Professional Documents

Culture Documents

Astm F409 2002 Spec. Themoplastic Accessible Replaceable Plastic Tube

Astm F409 2002 Spec. Themoplastic Accessible Replaceable Plastic Tube

Uploaded by

frank.chapmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm F409 2002 Spec. Themoplastic Accessible Replaceable Plastic Tube

Astm F409 2002 Spec. Themoplastic Accessible Replaceable Plastic Tube

Uploaded by

frank.chapmanCopyright:

Available Formats

An American National Standard

Designation: F 409 – 02

Standard Specification for

Thermoplastic Accessible and Replaceable Plastic Tube and

Tubular Fittings1

This standard is issued under the fixed designation F 409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 2564 Specification for Solvent Cements for Poly(Vinyl

1.1 This specification covers requirements and test methods Chloride) (PVC) Plastic Piping Systems3

for materials, dimensions and tolerances, hydrostatic pressure, D 2609 Specification for Plastic Insert Fittings for Polyeth-

joint integrity, and solvent cement for thermoplastic tube and ylene (PE) Plastic Pipe3

fittings for accessible and replaceable domestic waste connec- D 2657 Practice for Heat Joining of Polyolefin Pipe and

tions. Marking requirements are also included. Plastic which Fittings3

does not meet the material requirements specified in Section 5 D 2661 Specification for Acrylonitrile-Butadiene-Styrene

is excluded. (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

1.2 The text of this specification references notes, footnotes, and Fittings3

and appendixes which provide explanatory material. These D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

notes and footnotes (excluding those in tables and figures) shall tic Drain, Waste, and Vent Pipe and Fittings3

not be considered as requirements of the specification. D 3965 Specification for Rigid Acrylonitrile-Butadiene-

1.3 The values stated in inch-pound units are to be regarded Styrene (ABS) Compounds for Pipe and Fittings4

as the standard. The values given in parentheses are for D 4101 Specification for Propylene Plastic Injection and

information only. Extrusion Materials4

1.4 The following safety hazards caveat pertains only to the F 402 Practice for Safe Handling of Solvent Cements,

test methods portion, Section 8, of this specification: This Primers, and Cleaners Used for Joining Thermoplastic Pipe

standard does not purport to address all of the safety concerns, and Fittings3

if any, associated with its use. It is the responsibility of the user F 412 Terminology Relating to Plastic Piping Systems3

of this standard to establish appropriate safety and health F 1498 Specification for Taper Pipe Thread 60° for Ther-

practices and determine the applicability of regulatory limita- moplastic Pipe and Fittings3

tions prior to use. 2.2 Federal Standard:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)5

2. Referenced Documents 2.3 Military Standard:

2.1 ASTM Standards: MIL-STD-129 Marking for Shipment and Storage5

D 618 Practice for Conditioning Plastics for Testing2 2.4 ANSI/ASME Standard:

D 1600 Terminology for Abbreviated Terms Relating to B1.20.1 Pipe Threads, General Purpose (Inch)6

Plastics2 2.5 Other Document:

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC) Uniform Plumbing Code7

Compounds and Chlorinated Poly(Vinyl Chloride)

3. Terminology

(CPVC) Compounds2

D 2122 Test Method for Determining Dimensions of Ther- 3.1 Definitions—Definitions are in accordance with Termi-

moplastic Pipe and Fittings3 nology F 412, and abbreviations are in accordance with Ter-

D 2235 Specification for Solvent Cement for Acrylonitrile- minology D 1600, unless otherwise specified.

Butadiene-Styrene (ABS) Plastic Pipe and Fittings3 3.1.1 The plumbing terminology used in this specification is

4

Annual Book of ASTM Standards, Vol 08.02.

1 5

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. Robbins Ave., Philadelphia, PA 19111-5098, Attn: NPODS.

6

Current edition approved Apr. 10, 2002. Published June 2002. Originally Available from the American National Standards Institute, 25 W. 43rd St., 4th

published as F 409 – 75. Last previous edition F 409 – 99a. Floor, New York, NY 10036.

2 7

Annual Book of ASTM Standards, Vol 08.01. Available from the International Association of Plumbing and Mechanical

3

Annual Book of ASTM Standards, Vol 08.04. Officials, 20001 E. Walnut Drive, South Walnut, CA 91789-2825.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

in accordance with the definitions given in the Uniform 6.3 Straight Pipe Threads (NPSM)—For all fittings having

Plumbing Code, unless otherwise indicated. straight pipe threads, threads shall conform to ANSI B1.20.1

(NPSM) and be gaged in accordance with 8.6.

4. Significance and Use 6.4 All tube and fittings made from propylene plastic shall

4.1 The requirements of this specification are intended to be assembled by either mechanical connections or by heat

provide accessible and replaceable tube and fittings to convey fusion, in accordance with Practice D 2657.

domestic waste from fixtures to the drain, waste, and vent

(DWV) system. 7. Requirements

7.1 General—The tube and fittings shall be homogeneous

5. Materials and Manufacture throughout and free of visible cracks, holes, foreign inclusions,

5.1 Tube—The tube shall be made of one of the following or other injurious defects. They shall be as uniform as

materials: commercially practicable in color, opacity, density, and other

5.1.1 Virgin acrylonitrile-butadiene-styrene (ABS) plastic physical properties.

which shall meet the requirements of Specification D 3965, 7.2 Dimensions and Tolerances:

Cell Classification 4-2-2-2-2. 7.2.1 Tube:

5.1.2 Virgin poly(vinyl chloride) (PVC) plastic which shall 7.2.1.1 Tube Dimensions—The tube dimensions shall meet

meet the requirements for 12454C materials in accordance with the requirements given in Table 1 when measured in accor-

Specification D 1784, or dance with Test Method D 2122.

5.1.3 Virgin polypropylene plastic which shall meet the 7.2.1.2 Tube Length—The tolerance on tube lengths is 61⁄8

requirements of Specification D 4101, Cell Classification in. (63 mm).

PP0110B55140 and PP0105G20A33350. 7.2.2 Fittings:

5.2 Fittings and Mechanical Joint Components—The fit- 7.2.2.1 Fitting Dimensions—The dimensions of fittings

tings and components of mechanical joints shall be comprised shall meet the requirements of Table 2 when measured in

of one or more of the following materials: accordance with Test Method D 2122.

5.2.1 Virgin ABS plastic which shall meet the requirements 7.2.2.2 Fitting Laying Length Dimensions—The laying

of Specification D 3965, Cell Classification 2-0-2-1-1. lengths and other critical dimensions of fittings are shown in

5.2.2 Virgin PVC plastics which shall meet the requirements Tables 3-13.

of 12454C materials as defined in Specification D 1784, or 7.2.2.3 Where applicable for assembly, refer to Table A1.1

5.2.3 Virgin polypropylene plastic which shall meet the in Specification D 2661, ABS Schedule 40 Fittings.

requirements of Specification D 4101, Cell Classification 7.2.2.4 Where applicable for assembly, refer to Table 1 in

PP0110B55140, and PP0105G20A33350. Specification D 2665, PVC Schedule 40 Fittings.

5.3 Rework Material—The manufacturers shall use only 7.3 Hydrostatic Pressure—Tube, fittings, and assemblies

their own clean rework tube and fitting material and the tube or shall withstand a hydrostatic pressure of 25 psi (170 kPa) when

fittings produced shall meet all the requirements of this tested in accordance with 8.3.

specification. The different types of material shall not be 7.4 Axial Stress—Threaded connections shall withstand a

mixed. minimum axial load of 50 lbf (220 N) when tested in

5.4 Solvent Cement—The solvent cement shall meet the accordance with 8.4.

requirements of Specification D 2235 or Specification D 2564.

No cement joining of propylene plastic (PP) is permissible. 8. Test Methods

8.1 Sampling—Take at random a sample of the tube, fit-

6. Mechanical Connections tings, or assemblies from each lot or shipment that is sufficient

6.1 Compression or threaded connections shall incorporate to determine conformance with this specification.

American National Straight Pipe Thread, Mechanical Joints for 8.2 Conditioning—Unless otherwise specified, condition

Fixtures (NPSM). The thread form shall be the form of the specimens prior to test at 70 to 77°F (23 6 2°C) and 50 6

American National Straight Pipe Thread and the dimensions 5 % relative humidity for not less than 40 h in accordance with

shall be in accordance with ANSI B1.20.1 (NPSM). All threads Procedure A of Practice D 618 for those tests where condition-

shall have a minimum three-thread engagement for fittings and ing is required and in all cases of disagreement.

plastic nuts. 8.3 Hydrostatic Pressure—Subject the tube and fittings, as

6.2 Taper Pipe Threads—For all fittings having taper pipe an assembly, to an internal hydrostatic pressure of 25 psi (170

threads, threads shall conform to Specification F 1498 and be kPa) for 1 h. The tube, fittings, and joints shall show no

gaged in accordance with 8.5. evidence of leaking.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

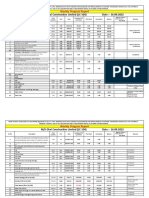

TABLE 1 Dimensions and Tolerances for Outside Diameters and Thickness of Plastic Tube

Outside Diameter Wall Thickness

Nominal Tube Size Average Tolerance on Average Out-of-Roundness Minimum

(maximum minus minimum)

in. in. (mm) in. (mm) in. (mm) in. (mm)

11⁄4 1.250 (31.75) 60.005 (60.127) 0.020 (0.51) 0.062 (1.575)

11⁄2 1.500 (38.10) 60.005 (60.127) 0.020 (0.51) 0.062 (1.575)

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 2 Dimensions and Tolerances for Plastic Tubular Fittings

NOTE 1—Chamfer or flat, optional.

NOTE 2—Radius or 45° chamfer, optional.

NOTE 3—Radius or chamfer, optional.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Nominal Tube Size Thread AA BA C1 C2 EB

60.005 in. 60.005 in. Minimum Minimum Minimum

in. in.

(60.127 mm) (60.127 mm) in. (mm) in. (mm) in. (mm)

11⁄4 11⁄4 - 111⁄2 NPSM 1.265 (32.13) 1.250 (31.75) 11⁄16(17.46) 13⁄8 (34.9) 0.062 (1.58)

11⁄2 11⁄2- 111⁄2 NPSM 1.515 (38.48) 1.500 (38.10) 11⁄16 (17.46) 2 (50.8) 0.062 (1.58)

FB S X AB EX BD

Minimum Minimum 60.005 in. Minimum 60.010 in. Minimum Maximum

in. (mm) in. (mm) (60.127 mm) in. (mm) (60.254 mm) in. (mm) in. (mm)

0.062 (1.58) 17⁄64 (6.75) 1.250 (31.75) 1.258 (31.95) 0.066 (1.68) 0.015 (0.38) 0.070 (1.78)

0.062 (1.58) 17⁄64 (6.75) 1.500 (38.10) 1.508 (38.30) 0.066 (1.68) 0.015 (0.38) 0.070 (1.78)

A

Average diameter, the maximum plus minimum diameter divided by 2. The permissible deviation of the diameter from the measured average, often called

out-of-roundness, is +0.010 to −0.010 in. (+0.254 to −0.254 mm).

B

The wall thickness is a minimum value except that a 610 % variation resulting from core shift is allowable. In such a case, the average of the two opposite wall

thicknesses shall equal or exceed the value shown in the table.

8.4 Axial Stress—Mount threaded connections in a tension- 8.6 Straight Pipe Threads (NPSM)—For all fittings having

testing machine to apply an axial load. Crosshead speed shall straight pipe threads, threads shall be gaged in accordance with

be 0.20 to 0.25 in. (5.0 to 6.3 mm)/min. The connection shall ANSI B1.20.1 (NPSM).

show no evidence of cracking or separation at the minimum

load specified in 7.4. NOTE 1—Some threads listed in Table 6, Table 9, and Table 12 are not

8.5 Taper Pipe Threads—All taper pipe threads shall be listed in ANSI B1.20.1 (NPSM).

gaged in accordance with Specification F 1498.

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 3 FittingsA

NOTE 1—Baffle optional.

NOTE 2—See Table 2 for solvent cement or slip socket hub dimensions.

Nominal

G J N

Tube Size

in. in. (mm)

11⁄2 ⁄

13 16 (20.6) 13⁄16(20.6) ⁄

1 16 (1.6)B

A

All dimensions are minimum.

B

See Table 2.

9. Retest and Rejection hub on both sides. The marking shall consist, at least, of the

9.1 If the results of any test(s) do not meet the requirements manufacturer’s name or trademark, the size, and “ABS Tubular

of this specification, the test(s) shall be conducted again only F 409,” “PVC Tubular F 409,” or “P Tubular F 409.”

by agreement between the purchaser and seller. Under such 10.3 All baffle tees and such fittings as so required shall be

agreement, minimum requirements shall not be lowered, marked with arrows indicating the direction of flow when

changed, or modified, nor shall specification limits be changed. correctly installed.

If upon request, failure occurs, the quantity of product repre-

sented by the test(s) does not meet the requirements of this 11. Quality Assurance

specification. 11.1 When the product is marked with this designation,

F 409, the manufacturer affirms that the product was manufac-

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

10. Product Marking tured, inspected, sampled, and tested in accordance with this

10.1 Tube—The tube shall be marked in letters not less than specification and has been found to meet the require-ments of

1⁄8 in. (3 mm) high in a contrasting color and shall at least this specification.

consist of the nominal size, manufacturer’s name or trademark,

and “ABS Tubular F 409,” “PVC Tubular F 409,” or “PP 12. Keywords

Tubular F 409” at intervals of not greater than 2 ft (610 mm). 12.1 ABS; cellular; DWV; fittings; pipe; plastic; Schedule

10.2 Fittings—All fittings shall be marked on the body or 40; thermoplastic

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 4 End Outlet Continuous Waste

NOTE 1—Radius optional.

NOTE 2—Baffle optional.

NOTE 3—Arm shall either be one-piece construction or assembled. If assembled, socket shall conform to Table 2.

NOTE 4—Shall be swivel nut, slip nut, or slip socket connection (shown in Table 5).

NOTE 5—Dishwasher branch optional.

NOTE 6—See Table 6.

NOTE 7—See Table 2.

L HJ GG

Minimum Minimum

Adjustable in four sizes, in. (mm)

in. (mm) in. (mm)

6 (152.4) 11⁄2(38.1) 12 (305) 16 (406) 21 (533) 25 (635)

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 5 Center Outlet Continuous Waste

NOTE 1—See Table 2.

NOTE 2—Radius optional.

NOTE 3—Baffle optional.

NOTE 4—Arm shall be either one-piece construction or assembled. If assembled, socket shall conform to Table 2.

NOTE 5—Shall also be swivel connection as shown in Table 4.

H L GG

Minimum Minimum

Adjustable in four sizes, in. (mm)

in. (mm) in. (mm)

11⁄2 (38.1) 6 (152.4) 12 (305) 16 (406) 21 (533) 25 (635)

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 6

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 6 Dishwasher Branch TailpieceA

NOTE 1—May be swivel or slip connect construction.

NOTE 2—Baffle optional.

NOTE 3—See Table 2.

NOTE 4—See footnote below.B

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

H P S Z LJC XN

Minimum

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

in. (mm)

11⁄4 (31.8) ⁄ (12.7)

12 1⁄4(6.4) ⁄ (15.9) or 7⁄8 (22.2)

58 4 (102) to 24 (610) ⁄ (15.9) or 7⁄8 (22.2)

58

A

All fractional dimensions are minimum.

B

Threads not listed in ANSI B1.20.1 (NPSM).

C

Lengths shall be agreed upon between the purchaser and the manufacturer.

Copyright ASTM International 7

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 7 Extension Tubes and Tail Pieces

NOTE 1—Bondable, belled, or two-piece bondable construction acceptable.

NOTE 2—See Table 2.

NOTE 3—Shall be swivel nut, slip nut, (with flanged tallpiece), or slip socket connection. See Table 8.

F, min L, min

in. (mm) in. (mm)

A

0.062 (1.58) 0.75 (19.1)

A

Lengths shall be agreed upon between the purchaser and the manufacturer. Tubes shall be single- or double-ended.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 8

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 8 Swivel Nut and Slip Nut

NOTE 1—Chamfer or radius optional.

NOTE 2—Wing nut design optional.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Size Thr’d E L DJA DNA FJ FN

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

in. in.

min min max min max min min min

11⁄4 11⁄4 - 111⁄2 NPSM 0.09 (2.3) 5⁄8(15.9) 1.390 (35.31) 1.260 (32.00) 1⁄8 (3.2)

11⁄2 11⁄2 - 111⁄2 NPSM 0.09 (2.3) 5⁄8(15.9) 1.665 (42.29) 1.580 (40.13) 1.655 (42.04) 1.525 (38.74) 0.09 (2.3) 1⁄8(3.2)

11⁄2 x 11⁄4 11⁄2 - 111⁄2 NPSM 0.09 (2.3) 5⁄8 (15.9) 1.390 (35.31) 1.260 (32.00) 1⁄8(3.2)

A

The part diameter shall be within this dimensional range. The out-of-roundness tolerance from the average measured diameter is +0.010 to –0.010 in. (+0.254 to

–0.254 mm).

Copyright ASTM International 9

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 9 DrainsA

NOTE 1—Metal flanges or inserts shall be molded or crimped in accordance with the manufacturer’s specifications.

C E M1 M2 M3 L1 L2 L3 S

in. (mm) in. (mm) in. (mm)

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

0.062 0.062 0.062

min min min min min min

(61.58) (61.58) (61.58)

15⁄16 (33.3) 0.062 (1.57) 213⁄16 (71.4) 21⁄8 (54.0) 47⁄16 (112.7) 11⁄8 (28.6) 5 (127.0) 2 (50.8) ⁄

7 16 (11.1)

A

Minimum wall thickness 0.062 (1.58).

B

Threads not listed in ANSI B1.20.1 (NPSM) .

Copyright ASTM International 10

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 10 P TrapsA

NOTE 1—Dimensions shall be suitable for solvent welding to Schedule 40 DWV or threads shall be in accordance with 6.2.

NOTE 2—Radius optional.

NOTE 3—Ribs optional.

NOTE 4—Ground joint construction optional.

NOTE 5—Single-radius or multi-radius traps shall provide a 2-in. minimum water seal.

NOTE 6—See Table 2 for P-trap inlet slip socket and spigot end dimensions.

NOTE 7—Socket dimensions suitable for solvent welding to 11⁄4 or 11⁄2-in. tubular trap arm as required.

NOTE 8—Threads and socket dimensions for compression joint connection optional. Threads to be either 11⁄4 -111⁄2 NPSM or 11⁄2 -111⁄2 NPSM as

required.

Size C E X CM GJ GN GGN L1 L2

in. (mm)

in. in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

60.010 (60.254)

11⁄4 13⁄8 (34.9) 0.062 (1.57) 1.250 (31.75) 14⁄ (6.4) 91⁄4 (235.0) 33⁄8 (87.5) 3 (76.2) ⁄

13 16 (20.6) 11⁄2 (38.1)

11⁄2 2 (50.8) 0.062 (1.57) 1.500 (38.10) ⁄ (6.4)

14 11 (279.4) 4 (101.6) 31⁄4(82.6) ⁄

13 16 (20.6) 11⁄2 (38.1)

A

All dimensions are minimum unless otherwise indicated.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 11

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 11 Lavatory Pop-up Drain

NOTE 1—Plastic or metal flanges shall be secured in accordance with the manufacturer’s specifications.

NOTE 2—Overflow openings are optional, when used they must have a combined area of at least 1 in.2 (654.2 mm2).

NOTE 3—See Table 2.

NOTE 4—Stop movement shall be 0 to 0.50 in. (0 to 12.7 mm) min.

NOTE 5—Must be adjustable between 0 to 2 in. (0 to 50.8 mm), or 11⁄2 to 2 in. (38.1 to 50.8 mm) when optional overflow is used.

NOTE 6—Pop-up shall operate at a minimum adjustable range from 41⁄8 to 7 in. (104.8 to 177.8 mm).

H L M

min max min in. (mm)

in. (mm) in. (mm) 0.062 (1.57)

33⁄8 (85.7) 53⁄8 (137) 81⁄2 (215.9) 21⁄8 (54.0)

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 12

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 12 Bath DrainA

NOTE 1—Tee seat-, pop-up-, and rubber stopper-type models are allowed.

NOTE 2—3⁄4 IPS condensate connection permissible on overflow.

NOTE 3—See Table 2.

NOTE 4—Slip joint or one-piece construction optional.

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

G N GG LJ LN MJ MN THR’D

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in.

1 ⁄8 (28.6)

1 3⁄32 (2.4) 6 (152.4) 10 ⁄8 (276.2)

7 4 (101.6) 2 ⁄ (69.1)

23 32 3 (76.2) 1 ⁄ - 111⁄2 NPSM

12

15⁄8- 16 NPSMB

A

All dimensions are minimum unless otherwise specified.

B

Threads not listed in ANSI B1.20.1 (NPSM).

Copyright ASTM International 13

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

TABLE 13 Transition Adapter

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

L LM LH G N A C Z

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

2.070 (52.58) 0.550 (13.97) 0.410 (10.41) 0.807 (20.50), min 0.452 (10.80) 0.300 (7.62) 0.150 (3.81) 0.465 (11.81)

J JG E GT S GB B

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

0.380 (9.65) 0.547 (13.89) 0.100 (2.54), min 1.272 (32.31), min 0.455 (11.56) 1.760 (44.70), min 0.510 (12.95)

NA JA GA EA ZA

in. (mm) in. (mm) in. (mm) in. (mm) in. (mm)

0.507 (12.88) 0.255 (6.48) 0.424 (10.77) 0.050 (1.27), min 0.308 (7.82)

Copyright ASTM International 14

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

SUPPLEMENTARY REQUIREMENTS

GOVERNMENT/MILITARY PROCUREMENT

These requirements apply only to federal/military procurement, not domestic sales or transfers.

S1. Responsibility for Inspection—Unless otherwise speci- S2.1 Packaging—Unless otherwise specified in the con-

fied in the contract or purchase order, the producer is respon- tract, the materials shall be packaged in accordance with the

sible for the performance of all inspection and test require- supplier’s standard practice in a manner ensuring arrival at

ments specified herein. The producer may use his own or any destination in satisfactory condition and which will be accept-

other suitable facilities for the performance of the inspection able to the carrier at lowest rates. Containers and packing shall

and test requirements specified herein, unless the purchaser comply with Uniform Freight Classification rules or National

disapproves. The purchaser shall have the right to perform any Freight Classification rules.

of the inspections and tests set forth in this specification where

such inspections are deemed necessary to ensure that material S2.2 Marking—Marking for shipment shall be in accor-

conforms to prescribed requirements. dance with Fed. Std. No. 123 for civil agencies and MIL-STD-

129 for military agencies.

NOTE S1.1—In U.S. federal contracts, the contractor is responsible for

inspection. NOTE S2.1—The inclusion of U.S. Government procurement require-

S2. Packaging and Marking for U.S. Government Procure- ments should not be construed as an indication that the U.S. Government

ment: uses or endorses the products described in this specification.

APPENDIX

(Nonmandatory Information)

X1. STORAGE AND INSTALLATION PROCEDURES FOR PLASTIC TUBE AND TUBULAR FITTINGS

X1.1 Storage—Do not store tubing and fittings in direct readily mate, thus ensuring a chemical fusion equal in strength

sunlight for long periods. Store tubing in such a manner as to to pipe or fitting. Attempting to correct a loose fit after

prevent sagging or bending. assembly by additional cement may result in an unsatisfactory

joint.

X1.2 Visibility of Marking—Position tubing and fittings so

that identifying markings are readily visible to inspection when X1.5 Joining Technique:

installed. X1.5.1 Cutting the Pipe—Cut the pipe square with saws or

X1.3 Solvent Cement—Use solvent cements meeting the pipe cutters designed specifically for this material; protect pipe

requirements of Specification D 2235 for ABS tube and fit- and fittings from serrated holding devices and abrasion.

tings. Poly(vinyl chloride) requires solvent cements meeting X1.5.2 Deburring Pipe—Remove burrs from inside and

the requirements of Specification D 2564. No cement joining outside pipe edges.

of PP is permissible. Cements should be packaged in containers X1.5.3 Cleaning Joining Surfaces—Wipe off all dust, dirt,

suitable for size of pipe being joined. Do not thin the cement. and moisture from surfaces to be cemented with a clean, dry

Discard cement that has thickened. Solvent cements are flam- rag or paper towel. Remove gloss and any oily film from the

mable. Keep away from heat, spark, and open flame. Avoid pipe and mating socket with clean steel wool, fine abrasive

prolonged breathing of vapors. Prolonged contact with skin is paper, chemical cleaner, or primer. In case of conflicting

harmful. Use with adequate ventilation and avoid contact with solvent cementing instructions, the instructions of the cement

eyes and skin. For further information, see Practice F 402. manufacturer should be followed.

X1.5.4 Application of Cement—Use a natural bristle or

X1.4 Socket Fit—Tubular pipe and fittings are manufac- nylon brush of adequate size (usually at least 1⁄2 the pipe

tured to close tolerances. Close tolerances are required to diameter) or applicator supplied with the can of cement. First

ensure satisfactory“ interference’’ fit between pipe and fitting apply a moderate even coating of cement in the fitting socket

during the solvent cement joining. Use only pipe and fitting completely covering the pipe joining surfaces only. Heavy or

combinations that give interference fits. Pipe loose in the excessive applications of cement may become an obstruction

socket may not properly fuse chemically. The allowable inside of the piping. Quickly apply a heavy even coat of

tolerances ensure a forced fit and when solvent is applied will cement to the outside of the pipe. Make sure that the coated

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 15

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

F 409

distance on the pipe is equal to the depth of the fitting socket. X1.6.2 Connection to Traps—Connect traps by means of

X1.5.5 Assembly—Make the joint as quickly as possible approved threaded trap adaptors.

after application of the cement and before the cement dries. X1.6.3 Connection to Non-Plastic Pipe—When connecting

Insert the pipe into the fitting socket, turning the pipe slightly plastic tube to other types of piping, use only approved types of

to ensure even distribution of cement. Make sure that the pipe fittings and adaptors, designed for the specific transition

is inserted to the full depth of the socket. Remove excess intended.

solvent cement from the exterior of the joint with a clean, dry

cloth. Reasonable handling of the assembly is permissible X1.7 Alignment and Grade—Align all piping system com-

within 2 min after joining. Do not attempt to disturb the ponents properly without strain. Do not bend or pull pipe into

pipe-fitting joint until after the cement has set; damage to the position after being solvent welded. The grade of horizontal

joint and loss of fit may result. Should the cement dry partially drainage and vent piping shall be as specified for other

before the joint is made up, reapply cement before assembling. materials in the applicable code.

Allow 15 min for the joint to develop good handling strength.

X1.6 Threaded Connections—Do not cut threads on tubular X1.8 Antifreeze Protection—When necessary protect traps

pipe. Molded threads are permitted. Only approved thread tape and fixtures from freezing. Do not use alcohol or petroleum

or thread lubricant specifically intended for use with plastic products. Use only approved plastic pipe antifreeze packaged

pipe should be used. Conventional pipe thread compounds, for this purpose or one of the following solutions:

putty, linseed oil-based products, and unknown mixtures shall X1.8.1 Sixty weight percent of glycerin in water mixed at

be avoided. 23°C (73°F).

X1.6.1 Thread Tightness—Where a threaded joint is made, X1.8.2 Twenty-two percent of magnesium chloride in water.

obtain tightness by maximum hand tightening plus tightening Strong solutions of common table salt (sodium chloride) may

with a strap wrench not to exceed one full turn. also be used.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--``,``,`,`,,`,`,`,,,``,,```,``-`-`,,`,,`,`,,`---

Copyright ASTM International 16

Provided by IHS under license with ASTM Licensee=Westinghouse/5911866001

No reproduction or networking permitted without license from IHS Not for Resale, 12/12/2007 06:10:40 MST

You might also like

- Astm D 2665 PDFDocument7 pagesAstm D 2665 PDFfayaz khan100% (2)

- 101 Reading Blueprints Course DescriptionDocument2 pages101 Reading Blueprints Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- Astm D3034 00 PDFDocument10 pagesAstm D3034 00 PDFngronau124545No ratings yet

- Astm F 480Document26 pagesAstm F 480ViswanathNo ratings yet

- ASTM F 1336 - PVC Gaseketed Sewer FittingsDocument8 pagesASTM F 1336 - PVC Gaseketed Sewer FittingsBenjie AlfelorNo ratings yet

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Slab On Grade Reinforcing DesignDocument11 pagesSlab On Grade Reinforcing Designsantylat100% (1)

- 3.25-In. Outside Diameter Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and FittingsDocument9 pages3.25-In. Outside Diameter Poly (Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent Pipe and FittingsMohammed NajahNo ratings yet

- ASTM D 2661 02 ABS Drain PipeDocument9 pagesASTM D 2661 02 ABS Drain PipeSurat - SonaliSolarNo ratings yet

- Astm F439Document7 pagesAstm F439Quat Le DinhNo ratings yet

- ASTM F437 Standard Specification For Threaded Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80 - 1-13-06Document4 pagesASTM F437 Standard Specification For Threaded Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80 - 1-13-06frank.chapmanNo ratings yet

- Astm F 437-99 PDFDocument4 pagesAstm F 437-99 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Astm D2672 (1996)Document4 pagesAstm D2672 (1996)hussein100% (1)

- Astm F 439Document7 pagesAstm F 439Dmitriy100% (1)

- Type PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForDocument2 pagesType PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForBuddhikaNo ratings yet

- D1785 PDFDocument11 pagesD1785 PDFDavid SolisNo ratings yet

- Norma Astm F794Document7 pagesNorma Astm F794WalterRamosNo ratings yet

- D 2751 - 96 - Rdi3nte - PDFDocument6 pagesD 2751 - 96 - Rdi3nte - PDFEnrike GarciaNo ratings yet

- Astm F441Document7 pagesAstm F441Quat Le DinhNo ratings yet

- Astm F 441-02Document7 pagesAstm F 441-02JORGE ARTURO TORIBIO HUERTANo ratings yet

- Astm F 439-02 E03 PDFDocument8 pagesAstm F 439-02 E03 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Astm F 439-02 E03Document8 pagesAstm F 439-02 E03JORGE ARTURO TORIBIO HUERTA100% (2)

- Astm f1803Document5 pagesAstm f1803filipeNo ratings yet

- F 2307 - 03 RjizmdcDocument5 pagesF 2307 - 03 RjizmdcLuis Emilio BosioNo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120Document11 pagesPoly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120Flor PeraltaNo ratings yet

- D2466 PDFDocument5 pagesD2466 PDFDavid SolisNo ratings yet

- D 2467 - 99 - Rdi0njctotk - PDFDocument8 pagesD 2467 - 99 - Rdi0njctotk - PDFAndre CasteloNo ratings yet

- Astm F 442Document7 pagesAstm F 442Zahoor Ahmed MohsanNo ratings yet

- D2665 PDFDocument6 pagesD2665 PDFDavid SolisNo ratings yet

- Astm F 679-03Document6 pagesAstm F 679-03JORGE ARTURO TORIBIO HUERTA100% (1)

- Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsDocument7 pagesChlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsAhmad Zubair RasulyNo ratings yet

- Poly (Vinyl Chloride) (PVC) Corrugated Sewer Pipe With A Smooth Interior and FittingsDocument10 pagesPoly (Vinyl Chloride) (PVC) Corrugated Sewer Pipe With A Smooth Interior and FittingsROHITNo ratings yet

- D 1785 - 03 - Rde3odutmdm - PDFDocument11 pagesD 1785 - 03 - Rde3odutmdm - PDFAndre CasteloNo ratings yet

- Astm D2241 (2000)Document8 pagesAstm D2241 (2000)Mohamed Reda Hussein SengarNo ratings yet

- Astm F789Document8 pagesAstm F789Mohd AshrafNo ratings yet

- Chlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80Document7 pagesChlorinated Poly (Vinyl Chloride) (CPVC) Plastic Pipe Fittings, Schedule 80mohanrulesNo ratings yet

- Astm D2241.78-1Document9 pagesAstm D2241.78-1PedroNo ratings yet

- Polyolefin Pipe and Fittings For Corrosive Waste Drainage SystemsDocument6 pagesPolyolefin Pipe and Fittings For Corrosive Waste Drainage SystemsYasmin AminNo ratings yet

- Astm F 438-04Document7 pagesAstm F 438-04JORGE ARTURO TORIBIO HUERTANo ratings yet

- Poly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40Document5 pagesPoly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40Andres Camilo BenitezNo ratings yet

- Threaded Poly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 80Document4 pagesThreaded Poly (Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 80Andres Camilo BenitezNo ratings yet

- D 2241 - 04 - Rdiynde - PDFDocument9 pagesD 2241 - 04 - Rdiynde - PDFAndre CasteloNo ratings yet

- F2658 PDFDocument10 pagesF2658 PDFAhmad Zubair RasulyNo ratings yet

- Smoothwall Polyethylene (PE) Pipe For Use in Drainage and Waste Disposal Absorption FieldsDocument4 pagesSmoothwall Polyethylene (PE) Pipe For Use in Drainage and Waste Disposal Absorption FieldsROHITNo ratings yet

- F2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsDocument7 pagesF2618-15 Standard Specification For Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and Fittings For Chemical Waste Drainage SystemsMohamedNo ratings yet

- F949 Tuberias y Acc Corrugadas Interior Liso DrenajesDocument10 pagesF949 Tuberias y Acc Corrugadas Interior Liso DrenajesFrancis VásquezNo ratings yet

- F 409 - 12Document16 pagesF 409 - 12juan fNo ratings yet

- F 1412 - 01 - Rje0mtiDocument6 pagesF 1412 - 01 - Rje0mtiYasmin AminNo ratings yet

- Acrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsDocument9 pagesAcrylonitrile-Butadiene-Styrene (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe and FittingsHernando Andrés Ramírez GilNo ratings yet

- Astm F758-14Document6 pagesAstm F758-14Muhamad HamandiNo ratings yet

- Polyolefin Pipe and Fittings For Corrosive Waste Drainage SystemsDocument6 pagesPolyolefin Pipe and Fittings For Corrosive Waste Drainage SystemsYasmin AminNo ratings yet

- Astm D3309 (1996)Document11 pagesAstm D3309 (1996)Thomas C. LaneNo ratings yet

- D 2665 - 00 - Rdi2njutmda - PDFDocument6 pagesD 2665 - 00 - Rdi2njutmda - PDFAndre CasteloNo ratings yet

- Poly (Vinyl Chloride) (PVC) Schedule 40 Drain, Waste, and Vent Pipe With A Cellular CoreDocument8 pagesPoly (Vinyl Chloride) (PVC) Schedule 40 Drain, Waste, and Vent Pipe With A Cellular Coreastewayb_964354182No ratings yet

- La Norme NormeDocument6 pagesLa Norme NormechouaibNo ratings yet

- Astm F-1871-02Document5 pagesAstm F-1871-02joe jackNo ratings yet

- D 2241 - 00 - Rdiyndetmda - PDFDocument9 pagesD 2241 - 00 - Rdiyndetmda - PDFAndre CasteloNo ratings yet

- D 2282 - 99 - Rdiyodi - PDFDocument7 pagesD 2282 - 99 - Rdiyodi - PDFAndre CasteloNo ratings yet

- Astm D2846Document11 pagesAstm D2846Gerardo Lopez GochiNo ratings yet

- Astm F894-19Document11 pagesAstm F894-19JC BoulangerNo ratings yet

- Astm d1785 1999 PDFDocument11 pagesAstm d1785 1999 PDFErwin ObenzaNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Hospital Eqipment PlanningDocument33 pagesHospital Eqipment PlanningPrasidha Prabhu100% (1)

- Pages From Iom LPG Comp - Ie101hDocument8 pagesPages From Iom LPG Comp - Ie101hRamius HamdaniNo ratings yet

- Green Building 2Document21 pagesGreen Building 2Halina HamidNo ratings yet

- Weekly Progress Report LC-104Document2 pagesWeekly Progress Report LC-104rohit singhNo ratings yet

- Stone Columns PresentationDocument21 pagesStone Columns PresentationFaheera Beigh100% (1)

- Pembangunan Transmart Carrefour Depok Metode Pelaksanaan Dan Perhitungan Kebutuhan Material Ramp Basement 2Document3 pagesPembangunan Transmart Carrefour Depok Metode Pelaksanaan Dan Perhitungan Kebutuhan Material Ramp Basement 2Muhammad RifqiNo ratings yet

- Dokumentips Bridge Engineering by Victor Johnson Essentials of Bridge Engineering VictorpdfDocument2 pagesDokumentips Bridge Engineering by Victor Johnson Essentials of Bridge Engineering VictorpdfVivek Kumar0% (1)

- Abb Compression LugDocument39 pagesAbb Compression LugBenoit LefebvreNo ratings yet

- Sika CureSealant (CuraSellador) STD - EnglishDocument2 pagesSika CureSealant (CuraSellador) STD - EnglishNelson IbarraNo ratings yet

- O07743 Specifications REV I FINDocument179 pagesO07743 Specifications REV I FINphaniscribd100% (1)

- AbstractDocument5 pagesAbstractSyed Azeem0% (1)

- Planning and Design of Ports and Harbours - Code of PracticeDocument18 pagesPlanning and Design of Ports and Harbours - Code of Practicevishal kumar100% (1)

- 2016 12 Darch HouDocument153 pages2016 12 Darch HouEman J. AlnajiNo ratings yet

- Recommended Practice For Soft Ground Site Characterization: Arthur Casagrande LectureDocument60 pagesRecommended Practice For Soft Ground Site Characterization: Arthur Casagrande LectureSharon_SKNo ratings yet

- 5 16 Engineered Installation InstructionsDocument14 pages5 16 Engineered Installation InstructionsNeil V. MonteleoneNo ratings yet

- NCH 731 - 1998 (EN)Document15 pagesNCH 731 - 1998 (EN)Jiaxin TanNo ratings yet

- Legend:: Single Phase Riser DiagramDocument1 pageLegend:: Single Phase Riser DiagramPrincess DimayacyacNo ratings yet

- Is: 1905 - 1987Document26 pagesIs: 1905 - 1987Amardeep Singh Multani100% (3)

- Week 6 Reading Comprehension - Architecture Preliminary DesignDocument6 pagesWeek 6 Reading Comprehension - Architecture Preliminary DesignRETNO AULIANo ratings yet

- Hydrants & AccessoriesDocument21 pagesHydrants & AccessoriesBrion Bara IndonesiaNo ratings yet

- Construction Waste Management Plan: County of San Bernardino Department of Public Works, Solid Waste Management DivisionDocument5 pagesConstruction Waste Management Plan: County of San Bernardino Department of Public Works, Solid Waste Management DivisionIwona JanusNo ratings yet

- Tango Philips 090828Document2 pagesTango Philips 090828Tino HardikaNo ratings yet

- Well Sinking ProceduresDocument7 pagesWell Sinking ProceduresAjit ThapaNo ratings yet

- Sahil Mathakiya 8th Sem 2011 2015 PDFDocument60 pagesSahil Mathakiya 8th Sem 2011 2015 PDFRishav MahatoNo ratings yet

- Journal 10 PDFDocument6 pagesJournal 10 PDFRuzengulalebih ZEta's-ListikNo ratings yet

- Thermoplastic PolyurethaneDocument2 pagesThermoplastic PolyurethaneEricNo ratings yet

- Pipe Fabrication Brochure CompressedDocument2 pagesPipe Fabrication Brochure CompressedLeDzungNo ratings yet