Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsTopic - 5 - Robotics Drives

Topic - 5 - Robotics Drives

Uploaded by

josephryanpara03Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Unit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetDocument89 pagesUnit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetBala mechNo ratings yet

- UNIT-1 Hydraulic and Pneumatic DrivesDocument56 pagesUNIT-1 Hydraulic and Pneumatic DrivesChetuNo ratings yet

- Introduction To Pneumatics and HydydraullicsDocument20 pagesIntroduction To Pneumatics and HydydraullicsDaniaNo ratings yet

- FLUID POWER SYSTEMS Theory and PracticeDocument31 pagesFLUID POWER SYSTEMS Theory and PracticeRAMAR MNo ratings yet

- A BatchDocument71 pagesA BatchVenkiteshNo ratings yet

- Presentation ON Hydraulic Control System Control Engineering (2151908)Document26 pagesPresentation ON Hydraulic Control System Control Engineering (2151908)Marwan NasserNo ratings yet

- R&A - Module 2Document85 pagesR&A - Module 2The UltimateNo ratings yet

- Industrial Fluid PowerDocument34 pagesIndustrial Fluid PowerPrasad varnekarNo ratings yet

- Presentation 4actuation System For MechatronicsDocument62 pagesPresentation 4actuation System For MechatronicswabdushukurNo ratings yet

- Hydraulic Pneumatic BrakesDocument14 pagesHydraulic Pneumatic Brakesabyzen100% (1)

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- Unit 1Document86 pagesUnit 1Kalaiselvan PunniyamoorthyNo ratings yet

- Correction ElementDocument20 pagesCorrection ElementKelvin Oscar nsituNo ratings yet

- IHP Micro ProjectDocument13 pagesIHP Micro ProjectROHANNo ratings yet

- ActuatorDocument42 pagesActuatorNyandaMadili MalashiNo ratings yet

- Actuators For Mechatronic SystemsDocument35 pagesActuators For Mechatronic SystemsSrinivasan V PNo ratings yet

- Aircraft System 1 - Pneumatic SystemDocument14 pagesAircraft System 1 - Pneumatic SystemAndreas.G100% (1)

- Unit 2: Actuation SystemsDocument10 pagesUnit 2: Actuation SystemsNaga RajanNo ratings yet

- Introduction To Fluid Power: Fluid Mechanics, Hydraulics & PneumaticsDocument41 pagesIntroduction To Fluid Power: Fluid Mechanics, Hydraulics & Pneumaticsshahzaibkhan ccpNo ratings yet

- AUTOMATION & Drives PDFDocument127 pagesAUTOMATION & Drives PDFMartinez 100No ratings yet

- Automation and Drive Lectures 1 Amd 2Document52 pagesAutomation and Drive Lectures 1 Amd 2Martinez MutaiNo ratings yet

- Topic 3 and 4 ElectiveDocument17 pagesTopic 3 and 4 ElectiveMeme ReviewNo ratings yet

- 2-Hydraulic Actuators and Control Compenents-2Document57 pages2-Hydraulic Actuators and Control Compenents-2akhilkrrish143No ratings yet

- Week 11 Lecture 1Document16 pagesWeek 11 Lecture 1muhammadtalhabilal6666No ratings yet

- Hydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Document58 pagesHydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Kim TanNo ratings yet

- Robotics Unit2 SlidesDocument104 pagesRobotics Unit2 SlidesJanarthanan BalakrishnasamyNo ratings yet

- PneumaticsDocument7 pagesPneumaticsrk krishnaNo ratings yet

- Industrial Automation & Robotics Final Exam AssignmentDocument2 pagesIndustrial Automation & Robotics Final Exam AssignmentSyed Dayyan AskariNo ratings yet

- CSC QB 1-7Document9 pagesCSC QB 1-7Vedang ChavanNo ratings yet

- PNEUDocument19 pagesPNEUHitwardhan DhadwalNo ratings yet

- Introduction To Fluid PowerDocument15 pagesIntroduction To Fluid PowerMoh AlsultanNo ratings yet

- Design of Fluid Power Systems: - Stuart J. WilliamsDocument37 pagesDesign of Fluid Power Systems: - Stuart J. WilliamsAnonymous Ms8nYcbxY2No ratings yet

- MODULE II (A)Document65 pagesMODULE II (A)Nazeema TTNo ratings yet

- HydraDocument2 pagesHydraMagesssNo ratings yet

- Fluid Power and Control-Lecture 1Document16 pagesFluid Power and Control-Lecture 1Barnaba DionizNo ratings yet

- Ch-2 PPT ActuatorsDocument12 pagesCh-2 PPT ActuatorsArganoNo ratings yet

- Accessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasDocument22 pagesAccessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasFaisal AwaisNo ratings yet

- Fluid Machine C H 1Document56 pagesFluid Machine C H 1abdisahurisa24No ratings yet

- Unit - 1 Hydraulic and Pneumatic SystemsDocument44 pagesUnit - 1 Hydraulic and Pneumatic Systemsren antoNo ratings yet

- Pneumatics SystemDocument10 pagesPneumatics SystemuthiraNo ratings yet

- HYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Document40 pagesHYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Marlowe Cris MenceroNo ratings yet

- Ece006 Homework1Document12 pagesEce006 Homework1JHOZEFUS SABREDONo ratings yet

- 3 ActuatorsDocument88 pages3 Actuatorsnunu100% (1)

- PneumaticDocument22 pagesPneumaticTäð Œvê MîðNo ratings yet

- Aircraft Pneumatic SystemsDocument10 pagesAircraft Pneumatic SystemsqzakryaNo ratings yet

- ActuatorDocument21 pagesActuatorkylechristiansarmientoNo ratings yet

- Hydraulic Systems in AircraftsDocument12 pagesHydraulic Systems in AircraftsTwinkleNo ratings yet

- Introduction To AC SystemsDocument229 pagesIntroduction To AC SystemsAnush R AminNo ratings yet

- Aircraft Pneumatic SystemsDocument46 pagesAircraft Pneumatic SystemsSasiKumar100% (1)

- Module 1: Introduction To Fluid MachineryDocument35 pagesModule 1: Introduction To Fluid MachineryJohn MameNo ratings yet

- Module 1 - 1Document93 pagesModule 1 - 1nojiv54944No ratings yet

- 3.3 Pneumatic CircuitsDocument50 pages3.3 Pneumatic CircuitsJash ShethNo ratings yet

- 1.topic 1 - Ind ControlDocument52 pages1.topic 1 - Ind ControlLoga HSNo ratings yet

- Presentation On Actuators: Prepared By: Shivi Varshney ME (I&C) Regular 2017Document26 pagesPresentation On Actuators: Prepared By: Shivi Varshney ME (I&C) Regular 2017Shivi VarshneyNo ratings yet

- Ch4 Drives, Actuators and ControlDocument80 pagesCh4 Drives, Actuators and ControlcactuswillsaNo ratings yet

- Systems 5 Hydraulic Systems S35 PDFDocument97 pagesSystems 5 Hydraulic Systems S35 PDFCemalettin öztoprakNo ratings yet

- Fluid Power ControlDocument12 pagesFluid Power Controlwhatsapp video statusNo ratings yet

- Mining Machinery: Department of Mechanical Engineering Aditya Engineering CollegeDocument35 pagesMining Machinery: Department of Mechanical Engineering Aditya Engineering CollegeRAJESH SAHNo ratings yet

- Parts 31200069 01-24-13 ANSI EnglishDocument456 pagesParts 31200069 01-24-13 ANSI EnglishСвятослав ВороновNo ratings yet

- Hurricane Construction ManualDocument111 pagesHurricane Construction ManualJorge José Figueiredo SiqueiraNo ratings yet

- Chap 007Document36 pagesChap 007Lee FeiNo ratings yet

- Think TankDocument5 pagesThink Tankdhruv khandelwalNo ratings yet

- Ho 107Document214 pagesHo 107Lavern SipinNo ratings yet

- ARDF DF3090 (D779-17) Parts CatalogDocument26 pagesARDF DF3090 (D779-17) Parts CatalogmaxmaracatuNo ratings yet

- (Karen Beler Case Study II) - Travel Demand ForecastingDocument5 pages(Karen Beler Case Study II) - Travel Demand ForecastingKaren BeeNo ratings yet

- M30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyDocument3 pagesM30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyЕвгений ДынникNo ratings yet

- Chapter5 - Drive CouplingsDocument90 pagesChapter5 - Drive Couplingsvijay219100% (1)

- Vacuum Braking System 222Document17 pagesVacuum Braking System 222Lalit Mohan67% (3)

- Classic 500 InvoiceDocument3 pagesClassic 500 InvoiceAman SharmaNo ratings yet

- APM Compressor Maintenance, Operation ManualDocument55 pagesAPM Compressor Maintenance, Operation ManualIngeniería AplicacionesNo ratings yet

- Universal, Independent Dual System Hydraulic Test Stand: 920 SeriesDocument8 pagesUniversal, Independent Dual System Hydraulic Test Stand: 920 SeriesSajad KarimiNo ratings yet

- Cycle Time Calculation GuideDocument2 pagesCycle Time Calculation GuideMohammad Choldun Mubarrak Syaefudin [BSI]No ratings yet

- 3dx SuperDocument16 pages3dx SuperBAHAA MANSOURNo ratings yet

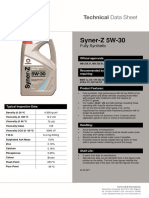

- Syner-Z 5W-30: Fully SyntheticDocument1 pageSyner-Z 5W-30: Fully SyntheticValeriy ValkovetsNo ratings yet

- 01 Clutch Construction and OperationDocument32 pages01 Clutch Construction and Operationdawit abebualNo ratings yet

- Shankar's Resume-3Document6 pagesShankar's Resume-3Green FarmersNo ratings yet

- Arriel 2DDocument2 pagesArriel 2DMUKESH CHAKRAWARTINo ratings yet

- Fuller 13 Speeds Gearbox Lista ComponentiDocument48 pagesFuller 13 Speeds Gearbox Lista ComponentiGIAN PAOLONo ratings yet

- EternaDocument6 pagesEternaSupermobile 786No ratings yet

- SERIES 200 & 220: Pumping PrincipleDocument12 pagesSERIES 200 & 220: Pumping PrincipleRSS RSSNo ratings yet

- Ashok LeylandDocument4 pagesAshok LeylandBelwin JoelNo ratings yet

- MRF (Company) : Madras Rubber Factory Commonly Known As MRF orDocument6 pagesMRF (Company) : Madras Rubber Factory Commonly Known As MRF orAjudiya MeetNo ratings yet

- Chairless Chair For Improved Ergonomics in Audi's Production PlantsDocument3 pagesChairless Chair For Improved Ergonomics in Audi's Production PlantsDeepak ChaurasiaNo ratings yet

- Navitas AC TAC2 Error Code and TroubleshootingDocument8 pagesNavitas AC TAC2 Error Code and Troubleshootingelectronics malayalamNo ratings yet

- Note TakingDocument2 pagesNote TakingLyy Avakin シNo ratings yet

- IEN560D00Document210 pagesIEN560D00Tiago SilvaNo ratings yet

- Salto-Datasheet-Xs4 Original Ax6xx EngDocument3 pagesSalto-Datasheet-Xs4 Original Ax6xx Eng3176985456No ratings yet

- Operation: Residential/Commercial Generator SetsDocument76 pagesOperation: Residential/Commercial Generator SetsАлексей Семикин100% (1)

Topic - 5 - Robotics Drives

Topic - 5 - Robotics Drives

Uploaded by

josephryanpara030 ratings0% found this document useful (0 votes)

2 views19 pagesOriginal Title

Topic_5_Robotics Drives

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views19 pagesTopic - 5 - Robotics Drives

Topic - 5 - Robotics Drives

Uploaded by

josephryanpara03Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 19

Robotic Drives

• A robot will require a drive system for moving

their arm, wrist, and body.

• The joints are moved by actuators powered by

a particular form of drive system.

• A drive system can also be used to determine

the capacity of a robot.

• there are three different types of drive systems

available such as:

– Hydraulic drive system,

– Pneumatic drive system, and

– Electric drive system,

Hydraulic Drive Systems:

• A hydraulic drive system is a quasi-

hydrostatic drive or transmission system that

uses pressurized hydraulic fluid to

power hydraulic machinery

• A hydraulic drive system consists of three

parts:

– The generator (e.g. a hydraulic pump), driven by

an electric motor;

– valves, filters, piping etc. (to guide and control the

system);and

– The actuator (e.g. a hydraulic motor or hydraulic

cylinder) to drive the machinery.

Examples of Hydraulic Drive Systems

Examples of Hydraulic Drive Systems

Examples of Hydraulic Drive Systems

Examples of Hydraulic Drive Systems

Pneumatic Drive System

• Pneumatic systems use air as the medium

which is abundantly available and can be

exhausted into the atmosphere after

completion of the assigned task

• The pneumatic drive systems are especially

used for the small type robots, which have

less than five degrees of freedom.

Components of Pneumatic Drive

Systems

Components of Pneumatic Drive

Systems

• Air filters: These are used to filter out the contaminants from the air.

• Compressor: Compressed air is generated by using air compressors. Air

compressors are either diesel or electrically operated. Based on the

requirement of compressed air, suitable capacity compressors may be

used.

• Air cooler: During compression operation, air temperature increases.

Therefore coolers are used to reduce the temperature of the compressed

air.

• Dryer: The water vapor or moisture in the air is separated from the air by

using a dryer.

• Control Valves: Control valves are used to regulate, control and monitor

for control of direction flow, pressure etc.

• Air Actuator: Air cylinders and motors are used to obtain the required

movements of mechanical elements of pneumatic system.

• Electric Motor: Transforms electrical energy into mechanical energy. It is

used to drive the compressor.

• Receiver tank: The compressed air coming from the compressor is stored

in the air receiver.

Pneumatic systems Examples

Pneumatic systems Examples

Pneumatic systems Examples

Pneumatic systems Examples

Electric Drive Systems

• The electric drive systems are capable of

moving robots with high power or speed.

• The actuation of this type of robot can be

done by either DC servo motors or DC

stepping motors.

Electric Drive Systems

Electric Drive Systems

Electric Drive Systems

Electric Drive Systems

You might also like

- Unit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetDocument89 pagesUnit Ii Robot Drive Systems AND End Effectors: Prepared by B.Balasubramanian Ap/Mech CcetBala mechNo ratings yet

- UNIT-1 Hydraulic and Pneumatic DrivesDocument56 pagesUNIT-1 Hydraulic and Pneumatic DrivesChetuNo ratings yet

- Introduction To Pneumatics and HydydraullicsDocument20 pagesIntroduction To Pneumatics and HydydraullicsDaniaNo ratings yet

- FLUID POWER SYSTEMS Theory and PracticeDocument31 pagesFLUID POWER SYSTEMS Theory and PracticeRAMAR MNo ratings yet

- A BatchDocument71 pagesA BatchVenkiteshNo ratings yet

- Presentation ON Hydraulic Control System Control Engineering (2151908)Document26 pagesPresentation ON Hydraulic Control System Control Engineering (2151908)Marwan NasserNo ratings yet

- R&A - Module 2Document85 pagesR&A - Module 2The UltimateNo ratings yet

- Industrial Fluid PowerDocument34 pagesIndustrial Fluid PowerPrasad varnekarNo ratings yet

- Presentation 4actuation System For MechatronicsDocument62 pagesPresentation 4actuation System For MechatronicswabdushukurNo ratings yet

- Hydraulic Pneumatic BrakesDocument14 pagesHydraulic Pneumatic Brakesabyzen100% (1)

- Hydraulic System 1Document28 pagesHydraulic System 1Udhaya Kumar100% (1)

- Unit 1Document86 pagesUnit 1Kalaiselvan PunniyamoorthyNo ratings yet

- Correction ElementDocument20 pagesCorrection ElementKelvin Oscar nsituNo ratings yet

- IHP Micro ProjectDocument13 pagesIHP Micro ProjectROHANNo ratings yet

- ActuatorDocument42 pagesActuatorNyandaMadili MalashiNo ratings yet

- Actuators For Mechatronic SystemsDocument35 pagesActuators For Mechatronic SystemsSrinivasan V PNo ratings yet

- Aircraft System 1 - Pneumatic SystemDocument14 pagesAircraft System 1 - Pneumatic SystemAndreas.G100% (1)

- Unit 2: Actuation SystemsDocument10 pagesUnit 2: Actuation SystemsNaga RajanNo ratings yet

- Introduction To Fluid Power: Fluid Mechanics, Hydraulics & PneumaticsDocument41 pagesIntroduction To Fluid Power: Fluid Mechanics, Hydraulics & Pneumaticsshahzaibkhan ccpNo ratings yet

- AUTOMATION & Drives PDFDocument127 pagesAUTOMATION & Drives PDFMartinez 100No ratings yet

- Automation and Drive Lectures 1 Amd 2Document52 pagesAutomation and Drive Lectures 1 Amd 2Martinez MutaiNo ratings yet

- Topic 3 and 4 ElectiveDocument17 pagesTopic 3 and 4 ElectiveMeme ReviewNo ratings yet

- 2-Hydraulic Actuators and Control Compenents-2Document57 pages2-Hydraulic Actuators and Control Compenents-2akhilkrrish143No ratings yet

- Week 11 Lecture 1Document16 pagesWeek 11 Lecture 1muhammadtalhabilal6666No ratings yet

- Hydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Document58 pagesHydraulic and Pneumatic System: M.E. Technical Elective 1 (Mechatronics)Kim TanNo ratings yet

- Robotics Unit2 SlidesDocument104 pagesRobotics Unit2 SlidesJanarthanan BalakrishnasamyNo ratings yet

- PneumaticsDocument7 pagesPneumaticsrk krishnaNo ratings yet

- Industrial Automation & Robotics Final Exam AssignmentDocument2 pagesIndustrial Automation & Robotics Final Exam AssignmentSyed Dayyan AskariNo ratings yet

- CSC QB 1-7Document9 pagesCSC QB 1-7Vedang ChavanNo ratings yet

- PNEUDocument19 pagesPNEUHitwardhan DhadwalNo ratings yet

- Introduction To Fluid PowerDocument15 pagesIntroduction To Fluid PowerMoh AlsultanNo ratings yet

- Design of Fluid Power Systems: - Stuart J. WilliamsDocument37 pagesDesign of Fluid Power Systems: - Stuart J. WilliamsAnonymous Ms8nYcbxY2No ratings yet

- MODULE II (A)Document65 pagesMODULE II (A)Nazeema TTNo ratings yet

- HydraDocument2 pagesHydraMagesssNo ratings yet

- Fluid Power and Control-Lecture 1Document16 pagesFluid Power and Control-Lecture 1Barnaba DionizNo ratings yet

- Ch-2 PPT ActuatorsDocument12 pagesCh-2 PPT ActuatorsArganoNo ratings yet

- Accessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasDocument22 pagesAccessory Gear Box: Accessory Drive Is A Gearbox That Forms Part of A GasFaisal AwaisNo ratings yet

- Fluid Machine C H 1Document56 pagesFluid Machine C H 1abdisahurisa24No ratings yet

- Unit - 1 Hydraulic and Pneumatic SystemsDocument44 pagesUnit - 1 Hydraulic and Pneumatic Systemsren antoNo ratings yet

- Pneumatics SystemDocument10 pagesPneumatics SystemuthiraNo ratings yet

- HYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Document40 pagesHYDRAULICS&PNEUMATICScontrol - diagram-AUTOMATION 1Marlowe Cris MenceroNo ratings yet

- Ece006 Homework1Document12 pagesEce006 Homework1JHOZEFUS SABREDONo ratings yet

- 3 ActuatorsDocument88 pages3 Actuatorsnunu100% (1)

- PneumaticDocument22 pagesPneumaticTäð Œvê MîðNo ratings yet

- Aircraft Pneumatic SystemsDocument10 pagesAircraft Pneumatic SystemsqzakryaNo ratings yet

- ActuatorDocument21 pagesActuatorkylechristiansarmientoNo ratings yet

- Hydraulic Systems in AircraftsDocument12 pagesHydraulic Systems in AircraftsTwinkleNo ratings yet

- Introduction To AC SystemsDocument229 pagesIntroduction To AC SystemsAnush R AminNo ratings yet

- Aircraft Pneumatic SystemsDocument46 pagesAircraft Pneumatic SystemsSasiKumar100% (1)

- Module 1: Introduction To Fluid MachineryDocument35 pagesModule 1: Introduction To Fluid MachineryJohn MameNo ratings yet

- Module 1 - 1Document93 pagesModule 1 - 1nojiv54944No ratings yet

- 3.3 Pneumatic CircuitsDocument50 pages3.3 Pneumatic CircuitsJash ShethNo ratings yet

- 1.topic 1 - Ind ControlDocument52 pages1.topic 1 - Ind ControlLoga HSNo ratings yet

- Presentation On Actuators: Prepared By: Shivi Varshney ME (I&C) Regular 2017Document26 pagesPresentation On Actuators: Prepared By: Shivi Varshney ME (I&C) Regular 2017Shivi VarshneyNo ratings yet

- Ch4 Drives, Actuators and ControlDocument80 pagesCh4 Drives, Actuators and ControlcactuswillsaNo ratings yet

- Systems 5 Hydraulic Systems S35 PDFDocument97 pagesSystems 5 Hydraulic Systems S35 PDFCemalettin öztoprakNo ratings yet

- Fluid Power ControlDocument12 pagesFluid Power Controlwhatsapp video statusNo ratings yet

- Mining Machinery: Department of Mechanical Engineering Aditya Engineering CollegeDocument35 pagesMining Machinery: Department of Mechanical Engineering Aditya Engineering CollegeRAJESH SAHNo ratings yet

- Parts 31200069 01-24-13 ANSI EnglishDocument456 pagesParts 31200069 01-24-13 ANSI EnglishСвятослав ВороновNo ratings yet

- Hurricane Construction ManualDocument111 pagesHurricane Construction ManualJorge José Figueiredo SiqueiraNo ratings yet

- Chap 007Document36 pagesChap 007Lee FeiNo ratings yet

- Think TankDocument5 pagesThink Tankdhruv khandelwalNo ratings yet

- Ho 107Document214 pagesHo 107Lavern SipinNo ratings yet

- ARDF DF3090 (D779-17) Parts CatalogDocument26 pagesARDF DF3090 (D779-17) Parts CatalogmaxmaracatuNo ratings yet

- (Karen Beler Case Study II) - Travel Demand ForecastingDocument5 pages(Karen Beler Case Study II) - Travel Demand ForecastingKaren BeeNo ratings yet

- M30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyDocument3 pagesM30B35M 6 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyЕвгений ДынникNo ratings yet

- Chapter5 - Drive CouplingsDocument90 pagesChapter5 - Drive Couplingsvijay219100% (1)

- Vacuum Braking System 222Document17 pagesVacuum Braking System 222Lalit Mohan67% (3)

- Classic 500 InvoiceDocument3 pagesClassic 500 InvoiceAman SharmaNo ratings yet

- APM Compressor Maintenance, Operation ManualDocument55 pagesAPM Compressor Maintenance, Operation ManualIngeniería AplicacionesNo ratings yet

- Universal, Independent Dual System Hydraulic Test Stand: 920 SeriesDocument8 pagesUniversal, Independent Dual System Hydraulic Test Stand: 920 SeriesSajad KarimiNo ratings yet

- Cycle Time Calculation GuideDocument2 pagesCycle Time Calculation GuideMohammad Choldun Mubarrak Syaefudin [BSI]No ratings yet

- 3dx SuperDocument16 pages3dx SuperBAHAA MANSOURNo ratings yet

- Syner-Z 5W-30: Fully SyntheticDocument1 pageSyner-Z 5W-30: Fully SyntheticValeriy ValkovetsNo ratings yet

- 01 Clutch Construction and OperationDocument32 pages01 Clutch Construction and Operationdawit abebualNo ratings yet

- Shankar's Resume-3Document6 pagesShankar's Resume-3Green FarmersNo ratings yet

- Arriel 2DDocument2 pagesArriel 2DMUKESH CHAKRAWARTINo ratings yet

- Fuller 13 Speeds Gearbox Lista ComponentiDocument48 pagesFuller 13 Speeds Gearbox Lista ComponentiGIAN PAOLONo ratings yet

- EternaDocument6 pagesEternaSupermobile 786No ratings yet

- SERIES 200 & 220: Pumping PrincipleDocument12 pagesSERIES 200 & 220: Pumping PrincipleRSS RSSNo ratings yet

- Ashok LeylandDocument4 pagesAshok LeylandBelwin JoelNo ratings yet

- MRF (Company) : Madras Rubber Factory Commonly Known As MRF orDocument6 pagesMRF (Company) : Madras Rubber Factory Commonly Known As MRF orAjudiya MeetNo ratings yet

- Chairless Chair For Improved Ergonomics in Audi's Production PlantsDocument3 pagesChairless Chair For Improved Ergonomics in Audi's Production PlantsDeepak ChaurasiaNo ratings yet

- Navitas AC TAC2 Error Code and TroubleshootingDocument8 pagesNavitas AC TAC2 Error Code and Troubleshootingelectronics malayalamNo ratings yet

- Note TakingDocument2 pagesNote TakingLyy Avakin シNo ratings yet

- IEN560D00Document210 pagesIEN560D00Tiago SilvaNo ratings yet

- Salto-Datasheet-Xs4 Original Ax6xx EngDocument3 pagesSalto-Datasheet-Xs4 Original Ax6xx Eng3176985456No ratings yet

- Operation: Residential/Commercial Generator SetsDocument76 pagesOperation: Residential/Commercial Generator SetsАлексей Семикин100% (1)