltiNo ratings yet

- Microfilter FinalDocument6 pagesMicrofilter FinalRobs BankNo ratings yet

- Dungs - Gas FilterDocument8 pagesDungs - Gas FilterBen ZithaNo ratings yet

- Low Pressure Filter: 1. FeaturesDocument8 pagesLow Pressure Filter: 1. FeaturesJamin SmtpngNo ratings yet

- 1 Hole D16.2: EN 10250-2: 1997, S355J2 orDocument3 pages1 Hole D16.2: EN 10250-2: 1997, S355J2 orKalite Güneş MakinaNo ratings yet

- (NBR)Document4 pages(NBR)Youghorta TIRNo ratings yet

- Elite Magna-Range Bridge PlugDocument2 pagesElite Magna-Range Bridge PlugJohanes GigihNo ratings yet

- NORGREN Pressure SensorDocument3 pagesNORGREN Pressure SensorWily WayerNo ratings yet

- 01 4TNV98T-ZCSTY 规格参数表-英文Document4 pages01 4TNV98T-ZCSTY 规格参数表-英文Eric CNo ratings yet

- ML 30, MLO 30 (1417G-English) PDFDocument2 pagesML 30, MLO 30 (1417G-English) PDFEESL AACNo ratings yet

- Series TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 JDocument4 pagesSeries TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 Jsanjay0910No ratings yet

- Contractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)Document4 pagesContractor: Project:Uopsl Flowstation Owner Block:Opl 280, Okwuibome Field, Nigeria. Title:Data Sheet For Level Gauge (Reflex Type)BABILIN VNo ratings yet

- Nor GrenDocument4 pagesNor GrenefrenNo ratings yet

- ME (Parker DF60 Duplex Filter F160 - 40 I - v1)Document7 pagesME (Parker DF60 Duplex Filter F160 - 40 I - v1)TuyenNo ratings yet

- Technical Details R1-1Document1 pageTechnical Details R1-1parth sapariaNo ratings yet

- 99151318Document1 page99151318vvkNo ratings yet

- Pressure Filter For Sandwich Stacking DFZ: Up To 80 L/min, Up To 315 BarDocument4 pagesPressure Filter For Sandwich Stacking DFZ: Up To 80 L/min, Up To 315 BarbetancralNo ratings yet

- 26 ಯ㘨⊍䏃 Fig.26 Fourth oil 2.0t-3.2t 2 㑻ܼ㞾⬅䮼ᶊ DUPLEX MASTDocument1 page 26 ಯ㘨⊍䏃 Fig.26 Fourth oil 2.0t-3.2t 2 㑻ܼ㞾⬅䮼ᶊ DUPLEX MASTВладимир ПутинNo ratings yet

- Filter Elements: FeaturesDocument14 pagesFilter Elements: FeaturesJamin SmtpngNo ratings yet

- Offline Filtration Systems: Filters - AccumulatorsDocument7 pagesOffline Filtration Systems: Filters - AccumulatorsKristianto CahyonoNo ratings yet

- Duplex Filter: 1. FeaturesDocument6 pagesDuplex Filter: 1. Featuresmostafa aliNo ratings yet

- 140 - 2LC0170 6ab11 0aa0Document3 pages140 - 2LC0170 6ab11 0aa0Bryan AlexisNo ratings yet

- Fiat Barchetta: Technical DataDocument8 pagesFiat Barchetta: Technical DatahallexNo ratings yet

- Vacuostato Norgren 18DDocument2 pagesVacuostato Norgren 18DBase SistemasNo ratings yet

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Document2 pagesFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCONo ratings yet

- Gas and Air Filter GF/1 RP 1/2 - RP 2 GF/3 DN 40 - DN 100 GF DN 125 - DN 200Document8 pagesGas and Air Filter GF/1 RP 1/2 - RP 2 GF/3 DN 40 - DN 100 GF DN 125 - DN 200TobiasAngererNo ratings yet

- Model Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenDocument2 pagesModel Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenjuampacervantesNo ratings yet

- Torchsheild P - 4160Document3 pagesTorchsheild P - 4160Chittaranjan PatraNo ratings yet

- Parts Catalogue For Pramac tx1016Document10 pagesParts Catalogue For Pramac tx1016Петр100% (2)

- Tank Top Return-Line Filter: 1. FeaturesDocument8 pagesTank Top Return-Line Filter: 1. FeaturesLuisFranciscoMarinMedranoNo ratings yet

- Filtro HydacDocument2 pagesFiltro HydacWendel AndradeNo ratings yet

- Port Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestDocument3 pagesPort Size: DN 8, G3/8 High Pressure Solenoid Valve Manifold Further Customized Solutions Available Upon RequestEnrique MurgiaNo ratings yet

- Air Breather Filter Pi0201 MahleDocument6 pagesAir Breather Filter Pi0201 MahleHIDRAFLUIDNo ratings yet

- 2020 2e6Document6 pages2020 2e6Jaikishan KumaraswamyNo ratings yet

- Carcasa Filtro Mahle Eg2Document4 pagesCarcasa Filtro Mahle Eg2HIDRAFLUIDNo ratings yet

- 06-2 Data Sheet Oil FilterDocument2 pages06-2 Data Sheet Oil FilterAnonymous 9WNqHZNo ratings yet

- Spare Parts Catalogue: Handling Systems - DeichselstaplerDocument10 pagesSpare Parts Catalogue: Handling Systems - DeichselstaplerDmitriyNo ratings yet

- 042032-1001-A - GB - Operating & Maintenance ManualDocument20 pages042032-1001-A - GB - Operating & Maintenance ManualRonald RoblesNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- E7200 10 02 08 - D Type FilterDocument8 pagesE7200 10 02 08 - D Type FiltermecambNo ratings yet

- Technical Service BulletinDocument9 pagesTechnical Service BulletinMultiAbderrahmaneNo ratings yet

- Model Normally Open, Modulating Element: Series 2 / Capacity: 30 GPM / Cavity: T-2ADocument2 pagesModel Normally Open, Modulating Element: Series 2 / Capacity: 30 GPM / Cavity: T-2ADhrubajyoti BoraNo ratings yet

- Fisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FDocument1 pageFisa Tehnica Panouri Din Lemn Pentru Placari Exterioare-Parklex Facade FPopa MarianNo ratings yet

- Hydrovane V37 RS (PSAS) ErsatzteilelisteDocument72 pagesHydrovane V37 RS (PSAS) ErsatzteilelisteSebastianNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- Return Line Filter Series TEF 55-320 145 PSI: Sheet NoDocument2 pagesReturn Line Filter Series TEF 55-320 145 PSI: Sheet NoRonaldNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- FI-05842 Rev 2Document16 pagesFI-05842 Rev 2luis carvajalNo ratings yet

- Valvula de RealifDocument2 pagesValvula de RealifJoyce AlmeidaNo ratings yet

- Filters Technical Data SheetDocument6 pagesFilters Technical Data SheetVăn HùngNo ratings yet

- FRDALAN Es Us LetterDocument1 pageFRDALAN Es Us LetterIsaac Ticona MenesesNo ratings yet

- Chemistry Project-2 KeshavDocument13 pagesChemistry Project-2 Keshavkeshavjain7No ratings yet

- HydrogenDocument10 pagesHydrogennuzulNo ratings yet

- Steripleat Vent: Sterile Tank Vent FiltrationDocument3 pagesSteripleat Vent: Sterile Tank Vent FiltrationPraful IngleNo ratings yet

- (Hydraulic Pneumatic) Quiz #3 HarithDocument4 pages(Hydraulic Pneumatic) Quiz #3 HarithWakwkaka JssjaaNo ratings yet

- High Efficiency Compressed Air Dryers: Adsorption Dryers Classical SystemDocument8 pagesHigh Efficiency Compressed Air Dryers: Adsorption Dryers Classical Systemneversig100% (1)

- Lab TechniquesDocument31 pagesLab TechniquesJohn Alek NacaytunaNo ratings yet

- AF Series - 16 Bar: AF - Aluminium Compressed Air Fi LtersDocument2 pagesAF Series - 16 Bar: AF - Aluminium Compressed Air Fi LtersThane MasureikNo ratings yet

- GlasswareDocument54 pagesGlasswareSwagath NNo ratings yet

- Inorganic Chemistry Lab ManualDocument25 pagesInorganic Chemistry Lab ManualAbhik SarkarNo ratings yet

- Pleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsDocument4 pagesPleated Media Filter Cartridges: High Efficiency, Long Life Cartridges For Industrial FluidsWarlexNo ratings yet

- Technical Data Sheet Y Plastic Filters: Ydv YDV: Product DescriptionDocument3 pagesTechnical Data Sheet Y Plastic Filters: Ydv YDV: Product DescriptionmujeebscribdNo ratings yet

- Kshara PDFDocument8 pagesKshara PDFVineet NavrangNo ratings yet

- Patent eDocument14 pagesPatent eLSara Martín GNo ratings yet

- Blattellaquinone Synthesis of A Cockroach Pheromone: CHEM 334L Organic Chemistry Laboratory Revision 1.0Document7 pagesBlattellaquinone Synthesis of A Cockroach Pheromone: CHEM 334L Organic Chemistry Laboratory Revision 1.0Tinna Devi ArmasamyNo ratings yet

- Rotary Screen Defender Toro EquipmentDocument16 pagesRotary Screen Defender Toro EquipmentAndiNo ratings yet

- Synthesis and Characterization of Phenytoin Drug and Alpha Benzilmonoxime From BEA711Document4 pagesSynthesis and Characterization of Phenytoin Drug and Alpha Benzilmonoxime From BEA711Jamila WazirNo ratings yet

- Dahl 150 ManualDocument6 pagesDahl 150 ManualTom LeonardNo ratings yet

- Observation and CalculationDocument6 pagesObservation and CalculationluqmancivilNo ratings yet

- Occurrence of Manganese PDFDocument464 pagesOccurrence of Manganese PDFionela21tmNo ratings yet

- The Digital Material Laboratory: Generate MaterialsDocument12 pagesThe Digital Material Laboratory: Generate MaterialsAndrea CorradiNo ratings yet

- PPG 4 Treatment and Disposal of Sewage Where No Foul Sewer Is Available PDFDocument12 pagesPPG 4 Treatment and Disposal of Sewage Where No Foul Sewer Is Available PDFjoseNo ratings yet

- Effluent Treatmnt Plant (ETP) : Akash TikheDocument44 pagesEffluent Treatmnt Plant (ETP) : Akash TikheArvind ShuklaNo ratings yet

- Doosan DX190WDocument20 pagesDoosan DX190WAndrea797No ratings yet

- CHP-0ER Service Maual English (100203)Document82 pagesCHP-0ER Service Maual English (100203)S LNo ratings yet

- CHM 474 Exp 3 4 5Document15 pagesCHM 474 Exp 3 4 5Syafiqah Ck100% (3)

- Rajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingDocument54 pagesRajalakshmi Engineering College, Thandalam Department of Biotechnology Finalyear-Vii Semester Sec A&B Bt-2401 Downstream ProcessingsumiNo ratings yet

- Act Polyols Private Limited Quality Assurance Department Integrated Audit ChecklistDocument32 pagesAct Polyols Private Limited Quality Assurance Department Integrated Audit ChecklistTanzila SiddiquiNo ratings yet