Professional Documents

Culture Documents

Mash Balance Diagram

Mash Balance Diagram

Uploaded by

nailulfalah17Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mash Balance Diagram

Mash Balance Diagram

Uploaded by

nailulfalah17Copyright:

Available Formats

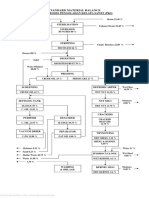

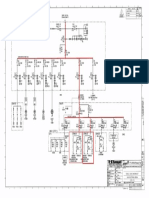

PROCESS FLOW DIAGRAM & MASS BALANCE CAPACITY CALCULATION

INTAKE OF WET PADDY 120 TPD

CHECK QUALITY OF PADDY ( RAW MATERIAL )

WEIGHT, % MOISTURE CONTENT, % IMPURITY & YIELD (LAB)

0 TPD OF IMPURITY CLEANING SECTION ASH~ 0.125 TPH

(ASSUMED 0%) CAP.120 TPD @30%mc (~25% OF HUSK) HUSK YARD

120TPD 0.82 TPH

(100% OF WET PADDY INPUT)

7,2 TPD (6%) OF IMMATURE GRAIN PADDY DRYING SECTION HUSK 0.5 TPH

CAP. 120 TPD @30%mc FURNACE HUSK BIN

19,2 TPD (16%) OF WATER REMOVAL

93,6 TPD @14% mc 1.32 TPH

(78% OF WET PADDY INPUT)

FILL UP SILO BY 64 DAYS SILO SILO SILO

WITH RICE MILL NOT RUNNING 2000 MT 2000 MT 2000 MT

FULL SILO RUN DRY BY 42 DAYS

WITH RICEMILL FULL RUNNING

EXTERNAL INTAKE

OF DRY PADDY

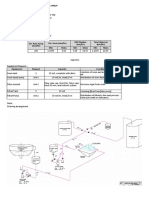

~0.12 TPH OF FINE IMPURITY HUSKING SECTION ~1.32 TPH OF HUSK

CAP. 6 TPH (DRY PADDY)

DUST (~ 2% OFF PADDY INPUT) (~22% OF PADDY INPUT)

4:56

(~76% OF DRY PADDY INPUT)

EXTERNAL INTAKE RICE MILLING SECTION 0.48 TPH OF BRAN

WHITE RICE/BROWN RICE 4.56 TPH (BROWN RICE ) BRAN ROOM

(Optional) (6-8% OF PADDY INPUT)

4.08 TPH White Rice

(68% OF DRY PADDY INPUT)

GRADING SECTION

CAP. 4.08 TPH (WHITE RICE)

HEAD RICE Medium Broken Small Broken Fine Broken

47% of 5% of 10% of 3% of

Paddy Input Paddy Input Paddy Input Paddy Input

2.82 TPH 0.3 TPH 0.6 TPH 0.18 TPH

Packing Directly,

PROPORTIONATE BLENDING SECTION Sellto Rice Noodle

& Rice Powder

Factory

COLOR SORTING SECTION PACKING SECTION 1-5 Vaccum Pack,5-10

3.0 TPH (WHITE RICE-50%) CAP. 3.9 TPH Plastic Sealing Pack, 10-50

(65%) KG Seawing Pack

DISC0LOUR RICE FINISHED

0.18 TPH TPH PRODUCT

(3% of Dry Paddy Input) WAREHOUSE

Note : BASE ON LONG GRAIN PADDY OF 30%mc, WATER REMOVAL 16%, INMATURE GRAIN 6%, RECOVERY YIELD MILLING 65%.

Yield % Distribution very much depends on the Quality of Raw Material or Dry/Wet Paddy.

You might also like

- Manual Book UPSDocument249 pagesManual Book UPSnailulfalah1767% (3)

- Hill Rom TotalCare Bed System Service Manual PDFDocument997 pagesHill Rom TotalCare Bed System Service Manual PDFjuan manuel50% (2)

- EYA60 R600A CompressorDocument6 pagesEYA60 R600A Compressorgusius100% (1)

- Coal Milling Combi GrindingDocument1 pageCoal Milling Combi GrindingNathaniel VillanuevaNo ratings yet

- Tech Bulletin 002: Inlet Pressure vs. Water TemperatureDocument2 pagesTech Bulletin 002: Inlet Pressure vs. Water Temperaturesf wNo ratings yet

- Fmip Summary Data On Agriculture Input Use: Name of Project: Bagmati Lift Irrigatin Project Location:Karmaiya, SarlahiDocument80 pagesFmip Summary Data On Agriculture Input Use: Name of Project: Bagmati Lift Irrigatin Project Location:Karmaiya, Sarlahirashmi bhailaNo ratings yet

- Basic Flow Diagrame: IntakeDocument4 pagesBasic Flow Diagrame: IntakeSondarva HardikNo ratings yet

- Balance de Masa para El Procesamiento de 100 T RFF PDFDocument1 pageBalance de Masa para El Procesamiento de 100 T RFF PDFkennyher caballero blancoNo ratings yet

- Balance de Masa para El Procesamiento de 100 T RFFDocument1 pageBalance de Masa para El Procesamiento de 100 T RFFkennyher caballero blancoNo ratings yet

- School of Agriculture and Natural ResourcesDocument27 pagesSchool of Agriculture and Natural Resourcespeter hillsNo ratings yet

- Automatic Powder Transfer System: 15 Januari 2016Document13 pagesAutomatic Powder Transfer System: 15 Januari 2016Haris PrawotoNo ratings yet

- JMF Ac-Wc, Hatu Teknik, Jalak HarupatDocument31 pagesJMF Ac-Wc, Hatu Teknik, Jalak HarupatFauzan AzizaNo ratings yet

- Sugar Glider Rat/ Mouse Rabbit Hedgehog Hamster Guinea Pig Gerbil Ferret Chinchilla DrugDocument4 pagesSugar Glider Rat/ Mouse Rabbit Hedgehog Hamster Guinea Pig Gerbil Ferret Chinchilla DrugN.RNo ratings yet

- Pu Ta02 - En-1Document5 pagesPu Ta02 - En-1HuNtER ripNo ratings yet

- PaintsDocument8 pagesPaintsazizNo ratings yet

- Paraloid Au-608 TBZDocument6 pagesParaloid Au-608 TBZCHIRE SARAYASI MANUELNo ratings yet

- PWV4 BS 001Document348 pagesPWV4 BS 001July HuaquistoNo ratings yet

- Dowex Marathon MSA 2 LDocument11 pagesDowex Marathon MSA 2 LBrianNo ratings yet

- Standard Material Balance: Untuk Proses Pengolahan Kelapa Sawit (PKS)Document1 pageStandard Material Balance: Untuk Proses Pengolahan Kelapa Sawit (PKS)wilda hafifaNo ratings yet

- Prakruti e Brouchure Hydraulic Briquetting MachineDocument5 pagesPrakruti e Brouchure Hydraulic Briquetting MachineAvinash AnburajanNo ratings yet

- Finepac Structures PVT - LTD: GAS Liquid (15000BPD) (Oil/Water)Document2 pagesFinepac Structures PVT - LTD: GAS Liquid (15000BPD) (Oil/Water)Dhanraj VasanthNo ratings yet

- 114 - Cleaner - DELTA - GB - PRELIMPIADORA 4TnDocument1 page114 - Cleaner - DELTA - GB - PRELIMPIADORA 4TnJimmy SanchezNo ratings yet

- ArfDocument3 pagesArflina komalasariNo ratings yet

- Face Mask, Gloves, PPE Kit Offer Price PDFDocument2 pagesFace Mask, Gloves, PPE Kit Offer Price PDFDipak GohilNo ratings yet

- HospynebDocument2 pagesHospynebee113051No ratings yet

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument16 pagesKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarNo ratings yet

- HWYH-1178 Mud Report - 7530073 - 01Document5 pagesHWYH-1178 Mud Report - 7530073 - 01KHALEDFEKAIRNo ratings yet

- Scum Filter SystemDocument2 pagesScum Filter SystemMade WidreNo ratings yet

- JMF Ac BCDocument35 pagesJMF Ac BCFauzan AzizaNo ratings yet

- TDS S-5060 (Ipa) - Long Soya Alkyd ResinDocument2 pagesTDS S-5060 (Ipa) - Long Soya Alkyd ResinAzhar Abdul RazakNo ratings yet

- En 14ho15154Document1 pageEn 14ho15154darghadevasi44No ratings yet

- Wet Tissue QuotationDocument1 pageWet Tissue QuotationPhượng ViêmNo ratings yet

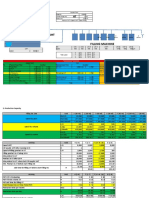

- Line Balancing Realgood: Planned Down Time TableDocument4 pagesLine Balancing Realgood: Planned Down Time TableArr ZevrillNo ratings yet

- Required Data and Information Sheet in Excel FileDocument3 pagesRequired Data and Information Sheet in Excel Filepyushgupta87No ratings yet

- Wa0021Document19 pagesWa0021Anonymous vrPpNvjRNo ratings yet

- 【英文】SDCコート#402TエコGDocument2 pages【英文】SDCコート#402TエコGDocholosoNo ratings yet

- Dow DowexhcrsofteningDocument4 pagesDow DowexhcrsofteningdapurayuenNo ratings yet

- Yellow Corn for Annimal Feed SpecificationDocument1 pageYellow Corn for Annimal Feed Specificationjulieburtoft55No ratings yet

- Philips Ev300 BrochureDocument2 pagesPhilips Ev300 BrochureErick PGNo ratings yet

- Base Oil SN-150 (IRANOL Refinery)Document1 pageBase Oil SN-150 (IRANOL Refinery)Mukesh LoharNo ratings yet

- Data For EorDocument2 pagesData For EorDivvya IndranNo ratings yet

- Reaknitt ZF - TDSDocument5 pagesReaknitt ZF - TDSasebaei95No ratings yet

- Day Lab ReportDocument3 pagesDay Lab Reportzaka1188No ratings yet

- 6 PointDocument3 pages6 PointGopal KrishnanNo ratings yet

- Product Costing of Palitaw With Cheese Filling - 1Document6 pagesProduct Costing of Palitaw With Cheese Filling - 1Ruth Vironic AbrogalNo ratings yet

- AX 900 Specification V3.0 2021.3.31Document7 pagesAX 900 Specification V3.0 2021.3.31LizzyNo ratings yet

- Pre Cleaner 144 2 Datasheet ENDocument1 pagePre Cleaner 144 2 Datasheet ENErdincNo ratings yet

- Housekeping ItemsDocument3 pagesHousekeping ItemsMOHIT SATOKIYANo ratings yet

- GR 2-0 UP: Ultra Pure GradeDocument2 pagesGR 2-0 UP: Ultra Pure GradeHidayat FirdausNo ratings yet

- Crystal H130A SeriesDocument5 pagesCrystal H130A Seriesaruna shantha kumaraNo ratings yet

- Ficha Técnica Wato 65newDocument4 pagesFicha Técnica Wato 65newSthefania GarzonNo ratings yet

- Quotation For SKS Oil Filling Line Capacity 18000BPH - 20230213Document26 pagesQuotation For SKS Oil Filling Line Capacity 18000BPH - 20230213kalam23No ratings yet

- Hydranautics Espa4 LD 4040Document1 pageHydranautics Espa4 LD 4040OuassouNo ratings yet

- Hydranautics Espa4 LD 4040Document1 pageHydranautics Espa4 LD 4040OuassouNo ratings yet

- Diversified Well LoggingDocument11 pagesDiversified Well LoggingRobertNo ratings yet

- Competitor Comparison Table - v2Document2 pagesCompetitor Comparison Table - v2Cherry EstradaNo ratings yet

- b737mrg HydraulicsDocument2 pagesb737mrg HydraulicsbnmmauricioNo ratings yet

- Kitchen Ansul UL 300 & NFPA 17A PYROCHEM TANDEM TANK SYSTEMDocument7 pagesKitchen Ansul UL 300 & NFPA 17A PYROCHEM TANDEM TANK SYSTEMJhoNo ratings yet

- Onm Zambales August 2020Document14 pagesOnm Zambales August 2020VWSSI Technical TeamNo ratings yet

- Chufang Agri Spray Drone Catalogue & - PriceDocument1 pageChufang Agri Spray Drone Catalogue & - PriceHad AnzhrNo ratings yet

- Vacuum Pump Selection For RMGDocument15 pagesVacuum Pump Selection For RMGvaibhavd123No ratings yet

- 1-6 Tmc-Tek-322 R6 AbDocument44 pages1-6 Tmc-Tek-322 R6 Abnailulfalah17No ratings yet

- Contoh Hazards1Document6 pagesContoh Hazards1nailulfalah17No ratings yet

- 1-8 Tmc-Tek-107 R3 As BuiltDocument2 pages1-8 Tmc-Tek-107 R3 As Builtnailulfalah17No ratings yet

- 1-6 Tmc-Tek-321 R6 AbDocument40 pages1-6 Tmc-Tek-321 R6 Abnailulfalah17No ratings yet

- Ladle Tilting MachineDocument17 pagesLadle Tilting Machinenailulfalah17No ratings yet

- 1-6 Tmc-Tek-323 R6 AbDocument36 pages1-6 Tmc-Tek-323 R6 Abnailulfalah17No ratings yet

- 1-6 Tmc-Tek-325 R5 AbDocument40 pages1-6 Tmc-Tek-325 R5 Abnailulfalah17No ratings yet

- Record Energize LSS-13Document8 pagesRecord Energize LSS-13nailulfalah17No ratings yet

- East Halmahera Ferronickel Development Project (P3Fh Project)Document2 pagesEast Halmahera Ferronickel Development Project (P3Fh Project)nailulfalah17No ratings yet

- Mark Up SLD 6.6 KV SWGDocument1 pageMark Up SLD 6.6 KV SWGnailulfalah17No ratings yet

- East Halmahera Ferronickel Development Project (P3Fh Project)Document2 pagesEast Halmahera Ferronickel Development Project (P3Fh Project)nailulfalah17No ratings yet

- East Halmahera Ferronickel Development Project (P3Fh Project)Document8 pagesEast Halmahera Ferronickel Development Project (P3Fh Project)nailulfalah17No ratings yet

- CTR Instrument Pipeline CY3Document28 pagesCTR Instrument Pipeline CY3nailulfalah17100% (2)

- Matindok Gas Development Project (MGDP) Check List System Diesel FuelDocument1 pageMatindok Gas Development Project (MGDP) Check List System Diesel Fuelnailulfalah17No ratings yet

- Form Motor Solo Run-Test SheetDocument12 pagesForm Motor Solo Run-Test Sheetnailulfalah17No ratings yet

- Technical Data Sheet - SDCDocument4 pagesTechnical Data Sheet - SDCnailulfalah17No ratings yet

- Matindok Gas Development Project (MGDP) Check List Potable Water TreatmentDocument1 pageMatindok Gas Development Project (MGDP) Check List Potable Water Treatmentnailulfalah17No ratings yet

- Table of Electrical DocumentDocument10 pagesTable of Electrical Documentnailulfalah17No ratings yet

- Project Master Schedule MatindokDocument102 pagesProject Master Schedule Matindoknailulfalah17No ratings yet

- Matindok Gas Development Project (MGDP) Check List System Dehydration UnitDocument7 pagesMatindok Gas Development Project (MGDP) Check List System Dehydration Unitnailulfalah17No ratings yet

- 374 Demin Water TreatmentDocument8 pages374 Demin Water Treatmentnailulfalah17No ratings yet

- Public - Information - Brochure - Feb2012 Dfccil Land Acquisition Process PDFDocument12 pagesPublic - Information - Brochure - Feb2012 Dfccil Land Acquisition Process PDFmanish goyalNo ratings yet

- DMG 6601 LVTDocument9 pagesDMG 6601 LVTChristian CristãoNo ratings yet

- Master Production ScheduleDocument18 pagesMaster Production Schedulerafazel hardyNo ratings yet

- FET 9 Production Planning 2Document21 pagesFET 9 Production Planning 2Aragaw MuluNo ratings yet

- Shared Bus ProposalDocument6 pagesShared Bus ProposalErnest EsoNo ratings yet

- Spesifikasi Teknis FinalDocument150 pagesSpesifikasi Teknis FinaliqbalmfNo ratings yet

- Book - Automotive Technology RoadmapDocument458 pagesBook - Automotive Technology RoadmapSunil Deshpande100% (1)

- How To Search & Impliment For BAdIsDocument40 pagesHow To Search & Impliment For BAdIsRupakbhattacNo ratings yet

- Business Requirement DocumentDocument8 pagesBusiness Requirement DocumentHUNTERNo ratings yet

- PGP PGM 500 600 Uk 845Document36 pagesPGP PGM 500 600 Uk 845Jorge Andres PozoNo ratings yet

- RDT Colombia - OffshoreDocument9 pagesRDT Colombia - OffshoreEder Leandro Vargas PontónNo ratings yet

- Ideapad Lenovo b460 ManualDocument88 pagesIdeapad Lenovo b460 ManualAdit LalNo ratings yet

- Process Plant and Equipment Integrity Management-Module 1Document93 pagesProcess Plant and Equipment Integrity Management-Module 1Naren SukaihNo ratings yet

- Broggi Flatware and HollowwareDocument342 pagesBroggi Flatware and HollowwareTabletopJournalNo ratings yet

- SAME: Feb 2010Document48 pagesSAME: Feb 2010promechmagsNo ratings yet

- Rev I Stage ArdsDocument92 pagesRev I Stage ArdsSebastián D. GómezNo ratings yet

- Advanced Information Systems Engineering WorkshopsDocument282 pagesAdvanced Information Systems Engineering Workshopslionking100% (1)

- FlangesDocument5 pagesFlangesNisarg PandyaNo ratings yet

- C 106 Components HandbookDocument50 pagesC 106 Components HandbookMauricio MpintoNo ratings yet

- KP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Document3 pagesKP-00+++-CQ712-G0006 - Rev.1 - ITP For Electrical Works (UnderGround Earthing Works)Utku Can KılıçNo ratings yet

- Expired On 28/02/2018: GEEKEN Product Price List July 2017 (As Per GST)Document61 pagesExpired On 28/02/2018: GEEKEN Product Price List July 2017 (As Per GST)abcdNo ratings yet

- NGN TTCL CaseDocument16 pagesNGN TTCL CaseNicholausJrNo ratings yet

- Fastener Weight ChartDocument9 pagesFastener Weight ChartTricolor C ANo ratings yet

- Audit Plan Plasmaco LTDDocument2 pagesAudit Plan Plasmaco LTDndayiragije JMVNo ratings yet

- Managerial Accounting Assignment 1Document11 pagesManagerial Accounting Assignment 1AhnifsajidNo ratings yet

- 494-13-09 Composite Fiberglass Reinforced Polymer Utility Poles PDFDocument4 pages494-13-09 Composite Fiberglass Reinforced Polymer Utility Poles PDFAhmed TahaNo ratings yet

- Precast Concrete For Building SystemsDocument9 pagesPrecast Concrete For Building SystemsmukundmgkNo ratings yet

- Pangibitan, Geojanni R. - Activity 3 - A5Document4 pagesPangibitan, Geojanni R. - Activity 3 - A5Geojanni PangibitanNo ratings yet

- Papa PublicDocument22 pagesPapa PublicKenneth LeeNo ratings yet