Professional Documents

Culture Documents

Moc217m D

Moc217m D

Uploaded by

krassi62Copyright:

Available Formats

You might also like

- DFL 500MKII Operation ManualDocument55 pagesDFL 500MKII Operation Manualcarlos martinezNo ratings yet

- SSP 298 Touareg ElectricsDocument29 pagesSSP 298 Touareg Electricsภูเก็ต เป็นเกาะ100% (1)

- ON - Semiconductor MOCD217M DatasheetDocument9 pagesON - Semiconductor MOCD217M DatasheetzakreaNo ratings yet

- Moc3043m DDocument12 pagesMoc3043m Diet mitNo ratings yet

- Moc3023m DDocument12 pagesMoc3023m Dchetan.foxtradeNo ratings yet

- f700 OptoDocument12 pagesf700 OptoTeyfik koyuncuNo ratings yet

- VOW135, VOW136: Vishay SemiconductorsDocument10 pagesVOW135, VOW136: Vishay Semiconductorspeter manthraNo ratings yet

- Vos 628 ADocument9 pagesVos 628 AСветлозар АнгеловNo ratings yet

- Moc3023m DDocument12 pagesMoc3023m Diet mitNo ratings yet

- Is Now Part ofDocument16 pagesIs Now Part ofJose BenitezNo ratings yet

- Vishay k3020pDocument8 pagesVishay k3020progerNo ratings yet

- Moc3072m D-2316360Document15 pagesMoc3072m D-2316360pauloNo ratings yet

- Moc3072m DDocument13 pagesMoc3072m DhiperdyniaNo ratings yet

- IL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsDocument9 pagesIL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsAhmed EmiraNo ratings yet

- SFH 6156Document8 pagesSFH 6156elcomandanteNo ratings yet

- 4N25/ 4N26/ 4N27/ 4N28: Optocoupler, Phototransistor Output, With Base ConnectionDocument9 pages4N25/ 4N26/ 4N27/ 4N28: Optocoupler, Phototransistor Output, With Base ConnectionbiswarupchakrabortyNo ratings yet

- K3020P, K3020PG Series Optocoupler, Phototriac Output, Non-Zero Crossing, 400 VDocument8 pagesK3020P, K3020PG Series Optocoupler, Phototriac Output, Non-Zero Crossing, 400 VCharbel TadrosNo ratings yet

- K3020P, K3020PG Series: Vishay SemiconductorsDocument7 pagesK3020P, K3020PG Series: Vishay SemiconductorsPiman MiriNo ratings yet

- 4N25 OptoacopladorDocument9 pages4N25 OptoacopladorLupiiTa QiiRoz CarliinNo ratings yet

- Sic 9653Document7 pagesSic 9653miria27No ratings yet

- MKP1847C AC Filtering: Vishay RoedersteinDocument17 pagesMKP1847C AC Filtering: Vishay RoedersteinJuan GarciaNo ratings yet

- Optocoupler, Phototransistor Output, With Base Connection: Vishay SemiconductorsDocument10 pagesOptocoupler, Phototransistor Output, With Base Connection: Vishay SemiconductorsJuan BejaranoNo ratings yet

- MCT 272Document9 pagesMCT 272jorgelaloca0% (1)

- 320573VSHDocument8 pages320573VSHJavier Mendoza CastroNo ratings yet

- Isow 7840Document56 pagesIsow 7840gwegawNo ratings yet

- Outdoor MCVCB PanelDocument2 pagesOutdoor MCVCB PanelNarayana SwamyNo ratings yet

- 4N25 DatasheetDocument9 pages4N25 DatasheetStavros KalapothasNo ratings yet

- Smf5v0a M Smf51a M - Vishay PDFDocument8 pagesSmf5v0a M Smf51a M - Vishay PDFJose Enrique Aguirre GuerreroNo ratings yet

- ILD217T Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageDocument4 pagesILD217T Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageSachin ThomasNo ratings yet

- Optocoupler, Photodarlington Output, High Gain, With Base ConnectionDocument8 pagesOptocoupler, Photodarlington Output, High Gain, With Base ConnectionCris_BodanezeNo ratings yet

- Moc3021m 196220Document14 pagesMoc3021m 196220Zohaib KhanNo ratings yet

- BZX84-V-G-Series: Vishay SemiconductorsDocument8 pagesBZX84-V-G-Series: Vishay SemiconductorsDuc VoquangNo ratings yet

- Datasheet en 20170526Document10 pagesDatasheet en 20170526LODELBARRIO RDNo ratings yet

- S Series Gap-Kap: Vishay BccomponentsDocument4 pagesS Series Gap-Kap: Vishay BccomponentsShibu Kumar SNo ratings yet

- SFH 628 ADocument8 pagesSFH 628 AEraldo HofelmannNo ratings yet

- Vol 628 ADocument9 pagesVol 628 ASuttisak SuriyachanhomNo ratings yet

- SFH 6315Document10 pagesSFH 6315Mohamed Ezzat MareeNo ratings yet

- VO3120 2.5 A Output Current IGBT and MOSFET Driver: Vishay SemiconductorsDocument10 pagesVO3120 2.5 A Output Current IGBT and MOSFET Driver: Vishay Semiconductorsfadapow4uNo ratings yet

- H11L3M D PDFDocument9 pagesH11L3M D PDFearthenwareNo ratings yet

- A82-00-0109 Datasheets USDocument3 pagesA82-00-0109 Datasheets UScarrei JohnNo ratings yet

- Vo 1263 AaDocument8 pagesVo 1263 Aa801400No ratings yet

- PV30K3225 StackpoleElectronicsDocument2 pagesPV30K3225 StackpoleElectronicsErnesto CamachoNo ratings yet

- MOC8101, MOC8102, MOC8103, MOC8104, MOC8105: Vishay SemiconductorsDocument8 pagesMOC8101, MOC8102, MOC8103, MOC8104, MOC8105: Vishay SemiconductorssawarNo ratings yet

- 2Document10 pages2Marcelo OemNo ratings yet

- Apex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VDocument3 pagesApex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VJulio Cesar Huachaca RodriguezNo ratings yet

- ISO1H812GDocument23 pagesISO1H812Gmar_barudjNo ratings yet

- Vsmis30352 1-2572788Document6 pagesVsmis30352 1-2572788bashar mohammedNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument5 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsAsadNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument3 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsИван ЧипNo ratings yet

- Optically Coupled Bilateral Switch Non-Zero Crossing TriacDocument3 pagesOptically Coupled Bilateral Switch Non-Zero Crossing TriacElectronicos CaldasNo ratings yet

- Fodm214 D OnsemiDocument10 pagesFodm214 D OnsemiWalter Martin Paz HolguinNo ratings yet

- Byv 26 DGPDocument5 pagesByv 26 DGPmuhammedasifNo ratings yet

- Diodo Entrada Digital SML4756, Marking Code 47Document6 pagesDiodo Entrada Digital SML4756, Marking Code 47samuelborgesNo ratings yet

- HYUNDAI HG 440W PERC Shingled Marco Negro HiE-S440HGDocument2 pagesHYUNDAI HG 440W PERC Shingled Marco Negro HiE-S440HGJohn WNSNo ratings yet

- ILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsDocument8 pagesILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsRohit SainiNo ratings yet

- CQY80N, CQY80NG: Vishay SemiconductorsDocument8 pagesCQY80N, CQY80NG: Vishay SemiconductorsHELLOGREGNo ratings yet

- Si8920 DatasheetDocument24 pagesSi8920 DatasheetJake MotorNo ratings yet

- Sony HCD bx5 dx5 dx5j ETDocument66 pagesSony HCD bx5 dx5 dx5j ETJorge PalacioNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- MTL Grounding Tp1121-1Document16 pagesMTL Grounding Tp1121-1mongo55No ratings yet

- 680-198-01 MXP-539 16-Way Input 48-Way Output CardDocument10 pages680-198-01 MXP-539 16-Way Input 48-Way Output CardAdriano CostaNo ratings yet

- Software Defined Radio Using Digital Modulation Techniques - A Matlab Simulink ApproachDocument6 pagesSoftware Defined Radio Using Digital Modulation Techniques - A Matlab Simulink ApproachChakri KamaniNo ratings yet

- Fix For Lack of Response From Touch Panels or TGC-LGC ControlsDocument4 pagesFix For Lack of Response From Touch Panels or TGC-LGC ControlsCarolina CuevasNo ratings yet

- Modelling and Control of CCM Boost PFC Using K-Factor MethodDocument1 pageModelling and Control of CCM Boost PFC Using K-Factor Methoddivya k sNo ratings yet

- F3 PWM Controller: Ice3Bs03LjgDocument25 pagesF3 PWM Controller: Ice3Bs03LjgАндрей КирюхинNo ratings yet

- Z Source Inverter Topologies-A SurveyDocument12 pagesZ Source Inverter Topologies-A SurveyViswanathanBalajiNo ratings yet

- CP 13Document43 pagesCP 13M Alwan Nur AjieNo ratings yet

- Catalogue-FRANKE GMKP LV Power CapacitorDocument9 pagesCatalogue-FRANKE GMKP LV Power CapacitorSuefrizal SuefNo ratings yet

- Ruby Hall BAS Point Schedule v1Document3 pagesRuby Hall BAS Point Schedule v1Wintun73No ratings yet

- Design of A Power Converter Based On UC3842 For Blade Electric VehicleDocument6 pagesDesign of A Power Converter Based On UC3842 For Blade Electric VehicleHossam SobhyNo ratings yet

- AGC300 AGC300 Rev0Document11 pagesAGC300 AGC300 Rev0raj_ritu_aNo ratings yet

- Short Circuit Manual CalculationDocument3 pagesShort Circuit Manual CalculationSridharan PriyadharsenNo ratings yet

- EVH 5150 III REAL 3 Channel and Stealth Mod PDFDocument13 pagesEVH 5150 III REAL 3 Channel and Stealth Mod PDFFelix AlmesbergerNo ratings yet

- Book Review - Blake PDFDocument64 pagesBook Review - Blake PDFOdellien SajaNo ratings yet

- Building A Smart Master - Slave SwitchDocument4 pagesBuilding A Smart Master - Slave SwitchdewasuryantoNo ratings yet

- Power Over Ethernet Injector: 12V: DescriptionDocument1 pagePower Over Ethernet Injector: 12V: DescriptionAakash MalviyaNo ratings yet

- 4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationDocument44 pages4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationThomas ThomasNo ratings yet

- SkyAir R410 Inv Cooling EDMT281537 PDFDocument524 pagesSkyAir R410 Inv Cooling EDMT281537 PDFAnh Thu Mai100% (2)

- Operator and Maintenance Manual DC Power Supply SERIES 3300Document35 pagesOperator and Maintenance Manual DC Power Supply SERIES 3300Tareq AzizNo ratings yet

- Chapter 3 - ElectrochemistryDocument8 pagesChapter 3 - ElectrochemistryMADHAVNo ratings yet

- Ent Microdebrider 24v b0512n4080 SpecificationsDocument1 pageEnt Microdebrider 24v b0512n4080 SpecificationsIman AzrbjNo ratings yet

- Manual Vision FMDocument10 pagesManual Vision FMIchsan DachiNo ratings yet

- VFDDocument151 pagesVFDMUHAMMAD UZAIR100% (1)

- GuitarNuts 00Document13 pagesGuitarNuts 00Geroldo 'Rollie' L. QuerijeroNo ratings yet

- W1000562 PDFDocument64 pagesW1000562 PDFJuan Carlos Alvarez MoralesNo ratings yet

- Nte 331Document2 pagesNte 331Cesar Augusto Arriaga ArriagaNo ratings yet

- Microchip Patch AntennaDocument9 pagesMicrochip Patch AntennaZayar HeinNo ratings yet

Moc217m D

Moc217m D

Uploaded by

krassi62Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moc217m D

Moc217m D

Uploaded by

krassi62Copyright:

Available Formats

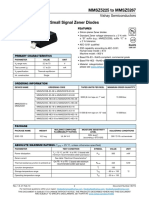

DATA SHEET

www.onsemi.com

8-pin SOIC Single-Channel

Phototransistor Output

Optocoupler SOIC8

CASE 751DZ

MOC205M, MOC206M,

MOC207M, MOC211M, MARKING DIAGRAM

MOC212M, MOC213M,

MOC216M, MOC217M ON XXX

VXYYS

Description

These devices consist of a gallium arsenide infrared emitting diode XXX = Specific Device Code

optically coupled to a monolithic silicon phototransistor detector, in a V = DIN EN/IEC60747−5−5 Option (only

appears on component ordered with this

surface mountable, small outline, plastic package. They are ideally option)

suited for high−density applications, and eliminate the need for X = Year Code

through−the−board mounting. YY = Work Week

S = Assembly Package Code

Features

• Closely Matched Current Transfer Ratios Minimum BVCEO of 70 V

Guaranteed SCHEMATIC

♦ MOC205M, MOC206M, MOC207M

• Minimum BVCEO of 30 V Guaranteed

♦ MOC211M, MOC212M, MOC213M, MOC216M, MOC217M ANODE 1 8 N/C

• Low LED Input Current Required for Easier Logic Interfacing

♦ MOC216M, MOC217M

• Convenient Plastic SOIC−8 Surface Mountable Package Style, with CATHODE 2 7 BASE

0.050” Lead Spacing

• Safety and Regulatory Approvals: N/C 3 6 COLLECTOR

♦ UL1577, 2,500 VACRMS for 1 Minute

♦ DIN−EN/IEC60747−5−5, 565 V Peak Working Insulation Voltage

• These are Pb−Free Devices N/C 4 5 EMITTER

Applications

• Feedback Control Circuits

• Interfacing and Coupling Systems of Different Potentials and

Impedances ORDERING INFORMATION

See detailed ordering and shipping information on page 6 of

• General Purpose Switching Circuits this data sheet.

• Monitor and Detection Circuits

© Semiconductor Components Industries, LLC, 2006 1 Publication Order Number:

December, 2023 − Rev. 3 MOC217M/D

Downloaded from Arrow.com.

MOC205M, MOC206M, MOC207M, MOC211M, MOC212M, MOC213M, MOC216M,

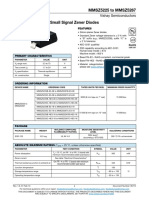

MOC217M

SAFETY AND INSULATION RATINGS (As per DIN EN/IEC 60747−5−5, this optocoupler is suitable for “safe electrical insulation”

only within the safety limit data. Compliance with the safety ratings shall be ensured by means of protective circuits.)

Parameter Characteristics

Installation Classifications per DIN VDE 0110/1.89 Table 1, For Rated Mains <150 VRMS I–IV

Voltage

<300 VRMS I–III

Climatic Classification 55/100/21

Pollution Degree (DIN VDE 0110/1.89) 2

Comparative Tracking Index 175

Symbol Parameter Value Unit

VPR Input−to−Output Test Voltage, Method A, VIORM x 1.6 = VPR, Type and Sample Test 904 Vpeak

with tm = 10 s, Partial Discharge < 5 pC

Input−to−Output Test Voltage, Method B, VIORM x 1.875 = VPR, 100% Production Test 1060 Vpeak

with tm = 1 s, Partial Discharge < 5 pC

VIORM Maximum Working Insulation Voltage 565 Vpeak

VIOTM Highest Allowable Over−Voltage 4000 Vpeak

External Creepage ≥4 mm

External Clearance ≥4 mm

DTI Distance Through Insulation (Insulation Thickness) ≥0.4 mm

TS Case Temperature (Note 1) 150 °C

IS,INPUT Input Current (Note 1) 200 mA

PS,OUTPUT Output Power (Note 1) 300 mW

RIO Insulation Resistance at TS, VIO = 500 V (Note 1) >109 W

1. Safety limit values – maximum values allowed in the event of a failure.

ABSOLUTE MAXIMUM RATINGS (TA = 25°C unless otherwise noted)

Symbol Rating Value Unit

TOTAL DEVICE

TSTG Storage Temperature −40 to +125 °C

TA Ambient Operating Temperature −40 to +100 °C

TJ Junction Temperature −40 to +125 °C

TSOL Lead Solder Temperature 260 for 10 seconds °C

PD Total Device Power Dissipation @ TA = 25°C 240 mW

Derate above 25°C 2.94 mW/°C

EMITTER

IF Continuous Forward Current 60 mA

IF (pk) Forward Current – Peak (PW = 100 ms, 120 pps) 1.0 A

VR Reverse Voltage 6.0 V

PD LED Power Dissipation @ TA = 25°C 90 mW

Derate above 25°C 0.8 mW/°C

DETECTOR

IC Continuous Collector Current 150 mA

VCEO Collector−Emitter Voltage 30 V

VECO Emitter−Collector Voltage 7 V

PD Detector Power Dissipation @ TA = 25°C 150 mW

Derate above 25°C 1.76 mW/°C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

www.onsemi.com

2

Downloaded from Arrow.com.

MOC205M, MOC206M, MOC207M, MOC211M, MOC212M, MOC213M, MOC216M,

MOC217M

ELECTRICAL CHARACTERISTICS (TA = 25°C unless otherwise noted)

Symbol Parameter Test Condition Min Typ Max Unit

EMITTER

Input Forward Voltage MOC216M, MOC217M IF = 1 mA − 1.07 1.3 V

VF

MOC205M, MOC206M, IF = 10 mA − 1.15 1.5 V

MOC207M MOC211M,

MOC212M, MOC213M

IR Reverse Leakage Current VR = 6 V − 0.001 100 mA

CIN Input Capacitance − 18 − pF

DETECTOR

ICEO1 Collector−Emitter Dark Current VCE = 10 V, TA = 25°C − 1.0 50 nA

ICEO2 VCE = 10 V, TA = 100°C − 1.0 − mA

BVCEO Collector−Emitter MOC205M, MOC206M, IC = 100 mA 70 100 − V

Breakdown Voltage MOC207M

MOC211M, MOC212M, IC = 100 mA 30 100 − V

MOC213M, MOC216M,

MOC217M

BVCBO Collector−Base Breakdown Voltage IC = 10 mA 70 120 − V

BVECO Emitter−Collector Breakdown Voltage IE = 100 mA 7 10 − V

CCE Collector−Emitter Capacitance f = 1.0 MHz, VCE = 0 V − 7 − pF

COUPLED

CTR Collector−Output Current MOC205M IF = 10 mA, VCE = 10 V 40 − 80 %

MOC206M IF = 10 mA, VCE = 10 V 63 − 125 %

MOC207M IF = 10 mA, VCE = 10 V 100 − 200 %

MOC211M IF = 10 mA, VCE = 10 V 20 − − %

MOC212M IF = 10 mA, VCE = 10 V 50 − − %

MOC213M IF = 10 mA, VCE = 10 V 100 − − %

MOC216M IF = 1 mA, VCE = 5 V 50 − − %

MOC217M IF = 1 mA, VCE = 5 V 100 − − %

VCE(SAT) Collector−Emitter MOC205M, MOC206M, IC = 2 mA, IF = 10 mA − − 0.4 V

Saturation Voltage MOC207M MOC211M,

MOC212M, MOC213M

MOC216M, MOC217M IC = 100 mA, IF = 1 mA − − 0.4 V

ton Turn−On Time IC = 2 mA, VCC = 10 V, − 7.5 − ms

RL = 100 W (Figure 12)

toff Turn−Off Time IC = 2 mA, VCC = 10 V, − 5.7 − ms

RL = 100 W (Figure 12)

tr Rise Time IC = 2 mA, VCC = 10 V, − 3.2 − ms

RL = 100 W (Figure 12)

tf Fall Time IC = 2 mA, VCC = 10 V, − 4.7 − ms

RL = 100 W (Figure 12)

ISOLATION CHARACTERISTICS

VISO Input−Output Isolation Voltage t = 1 Minute 2500 − − VACRMS

CISO Isolation Capacitance VI−O = 0 V, f = 1 MHz − 0.2 − pF

RISO Isolation Resistance VI−O = ±500 VDC, 1011 − − W

TA = 25°C

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

3

Downloaded from Arrow.com.

MOC205M, MOC206M, MOC207M, MOC211M, MOC212M, MOC213M, MOC216M,

MOC217M

TYPICAL PERFORMANCE CURVES

1.8 10

VCE = 5 V

IC, OUTPUT COLLECTOR CURRENT

NORMALIZED TO IF = 10 mA

1.7

VF, FORWARD VOLTAGE (V)

1.6

(NORMALIZED)

1

1.5

1.4

TA = −55°C

1.3

0.1

1.2 TA = 25°C

1.1 TA = 100°C

1.0 0.01

1 10 100 0 1 10 100

IF, LED FORWARD CURRENT (mA) IF, LED INPUT CURRENT (mA)

Figure 1. LED Forward Voltage vs. Forward Current Figure 2. Output Current vs. Input Current

10 IC, OUTPUT COLLECTOR CURRENT 1.6

IC, OUTPUT COLLECTOR CURRENT

1.4

1.2

(NORMALIZED)

(NORMALIZED)

1.0

1 0.8

0.6

0.4

0.2

IF = 10 mA

NORMALIZED TO TA = 25 °C NORMALIZED TO VCE = 5 V

0.1 0.0

−80 −60 −40 −20 0 20 40 60 80 100 120 0 1 2 3 4 5 8 7 8 9 10

TA, AMBIENT TEMPERATURE (°C) VCE, COLLECTOR−EMITTER VOLTAGE (V)

Figure 3. Output Current vs. Ambient Temperature Figure 4. Output Current vs. Collector−Emitter Voltage

10000 1.0

VCE = 10 V

0.9

IF = 20 mA

ICEO, COLLECTOR−EMITER

1000 0.8

DARK CURRENT (nA)

NORMALIZED CTR

0.7 IF = 10 mA

100 0.6

IF = 5 mA

0.5

10 0.4

0.3

1 0.2

VCE = 5 V, TA = 25°C

0.1 NORMALIZED TO:

CTR AT RBE = OPEN

0.1 0.0

0 20 40 60 80 100 10 100 1000

TA, AMBIENT TEMPERATURE (°C) RBE, BASE RESISTANCE (kW)

Figure 5. Dark Current vs. Ambient Temperature Figure 6. CTR vs. RBE (Unsaturated)

www.onsemi.com

4

Downloaded from Arrow.com.

MOC205M, MOC206M, MOC207M, MOC211M, MOC212M, MOC213M, MOC216M,

MOC217M

TYPICAL PERFORMANCE CURVES (continued)

1.0 4.0

VCC = 10 V

0.9 IC = 2 mA

3.5

RL = 100 W

0.8 IF = 20 mA NORMALIZED TO:

3.0 ton AT RBE = OPEN

NORMALIZED CTR

0.7 IF = 10 mA

NORMALIZED ton

2.5

0.6

IF = 5 mA

0.5 2.0

0.4

1.5

0.3

1.0

0.2

VCE = 0.3 V, TA = 25°C

NORMALIZED TO: 0.5

0.1

CTR AT RBE = OPEN

0.0 0.0

10 100 1000 0.01 0.1 1 10 100

RBE, BASE RESISTANCE (kW) RBE, BASE RESISTANCE (MW)

Figure 7. CTR vs. RBE (Saturated) Figure 8. Normalized ton vs. RBE

1.6

VCC = 10 V

1.4 IC = 2 mA

RL = 100 W

NORMALIZED TO:

1.2

toff AT RBE = OPEN

NORMALIZED toff

1.0

0.8

0.6

0.4

0.2

0.0

0.01 0.1 1 10 100

RBE, BASE RESISTANCE (MW)

Figure 9. Normalized toff vs. RBE

TEST CIRCUIT WAVEFORMS

V CC = 10 V

INPUT PULSE

IF IC RL

10%

INPUT OUTPUT OUTPUT PULSE

90%

R BE

tr tf

t on t off

Adjust IF to produce IC = 2 mA

Figure 10. Switching Time Test Circuit and Waveforms

www.onsemi.com

5

Downloaded from Arrow.com.

MOC205M, MOC206M, MOC207M, MOC211M, MOC212M, MOC213M, MOC216M,

MOC217M

REFLOW PROFILE

Max. Ramp−up Rate = 3°C/S

TP Max. Ramp−down Rate = 6°C/S

260

240 tP

TL

220

200 Tsmax

tL

180 Preheat Area

160

Tsmin

Temperature (°C)

140

ts

120

100

80

60

40

20

0

120 240 360

Time 25°C to Peak

Time (seconds)

Figure 11. Reflow Profile

Table 1.

Profile Freature Pb−Free Assembly Profile

Temperature Minimum (Tsmin) 150°C

Temperature Maximum (Tsmax) 200°C

Time (tS) from (Tsmin to Tsmax) 60 – 120 seconds

Ramp−up Rate (tL to tP) 3°C/second maximum

Liquidous Temperature (TL) 217°C

Time (tL) Maintained Above (TL) 60 – 150 seconds

Peak Body Package Temperature 260°C +0°C / –5°C

Time (tP) within 5°C of 260°C 30 seconds

Ramp−down Rate (TP to TL) 6°C/second maximum

Time 25°C to Peak Temperature 8 minutes maximum

ORDERING INFORMATION (Note 2)

Part Number Package Shipping†

MOC205M Small Outline 8−Pin 50 Units / Tube

MOC205R2M Small Outline 8−Pin 2500 / Tape & Reel

MOC205VM Small Outline 8−Pin, DIN EN/IEC60747−5−5 Option 50 Units / Tube

MOC205R2VM Small Outline 8−Pin, DIN EN/IEC60747−5−5 Option 2500 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

2. The product orderable part number system listed in this table also applies to the MOC20XM and MOC21XM products.

www.onsemi.com

6

Downloaded from Arrow.com.

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SOIC8

CASE 751DZ

ISSUE O

DATE 30 SEP 2016

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

DOCUMENT NUMBER: 98AON13733G Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

DESCRIPTION: SOIC8 PAGE 1 OF 1

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019 www.onsemi.com

Downloaded from Arrow.com.

onsemi, , and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

ADDITIONAL INFORMATION

TECHNICAL PUBLICATIONS: ONLINE SUPPORT: www.onsemi.com/support

Technical Library: www.onsemi.com/design/resources/technical−documentation For additional information, please contact your local Sales Representative at

onsemi Website: www.onsemi.com www.onsemi.com/support/sales

Downloaded from Arrow.com.

You might also like

- DFL 500MKII Operation ManualDocument55 pagesDFL 500MKII Operation Manualcarlos martinezNo ratings yet

- SSP 298 Touareg ElectricsDocument29 pagesSSP 298 Touareg Electricsภูเก็ต เป็นเกาะ100% (1)

- ON - Semiconductor MOCD217M DatasheetDocument9 pagesON - Semiconductor MOCD217M DatasheetzakreaNo ratings yet

- Moc3043m DDocument12 pagesMoc3043m Diet mitNo ratings yet

- Moc3023m DDocument12 pagesMoc3023m Dchetan.foxtradeNo ratings yet

- f700 OptoDocument12 pagesf700 OptoTeyfik koyuncuNo ratings yet

- VOW135, VOW136: Vishay SemiconductorsDocument10 pagesVOW135, VOW136: Vishay Semiconductorspeter manthraNo ratings yet

- Vos 628 ADocument9 pagesVos 628 AСветлозар АнгеловNo ratings yet

- Moc3023m DDocument12 pagesMoc3023m Diet mitNo ratings yet

- Is Now Part ofDocument16 pagesIs Now Part ofJose BenitezNo ratings yet

- Vishay k3020pDocument8 pagesVishay k3020progerNo ratings yet

- Moc3072m D-2316360Document15 pagesMoc3072m D-2316360pauloNo ratings yet

- Moc3072m DDocument13 pagesMoc3072m DhiperdyniaNo ratings yet

- IL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsDocument9 pagesIL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsAhmed EmiraNo ratings yet

- SFH 6156Document8 pagesSFH 6156elcomandanteNo ratings yet

- 4N25/ 4N26/ 4N27/ 4N28: Optocoupler, Phototransistor Output, With Base ConnectionDocument9 pages4N25/ 4N26/ 4N27/ 4N28: Optocoupler, Phototransistor Output, With Base ConnectionbiswarupchakrabortyNo ratings yet

- K3020P, K3020PG Series Optocoupler, Phototriac Output, Non-Zero Crossing, 400 VDocument8 pagesK3020P, K3020PG Series Optocoupler, Phototriac Output, Non-Zero Crossing, 400 VCharbel TadrosNo ratings yet

- K3020P, K3020PG Series: Vishay SemiconductorsDocument7 pagesK3020P, K3020PG Series: Vishay SemiconductorsPiman MiriNo ratings yet

- 4N25 OptoacopladorDocument9 pages4N25 OptoacopladorLupiiTa QiiRoz CarliinNo ratings yet

- Sic 9653Document7 pagesSic 9653miria27No ratings yet

- MKP1847C AC Filtering: Vishay RoedersteinDocument17 pagesMKP1847C AC Filtering: Vishay RoedersteinJuan GarciaNo ratings yet

- Optocoupler, Phototransistor Output, With Base Connection: Vishay SemiconductorsDocument10 pagesOptocoupler, Phototransistor Output, With Base Connection: Vishay SemiconductorsJuan BejaranoNo ratings yet

- MCT 272Document9 pagesMCT 272jorgelaloca0% (1)

- 320573VSHDocument8 pages320573VSHJavier Mendoza CastroNo ratings yet

- Isow 7840Document56 pagesIsow 7840gwegawNo ratings yet

- Outdoor MCVCB PanelDocument2 pagesOutdoor MCVCB PanelNarayana SwamyNo ratings yet

- 4N25 DatasheetDocument9 pages4N25 DatasheetStavros KalapothasNo ratings yet

- Smf5v0a M Smf51a M - Vishay PDFDocument8 pagesSmf5v0a M Smf51a M - Vishay PDFJose Enrique Aguirre GuerreroNo ratings yet

- ILD217T Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageDocument4 pagesILD217T Optocoupler, Phototransistor Output, Dual Channel, SOIC-8 PackageSachin ThomasNo ratings yet

- Optocoupler, Photodarlington Output, High Gain, With Base ConnectionDocument8 pagesOptocoupler, Photodarlington Output, High Gain, With Base ConnectionCris_BodanezeNo ratings yet

- Moc3021m 196220Document14 pagesMoc3021m 196220Zohaib KhanNo ratings yet

- BZX84-V-G-Series: Vishay SemiconductorsDocument8 pagesBZX84-V-G-Series: Vishay SemiconductorsDuc VoquangNo ratings yet

- Datasheet en 20170526Document10 pagesDatasheet en 20170526LODELBARRIO RDNo ratings yet

- S Series Gap-Kap: Vishay BccomponentsDocument4 pagesS Series Gap-Kap: Vishay BccomponentsShibu Kumar SNo ratings yet

- SFH 628 ADocument8 pagesSFH 628 AEraldo HofelmannNo ratings yet

- Vol 628 ADocument9 pagesVol 628 ASuttisak SuriyachanhomNo ratings yet

- SFH 6315Document10 pagesSFH 6315Mohamed Ezzat MareeNo ratings yet

- VO3120 2.5 A Output Current IGBT and MOSFET Driver: Vishay SemiconductorsDocument10 pagesVO3120 2.5 A Output Current IGBT and MOSFET Driver: Vishay Semiconductorsfadapow4uNo ratings yet

- H11L3M D PDFDocument9 pagesH11L3M D PDFearthenwareNo ratings yet

- A82-00-0109 Datasheets USDocument3 pagesA82-00-0109 Datasheets UScarrei JohnNo ratings yet

- Vo 1263 AaDocument8 pagesVo 1263 Aa801400No ratings yet

- PV30K3225 StackpoleElectronicsDocument2 pagesPV30K3225 StackpoleElectronicsErnesto CamachoNo ratings yet

- MOC8101, MOC8102, MOC8103, MOC8104, MOC8105: Vishay SemiconductorsDocument8 pagesMOC8101, MOC8102, MOC8103, MOC8104, MOC8105: Vishay SemiconductorssawarNo ratings yet

- 2Document10 pages2Marcelo OemNo ratings yet

- Apex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VDocument3 pagesApex Iv X5 240 SM: AC Surge Protector SPD APEX Panel 240 Vac Single-Phase SASD, MOV 30 Ka, UL 94-5VJulio Cesar Huachaca RodriguezNo ratings yet

- ISO1H812GDocument23 pagesISO1H812Gmar_barudjNo ratings yet

- Vsmis30352 1-2572788Document6 pagesVsmis30352 1-2572788bashar mohammedNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument5 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsAsadNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument3 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsИван ЧипNo ratings yet

- Optically Coupled Bilateral Switch Non-Zero Crossing TriacDocument3 pagesOptically Coupled Bilateral Switch Non-Zero Crossing TriacElectronicos CaldasNo ratings yet

- Fodm214 D OnsemiDocument10 pagesFodm214 D OnsemiWalter Martin Paz HolguinNo ratings yet

- Byv 26 DGPDocument5 pagesByv 26 DGPmuhammedasifNo ratings yet

- Diodo Entrada Digital SML4756, Marking Code 47Document6 pagesDiodo Entrada Digital SML4756, Marking Code 47samuelborgesNo ratings yet

- HYUNDAI HG 440W PERC Shingled Marco Negro HiE-S440HGDocument2 pagesHYUNDAI HG 440W PERC Shingled Marco Negro HiE-S440HGJohn WNSNo ratings yet

- ILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsDocument8 pagesILD205T, ILD206T, ILD207T, ILD211T, ILD213T: Vishay SemiconductorsRohit SainiNo ratings yet

- CQY80N, CQY80NG: Vishay SemiconductorsDocument8 pagesCQY80N, CQY80NG: Vishay SemiconductorsHELLOGREGNo ratings yet

- Si8920 DatasheetDocument24 pagesSi8920 DatasheetJake MotorNo ratings yet

- Sony HCD bx5 dx5 dx5j ETDocument66 pagesSony HCD bx5 dx5 dx5j ETJorge PalacioNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- MTL Grounding Tp1121-1Document16 pagesMTL Grounding Tp1121-1mongo55No ratings yet

- 680-198-01 MXP-539 16-Way Input 48-Way Output CardDocument10 pages680-198-01 MXP-539 16-Way Input 48-Way Output CardAdriano CostaNo ratings yet

- Software Defined Radio Using Digital Modulation Techniques - A Matlab Simulink ApproachDocument6 pagesSoftware Defined Radio Using Digital Modulation Techniques - A Matlab Simulink ApproachChakri KamaniNo ratings yet

- Fix For Lack of Response From Touch Panels or TGC-LGC ControlsDocument4 pagesFix For Lack of Response From Touch Panels or TGC-LGC ControlsCarolina CuevasNo ratings yet

- Modelling and Control of CCM Boost PFC Using K-Factor MethodDocument1 pageModelling and Control of CCM Boost PFC Using K-Factor Methoddivya k sNo ratings yet

- F3 PWM Controller: Ice3Bs03LjgDocument25 pagesF3 PWM Controller: Ice3Bs03LjgАндрей КирюхинNo ratings yet

- Z Source Inverter Topologies-A SurveyDocument12 pagesZ Source Inverter Topologies-A SurveyViswanathanBalajiNo ratings yet

- CP 13Document43 pagesCP 13M Alwan Nur AjieNo ratings yet

- Catalogue-FRANKE GMKP LV Power CapacitorDocument9 pagesCatalogue-FRANKE GMKP LV Power CapacitorSuefrizal SuefNo ratings yet

- Ruby Hall BAS Point Schedule v1Document3 pagesRuby Hall BAS Point Schedule v1Wintun73No ratings yet

- Design of A Power Converter Based On UC3842 For Blade Electric VehicleDocument6 pagesDesign of A Power Converter Based On UC3842 For Blade Electric VehicleHossam SobhyNo ratings yet

- AGC300 AGC300 Rev0Document11 pagesAGC300 AGC300 Rev0raj_ritu_aNo ratings yet

- Short Circuit Manual CalculationDocument3 pagesShort Circuit Manual CalculationSridharan PriyadharsenNo ratings yet

- EVH 5150 III REAL 3 Channel and Stealth Mod PDFDocument13 pagesEVH 5150 III REAL 3 Channel and Stealth Mod PDFFelix AlmesbergerNo ratings yet

- Book Review - Blake PDFDocument64 pagesBook Review - Blake PDFOdellien SajaNo ratings yet

- Building A Smart Master - Slave SwitchDocument4 pagesBuilding A Smart Master - Slave SwitchdewasuryantoNo ratings yet

- Power Over Ethernet Injector: 12V: DescriptionDocument1 pagePower Over Ethernet Injector: 12V: DescriptionAakash MalviyaNo ratings yet

- 4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationDocument44 pages4.8 KHZ, Ultralow Noise, 24-Bit Sigma-Delta Adc With Pga and Ac ExcitationThomas ThomasNo ratings yet

- SkyAir R410 Inv Cooling EDMT281537 PDFDocument524 pagesSkyAir R410 Inv Cooling EDMT281537 PDFAnh Thu Mai100% (2)

- Operator and Maintenance Manual DC Power Supply SERIES 3300Document35 pagesOperator and Maintenance Manual DC Power Supply SERIES 3300Tareq AzizNo ratings yet

- Chapter 3 - ElectrochemistryDocument8 pagesChapter 3 - ElectrochemistryMADHAVNo ratings yet

- Ent Microdebrider 24v b0512n4080 SpecificationsDocument1 pageEnt Microdebrider 24v b0512n4080 SpecificationsIman AzrbjNo ratings yet

- Manual Vision FMDocument10 pagesManual Vision FMIchsan DachiNo ratings yet

- VFDDocument151 pagesVFDMUHAMMAD UZAIR100% (1)

- GuitarNuts 00Document13 pagesGuitarNuts 00Geroldo 'Rollie' L. QuerijeroNo ratings yet

- W1000562 PDFDocument64 pagesW1000562 PDFJuan Carlos Alvarez MoralesNo ratings yet

- Nte 331Document2 pagesNte 331Cesar Augusto Arriaga ArriagaNo ratings yet

- Microchip Patch AntennaDocument9 pagesMicrochip Patch AntennaZayar HeinNo ratings yet