Professional Documents

Culture Documents

Sh-300pv-En - TDS-SC Solution

Sh-300pv-En - TDS-SC Solution

Uploaded by

teeskuncoro_12906321Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sh-300pv-En - TDS-SC Solution

Sh-300pv-En - TDS-SC Solution

Uploaded by

teeskuncoro_12906321Copyright:

Available Formats

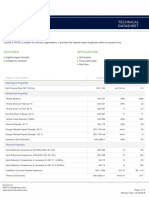

TECHNICAL DATA SHEET

Silane Cross-linkable HFFR(LSHF) compounds

SC SOLUTION Co.,Ltd SH-300PV-EN / CAT-100

Application: Silane Cross-linkable LSHF Insulation and Jacketing Compound for Solar Cables(Photovoltaic Cables)

Reference Spec: TUV HD 22 EI6, EI8 / TUV HD 22 EM2,EM3,EM8,EM10, IEC 62930-2017, EN 50618

# Properties Test Value Unit Test Method Remarks

1 Density 1.42 g/cm³ ASTM D 1505 20°C

2 Melt Index 2.0 g/10min ASTM D 1238 190°C, 21.6kgf

3 Moisture content 400 ppm ASTM D 6869 at 140°C

Tensile Strength 14.5 N/mm² IEC60811

Unaged

4

20°C, 200mm/min

Elongation at Break 250 % IEC60811

Tensile Strength-Retained 126 % IEC60811

After ageing

5

150°C, 240hrs

Elongation at Break-Retained 80 % IEC60811

Tensile Strength-Retained 88 % IEC60811

After 23°C, 168hrs

6

N-Oxalic acid

Elongation at Break-Retained 95 % IEC60811

HOT 70 % IEC 60811-507

250°C, 15min,

7

20N/cm²

SET 5 % IEC 60811-507

8 Oxygen Index 35 % ASTM D 2863

Flame Mode

9 Smoke Density(Flaming Mode) 90 Ds max ASTM D 662

(3mm Sheet)

10 Volume Resistivity 1.0× 1015 Ω•㎝ ASTM D 257 at 20ºC

11 UV Resistance PASS - EN 50618

IEC60811-504,

12 Cold Bending / impact Test PASS No Crack at -40℃

506

Halogen Content/Acidity of IEC60754-1/ IEC

13 0.2↓/6.5 %/pH

Combustion Gas 60754-2

14 Hardness (Share D) 48 - ASTM D 2240 at 20ºC

JUNE 2021, v.0618 © SC SOLUTION Page 1 of 2

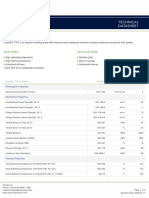

Processing Parameters:

Tolerance ± 5℃

200

190

180

170

Temperature in ºC

160

150

140

130

120

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Adapter Head Die

It is recommended that this product can be used conventional PE/PVC extruder. (L/D is 24:1 and C/R is 1.5:1)

Packaging: SH-300PV-EN is supplied in 25kg AL Bag or 700kg Octabin box with Inner AL bag.

Cross-linkable Method:Blending Ratio→SH-300PV-EN:Catalyst(CAT-100)=100%:1.6%(25kg+0.4kg)

Water Curing condition: thickness 1.0mm → 85℃ *1.5hrs.

It depends on the insulation

Sioplas method

thickness,

is SH-300IX-CD/CAT-100.

Hot water, Steam booth and Room temperature.

Hot Water curing Steam Booth Moisture 80% Rh, 30°

Thickness

time Curing time C

[Insulation & Jacket] [Curing rate 70%] [Curing rate 60%] [Curing rate 70%]

0.2~0.7mm 95°C, 2hours 80°C, 12 hours 7~10 days

0.8~2.0mm 95°C, 4hours 80°C, 24 hours 15~20 days

Handling: To ensure health and safety, Safety Data Sheet (SDS) is available on request.

Storage:Avoid the direct sun-light and After opening the bags, we recommend you to use those ASAP.

SC SOLUTION Co.,Ltd

RM 215, Dongmoon Tower 2, 358-25

Hosu-ro, Ilsandong-gu, Goyang-si

Gyeonggi-do, 10449, South Korea

Tel: (82) 31 901 0065

Fax: (82) 31 901 0066

JUNE 2021, v.0618 © SC SOLUTION Page 2 of 2

You might also like

- The Cubonomicon v1Document43 pagesThe Cubonomicon v1javandarNo ratings yet

- CYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Europe - Technical - Data - SheetmustafaNo ratings yet

- Toray Btcy-1: Description FeaturesDocument6 pagesToray Btcy-1: Description FeaturesAkhil HebbarNo ratings yet

- Dym 8650NFRDocument2 pagesDym 8650NFRpimsuwaNo ratings yet

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucNo ratings yet

- Petra 130 SpecsDocument2 pagesPetra 130 SpecssdecarlogaNo ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- HFX 500P Rev 6 - 2018 PDFDocument2 pagesHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNo ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Sioplas Aerial Bunched Cable KLJXL01 HSKLJXLMBBK7Document4 pagesSioplas Aerial Bunched Cable KLJXL01 HSKLJXLMBBK7Ashish bhattNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Raychem Heat-Shrinkable Heavy-Wall Flame-Retarded Tubing WCSF For Nuclear EnvironmentsDocument4 pagesRaychem Heat-Shrinkable Heavy-Wall Flame-Retarded Tubing WCSF For Nuclear EnvironmentsNicolas AguilarNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- PP Gf30 - Suplen v30 LCDocument2 pagesPP Gf30 - Suplen v30 LCarmandoNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- XENOY™ Resin - 5220U - Europe - Technical - Data - SheetDocument2 pagesXENOY™ Resin - 5220U - Europe - Technical - Data - SheetEduardo TreviñoNo ratings yet

- Datasheet VT-4A SeriesDocument3 pagesDatasheet VT-4A Seriesmccornejo1617No ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Document4 pagesF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- BLS Polymers TDS of PVC TM51FRLS COMPOUND TM 51FRLS OL70-4 - 4585Document2 pagesBLS Polymers TDS of PVC TM51FRLS COMPOUND TM 51FRLS OL70-4 - 4585Aroop Ratan SenNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- Epoxy Curing With INVISTA DiaminesDocument5 pagesEpoxy Curing With INVISTA DiaminesUnknownNo ratings yet

- Atlac-580 001610Document2 pagesAtlac-580 001610flavio fiumiNo ratings yet

- TDS Hips 2551Document3 pagesTDS Hips 2551jokotrianto13No ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- PA66-GF30LANXESS Durethan AKV30 000000 ISO ENDocument3 pagesPA66-GF30LANXESS Durethan AKV30 000000 ISO ENKalipse FerreiraNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- Data Sheet: FFKM: Material: PerfluoroelastomerDocument1 pageData Sheet: FFKM: Material: PerfluoroelastomerParth ShahNo ratings yet

- 6210GCFNC1 英文物性表 20161122Document1 page6210GCFNC1 英文物性表 20161122Sơn Nguyễn ĐắcNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Abs Absolac 300Document2 pagesAbs Absolac 300ShrikantNo ratings yet

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocument5 pagesEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuNo ratings yet

- 1125 (Eng)Document1 page1125 (Eng)Sarthak AggarwalNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Polyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)Document3 pagesPolyplastics TOPAS® 8007S-04 Cyclic Olefin Copolymer (COC)cir74636No ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Absolac 300 Ineos AbsDocument2 pagesAbsolac 300 Ineos Absadrian4santanaNo ratings yet

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- TDS Enus 1Document2 pagesTDS Enus 1Director ResearchNo ratings yet

- PA 6.6 Nylon 6.6Document2 pagesPA 6.6 Nylon 6.6Naeem KhanNo ratings yet

- TDS - Lexan 141R (141R-701)Document2 pagesTDS - Lexan 141R (141R-701)It WittayaNo ratings yet

- Christo Lube MCG 134 Tech DataDocument1 pageChristo Lube MCG 134 Tech Datarobertoalfaro492023No ratings yet

- AWS D1.8 Certificate-Primacore LW71Document1 pageAWS D1.8 Certificate-Primacore LW71edwinNo ratings yet

- Bao On AmazonDocument4 pagesBao On AmazonTrần ChâuNo ratings yet

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- Science Chapter 6Document13 pagesScience Chapter 6GM EstradaNo ratings yet

- EXAM in Statistics and ProbabilityDocument7 pagesEXAM in Statistics and Probabilityjennilyn bulaonNo ratings yet

- How To Design An Innovative WorkplaceDocument2 pagesHow To Design An Innovative WorkplacemuskanNo ratings yet

- Infineon IRLML2502 DataSheet v01 - 01 ENDocument10 pagesInfineon IRLML2502 DataSheet v01 - 01 ENabbaseftekhariNo ratings yet

- MiniThesis GenderDocument16 pagesMiniThesis GenderRica Pearl ZorillaNo ratings yet

- Bsi BS en 15073 - 2013Document20 pagesBsi BS en 15073 - 2013alferedNo ratings yet

- New TAWS Features: Based On EGPWS ExperienceDocument23 pagesNew TAWS Features: Based On EGPWS ExperienceShimeonNo ratings yet

- Examen de Ingles b1Document13 pagesExamen de Ingles b1GIANN CARLO GUTIERREZ GUERRERONo ratings yet

- 2000 Words EssayDocument6 pages2000 Words Essaylwfdwwwhd100% (2)

- (Template) Sprinkler and Micro Irrigation Systems Manual - PROOF 21072020Document84 pages(Template) Sprinkler and Micro Irrigation Systems Manual - PROOF 21072020Lakum Ravi N.No ratings yet

- Thomas Carlyle - A Sign of The TimesDocument11 pagesThomas Carlyle - A Sign of The TimesJack ReadNo ratings yet

- Entrepreneurial DNADocument6 pagesEntrepreneurial DNADylan GregerNo ratings yet

- MechanismsDocument22 pagesMechanismssilva, april joy c.No ratings yet

- 4k Solar Camera FlyerDocument4 pages4k Solar Camera FlyerElvis EmilianoNo ratings yet

- College-Algebra, Take Home Test 2Document3 pagesCollege-Algebra, Take Home Test 2Michelle Morgan LongstrethNo ratings yet

- Defence Presentation - Ekaterina NazarenkoDocument44 pagesDefence Presentation - Ekaterina NazarenkoЕкатерина НазаренкоNo ratings yet

- Sepl Esr GSRDocument4 pagesSepl Esr GSRSyed Mohd MehdiNo ratings yet

- Suggested ProjectsDocument2 pagesSuggested ProjectsCadever Y.TNo ratings yet

- Sameh Gamal Saad (Final PHD)Document321 pagesSameh Gamal Saad (Final PHD)Remon SamirNo ratings yet

- GPS PPT by Pankaj Palta 11092013Document27 pagesGPS PPT by Pankaj Palta 11092013Pankaj PaltaNo ratings yet

- KH53 US EnglishDocument12 pagesKH53 US EnglishmohamedsamimorsiNo ratings yet

- Overleaf Amsl Package PDFDocument44 pagesOverleaf Amsl Package PDFBruce LimNo ratings yet

- ComparisonofAxialLoadonColumn FormattedPaperDocument7 pagesComparisonofAxialLoadonColumn FormattedPaperVictor Omotoriogun100% (1)

- Presentation, Analysis, and Interpretation of Data: Tongco ST., Maysan, Valenzuela CityDocument10 pagesPresentation, Analysis, and Interpretation of Data: Tongco ST., Maysan, Valenzuela CityAnne BustilloNo ratings yet

- Cooling Water System (Training)Document34 pagesCooling Water System (Training)M. ade Dwi MaesandiNo ratings yet

- Constructing Basestations July27 RanjithDocument6 pagesConstructing Basestations July27 RanjithAkash MahalikNo ratings yet

- What Is Research Collaboration?Document19 pagesWhat Is Research Collaboration?adni_wgNo ratings yet

- Translating English Sentences To Mathematical Sentences and Vice-VersaDocument8 pagesTranslating English Sentences To Mathematical Sentences and Vice-VersaDana0% (1)

- MC74VHC00 D-2315589Document9 pagesMC74VHC00 D-2315589rajabur688No ratings yet